Rating of the best jointing for brickwork for 2022

Stitching is a special technique in brickwork that allows you to create neat and attractive seams. This results in an aesthetic result. It is important to choose the right tool. A rating of quality goods will help you find the best fixture.

Content

Why stitching is needed

When laying brickwork, the outer joints between the bricks must be filled with mortar. This can cause the following problems:

- sloppy look;

- deterioration of thermal insulation properties;

- reduction in the service life of masonry due to precipitation.

To solve these problems, a special seam processing technology is used. This is a stitching. The procedure is carried out until the solution solidifies. The seams should be filled evenly, creating their transverse profile.

Such work allows you to seal the suture material, improve the appearance, thermal insulation. The surface does not deteriorate from weather conditions. This processing must be performed to improve the quality of the seams: when building brick and stone buildings. Another procedure is carried out during the restoration, laying of ceramic tiles. If the wall is plastered, it is not necessary to embroider the seams.

Structural parts

Such jointing is the same trowel used in construction and repair. This tool consists of:

- working part;

- necks;

- handles;

- butt.

The working part is made of reliable steel. Most often it has a galvanized or stainless steel coating. The mount (neck) has not only a retention function. It also divides the working part and the handle. The neck determines the level of hand grip during operation.

The handle is usually made of rubber, plastic, wood. Combinations of materials may be used. Still handles are made of lead or steel, but they are rarely found on sale. Their main advantage is impact resistance.

The butt is located at the end of the handle and is created from hardened materials. This part is pressed onto the masonry mixture to make the surface neat. The butt must be fixed securely, and with incorrect play during construction, the handle may crack.

The scope of such devices is small. These are specialized devices with which masonry procedures are performed with solutions.The device will help distribute the mixture between the bricks, ensuring the reliability of the wall and an attractive appearance.

Since such products are considered professional tools, their creation is carried out according to GOST standards. These parameters must be taken into account by craftsmen when choosing a product for a particular operation.

Material

The working part is usually made of high carbon steel. Stainless steel is also used, which is also known for its excellent quality. It is important that the material be ground to ensure that the solution adheres to the working part and that the solution is transferred evenly.

Masters use steel types, as they are the most reliable. Such options are suitable for working with heavy substances. But plastic can also be used as a material. Although most often it is used for applying glue.

You also need to pay attention to the mass of the device. The lighter the weight of the tool, the easier it is to work. In addition, the hand with such a device will not get very tired.

Handles are usually made of wood. The slightly rough surface of the material protects against slipping, and in cold weather heat comes from it. Plastic handles are comfortable, but many craftsmen find them short-lived. Metal handles are very rare. Before use, they should be rubberized, otherwise the trowel is difficult to hold in hand.

Choice

How to choose an instrument? Devices differ in characteristics. But there are basic selection criteria:

- Curve shape. The device can be rectangular, rectangular recessed, concave, convex, beveled. Which option to choose depends on the desired result.

- Canvas material. Steel is considered the most practical option. This material is reliable and durable.

- Width of the working part. This setting may vary.An indicator of 10 mm is in demand.

- Handle material. A tree is considered a reliable option. It is very comfortable to work with such material.

These are the main points that you need to pay attention to first of all. These characteristics are considered the main ones. Optionally, it can be a purchased fixture. The homemade version is great too.

Before performing construction work, it is advisable to simply hold the tool in your hand. It should be checked whether it is comfortable, whether it causes discomfort. Only if the device does not cause inconvenience, it can be used to complete the finish.

Varieties

When choosing, you need to look at the types of devices, because each of them creates its own result. What are the jointing for brickwork? They are divided into the following types:

- Rectangular. The joint profile of the tool is rectangular. The formation takes place with the reverse side of the trowel. The border of the seam goes along the line of the facade. This is a simple and popular profile, has optimal waterproofing properties.

- Rectangular recessed. The profile is able to emphasize the beauty of the dressing of the rows, decorate the wall. It is better not to choose it for exterior facades that are affected by precipitation. Snow and ice can go into the depths, destroying the seams and masonry. But the tool is great for interior decoration in industrial style and loft.

- Concave. This profile is presented as a concave semicircle. Remarkably transforms masonry, resists precipitation. Slightly reduces thermal insulation by reducing the thickness of the wall in the area of the seam. It is used both at construction, and at restoration.

- Convex. In terms of aesthetic parameters, it is similar to concave instruments. At the same time, convex jointing is not able to reduce thermal insulation.In addition, it is more resistant to precipitation.

- bevelled. The formation takes place by the edge of the trowel, which is held at an angle to the masonry. Provides protection from the elements, especially when used with a dovetail double bevel. Degrades thermal insulation due to the small thickness of the wall in the seam area.

These are the basic stitching tools. In the artistic field, complex profiles are also used to transform the building and make it aesthetically attractive.

Which option to choose depends on the goal. If you need certain seams between bricks, you should choose the right tool that will help you do everything neatly.

Advantages

Using this device, you can get several advantages:

- Solution is saved if concave profiles are used.

- The durability of the masonry is ensured.

- Frequent cosmetic repairs are not required.

- Weather protection guaranteed.

- Experience is not needed, even a novice master will cope with the procedure.

- Improves the appearance of the masonry.

But it is important to take into account the presence of a disadvantage. The thermal insulation properties of the wall are reduced, but this is only if concave and beveled profiles are used.

It is important to consider that the thermal insulation of concave profiles is better than that of an unembroidered wall. And this is due to the complete filling of the suture space with a solution.

Tools 8 mm

In masonry work, fixtures with a working part width of 8 mm are often used. With such devices, the solution is perfectly distributed in the interstitial space. The following ranking includes the best products.

Stayer 0840-08

The device strengthens the seams when laying bricks. It is equipped with a steel sheet, which has a protective coating. The tool has a practical wooden handle.The size of the joint is 8 mm.

The manufacturer offers a high-quality device weighing 230 g. With proper operation, the product can last a long time.

- comfortable handle;

- sheet with a protective coating;

- practical handle;

- light weight.

- not detected.

Quick mix

The working part is made of stainless steel. The two-component handle of the tool is made of reliable plastic. The device allows you to create neat seams between bricks.

The device can be used in construction and repair. With it, internal embroidery is also perfectly performed. It is enough to carefully apply the mixture.

- stainless steel;

- durable plastic handle;

- reliable tool;

- durability.

- no.

Stayer 08412

The reliable design of the device allows you to perform accurate stitching. It is made using high quality material. The device also has an ergonomic design.

The handle is made of wood and the blade is made of steel. The tool allows you to create neat internal seams. This type of device will help to make high-quality masonry.

- durable handle;

- steel sheet;

- ergonomic design.

- not identified.

According to buyers, these are reliable devices that will be excellent helpers in repair and construction. With them, jointing of cracks of different surfaces is performed.

Tools 10 mm

These types of tools are considered the most popular. Even with self-processing, a neat result is obtained. You just need to choose the right device.

Stayer 0840-10

Used to strengthen brick and stone masonry. The device has a steel sheet and a protective coating.The comfortable handle is made of wood.

The tool in gray colors is suitable for interior and exterior decoration. It weighs only 240 g, so the job is done very easily.

- reliable quality;

- steel sheet;

- durable handle;

- light weight.

- missing.

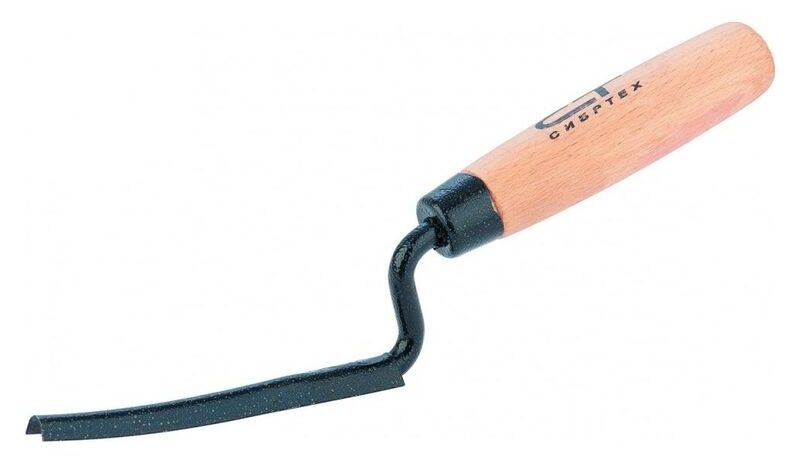

SIBRTECH

The device allows you to form and strengthen internal seams when laying bricks and stones. The blade is made of steel, the handle is made of beech. The weight is 134 g. The length of the working part is 117 mm. The product has a rounded edge.

The device is suitable for furnace, wall decoration during repair and construction. According to reviews, the device does its job perfectly, guaranteeing a high-quality result.

- steel sheet;

- beech handle;

- light weight;

- high quality.

- no.

LOW

The tool is suitable for laying stone and brick. It is made of steel, made in the form of a drop with a pointed nose. The device allows you to evenly apply the solution. The length is 250 mm. The handle is made of plastic.

The construction device has standard parameters. With proper use, the device can be used for a long time.

- quality steel;

- reliable handle;

- optimal length;

- convenience in work.

- missing.

These are inexpensive tools that are sold in all hardware stores. More items can be ordered online. The online store offers a wide range of accessories.

Features of the procedure

Only with a careful approach to each stage will it be possible to do everything right. Having familiarized yourself with the theoretical part of the procedure, you can immediately do the work. The procedure is divided into several important steps.

Training

Dust and dirt are removed from the wall. Cement joints are cleaned of "rough" lumps with a brush with a hard bristle. Often a high-pressure cleaner is used. Although it is expensive, it can be rented. The equipment allows you to eliminate even small particles of the solution.

Wet the seams that need to be processed with a wet roller. Masters do not advise to carry out jointing in the summer, since the solution dries quickly, which can disrupt the technology. Also, work should not be done in rainy weather, since the solution will turn out to be wet.

Solution preparation

The stitching agent can be sold ready-made. But most often it is a dry mixture that should be prepared. The product is diluted with water, as indicated on the package. Whatever product is used, you must follow the instructions, proportions.

It is necessary to take into account the time during which the remedy should be used. It is desirable to mix the composition with an electric drill equipped with a mixing nozzle. Do not immediately make a lot of solution. If you work with a wet or dry mixture, this leads to the destruction of the seam.

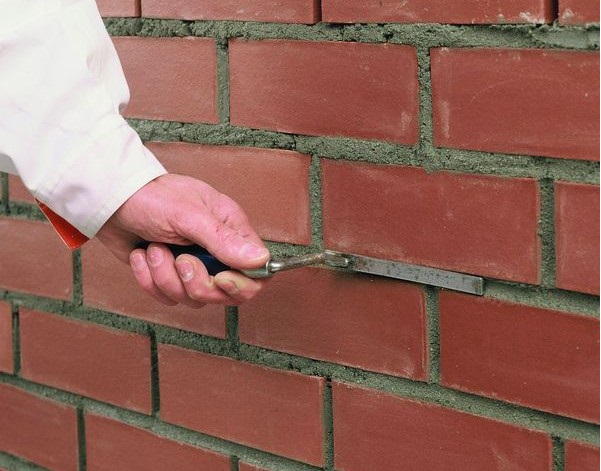

Stitching procedure

The old solution is removed up to 15 mm deep. With a hard-bristled brush, traces of mortar are removed from the wall. In hard-to-reach areas, a chisel can be used. To process the upper wall, a stepladder is used.

It is important that the mixture is applied uniformly, without lumps. The solution should be used in excess, immediately eliminating the excess. Then, with a narrow joint, the mixture is pressed into the vertical seams. In horizontal seams, you need to process with a long fixture.

It is required to carefully press the solution in, as this will help eliminate excess air from the seam.The desired shape is given thanks to improvised means - a hose or a plastic tube.

To get a beveled seam, a wooden plank is used. And recessed can be done with a wooden peg. This completes the finishing procedure.

Precautionary measures

When creating stitching seams, it is required to adhere to safety rules:

- personal protective equipment is needed - a helmet, goggles or a face shield, gloves, clothing, special shoes, a respirator;

- it is necessary to remember about the safety of working at height;

- do not hang on the wall or lean on the masonry;

- random supports should not be used, inventory scaffolding, ladders are needed;

- tools must not be left unattended;

- Before turning on electrical appliances, you need to check their serviceability.

If masonry is carried out at temperatures below zero in bright sunshine, do not make more than 5 rows of masonry. There will be freezing on one side, and thawing on the other. The result is still not good.

If it rains, the treated wall is covered with plastic wrap. A downpour can knock the mortar out of the masonry. Therefore, construction procedures must be carried out in suitable weather.

The acquisition of a suitable joint will allow you to do all the work yourself. Of course, a beginner can spend more time on this than an expert. If you work carefully, without haste, you get an excellent result.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127687 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124516 -

The best men's sneakers in 2022

Views: 124030 -

The Best Complex Vitamins in 2022

Views: 121937 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2022

Views: 113393 -

Ranking of the best wood paints for interior work in 2022

Views: 110317 -

Rating of the best spinning reels in 2022

Views: 105326 -

Ranking of the best sex dolls for men for 2022

Views: 104362 -

Ranking of the best action cameras from China in 2022

Views: 102214 -

The most effective calcium preparations for adults and children in 2022

Views: 102010