Rating of the best screening buckets for excavators and loaders for 2022

The main component of any road construction work is the horizontal leveling of the soil, i.e. the process of artificially changing the relief prior to the start of the main phase of construction. This stage includes various works on the development of a soil base, the construction of embankments and dumps, and the transportation of soil through construction areas. Accordingly, such operations will require the use of equipment equipped with special tools, through which it would be possible to weed out the soil with the required fraction size to create the necessary conditions provided for by the construction project. For such purposes, screening buckets are installed on loaders and excavators.

Content

General information

The screening bucket is an indispensable tool for sorting and transporting various fractional material - from construction debris and soil to large vegetable fruits. Its design is a conventional bucket, the surface of which is made in the form of a grid with cells of one size or another. By selecting the desired cell size, it is possible to carry out the transportation / loading of any fragmented material, while the fragments of the desired size will remain in the container, and smaller ones will simply fall through the grid. In this way, the transported material can be sorted automatically.

Modern varieties

In the current market, there are several main types of buckets that have gained the most popularity and are in demand in production. They are made of high quality metal, and each type has its own individual features:

- For sand and earth (ground) - a device for sorting and cleaning manipulations;

- For coal and peat - to screen out the smallest fragments (the design uses a spiral axis);

- For aeration - mixing compost or silage.

It is preferable to immediately choose a device with a universal mounting system in order to be able to mount the equipment on various equipment (usually loaders and excavators).

Basic purpose

The devices in question are used for cleaning, mixing, stabilizing, aerating a wide variety of solid substances. Its main feature is the possibility of transferring and backfilling this substance. For example, for separate sorting, you do not have to transport the soil to clean sites, and after the selection, bring it back - all operations can be carried out right on the spot using this attachment. Accordingly, after sifting the soil, it can immediately be poured onto the site or into the prepared trench. As a standard, this attachment is convenient to use on:

- Classic loader;

- Front loader;

- Excavator.

Due to the reduced weight, it is very convenient to transport such equipment in a disassembled state in cramped urban conditions, in difficult terrain, where it is very difficult to deliver a full-fledged complex.

Areas of use

In most cases, the tools are used to prepare the soil for landscaping, to prepare the soil in stadiums and sports grounds, as well as in nurseries. After sifting, the fraction of the material becomes clean and does not contain chips, pebbles, lumps of clay. Additionally, they can be used for mixing compost, clay and sand. Sometimes, even very wet soil on the site can become an obstacle to the continuation of work. Therefore, its unstable structure must be mixed with limestone, which, having reacted with it, quickly dries it. For these purposes, a screening bucket is perfect.

To work with peat, this attachment will also be useful, because peat itself is considered a very light substance, which in any case will have to be cleaned of small stones, tree and plant roots, as well as other inclusions. At the same time, they can also be used for waste processing processes, because. often, before disposal, it is required to clean the garbage mass and separate it into fractions of different sizes.

The sifting attachment can also be used to grind some organic substances, for example, before composting them, or to aerate the compost to speed up its decay process. Using the same technique, it is convenient to collect the compost itself, while simultaneously mixing it with other necessary elements.

Separately, it is worth mentioning the industrial sector, where this type is used to sort the most commonly used materials. With their help, it is very convenient to process caked chemicals and fertilizers.

Laying pipe lines and backfilling trenches will also not do without screening buckets. It is with them that you can conveniently and quickly clean the excavated soil and immediately fill the ditch with the laid pipe with the resulting material.

Fine mesh equipment can even be used to clear land of anti-personnel mines. But for such purposes, the body of the device itself is additionally strengthened and equipped with forced detonation devices.

As a result, it is possible to “entrust” the following tasks to the screening bucket:

- Preparation of the base base for the roadway;

- Formation of slopes with proper fraction;

- Strengthening of pits and trenches (due to backfilling with soil);

- Deepening and cleaning of reclamation canals;

- Cleaning of sewers along roads and main overpasses from unwanted vegetation, fallen tree trunks, bulky debris.

If we talk about specific industries, then screening buckets will be in demand:

- In construction - they are great for loading large stones, concrete battle, while not capturing dry soil and sand at the same time;

- In the field of waste disposal - they will perfectly sort out bulky and light waste;

- In the field of land improvement, they will allow you to properly separate peaty soil from small pebbles.

Also, this type of attachment can be used in agriculture when loading root crops. With the help of the transparent rear wall of the bucket, the operator can very easily control the entire process from the cab of the machine, respectively, there will be no unnecessary crushing of potato tubers and beets or cabbages.

Installation on equipment

They can be installed on:

- All types of caterpillar and full-revolving wheeled excavators with a mass of 12-35 tons of the Komatsu, Doosan, Hitachi, Volvo, CATerpillar brands;

- JCB 3СХ loaders-excavators and analogues;

- Excavators with an extended working "arm";

- Mini-excavators of the "YUCHAI-17" type.

IMPORTANT! A mini-loader, of course, is also able to level the surface of the roadway after re-filling it with the desired fraction, but the design features of its boom and when using a very wide bucket will not allow it to properly plan ditches and slopes.

Traditional carriers of screening equipment are full-revolving caterpillar models for 20 tons and vehicles with an extended working "arm" for 30 tons.

Regarding the width of the buckets themselves, the following standards apply:

- For full-circle excavators - 1800-2500 millimeters;

- For backhoe loaders - 1500-1800 millimeters (with a total volume of 0.3 to 0.4 "cubes");

- For mini-loaders - 1000-1200 millimeters.

Overview of the best foreign manufacturers of screening buckets

Hartl Engineering & Marketing GmbH

This Austrian company specializes in the design and manufacture of screening buckets, which are characterized by high performance, minimal wear and quality square cells. Products are shipped all over the world. The latest models use the innovative technologies "Hartl" and "Quattro", they provide the movement of the cheek of the device along the trajectory in the form of an infinity sign during the screening process. Due to such movements, the initial screening takes place in the upper chamber, and the final one in the lower chamber. The ergonomic shape gives it a look that is easy to recognize. In the modern line there are four models of equipment of this type. They are equally capable of cost-effective sorting of rocks, soil and waste. The design is a combination of a conventional bucket and a cellular mesh, the sieve of which can be changed in accordance with the required mesh sizes - from 20 to 80 millimeters. The mesh is made from different durable materials. The peculiarity of the product lies in the extended optionality, because it contains:

- Centralized lubrication system;

- Magnet to help sort metals;

- Dedusting spraying device (indispensable when working in a residential area);

- Submersible pump and remote control;

- A control block that allows you to track the occupancy, with an image displayed on the monitor of the operator-driver;

- Hydraulic attachments for quick change of equipment.

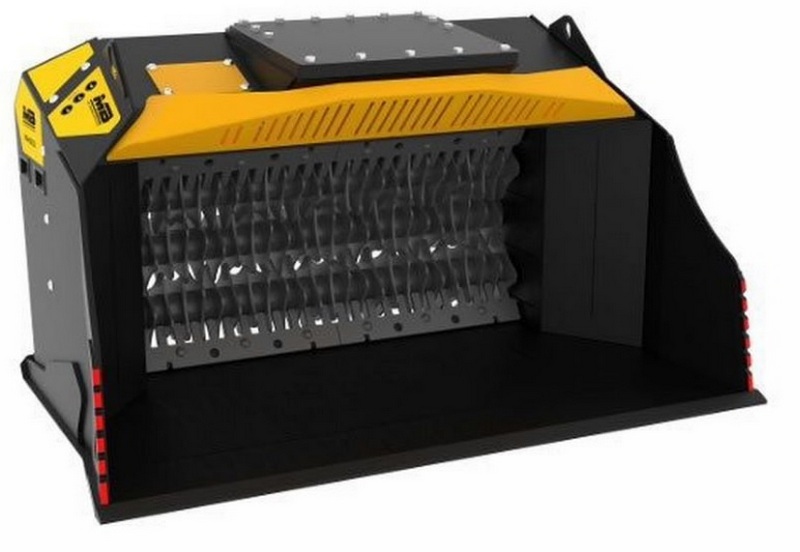

"JCB"

Products from this company are specially oriented to work in tandem with their own tracked excavators. They are able to sort small pieces of building materials, reinforced concrete, concrete rubble, cobblestones with a diameter of 20 to 100 millimeters on the spot. Also, with their help it is convenient to separate metal from loose substances for its subsequent processing. Hydraulic hoses and suspension brackets are included as standard. The modern line is characterized by three popular models - CB60, CB70, CB90 - they fully correspond in terms of carrying capacity and power to modern JCB tracked loaders. The usual weight of the bucket is a little less than a ton, the maximum productivity is 19 cubic meters / hour, the width and height of the opening are 600 x 450 millimeters. Limit indicators for the largest model can be as follows: weight - two tons, width and height - 900 x 450 millimeters, productivity - 40 cubic meters / hour.

"ALLU"

Considered a pioneer in the industry, this Finnish company offers a wide range of screening buckets. The latest developments include the DL model, which is perfect for compact machines weighing up to 12 tons and for skid steer loaders weighing up to 8 tons. The design feature of this series is the presence of an upper sieve with rotating legs. According to the manufacturer, such a technological solution overcomes cell clogging and allows maintaining increased productivity even when operating with wet material. Among other things, the base load is placed on the sieve, which clearly extends the life of the bearings and drums.Buckets from this series will perfectly cope with the screening of peat and soil and will help in the production of soil and landscape work during the laying of pipelines and cables.

Separately, it is worth mentioning the universal hydraulic mounted crushing and screening bucket of the all-in-one type, which is freely mounted on most modern excavators, loaders, backhoe loaders. This tool allows you to crush and sift, spray and blow, move and separate, feed and immerse most materials of various types in one sitting. This variation is suitable for processing asphalt pavement, topsoil, construction debris, waste / excavated soil, contaminated clay and soil, peat, compost, tree bark, biowaste, scrap coal, glass, oil shale, limestone and other substances. This model is capable of sifting/crushing a fragmented array of substance with fractions ranging in size from 15 to 150 millimeters.

Baughans

This company specializes in the production of sorting equipment and today offers a line of four bucket models with a width of 400 to 900 millimeters. These models are focused on cleaning construction debris, namely concrete battle. Products are intended only for excavators with a mass of 1.5 to 13 tons. The minimum cell diagonal is 36 millimeters. The productivity is: for small models - up to 3 tons per hour, and for large models - up to 25 tons per hour.

ANROSS

The Crusher series from this English company is intended for mini-excavators and can be installed on construction vehicles weighing up to 16 tons.The release of a new line is scheduled for mid-2022, which will allow the use of screening buckets already on machines weighing up to 20 tons. These products can be successfully used on small construction sites or places of deconstruction of buildings and structures. Brick, concrete and blocks are screened naturally when exposed to the cheek in automatic mode. The working range of fragments can be from 40 to 100 millimeters, which can be adjusted by the position of the buccal axis. Productivity can be up to 14 tons per hour. The structural structure uses steel of international grades "Hardox-450" and "500", which indicates an increased level of service life of the product.

BAV CRUSHERS

Another English company supplies the current market with five modern models of buckets with a mass starting from 255 kilograms and a size of 600 x 370 millimeters. The model range of products is intended for construction equipment with a mass of 2.5 to 25 tons. The products are equipped with replaceable carbide teeth "Kennametal", which replaced the cast armor teeth, which indicates increased strength. All models are supplied with removable grids, which allows you to skip the fraction with dimensions up to 50 millimeters. The most advanced BAV-RS models are equipped with rotary screening drums with diameters of 450, 600, 700, 900 millimeters. Delivery is made with removable sieves in three sizes: 12.5 mm, 25 mm, and 50 millimeters.

Rating of the best screening buckets for excavators and loaders for 2022

For backhoe loaders

4th place: Komatsu 220

This equipment is designed for large-sized construction equipment and is oriented for use on large construction sites or for laying long trunk networks. Easily sorts coarse soil right at the trenching site, and armored teeth are able to successfully cut even into frozen soil. The recommended cost for retail chains is 150,000 rubles.

- Narrow specialization;

- Suitable for most models of large-sized Japanese-made equipment;

- The presence of armored teeth.

- Not a generic model.

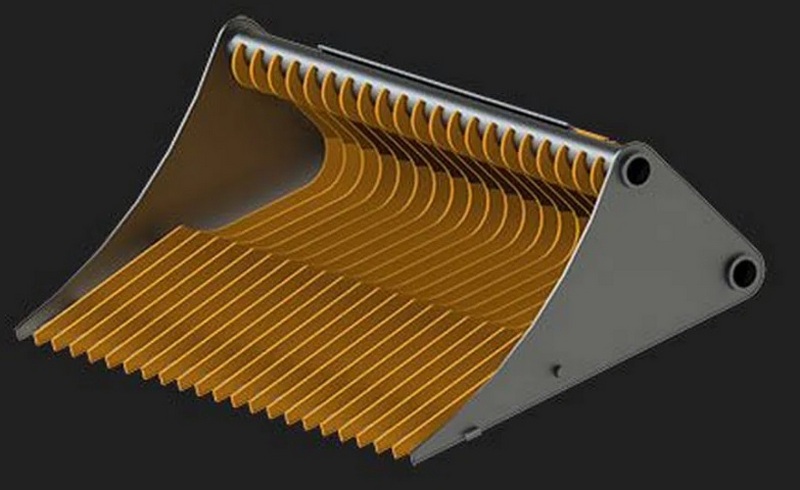

3rd place: Metatex Genie

This screening device is designed for use on a telescopic backhoe loader. With its help, it is easy to sift the soil for large inclusions, load and transport large stones, concrete breakage, coal and other materials. In agriculture, it can be used for the transportation of root crops. The width is 2450 mm, the volume according to SAE is 2.5 cubic meters. meters, height - 1300 mm, maximum extension - 1400 mm. The total weight is 650 kilograms. The recommended cost for retail chains is 205,000 rubles.

- Small mass;

- Variety of areas of use;

- Working with telescopic "arms".

- Not detected.

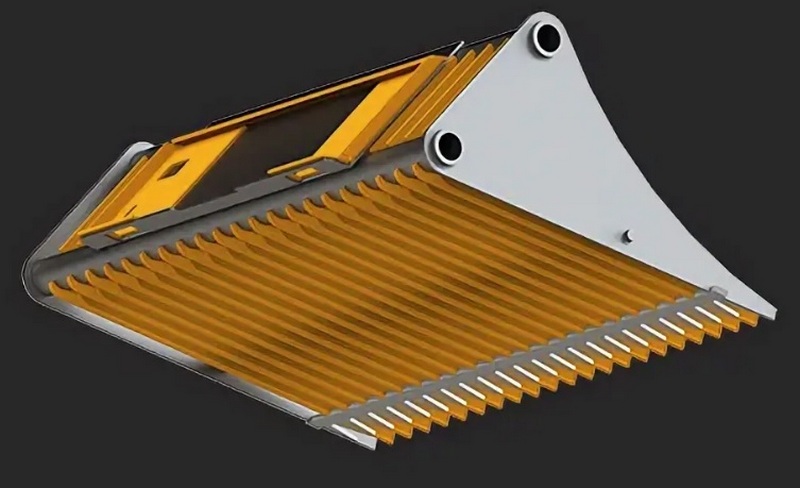

2nd place: Metatex Saez

Another model for telescopic loading equipment. The product is made of hard alloy and has only a sorting purpose. Works great with small fractions. Suitable for use in agriculture. It is installed on almost any type of modern excavators. It has the following specifications: width is 2450 mm, volume according to SAE is 3.0 cubic meters.meters, height - 1530 mm, offset - 1630 mm.

The total weight is 710 kg. The recommended cost for retail chains is 225,000 rubles.

- Simple and reliable fixation on the telescopic "arm";

- Sufficient volume of the exciting part;

- Increased width.

- Not detected.

1st place: Screening Rotary ANROSS MB Crusher

This model from the famous English brand is universal and has two functions - crushing and sieving. Attachments can be installed on almost any brand of large excavators. Applicable in the following areas: crushing drywall, screening wood (derived from trees and leaves), composting, crushing and sorting asphalt, wet inert material, crushing and sorting coal, aerating soil, screening wet soil and dry soil. It is characterized by high productivity, easy transportation of materials and a unique shape of the structure. All this makes the ANROSS MB rotary screening bucket an indispensable attachment for sorting and crushing various materials and substances. The recommended cost for retail chains is 270,000 rubles.

- Equipment with dual functionality;

- Quality European brand;

- Increased performance.

- Not detected.

For skid steer loaders

4th place: Brightum 440

This model can be installed on more than 30 different models of skid steer loaders from completely different manufacturers. The bucket is more focused on use in agriculture, it is less suitable for construction work. It has a good screening ability, can operate with any type of soil (up to frozen).The recommended cost for retail chains is 99,000 rubles.

- Installation versatility;

- Good screening ability;

- Adequate cost.

- Limited scope of use.

3rd place: "VIVO-spectech SFD SS-1800"

Designed for screening soil from large fragments, as well as for loading, transporting large stones, concrete breakage, coal and other materials. The bucket is made for loaders with attachments such as BobTech, ANT, MKSM. Specifications: width - 1800 mm, nominal volume - 450 liters, cell size - 70 mm, bucket height - 520 mm. The total weight is 390 kg. The recommended cost for retail chains is 101,000 rubles.

- Reliable and durable design;

- Wide cells;

- Sufficient height.

- Not detected.

2nd place: "Steel Power 120"

This model is intended for screening soil from large inclusions, it is focused on loading and transporting large stones, concrete breakage, coal and other materials. In agriculture, it is used to move root crops. Design features: the special shape of the ribs qualitatively retains large fractions at the very base, preventing them from falling out during unloading. The absence of a frontal edge and the reinforced ribs of the skeletal bucket make it possible to break through even the most difficult soil without any extra effort. Warranty 1 year. The recommended cost for retail chains is 105,000 rubles.

- Adequate ratio of quality and price;

- Sufficient warranty period;

- Special shape of the ribs.

- Not detected.

1st place: "Digger D-20"

With the help of this product, it is convenient to sift coal, concrete breakage, large fragments of rocky soil, as well as load and transport various agricultural products. Specifications: width is 1800 mm, nominal volume is 450 liters, cell size is 70 mm, height is 520 mm. The total weight is 390 kg. The recommended cost for retail chains is 106,500 rubles.

- Original universal model;

- The presence of a rear window;

- Easy installation on a mini loader.

- Not detected.

Conclusion

Of course, it's good if replacement equipment is purchased for a specific large project or tasks of the same type. However, it often plays the role of an additional accessory, therefore, in addition to the price of a screening bucket, when choosing, it is important to pay attention to several of the following criteria:

- The nature of the work ahead - it is more efficient to plan the site with a mini-loader, while the formation of slopes, coastal lines or digging and backfilling of trenches is best left to an excavator with a leveling bucket;

- The density of the working material - wet soil has a higher density, so its weight will be greater with the same volume. This can lead to a slowdown in work if the load capacity of the machine is not calculated correctly;

- Equipment load capacity — when choosing a screening bucket, you need to remember that the mass of high-density cargo (together with the bucket) should be at least 15-20% lower than the nominal load capacity.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131652 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127691 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124519 -

The best men's sneakers in 2022

Views: 124034 -

The Best Complex Vitamins in 2022

Views: 121940 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114980 -

The best paint for gray hair - top rating 2022

Views: 113396 -

Ranking of the best wood paints for interior work in 2022

Views: 110319 -

Rating of the best spinning reels in 2022

Views: 105330 -

Ranking of the best sex dolls for men for 2022

Views: 104367 -

Ranking of the best action cameras from China in 2022

Views: 102217 -

The most effective calcium preparations for adults and children in 2022

Views: 102012