Rating of the best industrial peelers for 2022

An industrial vegetable peeler is the most frequently used and necessary equipment in the kitchen of cafes, restaurants, and other catering establishments. Such devices are indispensable for retail stores (supermarkets) that sell finished products.

The wide scope of professional automatic vegetable peeling machines and the ability to process a large volume of products contribute to an increase in the popularity of models of such equipment.

A competent leader understands that it is not only physically difficult for employees to peel a large number of vegetables with their own hands, but also requires a lot of time, which is why he does not spare money to purchase such a necessary gadget.

Another area of use of vegetable peelers is the production and sale of already peeled vegetables.For professional use in large volumes, we recommend buying devices from well-known brands that have proven themselves to be reliable and durable. If you have a limited budget, you should consider cheaper analogues, which are practically not inferior to them in terms of basic parameters.

Content

Peeler device

Most devices have the same type of structure and consist of the following elements: housing, funnel for loading products, control panel, drive.

The control and launch of the device is carried out by acting on the buttons of the remote control. After the products are loaded into the device, the case is closed with a lid (usually transparent). A sprinkler is connected to it, which washes away the remains of the peel and promotes mixing of the products, as a result of which the peel is removed.

The principle of operation of devices for cleaning root crops

The process is fully automated and takes place without the participation of an operator (except for setting up, loading and unloading products). To remove the peel, special sharp knives or an abrasive surface are used.

After the user has loaded the products into the receiving funnel, they enter the drum, where mechanical peeling takes place using rotating discs.

After removing the skin, the vegetables are washed with water and transferred to a container, from where they can be removed for further processing. Water with the remains of the peel goes directly into the sewer. In some models, a husk trap is installed at the bottom, which allows you to separate the peel from the water in order to avoid clogging the sewer. Clean water is supplied automatically from the tap.

The user does not need to control the device, it works completely automatically. Consumables for the device are not required, maintenance consists in the periodic replacement or restoration of abrasive discs. The second option is preferable because it costs an order of magnitude cheaper than a complete replacement. Regardless of the installation location (floor or desktop), it is recommended to foresee the possibility of connecting the device to the water supply and sewerage.

The operator determines the degree of purification of products visually. Some models of vegetable peelers allow you to set the peeling time using a timer, but you still need to control the device, since too long a time will remove a thick layer of pulp, and a short period of work will not give the desired result.

Experts do not recommend loading too dirty root crops into the machine, as they can not only clog the sewer, but also contribute to the rapid blunting of abrasive and cutting elements. Manufacturers recommend rinsing the device after each cleaning in order to maximize its service life.After a full cycle of work, the operator receives the cleaned products, which must be independently removed from the tray and brought to perfection, removing minor defects and finalizing the places that were not cleaned.

The best manufacturers of food equipment guarantee 95% cleanliness of root crops.

How to choose the best vegetable peeler and what to look for

The main criteria for choosing a unit are the power declared by the manufacturer, the load volume and performance.

The power of appliances used in the food industry is measured in kW and varies from 0.5 to 0.9.

The load volume shows how many root crops can be placed in the working chamber at a time. Popular and most often bought models on average contain 7-10 kilograms of products. For large productions, potato peelers with a capacity of 18 kg or more are offered.

The productivity of the apparatus is the number of root crops processed in 1 hour. The minimum value is 150 kg/h, the maximum is 500 kg/h or more.

In order not to make mistakes when choosing a machine, it is important to know in advance the dimensions of the place where it is supposed to be installed, and not to forget about the weight of the device, which is especially important for electric machines installed on a table. In addition to installation difficulties, these parameters affect the transportation of the product from the store.

Other important selection criteria are:

- the presence of additional removable disks designed for cleaning seafood and fruits;

- the amount of marriage allowed by the machine. The lower this figure, the better. Average value - 5%;

- the amount of waste generated. Here you should also strive to a minimum, in which case the device will remove only a small top layer from the root crops;

- material of manufacture - according to buyers, it is best to pay attention to models with a stainless steel hopper (they are not subject to rust, they do not oxidize if mechanically damaged);

- the presence of a transparent cover is not necessary, but desirable - it allows you to observe the purification process and stop it at the right time;

- if you have problems with sewer clogging, we recommend choosing devices with a mesh filter that traps large waste and prevents blockages;

- an electronic display with a timer will be an additional plus, it allows the operator to leave and not be constantly near the device during its operation;

- design and appearance usually do not play a big role, since such devices are located in technical rooms, and only service personnel can see them.

Rating of quality vegetable peelers for street trade, for fast food establishments and other purposes for 2022

Fimar PPN/5

The device manufactured by the Italian company Fimar is designed for peeling potatoes, carrots and other root crops on an industrial scale. The company is well known all over the world, its products are widely distributed in the Russian market.

The removal of the top layer of the peel occurs by mechanical friction of the products against the abrasive disk, which rotates at high speed. The heterogeneous structure of the disk surface, as well as special guides, set the direction of movement for the vegetables and force them to constantly rotate in different directions.

The transparent plastic cover allows you to control the process throughout its entire length, and stop it at the right time. The husk remaining from processing is sent to the sewer through the drain hole under pressure.Peeled root crops are easily unloaded through a funnel into a container or other container.

The device is designed for installation on a table, has compact dimensions for a device of this level. The material of the frame is stainless steel, so the device is not subject to corrosion. The device is equipped with fuses against short circuits, the delivery set also includes an abrasive disc.

Specifications:

| Index | Meaning |

|---|---|

| Purpose | potato peeler |

| Volume of loaded products, kg | 5 |

| Productivity, kg/h | 60 |

| Possibility of connection to water supply / sewerage | Yes |

| Control type | mechanical |

| Voltage, V | 380 |

| Power | 0.37kW |

| Housing material | stainless steel |

| Working container material | stainless steel |

| Width, cm | 52 |

| Height, cm | 59 |

| Depth, cm | 63 |

| Weight, kg | 26 |

| Average price, rub. | 65000 |

- universal purpose (suitable for different types of root crops);

- unusual design;

- universal color suitable for any interior;

- in many online stores you can order online;

- there is a timer that allows the operator not to be constantly near the operating device;

- the functionality of the device includes the ability to connect to the water supply and sewerage.

- mechanical control;

- since the products of this company are considered branded, at a price it surpasses the closest similar competitors.

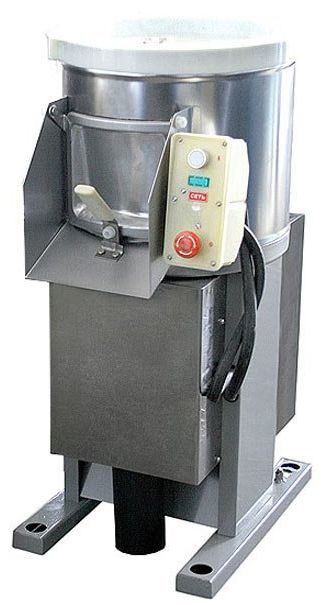

Kocateq PPHLP20

The device is designed for installation on the floor, has a capacious bunker (load weight - up to 20 kg). Almost all components, including the body, are made of stainless steel, which prevents rusting in high humidity conditions.

For the convenience of the operator, the top cover is transparent and allows you to control the process.The hopper is hermetically sealed, the device has a moisture protection class IP54. Around the loading hatch, special guides are organized to prevent spillage of products during loading and unloading.

The device is not too noisy for this type of equipment, the noise level does not exceed 74 dB. For the safety of the user, a blocking of switching on when the loading and unloading hatches are open is provided. The hopper with a quick release function allows you to separate it from the body in a matter of seconds and rinse it separately.

On the panel there is a timer and short-term switch button. In addition to the main delivery set, you can order separately a washing disc, a replaceable abrasive nozzle, and a brush. It is possible to connect a filter basket. Together with the unit, a step-by-step instruction is supplied with a description of how to install the device and use it yourself.

Specifications:

| Index | Meaning |

|---|---|

| Purpose | universal (potatoes, carrots, onions, garlic) |

| Volume of loaded products, kg | 20 |

| Possibility of connection to water supply / sewerage | Yes |

| Control type | mechanical |

| Voltage, V | 220 |

| power, kWt | 1.25 |

| Housing material | stainless steel |

| Working container material | stainless steel |

| Width, cm | 46 |

| Height, cm | 110 |

| Depth, cm | 59 |

| Weight (gross), kg | 84 |

| Average price, rub. | 66000 |

- suitable not only for potatoes, but also for other root crops;

- according to buyers, this is one of the best budget models;

- the duration of one cleaning cycle does not exceed 3-5 minutes;

- good capacity;

- almost all parts of the unit are made of stainless steel, which contributes to durable operation.

- mechanical control;

- large dimensions.

Exi PP8

The Chinese brand peeler has a universal purpose (used to peel potatoes, carrots, beets and onions) and an inexpensive price. They buy such units, mainly for use in small catering establishments, and this is due to the small capacity of the vegetable peeler (up to 8 kilograms of food can be loaded at one time).

For cleaning, a stainless steel disc is used here, as well as water pressure. Depending on the product to be cleaned, the force of the water supply must be adjusted. The abrasive surface is only on the disk, it is absent on the walls of the bunker. It is possible to connect the device to the water supply and sewerage.

The husks and cleanings are collected in a special bag, which is not included in the delivery set. The body and hopper are made of stainless steel.

Specifications:

| Index | Meaning |

|---|---|

| Purpose | universal (for potatoes, beets, carrots, onions, etc.) |

| Volume of loaded products, kg | 8 |

| Productivity, kg/h | 95 |

| Possibility of connection to water supply / sewerage | Yes |

| Control type | mechanical |

| Voltage, V | 220 |

| power, kWt | 0.37 |

| Housing material | stainless steel |

| Working container material | stainless steel |

| Width, cm | 43 |

| Height, cm | 72.5 |

| Depth, cm | 43 |

| Weight, kg | 52 |

| Average price, rub. | 26000 |

- budget price;

- universal purpose (can be used to peel potatoes, carrots, onions and beets).

- low productivity;

- short warranty period (6 months);

- low quality components.

Aurea PV23

This unit of a well-known Italian company is suitable for large catering organizations. First of all, it is interesting for its large load capacity (up to 23 kilograms) and versatility (it can peel potatoes, carrots, garlic, onions, shellfish).

To achieve fast and high-quality results, the device is equipped with an asynchronous motor. It has 2 speeds. Disc rotation speed - from 175 to 350 mm. For the safety of the user, when the loading or unloading cover is opened, the device switches off instantly. The lid is made of transparent plastic, which allows you to evaluate the quality of cleaning directly during the operation of the vegetable peeler. To collect cleanings, a special filter is provided, which must be cleaned after each cycle of work.

The small control panel has an on/off button and a timer. The device is placed on the floor, there are legs adjustable in height. To prevent tipping, it is possible to fix the unit body to the floor. The standard scope of supply includes a hopper and one abrasive wheel for potatoes and carrots. Additionally, you can purchase a disc for cutting potatoes, a basket for drying vegetables and herbs, an additional abrasive insert. The case of the device is made of stainless steel. A potential buyer may have difficulty with where to buy the unit, since it is not available for free sale, which is due to its high cost.

Specifications:

| Index | Meaning |

|---|---|

| Purpose | universal (for potatoes, beets, carrots, onions, garlic, shellfish, etc.) |

| Volume of loaded products, kg | 23 |

| Productivity, kg/h | 450 |

| Possibility of connection to water supply / sewerage | Yes |

| Control type | electromechanical |

| Voltage, V | 380 |

| power, kWt | 0.55 |

| Housing material | stainless steel |

| Working container material | stainless steel |

| Width, cm | 41.5 |

| Height, cm | 117.5 |

| Depth, cm | 66.5 |

| Average price, rub. | 250000 |

- large download volume;

- the technique has many positive customer reviews;

- motor with asynchronization function;

- applicable to most kinds of vegetables, fruits and shellfish;

- high performance.

- high price;

- the device is difficult to find in free sale due to the high price, basically all stores offer delivery on order.

Sirman PPJ20

The equipment of the Italian company is interesting for its non-standard design - a removable hopper is installed on a special stainless steel stand. This allows maintenance to be carried out with great convenience. The removable hopper can be safely washed in water. The engine transmits the impact to the working mechanism using a reliable belt drive. The engines are equipped with a ventilation system, thanks to which they are able to work for a long time without stopping. The legs of the stand are adjustable in height, can be attached to the floor if necessary.

The equipment of the Italian company is interesting for its non-standard design - a removable hopper is installed on a special stainless steel stand. This allows maintenance to be carried out with great convenience. The removable hopper can be safely washed in water. The engine transmits the impact to the working mechanism using a reliable belt drive. The engines are equipped with a ventilation system, thanks to which they are able to work for a long time without stopping. The legs of the stand are adjustable in height, can be attached to the floor if necessary.

Another notable feature of the device is the automatic unloading system for peeled vegetables. All main elements of the vegetable peeler are made of stainless steel, as they are constantly in contact with water. The manufacturer allows washing removable parts in the dishwasher. Cleaning is carried out due to the mechanical friction of vegetables on the surface of the abrasive disc and the walls of the hopper. The wall coating is also abrasive and can be easily replaced from the outside by the operator.

The remains of the peel are sent to the sewer, if necessary, a retaining filter can be installed (purchased separately).

Specifications:

| Index | Meaning |

|---|---|

| Purpose | universal (for potatoes, beets, carrots, etc.) |

| Volume of loaded products, kg | 20 |

| Productivity, kg/h | 340 |

| Possibility of connection to water supply / sewerage | Yes |

| Control type | mechanical |

| Voltage, V | 380 |

| power, kWt | 1.1 |

| Housing material | stainless steel |

| Working container material | stainless steel |

| Width, cm | 56 |

| Height, cm | 119 |

| Depth cm | 65 |

| Weight, kg | 52 |

| Average price, rub. | 157000 |

- due to the possibility of removing the hopper, it can be washed separately under running water or in a dishwasher, and there is free access to all units, making it easy to maintain;

- large download volume;

- good performance

- convenient replacement of abrasive surfaces located in the walls of the hopper (from the user's side).

- high price.

ATESY Typhoon MOK-300A

The review of the best vegetable peelers continues with the model of the Russian manufacturer Atesy. For those who doubt which company’s vegetable peeler is better to buy, we recommend paying attention to the products of this manufacturer. Its main advantage is the budget price. It can be used to peel potatoes, beets and carrots.

Products are loaded through a stainless steel funnel at the top. The bunker is also made of stainless steel, the frame is steel, with a paint and varnish coating. Unloading is carried out through a special hatch manually. When unloading vegetables, the work of the vegetable peeler does not stop, so this must be done very carefully.

The device is installed on vibration supports that prevent the device from moving along the floor. The engine also has vibration damping holders. During operation, water is supplied under pressure, which contributes to quick cleaning and flushing of the peel into the sewer. Its pressure is regulated by a crane. The cover of the unit is made of stainless steel, there is a small viewing window to control the cleaning process.

According to the advice of users, it is better to load the maximum amount of vegetables into the hopper - 10 kg, because with a small load, the disc rotation speed may decrease, which affects the quality of cleaning. The device is massively used in catering establishments in Russia, and, in general, has positive customer reviews. The design of the device provides for the installation of a special container that collects the husk and prevents it from entering the sewer (purchased separately). The timer is missing.

Specifications:

| Index | Meaning |

|---|---|

| Purpose | universal (for potatoes, beets, carrots, etc.) |

| Volume of loaded products, kg | 10 |

| Productivity, kg/h | 300 |

| Possibility of connection to water supply / sewerage | Yes |

| Control type | mechanical |

| Voltage, V | 380 |

| power, kWt | 0.55 |

| Housing material | stainless steel |

| Working container material | stainless steel |

| Width, cm | 59.6 |

| Height, cm | 87.9 |

| Depth cm | 58.8 |

| Weight, kg | 49.5 |

| Average price, rub. | 65000 |

- budget price;

- high performance;

- produced in Russia, so there are no problems with the purchase and maintenance.

- opaque cover;

- there is no blocking of the engine when opening the hatch for unloading, because of which there is a possibility of injury to personnel;

- small amount of one-time download.

Beltorgmash MOK300-M

Can only be used for certain products (potatoes, beets and carrots). This unit is produced in the Republic of Belarus and has an attractive price, even despite the cost of delivery from a neighboring state.

Operation of the device is allowed only at positive temperatures in the range from 1°С to 40°С. The machine is made of stainless steel and has a plastic cover that allows you to observe the cleaning process.The delivery set consists of the device itself, 2 abrasive discs, as well as a bowl in which the walls are covered with abrasive material.

The device consists of a working chamber, a funnel for loading vegetables, a frame (frame), a pulp collector, an output hose, an engine and a control panel. The cleaning process is carried out by means of mechanical friction of vegetables on abrasive wheels, as well as the walls of the device. The peel is removed through the holes at the bottom of the hopper, falling through the drain hose along with water into the sewer or into the retention filter. The machine is installed on the floor, it can be screwed to it with special bolts.

The device is controlled mechanically. After loading products into the hopper, the operator must turn on the water, start the unit. The degree of cleaning of vegetables is determined visually. After the desired result has been achieved, it is necessary, without turning off the device, to turn off the water and open the hatch for unloading, after which, under the influence of centrifugal force, the vegetables will move into the collection container. After that, it is possible to perform manual post-cleaning of products (remove eyes, peel residues, etc.). Peelers perform best when loaded with at least 10% of the total capacity (9 kg). The rotation speed of the discs reaches 300 rpm.

Specifications:

| Index | Meaning |

|---|---|

| Purpose | universal (for potatoes, beets, carrots, etc.) |

| Volume of loaded products, kg | 10 |

| Productivity, kg/h | 300 |

| Possibility of connection to water supply / sewerage | Yes |

| Control type | mechanical |

| Voltage, V | 380 |

| power, kWt | 0.75 |

| Housing material | stainless steel |

| Working container material | stainless steel |

| Width, cm | 65 |

| Height, cm | 87 |

| Depth cm | 45 |

| Weight, kg | 47 |

| Average price, rub. | 38000 |

- budget price;

- high power;

- average processing time does not exceed 2 minutes.

- small download volume;

- no safety shutdown when opening the hatch door;

- there is no timer, which forces the operator to constantly be near the working machine.

GASTRORAG PP-HLP-15

This Chinese brand is not well known in the Russian Federation, however, it deserves your attention. The device holds up to 15 kilograms of vegetables per load, while, compared with the previous model, it processes them almost twice as long.

The device is equipped with a powerful electric motor that can operate from a conventional electrical network - 220 V.

The process of starting the unit into operation is not difficult. First, you need to make sure that the unloading hatch is closed and the machine is turned off. After that, you can place the vegetables in the working chamber. Make sure that the volume of loaded products does not exceed the level of the line where the abrasive surface ends on the walls of the hopper. After that, close the lid and turn on the water (if any of the lids is accidentally opened, the device will automatically block). Using a special timer, you need to set the desired operating time (maximum 5 minutes). The unit will turn itself off after the end of the program. Unloading must be done after the machine is completely turned off. If a strainer is used, it must be cleaned daily to prevent clogging.

All parts of the machine are completely removable and must be inspected daily and, if necessary, washed. The top hatch for loading is opaque, made (like all other components) of stainless steel.

The device showed itself best of all in cleaning potatoes, but it can also be used for carrots, onions, and beets.

Specifications:

| Index | Meaning |

|---|---|

| Purpose | universal (for potatoes, beets, carrots, etc.) |

| Volume of loaded products, kg | 15 |

| Productivity, kg/h | 165 |

| Possibility of connection to water supply / sewerage | Yes |

| Control type | mechanical |

| Voltage, V | 220 |

| power, kWt | 0.75 |

| Housing material | stainless steel |

| Working container material | stainless steel |

| Width, cm | 64 |

| Height, cm | 122 |

| Depth cm | 52 |

| Weight, kg | 61 |

| Average price, rub. | 48000 |

- there is a timer;

- low cost compared to analogues;

- high power;

- large download volume;

- interesting design.

- low productivity;

- low-quality components can lead to a quick breakdown.

Conclusion

When first evaluating the market for industrial peelers, you can get confused about what they are and what products they are used for. Most of these devices have a universal purpose, and can be used not only to peel potatoes, but also vegetables of similar structure - beets and carrots. Expensive models have the ability to additionally install discs for processing more delicate products - garlic, onions, and even shellfish.

When choosing an industrial vegetable peeler, we recommend focusing not only on how much it costs, but also on such parameters as the volume of a single load, power, performance and the presence of a timer.

If you are constrained by free cash, you should think about buying models of Russian or Chinese production, which are practically in no way inferior to eminent counterparts, but, at the same time, due to their simple design and with proper use, they will last almost as long as cars famous brands. All devices of this type have a similar principle of operation, and perform the function assigned to them quickly and efficiently. The difference, in most cases, is only in design, as well as technical performance.

We hope that our article will help you make the right choice and buy a vegetable peeler with the best value for money, quality and reliability.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131652 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127693 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124520 -

The best men's sneakers in 2022

Views: 124034 -

The Best Complex Vitamins in 2022

Views: 121941 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2022

Views: 113396 -

Ranking of the best wood paints for interior work in 2022

Views: 110320 -

Rating of the best spinning reels in 2022

Views: 105330 -

Ranking of the best sex dolls for men for 2022

Views: 104368 -

Ranking of the best action cameras from China in 2022

Views: 102217 -

The most effective calcium preparations for adults and children in 2022

Views: 102012