Ranking of the best industrial Ethernet cables for 2025

The main insoluble problem when integrating a conventional Ethernet network for an industrial field is that the routing and delivery of information packets via the TCP / IP protocol cannot provide the desired level of performance on a real scale, which is essential for the operation of many automated control and processing systems, for example, the same factory. Industrial applications require a different communications protocol that fully utilizes the maximum Ethernet physical layers and can support some communication between multiple sensors, controllers, operating mechanisms, and applications.This is what Industrial Ethernet was designed for, which required special types of cables to maintain communication.

Content [Hide]

- 1 Ethernet industrial - general information

- 2 Differences between industrial Ethernet cables and office cables

- 3 Requirements for industrial cables and their mandatory technical parameters

- 4 The right cable = the right core protection

- 5 Industrial network transmissions require industrial cables

- 6 Choosing the right Ethernet cable for a particular industrial field

- 7 Ranking of the best industrial Ethernet cables for 2025

- 7.1 For areas up to 50 meters

- 7.1.1 4th place: "TWIST 35m, outdoor, CCA, PE, UTP, 4pair, Cat.5e, 24AWG, outdoor, black, 35m"

- 7.1.2 3rd place: "Twisted pair UTP4 CAT5E 24AWG Cu RIPO 50 meters 001-112012/50"

- 7.1.3 2nd Place: "RJ45 Ethernet - Outdoor Waterproof"

- 7.1.4 1st place: "TWIST 50 meters, indoor, Cu (pure copper class A), U/UTP, PVC, 4 pairs, Cat.5e, 24AWG, indoor"

- 7.2 For a full switching field (100 meters or more)

- 7.1 For areas up to 50 meters

- 8 Conclusion

Ethernet industrial - general information

This type of data transfer protocols belongs to the main set of Ethernet, which are "tied" to conventional equipment, i.e.work through the physical and link layers, both over network and transport Internet protocols, are focused on a specially developed application level (use of special programs). The entire network is focused on constantly maintaining the correctness of data transmission / receipt within the network, by constantly and even excessively monitoring them, especially for those points where it is more necessary for the production of a particular operation.

Industrial Ethernet uses more reliable equipment and cable consumables that have special connectors that can be very different from the usual ones. In particular, they are designed to withstand more severe environmental conditions, which is typical for most large manufacturing enterprises (a good example is the operation of a network in a large smelter with elevated temperatures). Accordingly, the type of wires under consideration should have a more powerful level of filtering, shielding, grounding, which will help it cope with the “dirty” ambient electromagnetic background (meaning both interference and radiation).

Differences between industrial Ethernet cables and office cables

In this matter, there are several criteria related to industrial wires:

- They do not require special ventilation and special cooling, so they can be laid in cramped conditions and where the air can be very dusty;

- Their installation reliability is very high, which means that all wire sections are fastened to DIN rails, and this speeds up installation and makes it easier;

- Low voltage power supply - the cables in question do not require a large number of Volts, but they are always provided with backup power supplies;

- They have technical redundancy, i.e. any site can be replaced and corrected as soon as possible, or its functions can be transferred to another site;

- Rigidity of regulatory requirements - industrial designs must strictly comply with international standards (vibration resistance, electromagnetic compatibility, appropriate degree of moisture protection);

- Extended service life;

- The obligation to have a technical support service at the enterprise, operating 24/7.

From this it is clear that local home or office switching fields may deviate from the specified criteria, since. their wiring is not operated in extremely difficult conditions and shutting down their operation is unlikely to stop any critical production process.

Requirements for industrial cables and their mandatory technical parameters

The main thing for the type of consumable under consideration is its performance and reliability. Performance will be made up of:

- Response period - the length of time that the slave device takes to respond to a request from the controlling one;

- Bandwidth is the amount of data that can be transferred in a given time unit. Here, much will depend not only on the cable, but also on the transceiver.

Reliability requirements include:

- The objective value of the chance of information delivery without loss;

- Readiness factor of devices for receiving and transmitting;

- The overall security of the transfer and the fault tolerance of the system as a whole.

Noise immunity

As for office cables, the level of protection against the negative effects of nearby areas with high electromagnetic activity is also important for industrial ones.For example, the field can be laid directly on the site where arc welding is carried out, whose devices strongly distort the background. The same applies to switching relays and other AC sources. Usually, in such areas, the network section may even need not general F / UTP protection, but individual S / FTP.

Mandatory shielding

Industrial wiring differs from conventional wiring in particular requirements for rated operating temperature and sheath material. For the consumables under consideration, the latter is standardly made of polyvinyl chloride, because it is not too expensive in terms of production. However, for specialized enterprises, a much more durable shell may be required. These include fluorinated ethylene polypropylene (FEP) or thermoplastic elastomer (TPE). Such protection is able to withstand extremely extreme temperatures from -50 to +125 degrees Celsius, while classic PVC is kept at a level from zero degrees to +75. Moreover, FEP and TPE casings are more flexible, resistant to direct ultraviolet radiation, can be placed in sea water, heavy liquid oily substances. Also, polyurethane is a popular shell material, it, of course, cannot work in such wide temperature ranges as TPE and FEP, but it has improved tensile strength, greater chemical resistance, and can successfully resist abrasion. From this we can conclude that polyurethane is mechanically stronger and practice shows that it is very difficult to break / cut it. They can perfectly equip the central cores through stamping. We should also mention thermoplastic polyurethane and chlorinated polyethylene.They are the most durable and expensive, but far from the most environmentally friendly (they are widely used in hazardous industries).

Flexibility and elasticity

Twisted-pair industrial Ethernet cable is also available as stranded or single-core. Stranded cables are used in large-scale production in exactly the same way as their counterparts in offices - for patch cords, which is due to their special flexibility. The only difference is that they are not only limited to the communication function, as there are many situations in production where the wire is in constant motion and can be subjected to twisting/stretching (for example, moving parts of conveyor robots).

Ground loops

When an industrial Ethernet wire comes into contact with any power cable, the parallel current-carrying cables and the Ethernet cable must be separated - there must be at least 20 to 30 centimeters of free space between them. The greater this separation, the more stable the data transfer will be. If the line is drawn inside a metal tube, then each section of such a protective cover must be firmly connected to the next, creating the effect of an unbreakable chain. If you have to lay wires inside the distribution panels, then there the minimum distance from the conductive elements should be at least 3 centimeters. In this case, strong bends should be avoided.

Hubs and switches

Standard distribution hubs are not used in industrial Ethernet, as they will act as nothing more than repeaters on multiple ports. It is better to use special managed switches on the line.Unmanaged switches in the industrial switching field are also acceptable, but the former are preferable, although they are more expensive.

Industrial Ethernet has three types of traffic:

- Transfer from one point to all devices;

- Transfer from one point to several;

- One-way transfer from point to point.

Typically, a standard enterprise cable can easily reach 100 transmissions per second. However, in any field there will be a certain amount of transfer (transmitted information) that does not directly perform any managerial / production function, for example, the printer periodically reports its status to the control center (roughly speaking, the printer must sometimes report to the host computer that he is ready to work or cannot work). In this way, supplying the cable network with managed switches will allow signals to be prioritized according to their importance, and give more attention to practical production teams.

The right cable = the right core protection

Even today, most network engineers in large enterprises use, so to speak, creative, but not always effective options for laying Industrial Ethernet cables. A vivid example can be (already a talk of the tongue) the method of attaching wires to water pipes with black electrical tape or adhesive tape. However, such a method, in the event of a failure situation, can significantly increase the cost of repairs and contribute to the restoration of high-speed information transfer far from quickly.

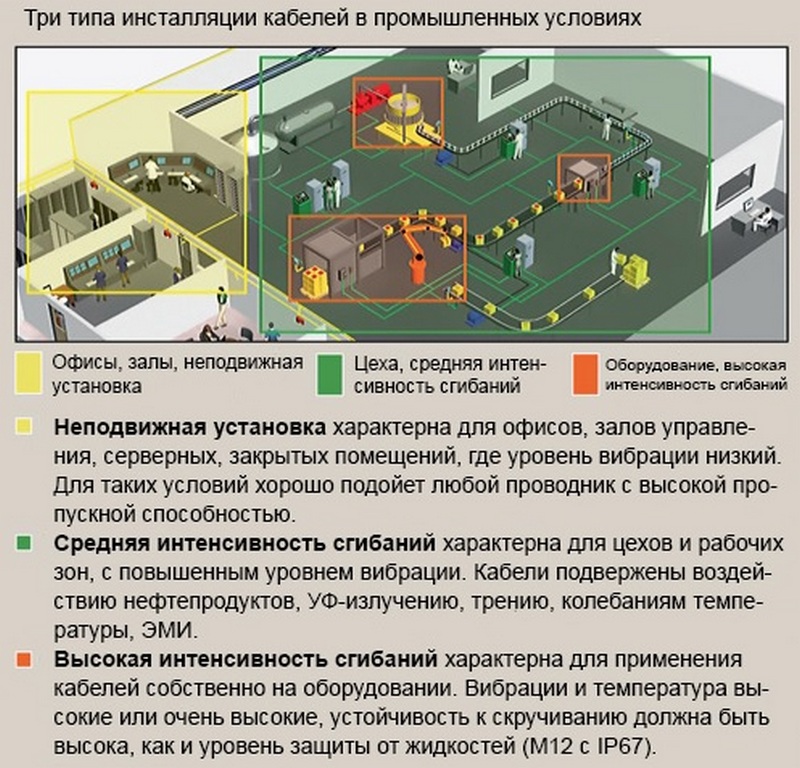

The installation of the cable, just like the cable itself, must comply with the future operating conditions and their specifics.For example, a cable designed for use in smelting metallurgical shops, on automatic conveyor assembly of cars, is unlikely to be suitable for work in a cold store. All the necessary information about the consumable can be gleaned from the accompanying documentation, which, due to the requirements for compliance with the level of international certification, has a maximum of data regarding the features of installation and use. Properly providing the industrial network with the right type of cords, you can qualitatively reduce downtime, as well as repair costs.

Industrial network transmissions require industrial cables

It is typical for a typical office that their Ethernet network is installed in a relatively quiet and clean environment, where wires can easily be hidden behind walls, under floors, or in ceilings. For the network equipment itself, whether it is active or passive, it is enough to simply find a secure zone.

In the industrial sector, the situation is completely different. All wires, connectors, etc. such elements, in fact, are an inseparable part of the overall automated control system and are permanently in difficult environmental conditions. Simple Ethernet wires, even the most expensive grade, simply cannot survive for long in such an environment. Accordingly, the industry requires a certain strength of the entire switching field. From this it is clear that office solutions are not suitable for industrial purposes.The consumables used must be suitable for operation in conditions of intense friction, take into account the possibility of direct contact with fuels and lubricants, respond calmly to high electromagnetic radiation, be able to work in conditions of very high or very low temperatures, successfully endure voltage fluctuations, as well as vibrations. and mechanical loads.

Choosing the right Ethernet cable for a particular industrial field

Before buying, you must complete several basic steps:

- Scenario definition - it is necessary to establish in what environment and in what environment the consumable will be used;

- Choosing the right wire sheath - A well-chosen sheath will help ensure the best performance and network security;

- Accounting for the difference between shielded and unshielded cables - the former is necessary for areas that have an increased degree of potential for interference, and the latter is suitable for other areas. In the former, there is always foil and a reinforced braid, which will qualitatively protect the transmitted data packet, preventing possible losses along the way.

- Selecting the type of conductor - here you should make a choice in favor of stranded or solid-core options. The latter is suitable for fixed installation, i.e. for simple switching, it should not be used on moving mechanisms. The next point is the choice between solid execution (sheaths attached to each other) and twisted pair. Solid samples are preferable to use for complex industrial work, because the sections of insulation connected along the length will not allow the formation of gaps between paired conductors.If such a gap is formed, then a resistance difference will be created, which will lead to a network break and the impossibility of data transmission.

Ranking of the best industrial Ethernet cables for 2025

For areas up to 50 meters

4th place: "TWIST 35m, outdoor, CCA, PE, UTP, 4pair, Cat.5e, 24AWG, outdoor, black, 35m"

votes 0

Designed for UTP 4 networks with a length of 35 meters, used to build wired industrial LANs. The black sample is used for laying outside the building, suitable for transmitting commands to automated production equipment from a controlling device. Transfer speed does not exceed 100 Mb/sec. The product consists of copper-plated aluminum, guaranteed to provide the specified speed without drawdowns. Conforms to ANSI\TIA\EIA-568-B standards. The kit comes with a set of RJ-45 connectors with caps, which allows you to make twisted pair segments of the desired length in the form of patch cords. Twisted pair works and is stored indoors and outdoors in the temperature range from -40 to +75 °C. The recommended cost for retail chains is 878 rubles.

- Inside is a kapron thread;

- Sufficient quality;

- Facilitated installation.

- Not detected.

3rd place: "Twisted pair UTP4 CAT5E 24AWG Cu RIPO 50 meters 001-112012/50"

votes 0

This is a 4-pair sample, made of copper wire, classified in improved category 5E. Each core is insulated with a dielectric layer - high density polyethylene with a color difference.This product is used in the installation of small networks in production. It is mainly used in rooms where the impact of third-party electromagnetic radiation will be minimal. The designation of the UTP cable consists of the type, indication of the category and structure of the core, the number of pairs and the diameter of the conductive core in mm. If the cable has conductors according to the American standard of diameters, then the AWG number is often indicated instead of the diameter, where the number 24 corresponds to a core diameter of approximately 0.51 mm. The most typical sheath is typical for horizontal cables and is a gray PVC plastic tube with chalk added for better breaking off during cutting. The recommended cost for retail chains is 2200 rubles.

- Foil shielding;

- Good quality of data transmission;

- Adequate price.

- Somewhat fragile base.

2nd Place: "RJ45 Ethernet - Outdoor Waterproof"

votes 0

The core of this product is made of high-strength, bend-resistant and wear-resistant PVC material, which is recommended for high-speed transmission in harsh environments. There is super-noise immunity, which ensures high-speed signal transmission. By using very soft heat-resistant PVC material, the number of possible bends can reach more than 30 million times. The sample itself is waterproof, oil resistant, heat resistant (+80 Celsius), UV resistant, flame retardant. The recommended cost for retail chains is 2260 rubles.

- Transfer rate - 80 kbps;

- Working temperature — +30 ~ +40 (Celsius);

- Tensile strength - 200 N;

- Compressive strength - 2000 N.

- Not detected.

1st place: "TWIST 50 meters, indoor, Cu (pure copper class A), U/UTP, PVC, 4 pairs, Cat.5e, 24AWG, indoor"

votes 0

This twisted pair TWIST consists of 4 twisted pairs with different pitches. Each pair consists of two 24 AWG copper strands, each strand is insulated with polyethylene (HDPE) insulation. The overall tough PVC outer shell is quite soft, yet the coating is highly durable.

Solid conductors are made of oxygen-free electrical copper with a diameter of 0.48 mm, which provides a bandwidth of 100 MHz and cable compliance with modern telecommunication standards. The bandwidth limit is higher than that of CCA (Copper Clad Aluminum) as the signal travels throughout the core, not just the outer copper clad circuit. A single-core copper cable is not afraid of bends, it is more resistant to breaks, compared to copper-plated aluminum (CCA). The recommended cost for retail chains is 2500 rubles.

- Relative signal propagation velocity (NVP) - 68%;

- Quality connectors included

- Excellent insulation.

- Not detected.

For a full switching field (100 meters or more)

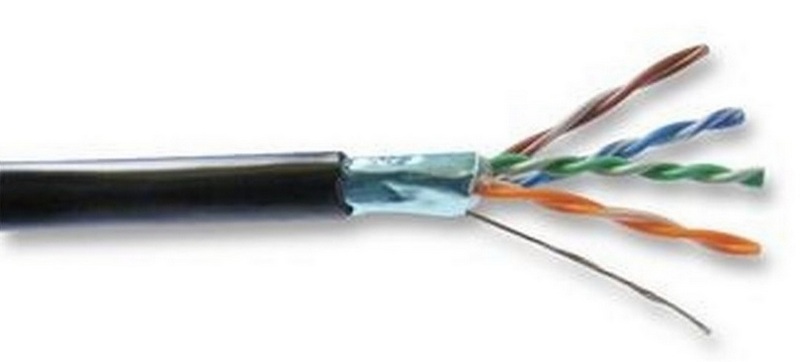

4th place: "Cabeus IE-4-SOLID F/UTP Cat5e 4X2X24AWG"

votes 0

Such a four-pair sample has category 5e, is made on the basis of twisted pair and is designed for use in Industrial Ethernet networks, for data transmission at speeds up to 1 Gbit / s.The product is made in a shielded F/UTP design and is intended for fixed laying both inside and outside buildings. The conductor diameter is 0.50 mm (24 AWG). The shielding is made of polyester aluminum foil with a drain conductor. The outer sheath is made of UV resistant PVC. The inner shell is also made of PVC. On the outer sheath there are meter marks of the cable length. It can be used in systems with protection class IP67, in aggressive industrial environments. The recommended cost for retail chains is 30,600 rubles.

- High-quality protection;

- Increased transmission speed;

- Possible street laying.

- Not detected.

3rd place: "Belden 8761.01305"

votes 0

This is a single twisted pair, 22 AWG, tinned copper stranded conductors, polyethylene core insulation, overall Beldfoil Z-Fold aluminum foil shield with improved shorting fold (100% coverage), stranded drain wire included, PVC outer sheath . Scope: industrial appointment. It is used to implement the functions of control and monitoring, transmission of low-frequency signals. Shielding

Made with Beldfoil Z-Fold aluminized polyester film with improved short fold, 100% coverage. The recommended cost for retail chains is 53,000 rubles.

- External cable diameter - 4.4 mm (nominal);

- Operating temperature: -20°C - +60°C;

- Max. tensile force: 120 N;

- Minimum bending radius: 44.0 mm.

- Not detected.

2nd place: "Belden 7929A 0101000"

votes 0

The model is used in Industrial Ethernet, Gigabit Ethernet, 100BaseTX, 100BaseVG ANYLAN, 155ATM, 622ATM, NTSC/PAL, AES/EBU digital video, AES51, RS-422, RJ-45 networks. It is used in an unfavorable, noise-saturated environment. Operates at frequencies up to 200 MHz. Suitable for use in aggressive environments and outdoors (CMX-Outdoor). Suitable for installation in risers and cable ducts (CMR). Meets ISO/IEC 11801 Cat. 5e, ANSI/TIA/EIA 568B.2 cat. 5e, NEMA WC-63.1 cat. 5e, complies with NEC / (UL): CMR, CMX-Outdoor, UL 444. The recommended retail price is 112,700 rubles.

- Full certification according to foreign standards;

- Wide scope of use;

- The reported signal transmission rate is 70% (nom.).

- Somewhat overpriced.

1st place: "Hyperline IUUTP4-C5E-S24/1-FRPVC-GY"

votes 0

This conductor design is solid, AWG - 24, conductor diameter in insulation - 0.85 mm, maximum deviation in conductor diameter in insulation - 0.05 mm, conductor insulation is FEP (fluorinated ethylene propylene) Teflon. The length of a full bay is 500 meters. The recommended cost for retail chains is 181,000 rubles.

- From one bay it is possible to organize a full-fledged field;

- Heavy-duty insulating material;

- Good combination of quality and price.

- Not detected.

Conclusion

Proper industrial Ethernet cabling is critical to keeping any automated manufacturing equipment accessible.Failure of network components and conductors is responsible for more than 70% of network failures, while the OS is responsible for the remaining 20%, and production applications for the rest. The cost of these components is minimal compared to the damage caused by network failures, where the cost of downtime can be measured in thousands of dollars per minute.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131655 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127695 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124522 -

The best men's sneakers in 2025

Views: 124040 -

The Best Complex Vitamins in 2025

Views: 121943 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114982 -

The best paint for gray hair - top rating 2025

Views: 113399 -

Ranking of the best wood paints for interior work in 2025

Views: 110323 -

Rating of the best spinning reels in 2025

Views: 105333 -

Ranking of the best sex dolls for men for 2025

Views: 104371 -

Ranking of the best action cameras from China in 2025

Views: 102220 -

The most effective calcium preparations for adults and children in 2025

Views: 102014