Ranking of the best brake hose manufacturers for 2025

The brake hose is a part of the vehicle system that faces enormous loads every day. But although it is made of high-strength materials, it also requires no less scrupulous attitude than other main components of the car. In essence, such designs are designed for a mileage of 100,000 km, but with bad roads, this figure is significantly reduced. Therefore, it is necessary to proceed in the calculations not only from the popularity of models, but from time to time to carry out an inspection with the replacement of this element. Which one is better to buy in order to avoid an emergency during a trip, we will consider in the review below.

Content [Hide]

Description as well as selection criteria

In its structure, the part resembles a high-pressure plastic tube, with a metal cap, which is responsible for supplying a special fluid to the caliper. Usually, there are 4 such details:

- two connected to the front drive;

- pair with back.

Due to a malfunction of the latter, an emergency often occurs, so it is so important to know how to choose the right rubber product or where to buy it. According to the recommendation of experienced drivers, you can avoid mistakes when choosing, given the following characteristics:

- Structural elasticity. Since said part provides free circulation of lubricant between the elements of the chassis of the car with the parts located under the bonnet, it is expected to be extremely flexible.

- Deformed surface. The appearance of shallow cracks or bubbles along the base of the tube is unacceptable. Even such a trifle can reduce the pressure when you press the pedal, thereby increasing the braking distance of the car.

- Strong fixation of a sleeve with a tip.

- Microthread position on both sides.

Tube caps - fittings, are responsible for joining the main line with a caliper or functional cylinder. Such a clutch part happens:

- “Daddy” - differs in external thread.

- “Mom” - this type of fitting already has internal notches.

- "Ear" - with a loop for fixing with a bolt.

- "Nipple" - threaded sleeve.

In addition to the above-mentioned basic features, mounting fittings may have additional links.

What are the elements, and the basis for their manufacture

All of them are divided into two types, which affects the material for production.

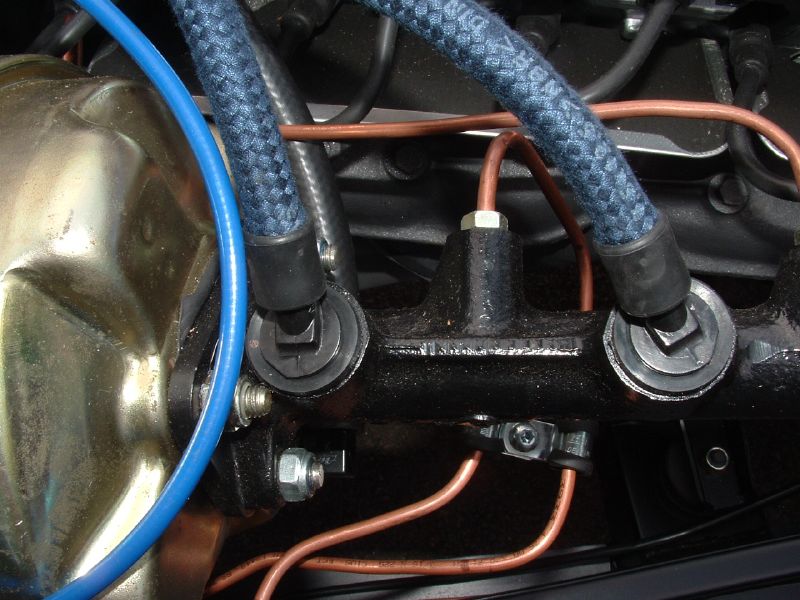

1 Rubber brake hoses. Such tubes seem rather unpretentious, but only at a superficial glance. These systems are very reliable and usually consist of three layers:

- well rubberized from the inside - regularly retain the running liquid, preventing it from leaking at the most inopportune moment;

- the second layer is a steel mesh, it is responsible for the integrity of the shape of such a tube, maintaining the entire structure even at high pressure;

- the last, outer covering, is made of very thin rubber, which allows the tube to move while at the same time protecting it from the penetration of moisture from the outside;

- although rubber structures are very strong, it is generally accepted that they significantly slow down the functioning of the entire system, as they are more susceptible to changes that occur when working under pressure than their hardened counterparts.

2 Reinforced brake hoses. They differ from the previous ones in that they have more rigid walls in the presence of only a couple of layers:

- internal - is a tube made of high strength plastic.

- external - its role is played by a special metal network-braid.

This type of coating protects the tube itself from deformation, since its composition differs from the metal mesh of the rubber counterpart. According to buyers, both amateurs and experienced drivers, the latter option is considered the most reliable, since it makes it possible to clearly control the braking process.

Advantages and disadvantages

Regardless of which company has the best brake hoses, they all have their own characteristics. So, ordinary rubber sleeves, as a rule, already installed on the car at the time of purchase, with careful driving, will serve for more than one year. However, with the acceleration of progress, the load itself has also increased significantly, making such hoses less resistant to wear. What affected the stability of this design. Given the numerous reviews of motorists, their reinforced representatives, who have a large number of advantages, took the leading positions:

- PTFE base, a high-strength plastic that can withstand the hostile environment that various additives, often found in brake fluid, can create. The material has good tightness, preventing the ingress of air or foreign impurities from the outside;

- thanks to the steel shell, the hose is protected from corrosion;

- reinforced structures can withstand even sudden pressure drops during emergency braking without being damaged, and rubber products by this point expand greatly, which makes the braking distance longer.

- there is an improvement in system response.

- the quality of the matter itself, for example, its excellent heat resistance, which allows it to retain its shape even under conditions from -70 to +270 C.

- it can be repaired if any element is damaged, without manipulating the serviceable part.

- wear resistant.

These parts are responsible for the durability, productivity, and stable functionality of the entire system. The only disadvantage of such elements is that the metallized surface can scratch the parts surrounding it. Given this fact, the best manufacturers cover them with an additional, transparent PVC layer.Which reflects how much such a system would cost.

How to know when it's time to replace

Since these devices are attached to the most moving part of the machine, they experience not only mechanical loads, because their service life is determined by several factors at once.

Line faults - causes

Any damage to this small part of the car, even the most minimal, is dangerous and can cause an accident. Since pressure increases when the pedal is pressed sharply, the hoses can simply burst, making braking impossible. Usually the following facts can lead to problems:

- frequent overload;

- wear of the base itself;

- internal damage that appears due to the use of stale brake fluid that has lost its previous anti-corrosion qualities.

- external deformation - which can be triggered by the destruction of the anti-corrosion layer due to contact with road reagent, moisture or dirt.

What to look for in order to timely contact the service station

- Illuminated dashboard light;

- "Drowning" brake pedal;

- reduction or complete disappearance of lubrication;

- traces of additives under the car itself or on wheels;

- the presence of a liquid substance on the clamps;

- the car drifts to the right or to the left;

- sluggish drive operation;

- noticeable defects on the metal body of the brake hoses.

These are the main reasons for immediately contacting the nearest car repair shop to repair the damage.

A little advice: for extreme drivers or just fans of aggressive driving, it is better to opt for reinforced products, which, if installed correctly, will honestly serve for more than one year. But lovers of a quiet ride, by the way, will have the usual, not so expensive, rubberized options.

Ranking of the top 10 brake hose manufacturers, according to car owners

Nk

votes 0

This is a bright representative of the industry, although the brand's products are more likely to be budget options, all systems are of high quality. Often their products are quoted in the secondary markets of a number of EU countries. The brand creates brake parts with a variety of caps for any type of car. The average price of a structure is 400 rubles.

- There is a complete set, including fastening elements;

- parts are highly reliable;

- long warranty period;

- a wide range of;

- nice product price.

- They may not tolerate sudden pressure surges and become covered with bubbles;

- there is a cull.

BRT

votes 0

For 2025, the enterprise is actively developing in the field of creating and improving such products. Balakovo Rezino Tekhnika JSC produces about 6,000 different items, guaranteeing the uninterrupted operation of such auto giants as VAZ, KamAZ, GAZ. The company successfully masters new developments in the field of equipment, also offering its own innovative ideas. The brand delivers to the secondary market, being one of the leaders in the production of systems. The average price of a structure is 550 rubles.

- Long service life;

- quality material;

- pleasant flexibility;

- resistant to deformation;

- inexpensive systems.

- For smart drivers.

Fenox

votes 1

A brand that is actively developing its activities in Russia, Belarus and Germany. Factories produce spare parts for the running system. Including for classic VAZ cars. The average price of a brake structure is 600 rubles.

- Fenox products have a pretty nice price tag;

- a good choice for self-repair;

- acceptable quality;

- the assortment is constantly updated;

- you can find tubes for foreign cars.

- The products from the German representative are much better;

- are often faked.

Goodridge

votes 0

Another European brand that has gained popularity among motorists. It also has its branches in Russian enterprises. These spare parts are more affordable, and their distinguishing feature is the absence of a company logo on the hose body. The company's products are distinguished by excellent quality, combining it with a great working potential. The corporation creates parts for the brake system for popular car models. The average price of a structure is 600 rubles.

- Acceptable quality;

- there are both reinforced and standard types;

- wide selection;

- made in color;

- inexpensive.

- More often supplied for secondary markets;

- the possibility of marriage.

Rating of quality products of the middle class

K&K

votes 0

The brand from Hungary has long been known to Russian motorists as a manufacturer of reliable parts, including brake hoses for cars and minibuses. By 2025, the corporation produces almost 850 different parts. By creating such an important part of the system as the brake hose, K&K exercises careful control over its production. And before releasing products for free access, products undergo a series of tests - this is already an established tradition of the company. Including tests:

- for water and air tightness;

- axial overload check;

- work in critical temperature conditions;

- even for cyclic endurance;

- tensile strength test.

This approach to its products gives significant guarantees of quality and confidence on the road.The average price of a brake structure is 700 rubles.

- Budget options are easy to find;

- the quality of the materials used.

- Not suitable for extreme driving;

- there are imitations under the brand.

Carteco

votes 0

A representative from Germany, a subsidiary of the Freudenberg Group, specializes in the creation and packaging of high quality components confirmed by the ISO 9001-2015 certificate. Each of their products is subjected to rigorous testing at the exit, which reduces the number of possible product rejections. According to the reviews of numerous users, such hoses will honestly serve for 5 years. The average price of a brake structure is 700 rubles.

- Parts are sold in sets, as well as individually;

- a long-term warranty is provided;

- precise carving;

- quality of materials;

- broad name;

- good service life.

- Lots of imitations of this brand.

Trw

votes 0

The company of German origin has long been appreciated by car owners, and has repeatedly proven its reliability by passing a series of tests from the world automotive agency AMECA. The corporation uses only the most innovative production technologies with a high-quality polytetrafluoroethylene base, and reinforcement is carried out using the highest grade steel. The hose caps themselves are made of zinc with the function of protecting the mechanism from oxidation and corrosion, extending their service life. The average price of a brake structure is 800 rubles.

- Reliable materials;

- durable;

- optimal mobility and elasticity;

- high strength.

- Possible fake.

The best, but already expensive systems

Bosch

votes 0

One of the most popular foreign manufacturers occupying 65% of the aftermarket in Europe. The company provides various consultations on car maintenance, as well as its own software. The company produces spare parts for foreign cars, including for the braking system. The brand's original products are easy to identify by a special KeySecureSystem sticker available in the smartphone application. The average price of a brake structure is 900 rubles.

- Hold up well;

- reinforced.

- There is a mismatch of the threaded part.

Ate

votes 0

The company focuses on equipping cars with mechanisms responsible for traffic safety, in particular, the brake system. For its activities, the corporation uses advanced developments in this area. Responsible for the quality and reliability of parts, which is confirmed by certificates of compliance with international standards. And the reinforced products of the company are also in high demand among ordinary motorists. The average price of a brake structure is 1000 rubles.

- Hoses maintain a stable state for a long time;

- sold with mounting hardware;

- manufacturing materials;

- good service life;

- pleasant appearance;

- resistant to temperature changes in the atmosphere.

- There are many poor quality copies.

Hel

votes 0

This manufacturer is from the United Kingdom. By 2025, HEL Performance Corporation has achieved popularity in a number of countries around the world, including the launch of a franchise for domestic manufacturers.Brake hoses from HEL have a more complex composition, which makes it easy to withstand even sudden pressure drops. The company was one of the first to produce such novelties as multi-colored polymer shells, which not only improves the presentation of the product, but also allows you to detect and fix a malfunction as soon as possible. In total, there are 13 different colors, so the company is struggling with the possibility of counterfeiting the brand. The plastic base is coated with Teflon, which protects it from the damaging effects of additives and chemicals, and the sleeves are strengthened by a stainless steel mesh, caps are made from it, which prevents the appearance of rust. The average price of a brake structure is 2000 rubles.

- Hoses are sold with fasteners;

- long service life;

- available in the online store;

- durable;

- effective protection against falsifications;

- high-quality work of the car;

- when you press the brake pedal, the system works instantly.

- Expensive.

Summing up this review, it is worth noting that by 2025 there are many brands specializing in the creation of the mentioned element. And although the best ones are native systems, if necessary, picking up and ordering the right pair online is not difficult even for a novice car enthusiast.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131651 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127690 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124518 -

The best men's sneakers in 2025

Views: 124033 -

The Best Complex Vitamins in 2025

Views: 121939 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114979 -

The best paint for gray hair - top rating 2025

Views: 113395 -

Ranking of the best wood paints for interior work in 2025

Views: 110318 -

Rating of the best spinning reels in 2025

Views: 105329 -

Ranking of the best sex dolls for men for 2025

Views: 104366 -

Ranking of the best action cameras from China in 2025

Views: 102215 -

The most effective calcium preparations for adults and children in 2025

Views: 102011