Ranking of the best suspension arm manufacturers for 2022

Control arms are the connecting link between the vehicle's suspension and the chassis. They come in different shapes and sizes, yet they are easy to recognize. These are visible metal structures that run from the body to the wheel, where they are bolted to rubber, polyurethane bushings. At the wheel, the spare part has a ball bearing, so the component is able to move from both ends.

Levers are installed for cars, trucks, their cost ranges from 240 to 23,000 rubles, depending on the quality of the material. In our review, we will provide recommendations: “what to look for in order not to make a mistake when choosing a product”, “which company model is better to buy”. We will get acquainted with popular manufacturers, a description of their parts, and we will orient you at an average price.

Content

Types of levers, how to choose them correctly

Basically, the levers are on the front axles, where they are mounted to the steering knuckle. Some heavy, high-end machines have a lever on the rear axle. Most products are wide at one end, tapering towards the other. They can be A or L-shaped, some are made as a simple rod.

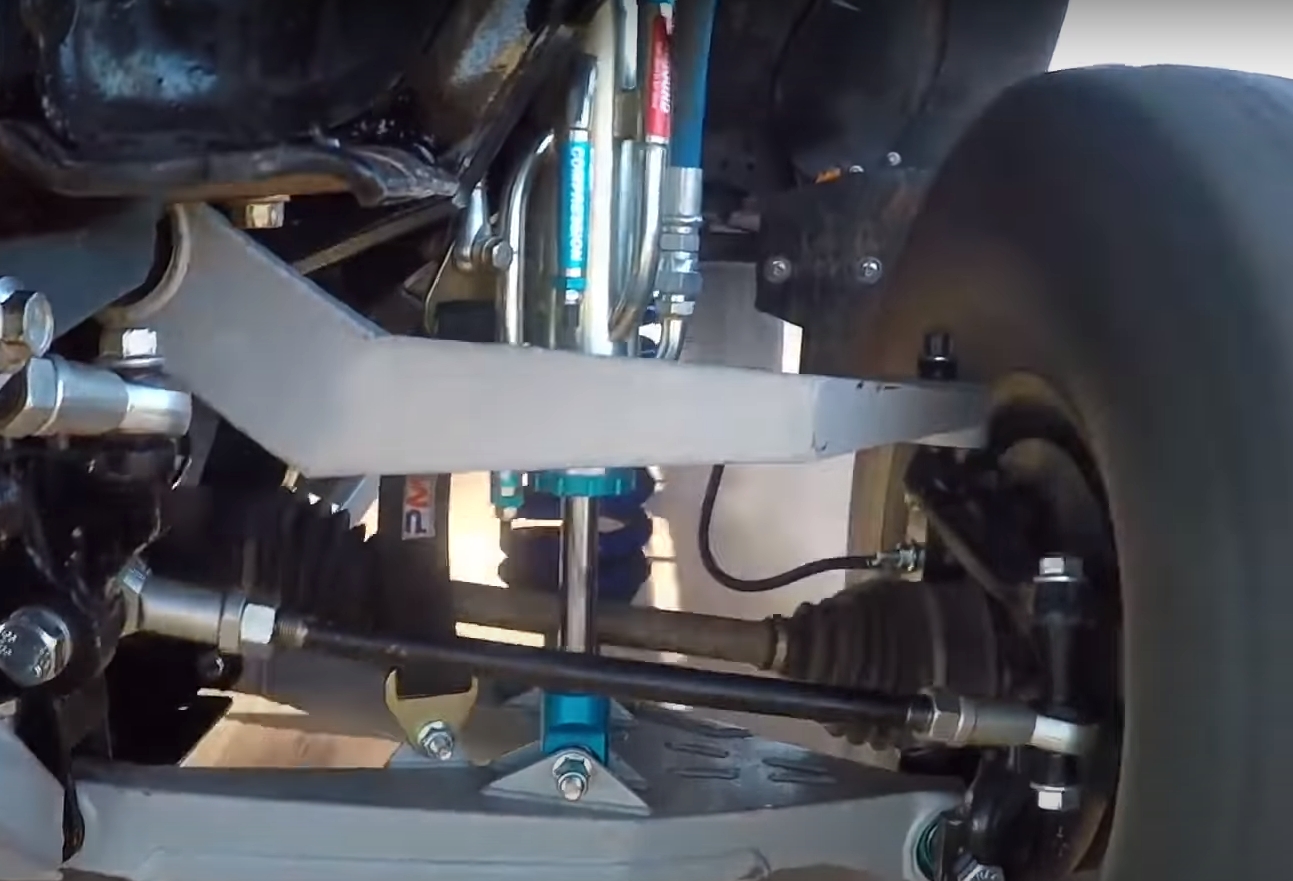

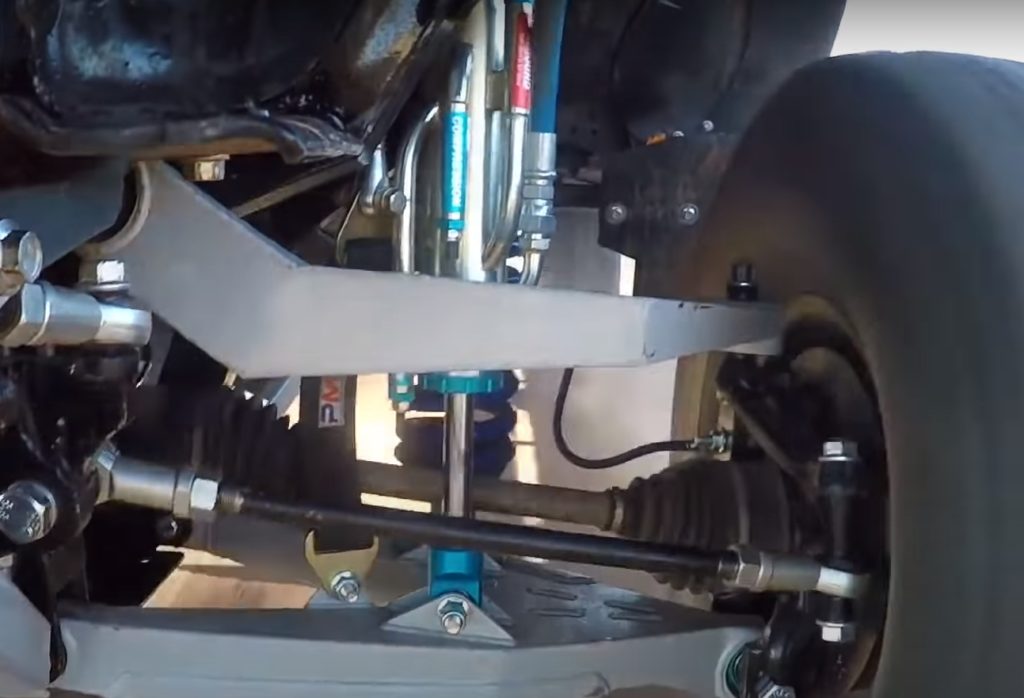

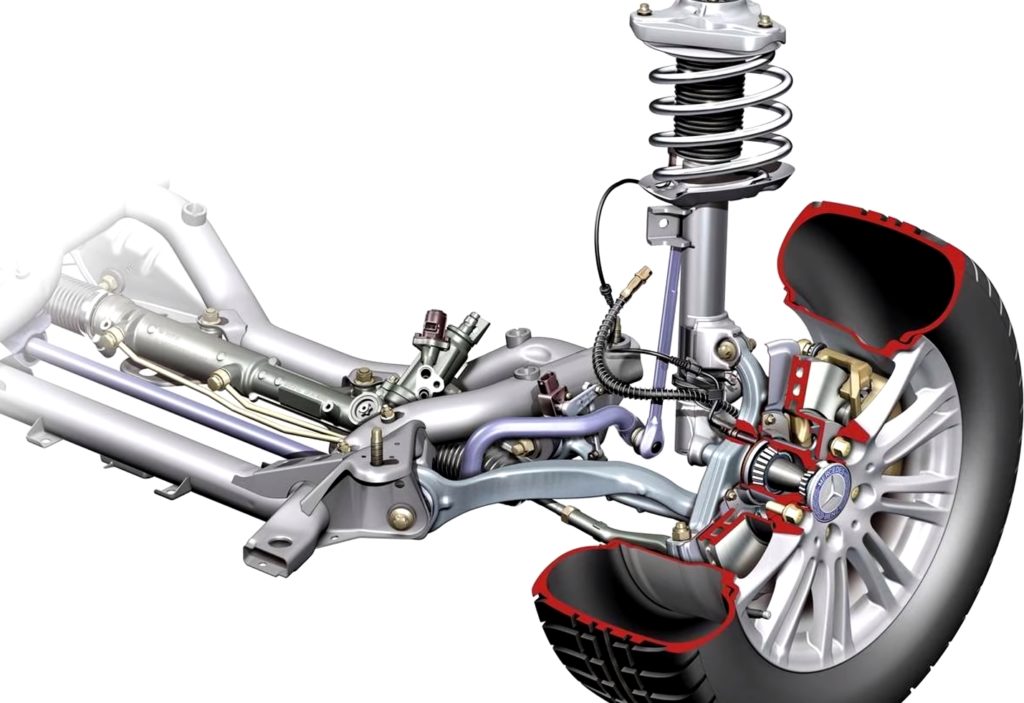

The number of levers on one wheel depends on the model. Some of them have two on both sides - upper and lower. They are attached to the wheel assembly through hinges, while the other ends are bolted to the frame of the machine. This type is called "double wishbone suspension".

Modern inexpensive car brands for the most part have one spare part on each wheel - the lower arm (MacPherson suspension). This type holds most of the weight of the body on the rack. It has its own merits and demerits.

Products consist of 3 main parts: bushings (help reduce friction and vibration), main body (connects elements), hinge (forms a steering knuckle). The design can be made of stamped steel, cast iron, aluminum alloy. Here is a diagram showing the different parts:

When you're riding rough trails, the levers help make the ride comfortable. The components synchronize wheel and frame movements to help dampen vibrations with articulated edges that improve vehicle control.

Longitudinal adjustable models are popular, they are used to control camber, vertical alignment, body roll when cornering.

Positive camber means the wheel is leaning outward, while negative camber is inward.If this parameter is adjusted correctly, it provides uniform tire wear, proper traction while driving.

The struts hold the wheels to the frame, so they need to be strong enough. A broken or bent part will cause an accident. This means that manufacturers must carefully select materials, control the process.

- Stamped steel is the main material for the manufacture of vehicles, it is inexpensive. This means that the products can be mass-produced and this is one of the reasons for their low market price. The metal flexes under load, this is an advantage when using the part as a suspension, as a result there are fewer cases of breakage, cracking of the structure during off-road driving or under load. The main disadvantage of steel models is their inability to resist corrosion. Since these components are low, they are exposed to moisture, salts, so rust is almost inevitable. This means a shorter service life. When rusted, the hinge and bushings will be difficult to remove. Metal has a heavy mass, as a result, driving comfort is reduced. Today, many manufacturers strive to make all components lighter, so they are moving away from the use of stamped steel.

- The use of cast aluminum has several advantages, it is lightweight, which makes it easier to taxi. The products are quite durable, which is a necessary characteristic of suspension parts. Some of them may be stronger than steel. Another important advantage is its ability to resist corrosion. Aluminum does not rust, which means a longer service life, even if the components are exposed to harsh environmental conditions.The disadvantage of this material is its reduced ability to bend under pressure. In this it is inferior to steel, another disadvantage of aluminum is its softness, which can cause accelerated wear, especially at the end of the hinge.

- Cast iron is a popular material used by most domestic, foreign car manufacturers. It has several benefits. The strength of the product, it can withstand a lot of weight. This makes cast iron models popular for trucks and SUVs. Cast iron is lighter than steel, which increases the handling of the car.

Suspension arms are simple components that break quite often. Malfunctions most often occur on bushings and ball mechanisms, less often in the main body. In such cases, the problem is solved by replacing the damaged levers. But not all models allow the replacement of bushings. Some of them have built-in ball joints and require replacement of the entire assembly.

Bushing failure leads to contact of metal parts to each other. Ball joints wear out causing excessive play. The main body may rust, bend, or break, resulting in handling problems. Turning on the drive and gas immediately after starting the car affects the suspension, especially the bushings, the ball mechanism. Such a driving style leads to rapid wear and tear of these elements.

To avoid breakdowns, it is recommended to gradually switch from starting the car to gas. In other words, do not increase speed immediately so that the suspension moves in sync with the car frame. This will significantly increase the life of the transverse arm. Severe road conditions also destroy the suspension components, they can get out of control and cause an accident.It is recommended to slowly, carefully overcome potholes and bumps.

It is important to be able to identify the signs of malfunctions in time, the symptoms that you should pay attention to.

- Firstly, this is the occurrence of vibration when you press the gas pedal or turn. The wheel shimmy can be completely transferred to the handlebar, if you feel it shaking, check the levers, make sure the bushings are not worn.

- Secondly, noise, clanging, crackling, also creaking when you stop the car, are the result of suspension failure. These symptoms are initially mild and can be ignored. Further, they will increase, if you do not take any action, then serious damage to the parts will occur.

- The third important symptom of a malfunction is the appearance of stiffness in the steering wheel, when it sometimes seems "sluggish". This may mean that the ball joints are too dry and need to be lubricated.

How to replace a defective part

It is one thing to suspect that the lever is bad, and another to know what the problem is. Automotive experts advise keeping a close eye on any symptoms that affect suspension components so that you take action as soon as possible. Although the symptoms are subtle at first, performing tests can help identify problems. Strong bends, cracks and breakages are easy to detect by visual inspection.

If you want to attach new levers to replace the bad ones, you will be faced with two options: take the car to a repair shop or do it yourself. Control stands are simple, accessible, easily removable elements. The process of replacing a damaged part is easy and straightforward. Almost every car owner can do this with several types of tools.You will need some technical skills such as wheel removal, torque adjustment when changing bolts.

The procedure described below is applicable to most vehicles. Make sure you wear protective gear (goggles, gloves) so you don't injure your body, especially your eyes. Make sure the vehicle is securely anchored. In some machines, when the carrier ball and control arm are removed, the weight remains on the coil spring. This is a dangerous situation. If the jack slips out of the holder, it will break off, which could result in fatal injury. For this reason, you need to make sure that the body of the car is properly raised and the wheels are fixed, the ground is level and free of obstructions.

You will need: a new part; floor jack and its supports, joint separation tool, hammer, crowbar, brake rod, torque wrench, wrench, ratchet wrenches, cleaning fluid:

- Find a secure, level surface and loosen the lug nuts.

- Raise the equipment with a jack, dismantle the wheel.

- Locate the end of the lever near the ball mechanism. This is a hinge that connects the steering knuckle to the replacement part. You will need to push the ball joint out so it can separate from the suspension strut. Spray any bolts you need to remove with penetrating lubricant. This will make it easy to unscrew them.

- Remove the cotter pin, castle nut holding the support to the suspension arm. Use a hammer and hand tools to separate the hinges. If you have a press, use it. For a non-removable ball joint, it is enough to remove the mounting bolt to the steering knuckle.

- A wrench will help unscrew the bolts that secure the rack to the frame. After they are taken out, dismantle it.

- Remove the fasteners holding the top ball joint in place.

- Using a crowbar, remove it from the steering knuckle.

- Unscrew the other end of the upper suspension strut where it attaches to the frame.

- Insert the new lever into the mounting location, lightly tighten the bolts.

- Lift and insert the pivot on the end of the transverse arm into the steering knuckle. Tighten the castle nut. If you removed the top, replace it using the reverse procedure.

Then fully tighten the bolts. Install the wheel, lower the car. If necessary, reproduce the algorithm on the left and right sides. Carry out a test drive to ensure that the installed parts are in good working order.

Buying the best rack requires a careful assessment of the criteria (type, model, year of manufacture of the machine), studying the functionality of all options. The secondary market offers a wide range of prices, there are products from a large number of manufacturers. Budget novelties are purchased in car dealerships, supermarkets.

Managers will tell you the points you are interested in: how much the model you like costs, what they are. The lever can be looked after in the online store by ordering online.

You need to know the installation side, the bridge, because racks vary depending on where they are used. There are lower, upper rear elements. Decide on the material, taking into account the style of driving. In adverse conditions, special levers will be required if you want them to last long enough.

OEM (Original Parts) or Aftermarket is one of the dilemmas that car owners face when buying various parts. OEM racks will have standard features. This means that they will not have additional benefits.They are more expensive compared to aftermarket options. Non-genuine parts are designed to improve performance. They can be more durable, flexible. Reviews about them are good, according to buyers, they offer a wide selection in terms of quality and price.

Experts advise to purchase complete sets. The reason is that it is more convenient to mount them on both sides, and not just on one. Given the high cost of replacement, this may be more economical in the long run. Complete kits include all the necessary fasteners, which means that you will not need to buy additional items.

Powder coated products are corrosion resistant and long lasting. If a company offers a long-term warranty, this may mean that they are convinced of the quality of the products. Choose parts at a reasonable price. Below you will find a list of organizations that provide only quality products.

Suspension arm manufacturers ranking in 2022

Our list is based on real reviews, it takes into account the opinion of buyers familiar with the product, its functions.

CTR

CTR products enhance travel safety by providing harness components. The history of the brand begins with the hardware store "Shilla", which was founded in Busan, Korea in 1971. After moving to Changwon, the organization expanded to 14 factories, including abroad (USA, Europe, Germany). CTR was the first to innovate with a forged aluminum post.

R&D has strengthened the brand's position as an original equipment supplier for global automotive companies. CTR's efforts have been recognized by customers around the world, resulting in record sales ($1 billion). The company is aiming for a new milestone of 3.5 billion by 2030.

CTR entered the aftermarket with growth ambitions, building Auto Valley with partners based on 50 years of know-how and technology in original equipment manufacturing. It provides excellent quality products equivalent to original parts. The company offers more than 87,000 articles in a wide range for Koreans, Japanese, Americans and Europeans. The production capacity is up to 54 million spare parts.

Guaranteed fulfillment of orders to distributors in about 45 days is an important competitive advantage. "CTR" has 300 major customers in 100 countries around the world, the sales network is still expanding (Russia, Kazakhstan). "CTR" strives for cooperation, appreciates its customers, more than profit, it values the safety of drivers.

- a wide range of spare parts;

- offices in 100 countries of the world;

- guaranteed deliveries to distributors within 45 days.

- not detected.

Kortex

The quality of parts is the main condition for safe driving. The creators of Kortex have made this their motto, and efficiency has become synonymous with the brand. Equipment from the manufacturer is popular in the market, it has reliability and quality at a bargain price.

In 2010, spare parts from Cortex are sold in the Russian Federation. They have become quite popular, having won a significant market share, due to their low price, excellent quality of products, and variety of assortment. Factories are located in South Korea, China; spare parts for most well-known European and Asian models of premium, middle-class cars are produced here.

At the moment, Cortex is one of the best brands of quality inexpensive levers.The management carefully plans the schedules for loading the production line, monitors the consumption of its products, organizes delivery. Cortex does not invest heavily in advertising, this significantly affects the margin, making it minimal.

- acceptable product quality;

- profitable price;

- spare parts for premium, middle class cars.

- not detected.

Febi

Ferdinand Bilstein's product range includes more than 40,000 different products, sourced from carefully selected partner manufacturers or original equipment suppliers. In addition, "Febi" has many patented products, under the brand name "Febi - Made in Ennepetal".

Ferdinand Bilstein has been active in the metalworking industry since the middle of the nineteenth century and has a wealth of experience in this sector. The Bilstein group Engineering manufactures various parts for the automotive industry, from chain tensioners to oil and water pumps or wheel hubs.

The technology site of the company covers almost the entire production chain, its size is 10,000 square meters. Here, machining and hardening tools are manufactured, quality control is carried out, thanks to our own metrological department. Febi is the benchmark for the highest quality standards.

- German quality;

- production control at all stages;

- production of original spare parts.

- not detected.

Daewoo

Daewoo electronics was founded on March 22, 1967 by Kim Woo Chung, a young businessman with a degree in economics from Yonsei University in Seoul.Thanks to government policy and financial assistance, the company quickly developed into a leading manufacturer of cars, boats, components and parts. Thanks to the South Korean administration, Daewoo has received contracts in various sectors.

In the early years of its existence, the company concentrated on the textile business, but in 1973 the South Korean government forced Daewoo to diversify its activities. With the liberalization of South Korea's economy, Daewoo has embarked on a major international expansion, offering manufacturing services with low cost and cheap labor, especially in the production of commercial ships, ships and oil tankers.

- stable financial position;

- a wide range of.

- not detected.

Fenox

Phenox Automotive Components is part of the huge Phenox Global Automotive Components holding. The production division of the international concern was founded in 1989. The portfolio with a wide range of products is constantly updated with the most popular novelties for motorists from the European Union, Russia, the CIS.

Phenox manufactures more than 50 million parts for the secondary market, the company serves the conveyors of leading automotive brands: Volkswagen, Fiat, Peugeot, Citroen, Renault, AvtoVAZ, GAZ, UAZ, MAZ, MTZ . The successful activity of the organization is associated with the effective functioning of research centers in Germany and Belarus, which are responsible for the design, implementation, patenting of technological processes. "Phenox" organizes the promotion of spare parts on the conveyor, the selection of suppliers of raw materials and equipment, advanced training of engineers.

- careful selection of suppliers of raw materials;

- quality control;

- use of German research centers.

- not detected.

Track

Production Association "Trek" manufactures parts for vehicles of domestic and foreign models. The Trek trademark has been trusted by the consumer market for many years:

- 14-time winner of the competition of the program "100 Best Goods of Russia";

- graduate and holder of a diploma of the Government of the Russian Federation;

- Diploma of the State Prize for Quality in 2013.

Today the company manufactures spare parts: ball joints, stabilizers, steering wheel tips, CV joint covers, wishbones, axles, rear suspension rods and other products. You can purchase original Trek spare parts in bulk:

- WHA;

- Gazelle, Volga, UAZ, ZIL.

Trek uses the equipment of companies:

- "EMAG", "GTS", "Topper", "Wenzel", "LG";

- own production of tools, equipment;

- service for repair, maintenance using the "1C: UPP MRO" system.

- a wide range of spare parts of Russian brands;

- quality equipment;

- the company is located in the Russian Federation.

- not detected.

Lemforder

Lemforder is the N1 brand in the production of original steering and chassis components. The organization is a trusted partner for more than 50 car brands worldwide, Lemforder is a leader in the development of advanced technologies for passenger cars, motorcycles, off-road chassis and SUVs. For over 70 years, the Lemforder brand has been known for its pioneering spirit and passion for detail, setting the bar in steering and chassis manufacturing.

Based in Lemferde, Germany near Bremen, the organization still designs over 90% of its products. As part of a global organization, the company has manufacturing, engineering facilities around the world. Before entering the market, each product undergoes rigorous testing.

As an OE supplier for decades, Lemferd has a reputation for developing parts that are perfectly matched to the entire vehicle system. With excellence in design, development and testing, Lemforder is successful in the aftermarket.

- quality certificate according to regulation (EU) No. 461/2010;

- German quality;

- not detected.

Febest

The Febest brand manufactures parts for Japanese and Korean vehicles. The company's motto is "German efficiency for vehicles from Japan". Each car should have its own repair kit! Febest spare parts have an original rubber composition based on natural rubber with additives, which allows the products to be used at extremely low temperatures.

Hydraulic bushings and pads are filled with a synthetic lubricant containing additives that allow parts to be used at -45 degrees Celsius. The technological process is regularly optimized and controlled. Particular attention is paid to the accuracy of the dimensions of spare parts. Febest is certified according to the international regulations DIN ISO 9001 [1], [2], [3].

- affiliate program;

- a wide range of;

- quality management certificate.

- not detected.

Mando

Technology and quality are important for all companies, these are the foundations of Mando's operation. The brand's long history, Mando's passion for providing independent technology that puts quality first, has now become a living history of South Korean automobiles. The organization is in good standing and is recognized by the world community.

Mando has grown into a global brand that manufactures components that are the foundation of safe vehicle operation. Advanced production technology of high value-added spare parts, based on talented human resources, technological capacity, competitive quality control department.

- global brand;

- thoughtful logistics;

- fifty years of manufacturing experience.

- not detected.

High lifter

High Lifter Product Inc. Since 1996, has been developing and marketing unique accessories for the aftermarket, and for all-wheel drive ATVs, "UTV", "RUV". In that short time, the company has grown from a personal backyard hobby to a multi-million dollar company. Operations are carried out on a 5,000 square meter facility in Shreveport, Louisiana. This building includes a retail showroom, production workshop, executive offices, 3 large warehouses.

In 2007, High Lifter announced a partnership with Polaris to create high performance modifications and accessories for the Ranger RZR. Shortly thereafter, High Lifter-Polaris Racing was formed.This team brought together the most experienced racers, manufacturers and mechanics with Polaris' world-class engineers to create a race car that won nine trophies in its first two events. The team continues to dominate ATV dirt racing.

Building on the success and popularity of the High Lifter, Mud Nationals, the company announced the construction of a new off-road racing park located on 2.5 square kilometers of land in Keithville, Louisiana.

- high-quality production of spare parts for ATVs.

- not detected.

Suspension arms provide smooth movement, efficient control. Not many car owners understand this. As a result, they neglect the components, resulting in inconvenience. The guide contains information on how to troubleshoot, choose a popular manufacturer. It is important that you know how to buy the product. The article will help you with this by explaining the concepts that should be considered.

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124516 -

The best men's sneakers in 2022

Views: 124030 -

The Best Complex Vitamins in 2022

Views: 121937 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2022

Views: 113393 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105327 -

Ranking of the best sex dolls for men for 2022

Views: 104363 -

Ranking of the best action cameras from China in 2022

Views: 102214 -

The most effective calcium preparations for adults and children in 2022

Views: 102010