Rating of the best manufacturers of corrugated board for 2025

Decking is corrugated sheets of black or galvanized steel or iron with a thickness of 1.0-1.8 mm. Corrugated iron is made from cold rolled sheets between two shaped rolls or stamped on mechanical presses. To avoid overstretching, the sheet waves are formed one after the other. To do this, the mill rolls are shaped so that the waves are distributed along their axes. Sheets are usually moved between rolls in the transverse direction. The presence of corrugations gives corrugated iron considerable strength, especially in bending during operation. Corrugated iron is used for wingless coverings of industrial buildings, vaulted structures, gutters and railways, as well as for field defense work (light vaults covered with a protective layer of earth).

Content [Hide]

Advantages of corrugated board over other materials

Galvanized iron is iron that has been coated with a layer of zinc to help the metal resist corrosion. Steel can also be galvanized. When the metal is to be used in an environment where there is a possibility of corrosion, it is often galvanized to be able to prevent this process. However, even with galvanizing, corrosion will eventually start to occur, especially if the conditions are acidic.

There are two main ways to make galvanized iron. The most common is hot dip galvanizing, in which the iron is moved through an extremely hot bath of molten zinc, which may be mixed with a small amount of lead, as the case may be. When the iron comes out, the zinc will combine with it, creating a layer on its surface. Sometimes the metal may be passed through a mill to level the coating. Another method that can be used is electrodeposition, also known as electroplating, although this is rarely used. Galvanized iron can be used to make pipes.

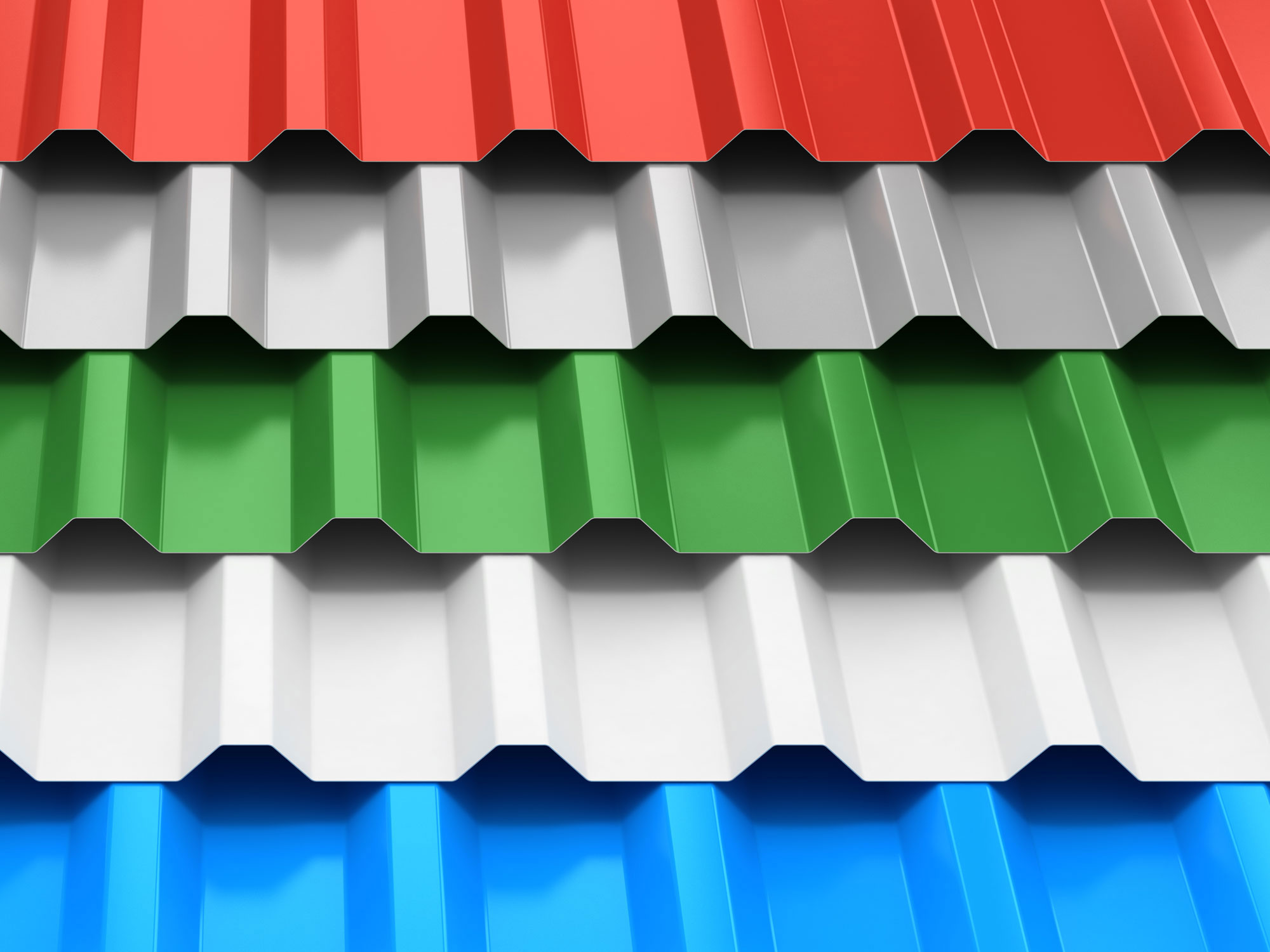

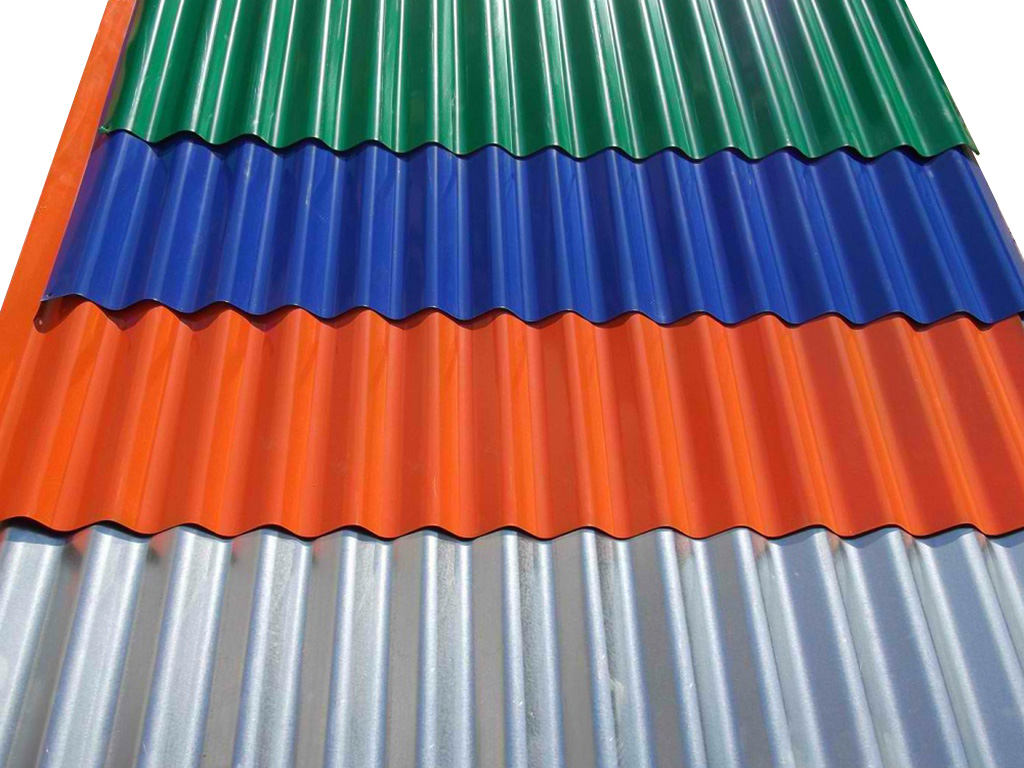

After galvanizing, the iron is covered with a coating that can be in color from shiny to dull gray. If desired, the zinc can be dyed or left in its natural color. Staining is often done when iron needs to match other building materials, or when people want to make it look more original.For example, in a garden, iron can be painted green to blend in with the foliage.

As long as the zinc coating remains intact, the galvanized iron should remain in relatively good condition. However, acidic conditions can degrade zinc over time, creating areas where corrosion can occur. It can also occur when a coating is penetrated, such as when someone drives a nail through a sheet of galvanized iron, setting off chemical reactions between the elements within. Once corrosion begins, it can spread under the zinc, eventually leading to metal failure.

This type of iron is widely used in pipes, stakes, sheets and wire, among other formats. Many household and household products contain galvanized iron products and may have custom-sized parts if necessary. People sometimes turn to professionals who weld or cut galvanized iron to meet the requirements of a particular project.

The history of the appearance of corrugated board

For many people, the term "corrugated iron" instantly evokes images of tattered barn roofs, bare industrial headquarters, or rugged Scandinavian homes. Fair enough, given its seemingly exclusive use as a durable and practical building material. The last decade has seen an increase in the use of corrugated iron in residential properties around the world.

Unlike cheap alternatives like aluminum and vinyl siding, which seem to be installed in poorly designed buildings before it's too late to fix technical flaws, the expanding market for corrugated iron has been largely slow-moving and deliberate.Consumer concerns in the housing market have created a kind of architectural bottleneck in the sense that there is only a certain list of companies that can consistently meet people's expectations.

In addition, there are only a few consumer groups who are open to the idea that corrugated iron is part (or whole) of their new home. But corrugated board turned out to be better than other cheap building materials.

Corrugated iron huts, also known as Nissen huts, have been built in Bazentin, France since 1916. Photo courtesy of the Imperial War Museum, London, UK.

At the beginning of the 20th century, newly built residential buildings made of corrugated iron were in short supply, but existed after several years of exhibitions that demonstrated the versatility of the material. During this time, corrugated iron became synonymous with war materials: in 1916, Peter Nissen's name entered the English language when he designed a semi-circular section hut made of corrugated iron sheet. By the end of World War I, over 100,000 Nissen huts sheltered over 2,500,000 Allied troops. The Americans developed their own version of such a building - the Quanset hut. And some of the largest metal structures were built to house the ill-fated new airships whose fate was sealed by the Hindenburg disaster in 1937. The Germans even developed corrugated metal aircraft such as the Junkers 'J1'. The British responded during World War II by building 2,000,000 corrugated iron bomb shelters in their gardens.

In more recent times, sheets of corrugated metal provided shelter to millions of people in the barrios, huts, and bidonville (bidonville is the French name for a corrugated metal drum) that grew up around the metropolitan areas of South America, Africa, and Asia. In disaster areas, metal sheeting is still an ideal material: it is easy to transport, it is lightweight, it can be installed by unskilled personnel, it can withstand the weight of snow, it is excellently protected from cold and heat, it can resist fire, and it sells well in the market because it performs well. their tasks.

It is noteworthy that corrugated metal sheet has become fashionable again. In the 1920s, architects such as Walter Gropius and Buckminster Fuller experimented with the material. In the 1950s, shiny and streamlined, it suited the "desert modernists" of Palm Springs and the avant-garde architects of California. Pierre Koenig's Stahl House made this utilitarian material charming again. From this California ancestry emerged Frank Gehry with his distinctive style of distorted sheet metal; and perhaps the most influential and iconic building of the late 20th century, the Guggenheim Museum Bilbao.

Australia remains a spiritual home of corrugated iron. It has even gained acceptance in Aboriginal communities, who consider the leaves to be "artificial bark" that lightly touches the ground. No one has done more than the 2002 Pritzker Prize-winning Australian architect Glenn Murcutt, who has employed corrugated iron in the service of world-class architecture.

More efficient production allowed iron sheets to be mass-sold and widely distributed during the early years of the Industrial Revolution in Britain.Events such as the California and Australian gold rushes and World Wars I and II accelerated the rise in popularity and demand for cheap, durable materials that could be easily transported - corrugated iron fits the bill.

If we fast forward to the 21st century, we can see that the introduction of corrugated iron into residential real estate is not uncommon. Take, for example, award-winning architect Glenn Murcutt. Merkutt has made a worldwide name for himself due to his particular attention to the topography and climate of the regions in which he works.

The unique ability of corrugated iron to resist temperature changes allows the interior to maintain a constant internal environment even in extreme heat conditions, while its ability not to burn out only adds to the practicality of the material. Architects are now realizing, perhaps more than ever before, that using materials that are resistant to extreme and unpredictable weather conditions is just as important as their resistance to corrosion.

Design projects using corrugated board

The delicate balance of wood and iron used in the design of the Iron Maiden home gave the hard lines of the exterior a satisfying texture. Vertically stacked wood planks at the entrance, along with continuous sheets of corrugated iron, draw the eye upwards, while warm tiles are used at the back of the house to offset the geometric structure of the iron.

The HHF Architects project consists of four boxes interconnected by small passageways, all in an iron look compared to the lush greenery of upstate New York.The Tsai residence and accompanying guest house, commissioned two years later, show how simple architectural design is backed up by inexpensive materials.

Shoreham House was a successful attempt to transform a previously dysfunctional home into a well-maintained, sustainable and practical design. Long sheets of iron siding complete the whimsically built and low-lying dwelling, while large double-glazed windows reveal the interior.

Situated along the shores of Lake Femunden in southern Scandinavia, this charming structure was originally two small log cabins. The now connected cabin sits on a cantilevered deck and is accompanied by an overhanging corrugated steel roof that has created a protected outdoor space (translucent panels have been added in some areas to maximize light inside the cabin). The objective of the project was "to carry out traditional construction work and initiate a dialogue with the management of the corrugated board production."

The Seal Rocks House Two is nestled among the trees south of the coastal town of Forster, Australia. The simple structure mimics the retro feel of the early years of modern construction, but at the same time represents many of the simple architectural techniques that dominate this part of the country.

The concept of "Inland House" can be interpreted as a "modern farmhouse", which seems appropriate for its location, because the housing is hidden from human eyes in a valley in Auckland, New Zealand. Corrugated iron siding was chosen exclusively for the highest part of the three structures and balances a sleek look with rustic materials.

Classification of corrugated board by processing method

- DIP List

Sheet steel is immersed in a bath of dissolved zinc, and its surface is coated with this compound. Currently, continuous galvanizing machines are popular. This means that people put the steel coil into a zinc-dissolving bath to get galvanized steel.

- Alloy galvanized steel

Steel is also made by hot dip. But after leaving the zinc bath, it is immediately heated to 500 degrees, which creates a thin film of zinc and iron alloy. This is the main difference between galvanized corrugated board and alloyed galvanized steel. It has good adhesion and welding properties.

- galvanized sheet

The electroplating process is very convenient for the production of electrogalvanized sheet. But the clad layer is too thin to resist corrosion.

- Single sided galvanized steel

Galvanized steel is processed only on one side of the material. Compared with double-sided galvanized steel, this kind of corrugated board is much better in welding, paint coating, rust prevention and processing.

Manufacturers of load-bearing corrugated board

Bearing corrugated board is a material that is used for roofing. Its feature is a thickness of 0.5 millimeters, deformation resistance and ease of fastening.

Ural Plant of Roofing Materials

votes 0

UZKM uses only raw materials of domestic brands in production. The company produces not only standard corrugated iron, but also polymer-coated corrugated board for greater resistance to corrosion and damage. It also provides the opportunity to manufacture products according to the parameters of the consumer.The company has proven itself in the market thanks to the low cost of sheets with excellent building properties. In addition, it was one of the first in Russia to use a velvet coating for corrugated board, which significantly increased the aesthetic appeal of the material.

- excellent quality of corrugated board;

- Possibility of turnkey production;

- the use of polymers in production.

- not detected.

Cost: from 250 rubles per m²

Plant Pokroff

votes 0

The company is quite popular in Russia and has been operating for over 20 years. The production uses foreign and domestic raw materials, which determines the final cost of corrugated board. Budget options are distinguished by high wear resistance and lightness, and more expensive ones - by the Finnish technology for manufacturing and rolling sheets.

- domestic raw materials;

- availability of inexpensive corrugated board;

- factories are based in 5 cities of Russia.

- corrugated board from imported raw materials is several times more expensive.

Cost: from 250 rubles per m²

insi

votes 0

The company has been operating since 1992 and is currently a federal holding company. The plant has a research center, which has already received 9 patents for the production of its own innovative developments. Insi provides the buyer with the opportunity to choose the color of the sheet according to the international RAL color palette. In addition to each order, there is an instruction for the installation of the material, which allows you to avoid contacting construction companies if it is not possible to do it yourself.

- impressive color range of profiled sheet;

- the possibility of applying a polymer coating;

- use of innovations in the production process.

- not the most budget-friendly manufacturer on the market.

Cost: from 350 rubles per m²

Wall deck manufacturers

Wall corrugated board is corrugated galvanized iron, intended for the manufacture of fences, fences and finishing and facing works. It is characterized by high aesthetic value and a long service life of up to 50 years.

Grand Line

votes 0

Grand Line Center LLC is a Russian company headquartered in Belousovo. The company operates in the field of metalworking and wholesale trade with other metals. It was registered on May 21, 2008. The latest financial results indicate that net sales decreased by 7.01% in 2018. The total assets of the company showed a negative growth of 19.42%. The net profit margin of Grand Line Center LLC increased by 0.15% in 2018.

- availability of own laboratories for the development of material;

- more than 55 points of flagship stores in Russia;

- provides a guarantee for corrugated board for up to 50 years.

- not the lowest price for 1 m² of corrugated iron.

Cost: from 330 rubles per m²

Neva Steel

votes 0

The company has been operating on the Russian market for over 50 years. The corrugated board is distinguished by the presence of high-quality steel in the composition, which perfectly resists corrosion. The company offers not only classic corrugated iron, but also options made to look like wood, antique copper or stone. A feature of the product is its relatively low weight compared to competitors, coupled with resistance to mechanical damage.Such material reduces the financial costs of construction work by one-fifth.

- time-tested quality;

- the ability to choose a custom color corrugated board;

- brand prevalence.

- high price per m² sheet.

Cost: from 500 rubles per m²

Metal Profile

votes 0

The company is the largest manufacturer of corrugated board in the CIS. There are 18 factories on the territory of this association. In addition, in 2011, Metal Profile was included by Forbes in the list of the 200 most successful non-public enterprises. Branded coatings PURETAN and PURMAN have no analogues in the domestic market. On sale there are both budget options for a wide variety of colors, as well as more expensive lines.

- a wide range of goods;

- products for any wallet;

- popularity of the enterprise not only in the Russian Federation, but abroad.

- not detected.

Cost: from 200 rubles per m²

Over 35 corrugated board manufacturers are represented in Russia, one third of which managed to reach the world level. Each of them offers something special, so the buyer has plenty to choose from.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131654 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127694 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124521 -

The best men's sneakers in 2025

Views: 124037 -

The Best Complex Vitamins in 2025

Views: 121942 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2025

Views: 113398 -

Ranking of the best wood paints for interior work in 2025

Views: 110321 -

Rating of the best spinning reels in 2025

Views: 105332 -

Ranking of the best sex dolls for men for 2025

Views: 104370 -

Ranking of the best action cameras from China in 2025

Views: 102218 -

The most effective calcium preparations for adults and children in 2025

Views: 102013