Rating of the best engineering board manufacturers for 2025

Engineered board (ID or engineered flooring) is a popular flooring material. At its base is ordinary plywood or wood chipboard, and the surface layer is made of veneer. Usually, durable and valuable wood species are used for this. The materials in the composition of such a flooring have the following standard proportions: 75% or less - plywood, 25% or more - valuable wood. The main sign of quality and durability of the canvas in question is the thickness of its outer layer, which must be at least 2 millimeters. All constituent layers of the material are pressed and glued, so the structure of the board is not damaged even under conditions of excessive use.In terms of popularity, the engineered board approaches parquet, surpassing the latter in terms of durability and strength, but losing to parquet in terms of the stability of the structure itself. At the same time, the price of a parquet board is slightly lower than that of an engineering board. However, most buyers agree that the ID is worth the money.

Content [Hide]

Pros and cons of engineering canvas

Most of the ID samples on the market today have the following average values (for a single element, that is, roughly speaking, for each board):

- Thickness - from 15 to 25 mm;

- Length - from 500 to 3000 mm;

- Width - from 110 to 450 mm.

The positive qualities of an engineering board undoubtedly include the following qualities:

- The engineering canvas is a material glued together from several layers, which means that it is less susceptible to mechanical deformation. It also has the highest geometric stability.

- You can lay the ID directly on the concrete, while additionally laying plywood as a base is not required.The main thing is that the concrete is even and has increased waterproofing. The versatility of ID also lies in the fact that it can be laid directly on top of the "warm floor".

- The engineering canvas is durable, it can be varnished and sanded several times. However, in order to produce reprocessing, the top layer of ID must initially be greater than the minimum by 2 millimeters (i.e., not less than 4 mm).

- The material under consideration is characterized by resistance to external influences: the percentage of the probability of cracking / drying out is much less than that of parquet.

- Its installation process is extremely easy - a sleeve-groove (thorn-groove) connection is used.

- The designer range is very large - the veneer coating can be “aged” for a retro style, brushed (painted) for a classic one, tinted in light gray colors for “hi-tech”.

- Engineering flooring is also famous for its environmental friendliness and high level of noise and thermal insulation.

There are few drawbacks to the engineering board, and they are purely repair and technical in nature:

- Individual elements of the coating are difficult to repair, it is difficult to re-lay the entire board;

- The high cost of the canvas itself;

- Each batch is painted individually, so it can be difficult to choose a replacement for repairs from a similar one and get into the color tone;

- The markets are filled with low-quality counterfeit;

- Floating laying is not possible.

Manufacturing technologies and main characteristics of ID

Initial drying of wood

This stage is extremely time-consuming and directly affects the quality of the material, so responsible manufacturers spend a fair amount of time on it:

- Felled wood blanks are laid out for drying only in open space;

- During air drying, the wood gradually rejects moisture, drying evenly along the entire length;

- Upon completion of natural drying, the blanks are transferred to the drying chamber, where they are brought to the desired moisture level of 8% (plus / minus 1%).

IMPORTANT! Unscrupulous manufacturers prefer to dry the tree "in haste" and almost immediately send it to the drying chambers. But such rapid drying has a very negative effect on the final quality of the board - the material instantly loses its main property - its strength. Properly seasoned wood absorbs mechanical pressure better and is less prone to delamination.

Main stage of production

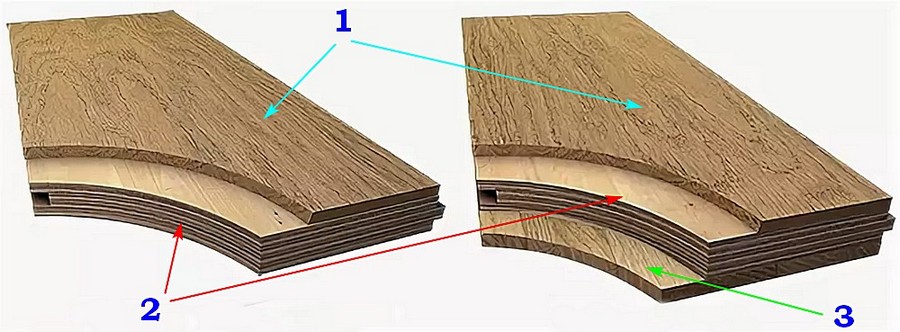

According to the number of layers, the board can be two- or three-layer. The first layer is always valuable wood species, and the next one is cheap wood or plywood, which is laid perpendicular to the fibers of the top layer. In the case when there is a third layer in the structure, it is laid parallel to the veneer fibers.

The production process of an engineering board consists of the following steps:

- Special machines cut the lamellas according to the given dimensions, while simultaneously producing plywood blanks;

- By means of a special adhesive composition, the layers are combined into a single material. With the help of a press, increased adhesion between the layers is achieved and the strength of the workpiece is stabilized;

- At the board ends, joints are cut out in the form of locks (usually this is a “thorn-groove”);

- At the end of the process, the board element is varnished in 5 layers in order to increase wear resistance. In this process, each manufacturer uses their own wax-based oils or blends.

IMPORTANT! Based on the thickness of the top layer, you can find out how many times the production of restoration (grinding) of the ID surface is available. It should be remembered here that each such operation will “remove” approximately 1 mm of the layer.

Dependence of quality on the adhesive base

A high-quality adhesive mixture will securely fasten all layers of the board, prevent the layers from shifting, and compensate for the tension between them. From the point of view of production technology, the adhesive base is the weakest link in the construction of the material. It is believed that the fewer layers of glue in the board, the stronger it is. For example, a standard two-layer board has only 1 adhesive layer. However, do not forget that the plywood used in the construction is already a multilayer material in itself, which means an increased risk of deformation of the entire structure.

The adhesive base used in the ID must comply with the requirements of environmental friendliness and ensure reliable adhesion of the layers to each other. It is possible to check the quality of the gluing, but the test will take too long. It consists of the following steps:

- It is necessary to cut the board into small pieces;

- Leave them in water for 100-120 hours;

- Then dry the cut samples on the battery for the same amount of time;

- After drying on the battery, dry in the open air for at least 14 days.

The quality of ID is determined by the degree of delamination of the tested samples. If they began to exfoliate while still in the liquid, then even with the help of professional installation it will not be possible to make a high-quality floor covering from such material (the corners will rise, the upper lamella will peel off, any grinding will reveal flaws). Also, it is impossible to cover this board with LKM - it will immediately “fold”, and then the layers will simply disperse and peel off.Thus, the above test should be carried out in any case when large-scale finishing work is to be done.

Protective covering

This coating should only be done in two coats with varnish or oil on hard wax - it will best protect against moisture. The coating can be done independently (if a board without protection is purposefully purchased), however, practice shows that self-treatment can be even more expensive than the factory one.

IMPORTANT! Unscrupulous manufacturers can save on protection by applying only a single layer of natural oil, and at the same time indicate that the board is protected. If you spill coffee, wine or tea on such a coating and do not immediately wipe it off, then a stain will remain on the surface forever.

There is a special test for checking the protective layer, which will not take too long:

- A colored liquid (tea, coffee, wine) is specially poured onto a small sample of the board;

- The sample is left to dry in the natural conditions of the domestic premises at room temperature for 50-60 minutes;

- At the end of the specified time, the board is wiped dry.

If there are no traces left, then the protection is carried out in two layers and with high quality. But the advanced parameters of varnish protection can only be determined by professionals.

Working layer and its thickness

The modern engineering board market can offer the following material options:

- A board based on HDF fibreboard with a working layer less than 2 mm thick. According to European standards, such material does not even belong to an engineering canvas, but is considered only a floor covering. Its reconstruction (grinding) is simply impossible, and if signs of wear or various abrasions occur, the entire floor will have to be dismantled;

- A board on a layer base from 3 to 6 mm is the most practical and cost-effective option. For example: a 5 mm lamella withstands at least 4 grinding operations.

IMPORTANT! It is worth remembering that the engineered board floor is usually re-sanded after ten to fifteen years of use. Thus, depending on the intensity of use of the future flooring and the load on it, the top layer should also be selected. Experts advise that using ID with a greater layer thickness is much more practical than a 2 mm disposable one.

Features of choice

Due to the fact that engineering coating is far from a cheap material, it is necessary to approach its choice with all responsibility. First you need to choose the optimal grade of the board, which is represented on the modern market by the following types:

- "RUSTIC" - it differs in that during the production of the surface layer in the lamellas at the primary stage, veneer is prepared, sawn at various angles. Because of this, some items may vary slightly in texture / color. Also, the manifestation of insignificant, insignificant defects for operation is not excluded. The cost of this product in the building materials market is minimal. They try to use this ID for small dachas and country houses. In connection with such unpretentiousness, the material is placed in the hallways, in offices, in the foyer of kindergartens and schools.

- "NATUR" – this variety is characterized by an average price / quality ratio. The veneer for it is produced using the tangential sawing method, i.e. along a tangent line to the fibers. Because of this, it is difficult to visually detect defects on it.Such a coating is suitable for the kitchen, bedroom, living room - in general, for those places where there is no heavy load on the movement of people in shoes. However, it is worth noting that this material does not possess special aesthetics. Its advantages include the fact that it perfectly tolerates sudden changes in temperature.

- "SELECT" - samples of the elite level, in the same batch it is difficult to find elements that differ in color / texture. This is all due to the fact that they are produced in the so-called radial way, which means cutting along the fibers. This variety is very expensive, characterized by a special durability, it is usually laid in large city apartments, management offices, conference rooms. The top layer of the "SELECT" grade cannot be less than 3 mm, which indicates at least two possible restorations.

General overview of engineering boards from popular precious woods

Oak

Oak is used in elite coatings and it is in sufficient demand among customers. A standard board made of it has two layers, which are glued perpendicularly, which indicates the additional strength of the entire material as a whole. The same factor significantly reduces the risk of mechanical damage, and is also the key to successful resistance to humidity and temperature extremes.

The main advantages of an oak surface include:

- Possibility of use in rooms of various types, as well as installation directly on the "warm floor" system;

- Long service life - from 20 years;

- Excellent sound insulation properties, does not emit extraneous sounds and creaks when walking;

- Heat resistance - delays the cold emanating from the concrete floor base;

- Does not require frequent renewal and scraping;

- Easy to care for and does not absorb dirt.

In the design field, white-tinted oak ID is especially popular - it is often used in the design of modern minimalist styles, for example, "hi-tech". However, there are also dark variations on the market for the classics - dark brown or dark gray shades. These materials create a wonderful contrast if the ceiling is painted in lighter colors. Western European brands are considered leaders in the production of oak-based IDs.

american walnut

This type of wood attracts a potential buyer with its wide color palette. At the same time, walnut is considered a very, very reliable tree, which indicates high performance. Professionals distinguish the following positive properties from the American walnut:

- It fits perfectly both on a draft concrete floor and on top of a "warm floor" system;

- Over time, the surface will acquire a rich and deep color;

- Before laying, the material almost does not require facing, fitting and grinding;

- Ideally used in rooms with a large throughput load and high humidity;

- Not prone to fading when exposed to direct sunlight;

- It has optimal bending characteristics and is resistant to mechanical stress;

- Internal stress is practically eliminated due to the correct balancing of the structure.

Designers note that the American walnut floor looks extremely presentable and unusual. Walnut gives out a very original pattern pattern, peculiar only to him. If high-temperature oven drying was used during the manufacturing process, then the board may have a special purple-brown color with some admixture of a shade of crimson and with dark streaks.

Ash

Ash is one of the most popular wood species for flooring purposes. This breed is distinguished by high strength and hardness, such lamellas must be used in rooms with high traffic intensity. Other benefits of ash include:

- The harmonious geometry of the pattern, which can visually increase the area of the room;

- Outwardly, it is similar to more expensive varieties of wood;

- It has low thermal conductivity, which means it does not require a special substrate as a heater;

- The flooring itself is very practical, it can be restored both in parts and the entire area.

In the design environment, white ash with a sandy yellow, gray or pink-beige tint is especially popular. In general, its color scheme gives a wide field for the possibilities of design experiments. This board coating looks very good on large areas of city apartments - they are often decorated with living rooms and bedrooms.

Rating of the best engineering board manufacturers for 2025

foreign brands

3rd place: Coswick

votes 0

An excellent sample from a Canadian manufacturer, in the production of which innovative technologies of the protective layer are applied. Now this layer is also a decorating element. Additionally, UV protection is provided. Has an aesthetic appearance.

| Name | Index |

|---|---|

| Manufacturer country | Canada |

| wood species | ash |

| base color | Dark brown |

| Effect | Coloring |

| Coating | oil |

| Number of lanes | 1 |

| The presence of a chamfer | In stock |

| Installation on "warm floor" | Not possible |

| Surface layer thickness, mm | 4 |

| Cost, rubles | 6100 |

- Pleasant appearance;

- Original painting technique;

- Durability.

- Insufficient resistance to high humidity (separation).

2nd place: "Wood Bee"

votes 0

A canvas from a Dutch manufacturer that has three layers, which means an increased level of quality. The protective coating is made using as many as seven layers of paintwork materials, which means a special resistance to ultraviolet radiation and mechanical stress. Although the manufacturer does not provide a guarantee, the average life of the coating is stated to be 15 years with two possible restorations.

| Name | Index |

|---|---|

| Manufacturer country | Netherlands |

| wood species | oak |

| base color | Beige gold |

| Effect | Coloring |

| Coating | Oil and varnish |

| Number of lanes | 1 |

| The presence of a chamfer | In stock |

| Installation on "warm floor" | Available |

| Surface layer thickness, mm | 3 |

| Cost, rubles | 3500 |

- Good price/quality ratio;

- Wide range of colors;

- Possibility of installation on the "warm floor".

- Not found (for its segment).

1st place: "Marco Ferutti"

votes 0

It is positioned as an exceptional solution for use in design purposes. It is distinguished by a stable and durable base, a powerful outer operational layer. Only exotic varieties of wood are used for it. The brand is the official supplier of the Italian Parliament.

| Name | Index |

|---|---|

| Manufacturer country | Italy |

| wood species | Nut |

| base color | Dark brown |

| Effect | Coloring |

| Coating | UV varnish |

| Number of lanes | 1 |

| The presence of a chamfer | In stock |

| Installation on "warm floor" | Not possible |

| Surface layer thickness, mm | 2 |

| Cost, rubles | 5900 |

- Democratic price;

- UV protection;

- Long structural elements.

- Impossibility of restoration (thin top layer).

domestic brands

IMPORTANT! At present, there are very few wholly Russian firms involved in the production of ID that can compete with Western companies. It is worth noting that it is Russian small firms that can produce low-quality products (along with Asian brands). Basically, all high-quality Russian production is just joint ventures with Western manufacturers operating in the Russian Federation under the license of the parent company.

3rd place: "Boen"

votes 0

Initially, this Norwegian company entered the Baltic market, and then it entered the Russian market - at present, a plant for the production of ID near St. Petersburg is operating in the Russian Federation. The products are of high quality and belong to the premium class. As a result of careful selection of the material for the top layer, the coating has a smooth and beautiful pattern.

| Name | Index |

|---|---|

| Manufacturer country | Russia (under Norwegian license) |

| wood species | Oak |

| base color | brown pastel |

| Effect | Coloring |

| Coating | Waxed oil |

| Number of lanes | 1 |

| The presence of a chamfer | In stock |

| Installation on "warm floor" | Not possible |

| Surface layer thickness, mm | 3.5 |

| Cost, rubles | 9100 |

- Ease of repair;

- Wide range of products;

- Flat drawing.

- High price;

- Oil coating requires frequent renewal.

2nd place: "Goodwin"

votes 0

A relatively new Russian-German conglomerate (founded in 2017), producing low-cost engineering coatings. At the same time, its reliability and good quality are noted. For the outer layer, mainly ash is used, which will emphasize the massiveness of the floor.The canvas will have increased impact strength, successfully resist moisture.

| Name | Index |

|---|---|

| Manufacturer country | Russia (under German license) |

| wood species | Ash |

| base color | Brown light |

| Effect | Matte |

| Coating | Oil |

| Number of lanes | 1 |

| The presence of a chamfer | In stock |

| Installation on "warm floor" | Not possible |

| Surface layer thickness, mm | 4 |

| Cost, rubles | 3600 |

- The use of birch plywood kept the price down;

- Large thickness of the top layer;

- There is no significant tint difference in one batch.

- Not found.

1st place: "Greenline"

votes 0

Probably the only completely Russian company that can compete with the West. She has developed her own production technology, focused on expensive wood species. Buyers note that at a modest price, the quality of the flooring is not inferior to foreign samples.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| wood species | Oak |

| base color | Dark brown with a gray tint |

| Effect | brushing |

| Coating | varnish |

| Number of lanes | 1 |

| The presence of a chamfer | In stock |

| Installation on "warm floor" | Not possible |

| Surface layer thickness, mm | 3.6 |

| Cost, rubles | 4100 |

- Resistance to mechanical stress;

- High-quality plywood base;

- Durable top layer.

- Works only with expensive wood.

Instead of an epilogue

It is better to purchase engineering coating, of course, in retail chains, because manually checking the quality when buying via the Internet will not work. Yes, in fact, there is no special need for this: the difference in price between retail and the Internet is small due to the general high cost of the material.At the same time, if the buyer has set his sights on large volumes of purchases, then it is imperative to carry out the quality tests given in the article to determine the positive properties of the future floor.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127687 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124516 -

The best men's sneakers in 2025

Views: 124030 -

The Best Complex Vitamins in 2025

Views: 121937 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2025

Views: 113393 -

Ranking of the best wood paints for interior work in 2025

Views: 110317 -

Rating of the best spinning reels in 2025

Views: 105326 -

Ranking of the best sex dolls for men for 2025

Views: 104363 -

Ranking of the best action cameras from China in 2025

Views: 102214 -

The most effective calcium preparations for adults and children in 2025

Views: 102010