Rating of the best manufacturers of aerated concrete blocks for 2022

Working with aerated concrete blocks is a pleasure. It is not without flaws, but it can be used to complete the designated scope of work much faster. In addition, the walls erected with its help become warmer, which is extremely important during the ongoing financial crisis. However, such functionality is inherent only in high-quality raw materials, which are produced by the world's best manufacturers. The modern market is full of building materials of various types, and in order not to make common mistakes in the selection process, products of reliable brands should be preferred. We propose to talk about them in our article.

Content

What it is

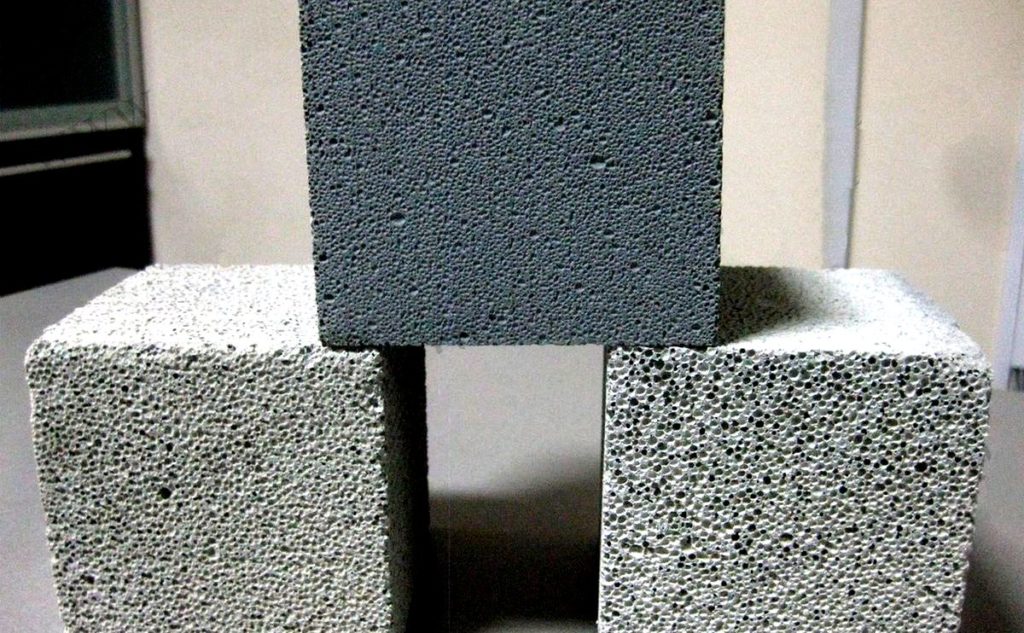

Aerated concrete is a category of building material, for the manufacture of which sand, cement and a number of reagents are used, which turn into foam in the process of interaction with cement. Often we are talking about a paste or powder made on the basis of aluminum. As a result of interaction with lime or cement, pores are formed. The bubbles are evenly distributed throughout the volume. Their shell consists of lime or cement. The raw material is called cellular because of its structure, and has a low weight.

Features of choice

Every year the technology improves, and raw materials become cheaper. This is due to the applied production technology and the cost of purchasing raw materials. Aerated concrete is a simple and, at the same time, inexpensive solution. Gas blocks are a kind of porous concrete, which, in fact, is a subspecies of artificial stone. It contains a number of cells. For the manufacture of used blowing agent, cement and quartz sand. Gypsum, ash or lime may also be added. After prolonged exposure to temperature and high pressure, a series of chemical reactions occur, which contribute to the formation of pores.

When choosing gas blocks, you should pay attention to the following selection criteria:

- Price.

- The methodology of the applied construction process.

- Permissible load on the walls (construction of a building on several floors).

- Thermal performance indicators.

- The proportion of masonry.

- The dimensions of the blocks used.

- Manufacturer brand.

Specifications and Designated Functions

Aerated concrete are cellular autoclaved blocks. The components used are thoroughly mixed, after which they undergo a long heat treatment at the factory.

What are:

- D300 - D Heat insulating.

- D500 - D Structural - heat-insulating.

- D1000 - D Structural.

| The nicest properties | Description |

|---|---|

| Ease of processing | This advantage is considered undeniable. You can saw, cut and give an unusual shape to the blocks yourself, using improvised building tools. Largely due to the production technology used, the material is often used in the construction of various kinds of objects, both residential and non-residential, as well as in the implementation of finishing work. The thermal conductivity of a dry block reaches 0.12 W / m ° C. With it, you can create unusual arches, partitions and other decorative elements. When building walls, such elements are simply irreplaceable. |

| Strength index | Despite its low weight, this characteristic is amazing. Such a building element is considered an excellent compromise between thermal insulation, weight and strength. Depending on the brand being purchased, the compression ratio will be 1.5-3.5 kgf/cm2. |

| Soundproof performance | The structure perfectly dampens extraneous noise. The degree of absorption depends on the brand used, the thickness of the walls being erected, the density of the mortar and the masonry technology. |

| Thermal insulation properties | Blocks marked D500-600 are considered excellent thermal insulation materials, which have a low thermal conductivity. For self-supporting structures, this is extremely important, as it is guaranteed that the developer will receive excellent thermal protection during the cold months of the year.However, observance of exact geometry, in this case, is obligatory. During the summer, the rooms will be maintained at an optimal temperature, without the risk of significant heating due to sunlight. |

| The weight | The dimensions of the standard block will be 62.5x10x25 cm. The weight of the product is 8 kg. Density factor 500 kg/m3. Thus, it will be possible not only to complete the construction in the shortest possible time, but also to save on mortar and other consumable components. |

| fire resistance | Such raw materials belong to the category of non-combustible, therefore they have the highest class of fire resistance. Structures erected from aerated concrete, fences and other types of buildings belong to fire safety classes I and II. |

| Resistance to environmental factors | Bacteria and other harmful organisms will not multiply in such material. For insects, such an environment is also considered unfavorable for life. Fungal spores cannot be detected even in the presence of high humidity in warm weather. It should be noted that raw materials do not need additional (protective) impregnations, unlike wood and other expensive building materials. The moisture resistance is excellent. |

| Environmental friendliness | In order to measure the level of radioactivity of individual components, a special laboratory and a whole staff of qualified personnel will be needed. In the field, it is impossible to calculate this indicator. Empirically, it was found that the radioactivity of blocks of aerated concrete is within the normal range. No toxic components are used in the manufacturing process, so it can be compared with the characteristics inherent in natural materials. |

Types and varieties

How to choose high-quality and inexpensive building material? To do this, you will have to familiarize yourself with their varieties and basic characteristics. In the production process of aerated concrete, various binders, including those of mineral origin, can be used. The type of additives is strictly established by GOST. Overview of the main types:

- Zologazobeton. 50% or more of the total weight will be high quality ash.

- Silica concrete. It consists of lime - at least 50% and cement - 15%. The rest of the mass is gypsum, slag or other additives. Their distinguishing feature, according to most buyers, is white. When used as a binding cement, they take on a gray color.

- Aerated concrete. Cement (Portland cement) acts as a binder component, in a volume of at least 50%. Such material is considered one of the best.

- Slag-gas concrete. In this case, 50% of the total volume will be used slag. Lime or cement acts as an auxiliary binder.

Such information is indicated by the manufacturer in the form of appropriate markings and in the name of the material. Also, waste from thermal power plants (ash) or quartz sand can act as a filler. Wastes from various technological processes, enriched ore or ferroalloys can also be used.

Which company is better to buy an imported aerated concrete block

H+H

The rating of high-quality gas blocks opens the budget product of the Danish company, which has Scandinavian roots. They started producing building materials in 1979. The company has many subsidiaries, and in 2009 one of the production facilities was established in Russia. Size range: length 62.5 cm, height 25 cm, width can be 10, 15, 20, 25, 30, 37.5 cm.The comparison table looks like this:

| brand | Thermal conductivity | Strength class | Frost resistance |

|---|---|---|---|

| D300 | 0.072 | 1.5-2 | 100 |

| D400 | 0.096 | 2.5 | 100 |

| D500 | 0.12 | 3.5 | 100 |

| D600 | 0.14 | 5 | 100 |

The average price is 4700 rubles. per cube

- European quality standard;

- marriage is extremely rare;

- correct geometry;

- product range;

- the possibility of ordering through the company's online store;

- raw materials used;

- ease of installation;

- light weight;

- can be given any shape using improvised cutting tools.

- not identified.

XELLA (Ytong)

One of the best German manufacturers, based on numerous reviews on the net. This brand is considered one of the youngest, but has already managed to gain general popularity. The novelty is in demand not only among wholesale customers, but also among professional developers. On the territory of our country has a representative office. Only time-tested technologies and the latest equipment are used. The base also has its own laboratories, which allows them to improve their products. The possibility of building skyscrapers and private houses with your own hands. On the manufacturer's website you can also find a convenient calculator for making calculations.

| brand | Thermal conductivity | Strength class | Frost resistance |

|---|---|---|---|

| D400 | 0.099 | 2.5 | 100 |

| D500 | 0.13 | 3.5 | 100 |

| D600 | 0.16 | 5 | 100 |

You can buy a cube at a price of 5200-5600 rubles.

- inexpensive product;

- used filler;

- correct forms;

- geometry;

- a wide range of sizes;

- autoclave drying;

- manufacturer's warranty;

- use of innovative technologies;

- form of payment - any;

- delivery to any region.

- the price is not the lowest, so it is recommended to wait for the next "promo".

UDK

The most correct and even ideal geometry.The product from the Ukrainian manufacturer rightfully occupies one of the highest lines of our rating. The basis of success is the use of the latest and high-tech equipment. This made it possible to achieve compliance not only with established European quality standards, but also with the correct geometry. Special attention deserves the cost of products that do not belong to the budget category. Positions itself as a premium manufacturer. The firm trains specialists on its own, having its own educational institution, which trains highly qualified specialists in this field.

| brand | Thermal conductivity | Strength class | Frost resistance |

|---|---|---|---|

| D400 | 0.10 | 2-2.5 | 100 |

| D500 | 0.12 | 2.5 | 100 |

The average cost is 7500 rubles.

- low reject rate;

- correct forms;

- lack of chips;

- durability;

- delivery is available to any region of our country;

- a wide range of sizes;

- European quality.

- the declared characteristics will cost a pretty penny.

Bonolit

The brand is from Germany. Production is established in many European countries, including Russia. It should be noted that the block manufacturing technology differs from most similar concerns. To begin with, the elements are cut and only then placed in an oven for further drying, as well as shrinkage. From a practical point of view, such a technology is more complicated, but this allowed us to achieve amazing characteristics and geometry of the final product. Factories are equipped with only high-tech innovations.

| brand | Thermal conductivity | Strength class | Frost resistance |

|---|---|---|---|

| D400 | 0.096 | 1.5 | 75 |

| D500 | 0.012 | 2.5 | 75 |

| D600 | 0.014 | 3.5 | 75 |

You can buy at a price of 3600-4200 rubles. per cube

- durability;

- resistance to environmental factors;

- environmental friendliness;

- frost resistance;

- minimal heat loss;

- the use of high-tech equipment;

- correct geometry;

- ease of installation;

- reliability;

- functionality;

- universality;

- significant range of products.

- you will have to pay for the declared properties.

Hebel

A German firm that has located its factories in many other cities around the world. When ordering products online from the factory website, you can be sure that they will come in the appropriate size. No chips, cracks or irregularities will be detected. The production process consists of several stages, including drying and subsequent shrinkage. This affects the visible geometry. The construction work will be completed on time, in addition, the amount of waste will be significantly reduced, provided that the customer follows the step-by-step instructions proposed by the manager and calculates the necessary building material online.

| brand | Thermal conductivity | Strength class | Frost resistance |

|---|---|---|---|

| D400 | 0.088 | 2.5 | 100 |

| D500 | 0.099 | 3.5 | 100 |

| D600 | 0.112 | 5 | 100 |

You can buy at a price of 5200-5600 rubles. per cube

- maximum deviation 2 mm;

- range;

- it is possible to purchase an arched structure of an unusual shape;

- quality control (including finished products);

- marriage is minimized;

- environmental friendliness;

- aesthetics;

- safety;

- reliability;

- practicality;

- compliance with international standards.

- not identified.

Stonelight

The goods are manufactured by a company that has production facilities in the city of Brovary, Kyiv region. The basis is the use of automated lines made according to German technology. The indicators of the supplied product are controlled at each stage of production. Compliance with technology is constantly checked at the level of intermediate operations.Thanks to this, it is possible not only to identify the defect in a timely manner, but also not to redirect it to the consumer. Quality worthy of our rating. It is in demand due to the declared characteristics, low weight and the absence of defects.

| brand | Thermal conductivity | Strength class | Frost resistance |

|---|---|---|---|

| D400 | 0.10 | 1.5 | 100 |

| D500 | 0.088 | 2.5 | 100 |

| D600 | 0.015 | 2,5 | 100 |

The price ranges from 1900 to 2400 rubles.

- production control;

- indicators;

- frost resistance;

- resistance to external factors;

- environmental friendliness;

- raw materials;

- ease of use;

- does not require special tools for masonry;

- German equipment.

- may crumble a little;

- lack of correct geometry.

Ytong

The discoverer of autoclaved aerated concrete. A time-tested German company that has established production, including in the Moscow region. It specializes in the production of aerated concrete products using German technology. The quality of the equipment corresponds to the declared characteristics. For the manufacture of products, only high-quality, environmentally friendly and natural components of a non-toxic nature are used. Often used at home for repairs and small construction. It is such a product that is better to buy, provided that it is planned to build something small and reliable with your own hands.

| brand | Thermal conductivity | Strength class | Frost resistance |

|---|---|---|---|

| D400 | 0.088 | 2.5 | 100 |

| D500 | 0.099 | 3.5 | 100 |

| D600 | 0.112 | 5 | 100 |

How much does a cube cost? The purchase will cost 5200-5500 rubles.

- a wide range of finished products;

- taking into account the individual wishes of the customer;

- minimum consumption;

- minor remainder;

- profitability;

- ease of processing;

- the possibility of laying with minimal experience and knowledge;

- reliability;

- long operational period.

- not identified.

Rating of the best Russian manufacturers of aerated concrete blocks

Aeroc

Our rating is opened by the largest domestic manufacturer of aerated concrete products. The concern was founded more than 15 years ago, and is the undisputed sales leader in the Russian market. It should be noted that current issues regarding the purchase of materials can be resolved online with one of the many managers of the company. This also applies to the calculation of the number of required products. Models marked D500 are considered popular, but if necessary, you can also give preference to the D300, which is not often seen on the shelves of hardware stores. We advise you to pay attention to products that have received a huge amount of positive feedback throughout Europe.

| brand | Thermal conductivity | Strength class | Frost resistance |

|---|---|---|---|

| D300 | 0,088 | 2,5 | 100 |

| D400 | 0,096 | 2,5 | 100 |

| D500 | 0,12 | 2,5 | 100 |

| D600 | 0,15 | 3,5 | 100 |

Cost - 4200-5100 rubles.

- environmental friendliness;

- strength;

- thermal conductivity index;

- insignificant weight;

- raw materials;

- ease of use;

- good value for money;

- geometry.

- not identified.

Aerostone

Well-known plant for the production of aerated concrete products. It is considered one of the largest in our country. Equipped with the latest German equipment, which is responsible for such a high quality of the proposed building material. There are only two types of structures, but they are considered the most popular in the modern market. With their help, you can build a five-story building, without additional costs and any risk. Also available are auxiliary belts and lintels that are necessary during construction.

| brand | Thermal conductivity | Strength class | Frost resistance |

|---|---|---|---|

| D500 | 0,12 | 2,5-3,5 | 100 |

| D600 | 0,135 | 3,5-5 | 100 |

Price per cube - 3800 rubles.

- additional packing of each cube;

- own delivery service;

- raw materials;

- geometry;

- price;

- environmental friendliness;

- ease of use;

- declared performance indicators;

- strength.

- the coefficient of thermal conductivity is high;

- peculiar distribution of brand classifications.

Poritep

The company provides noteworthy products to the domestic market at an affordable price. The quality of goods is above average. Production facilities are located in the city of Bogorodsk. The declared quality class is fully true, which many manufacturers cannot boast of. The thermal conductivity index of 3.5 indicated in the description opens up wide opportunities in private construction. It is practically not used by professional developers, since the technology used does not allow more than three floors to be driven out of it.

As a nice addition, the buyer is offered various partitions and their variations. Adhesive foam deserves special attention, which allows you to build from aerated concrete elements at an accelerated pace. They have good geometry.

| brand | Thermal conductivity | Strength class | Frost resistance |

|---|---|---|---|

| D400 | 0,09 | 2 -2,5 | 100 |

| D500 | 0,12 | 2,5-3,5 | 100 |

| D600 | 0,14 | 3,5-5 | 100 |

Price - 3500 rub.m3.

- declared indicators;

- environmental friendliness;

- strength;

- price;

- practicality;

- accurate calculation under the guidance of a manager;

- reliability;

- durability;

- universality;

- practicality;

- functionality;

- raw material quality.

- +-250mm per side (difference);

- the range is not as wide as required by the needs of modern consumers.

Thermocube

The main facilities of the concern are located at the Kostroma plant, which specializes in the production of building materials.This made it possible to put the brand in the ranks of the largest manufacturers not only in the region, but also in the country. In fact, they work on the basis of German technology and equipment of the same origin. The range includes three grades, where the thickness of the finished products may vary. Also, the consumer is offered a choice of several varieties of jumpers and belts of unusual shapes and sizes.

Special attention deserves glue, which is adapted to the products of the same name. All the necessary tools for the upcoming construction can also be purchased at the company's online store.

| brand | Thermal conductivity | Strength class | Frost resistance |

|---|---|---|---|

| D400 | 0,096 | 2,5-3,5 | 100 |

| D500 | 0,135 | 3,5 | 100 |

| D600 | 0,135 | 3,5-5 | 100 |

The average price is 4000 rubles.

- environmental friendliness;

- low marriage rate;

- helpful and experienced staff;

- European quality;

- high quality raw materials;

- strength;

- resistance to temperature fluctuations.

- the difference in size is very noticeable;

- increased thermal conductivity.

EL Block

An advertised company whose office is located in the center of the capital. Such a high-quality and sought-after product is based on the use of German technologies and appropriate equipment. In addition to blocks, the concern is engaged in the production of various fixtures, adhesives, accessories, parts and tools that can be useful in the construction of aerated concrete structures. It is also allowed to manufacture or adjust elements by the plant, according to the personal sketches of the customer.

| brand | Thermal conductivity | Strength class | Frost resistance |

|---|---|---|---|

| D400 | 0,09 | 2 | 100 |

| D500 | 0,12 | 2,5 | 100 |

| D600 | 0,14 | 3,5 | 100 |

Cost - 3800 rubles.

- coefficient of thermal conductivity;

- geometry;

- environmental friendliness;

- safety;

- manufacturer's warranty;

- delivery at the expense of the company;

- range of products and accessories.

- strength is not the most impressive.

EuroBlock

It is this popular manufacturer that is recommended by many construction companies that focus on the quality and appearance of the building. In addition, such a choice can save a certain amount of money, since the products belong to the budget category. The production technology they use is patented, which already says a lot. They are not accustomed to standing still, regularly investing huge amounts of money to improve the technology used. It should be noted that there is close cooperation with one of the leading Polish companies - Solbet, which is considered one of the largest suppliers of building materials to the EU.

| brand | Thermal conductivity | Strength class | Frost resistance |

|---|---|---|---|

| D400 | 0,096 | 2,5 | 75 |

| D500 | 0,12 | 2,5-3,5 | 75 |

| D600 | 0,12 | 3,5 | 75 |

Cost - 3000-4500 rubles.

- environmental friendliness;

- patented technology;

- the main supplier of raw materials is the largest Polish distributor;

- acceptable thermal conductivity;

- numerous positive reviews;

- geometry;

- low reject rate;

- price.

- frost resistance loses somewhat compared to competitors.

Conclusion

In the process of laying blocks of aerated concrete, it is necessary to take into account such indicators as the length of horizontal joints, which should not exceed 0.8 cm. 0.3 cm is the maximum available vertical joint. Excess solution does not need to be rubbed or washed out; a special trowel is used for this.If you plan to carry out the installation yourself, then you should acquire scaffolding, without which it will not be possible to complete the construction. With such a device, it is not only convenient, but also safe to work with.

The quality of the wall will largely depend on the level of masonry of the first or starting row. That is why the masters of their craft recommend not to neglect the building level from the very beginning of the manipulations. Only with its help can you be sure that the row is laid out correctly. If any inconsistency or oversight is found, every possible effort should be made to eliminate it.

In the process of working with aerated concrete blocks, only specialized fasteners are used. Ordinary self-tapping screws will not hold in the elements as firmly and reliably.

Glue consumption will increase if the blocks have handles or other protruding elements. The technology used implies the filling of absolutely all cavities in the process of manipulation. It is better to entrust transportation to professionals, as their surface is easily damaged. It will not be superfluous for a while to cover the blocks with polyethylene. Thus, you can protect them from negative external influences. In the process of laying door and window openings, it is difficult to get into the length of the existing row. In this case, a hacksaw will come to the rescue, with which you can remove an extra piece of the part. Aerated concrete belongs to the category of pliable materials that are easy to process.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131651 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127690 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124518 -

The best men's sneakers in 2022

Views: 124033 -

The Best Complex Vitamins in 2022

Views: 121939 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114979 -

The best paint for gray hair - top rating 2022

Views: 113395 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105329 -

Ranking of the best sex dolls for men for 2022

Views: 104366 -

Ranking of the best action cameras from China in 2022

Views: 102215 -

The most effective calcium preparations for adults and children in 2022

Views: 102011