Ranking of the best chainsaw chain manufacturers for 2025

When a chainsaw is operating, the main load goes to its cutting element - the chain. With the right selection, sharpness and quality, the productivity of the workflow will depend. If you do not pay attention to these parameters, then even the goods of the best manufacturers will operate with a significant overload, which will significantly slow down the work.

Content [Hide]

- 1 History of occurrence

- 2 What are

- 3 How to choose the best option

- 4 Tire classification

- 5 Recommendations of experts on the use of the unit

- 6 What is the best product to buy

- 7 Ranking of the best chainsaw chain manufacturers for 2025

- 8 Conclusion

History of occurrence

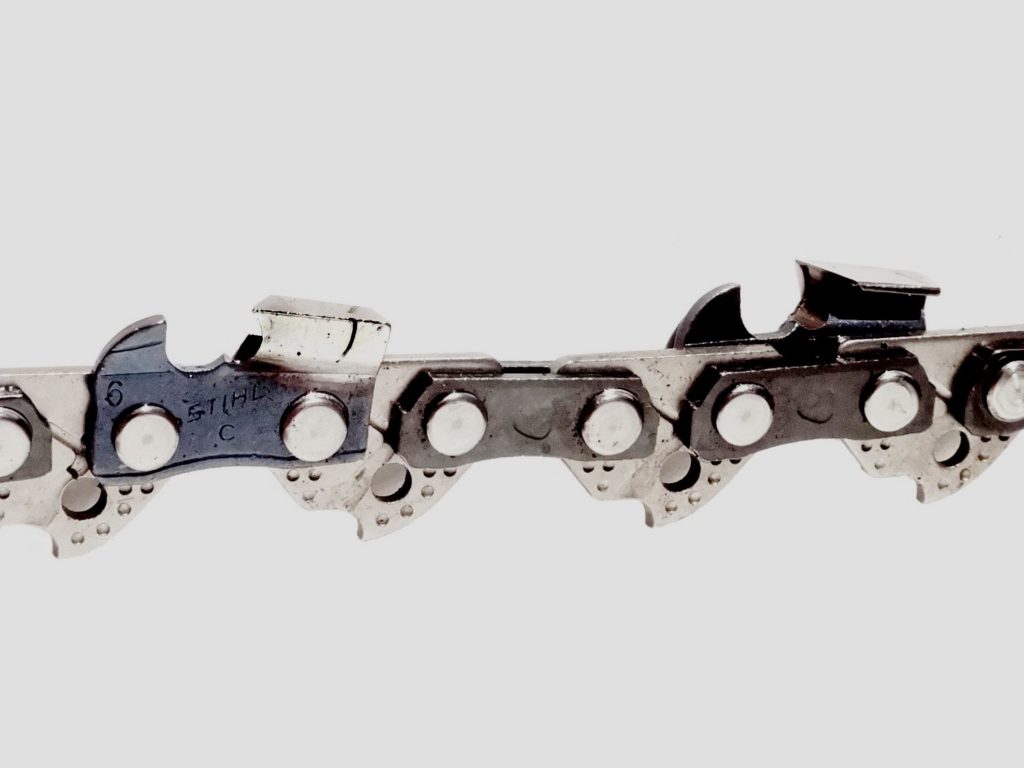

Chainsaws were first discovered in 1920. The devices were equipped with targets with flat and straight teeth, which made them not entirely effective, and the process too laborious. After 27 years, Joseph Cox invented a new kind of L-shaped design, which greatly increased the productivity of the product and simplified the sharpening process.

Cox's invention removed all competitors from the market in a short time, and holds a leading position at the present time. Today, all popular models are equipped with just such systems. Their main feature is a crescent-shaped cutting profile that allows you to cope with various types of wood.

It is worth noting that the concept developed by Joseph Cox was so successful that for many decades it has not undergone any drastic changes. Only the lubrication system has been improved, the kickback has been improved and vibration has been minimized.

What are

Any saw chain for a chainsaw has three types of links:

| Varieties | Description |

|---|---|

| Connecting | Connects leading and cutting elements. |

| Leading | Popularly referred to as "tails".Thanks to the drive sprocket, rotation is transmitted to the structure from the engine, which ensures its exact position on the tire. |

| cutting | Quite a complex device. It consists of a cut depth limiter and a cutting element, where there is a contour cutting angle. |

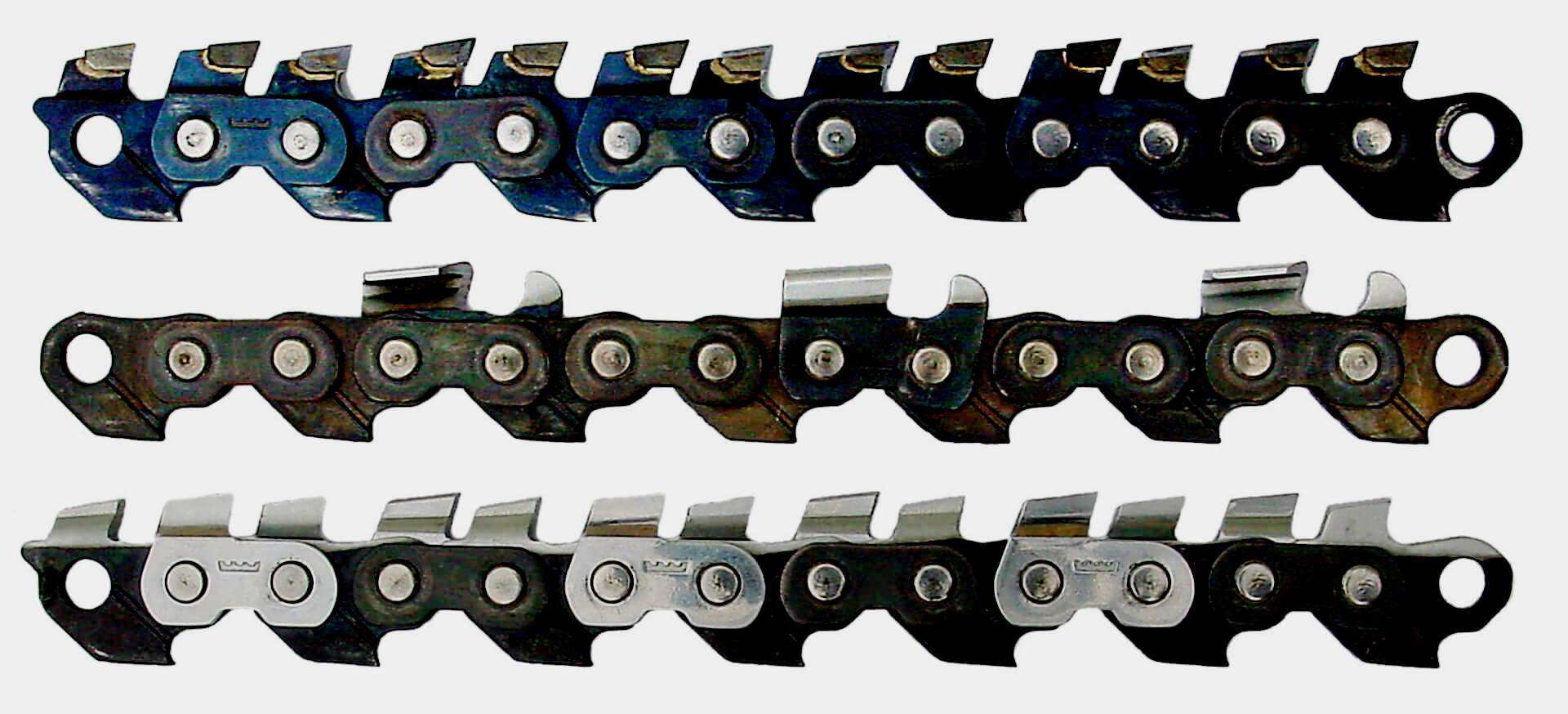

The main one is considered to be the cutting link. They are made right and left handed. Cutters are divided into two types:

- Chisel. Differ in high productivity and excellent cutting speed. The configuration provides a smaller area of contact with the wood, which helps to reduce surface resistance. The main disadvantage is excessive sensitivity to abrasives, as well as difficulty in sharpening.

- Chipper. Differs in the increased contact area that reduces efficiency of a cut. The main advantage is ease of maintenance. The main area of use is cutting contaminated wood.

How to choose the best option

Each chainsaw owner, no matter how carefully he worked with the tool, was faced with the need to replace the saw device. Popular models differ in configuration and link thickness, pitch, average price and other characteristics.

The chain and guide bar belong to the category of replacement equipment, so when purchasing budget options, you can replace these elements with more wear-resistant and durable ones. Changing the headset to a longer one will help increase efficiency, but this will only work if there is sufficient engine power and a rotation element. In order to avoid mistakes when choosing, it is worth getting the advice of profile masters.

Tire classification

Manufacturers produce products that differ in size. The main parameter of the saw chain is considered to be the number of links.The length of the product depends on this indicator. Apart from this, the systems have a specific pitch. Its indicator is the distance between the series-connected links, divided in half. Let's take a closer look at each parameter.

step by step

It is customary to distinguish between the following classes:

- 0.25 (1/4"). It's called a "small step". These designs are installed on single-handed chain saws with low power, but high accuracy and the ability to use in hard-to-reach places.

- 0.325 (3/8"). The most common models. The lion's share of products is equipped with such headsets.

- 0.404 (3/4”). Equipped with powerful tools with high productivity, such as harvester equipment, felling systems and so on.

Shank thickness

The parameter must match the tire groove. This increases the security of the fit and prevents slippage during operation. In this case, the course will be smooth, without excessive vibration and sudden movements. Branded products are produced with the following values:

| Parameters (mm) | Purpose |

|---|---|

| 1,1 | Small chains for mini saws. |

| 1,3 | Used for household and semi-professional power saws. |

| 1,5 | More powerful tools are provided. |

| 1,6 | Designed for professional saws. |

| 2,0 | Equipped with industrial saws. |

Cutting depth, profile height, engine size

What should you pay special attention to when choosing a product? It is for this data. The height of the cutting edge is different, and therefore distinguish between low-profile and high-profile designs. The latter are distinguished by excellent performance, the former by an increased area of the cutting link support, which has a positive effect on operational safety.

The depth of cut has an impact on productivity. The larger it is, the stronger the vibration.To balance the performance of products with a large pitch, they are equipped with cutting teeth with a small depth. The most popular clearances are 0.025” and 0.03”. Designs with a value of 0.07” have found their way into commercial felling.

Engine size plays an important role in choosing the optimal unit. If you install a saw chain on a tool with significant power, then increased loads will soon disable it and you will have to buy a new one. Therefore, before purchasing a new headset, it is necessary to review the technical characteristics of the saw.

Material

The rating of quality goods is always headed by representatives made of wear-resistant material. According to buyers, this is an important aspect when making a final decision, along with design features and functionality. Household and professional units use high quality designs at a significant cost and with a long service life. Which company is better depends on the preferences of the master. In specialized outlets, you can see devices for cutting concrete. They are equipped with a wear-resistant diamond chain belonging to the category of emergency products. They are not intended for gardening equipment.

The main selection criterion is by no means the brand and how much it costs, but the wear resistance of the carbide construction and its maintainability. It will not be necessary to constantly replace the product, provided that there is special equipment for sharpening it, which will significantly extend the service life. Carbide construction is used for sawing hardwood or light building materials.

If you use a device for working with aerated concrete or foam concrete blocks, then even the best models with additional functions will last two or three times less than the prescribed period.

Cross and longitudinal sawing

If the angle of sharpening the links is 25 - 35 degrees, then they are used for transverse cutting of a tree. This is the main assortment of manufactured goods, both Russian and foreign. Products for longitudinal sawing are quite rare. You can eliminate the deficit by changing the sharpening angle yourself at home, making it standard from 5 to 15 degrees. In this case, the tire is operated without changing the structural elements. If you encounter difficulties, you can use the step-by-step instructions.

When to Sharpen

If the teeth are dull, the work will move slowly. There will be increased vibration, reverse impacts in the process of entering the headset into the cut, too many small chips and a clear smell of burnt wood.

If the tool kit includes an installed manual sharpening device, a flat or cylindrical file, then there is no need to remove the element from the bar. Sharpening will take place automatically. If necessary, it is possible to perform a better sharpening in a specialized workshop, in which the action takes place on a stationary grinding machine. Restoration of the working capacity of the teeth is carried out quickly and efficiently with a guarantee of the same angle. User reviews boil down to the need to resort specifically to the professional method of sharpening.

Lubricant

The tool will function reliably and efficiently with timely lubrication.For this purpose, an oil pump is provided, thanks to which oil is supplied to the cutting system through special holes. The oil is evenly distributed thanks to the shanks.

Lubrication is intended primarily to reduce friction and overheating of the unit, which allows you to increase its service life and maintain performance at the proper level. The lubrication process must be controlled. It is worth paying attention to the presence of an oil trace on the cut line. Its absence indicates that the device is overheated, which can lead to blunting or complete failure.

To avoid negative consequences, manufacturers of rating products use an organic basis in the manufacture of oils. Such novelties are more expensive than their counterparts, but at the same time, lubricant consumption is significantly reduced, automatically increasing the resource.

Recoil and vibration

Whatever the quality of the product, significant vibration and recoil appear at high loads. With low loads, such inconveniences cannot be avoided either, but their power and intensity can be reduced. To reduce vibration, you should use:

- cushioning protrusions on connectors and shanks;

- beveled cut limiter;

- beveled or overestimated heel of the incisor.

These actions can be carried out with your own hands, without the involvement of third-party help. These design features will help minimize the risk of injury due to tool kickback.

Recommendations of experts on the use of the unit

In most cases, structural elements do not fully develop their potential. That's to blame:

- Significant degree of wear of the drive sprocket.

- Ineffective lubrication or its complete absence.

- The saw structure is too tight.

- Use of poor quality oils.

Masters are advised to purchase additional equipment and change them as needed. It is worth constantly monitoring the condition of key products. If they are damaged, they must be discarded and replaced with a new one.

The use of low-quality components or components that have completely exhausted their resource is fraught with injuries.

What is the best product to buy

The question arises when there is a need for sawing wood, and there is not enough experience and knowledge. Experts recommend following these tips:

- Understand how much work to do, and what material will have to deal with. For a cross cut, a chisel tool is selected, for a longitudinal cut, a chipper tool.

- Understand the characteristics of a chainsaw, especially bar length and pitch. You should not choose a specific brand, this indicator is not fundamental.

Where to buy the unit, everyone chooses independently. It is best to visit specialized points, talk with the sales manager, decide on the equipment, hold the tool in your hands, and ask the price. There is an option to order products online in the online store. The main thing is not to face counterfeit. This is the advantage of a company store, where there is a minimal probability of buying a low-quality Chinese-made product instead of a branded product.

Ranking of the best chainsaw chain manufacturers for 2025

Inexpensive models

MaxCut 91 LV - 52 E

votes 5

Acquired by the owner of chain saws equipped with chains with a tire of 35 centimeters. Due to the hardening of the links, it has a long service life. There are 52 links, pitch 9.3 mm, groove width - 1.3 mm.

High-quality Chinese goods are sold at a price of 399 rubles per unit.

- durability;

- stable tension;

- minimum vibration level;

- the presence of special holes for hanging on a vertical surface;

- optimal combination of price and quality.

- not identified.

DDE 90 SG 3/8” – 44 249 – 235

votes 0

Produced in the Middle Kingdom. The manufacturer provides a one year warranty. The element is equipped with a saw with a gasoline engine, the volume of which is 35 cm3. Differs in the extended cutting edge of a tooth.

The average cost in shopping malls is 410 rubles.

- in the manufacture of teeth, wear-resistant alloy steel was used;

- special design reduces recoil force;

- high cutting speed;

- reliability;

- chisel teeth;

- long service life.

- not installed.

MaxCut 91 LV - 56 E

votes 0

A good model from a Chinese manufacturer is suitable for both electric and gasoline saws. Guide bar 16 inches. There are 56 chisel links in 3/8" increments.

The average cost is 420 rubles.

- durable consumable;

- repeated sharpening is possible;

- effective;

- the set includes packaging - a box;

- universal;

- inexpensive.

- missing.

Oregon 91PO50ER

votes 3

The product is made in China, but there are no complaints about the quality. Equipped with fifty links, operated in conjunction with a tire 35 centimeters long. Chisel teeth make it possible to use the device in professional activities, if it is necessary to master a significant amount of work in a short period of time.The pitch of the links is 9.3 mm, the groove is 1.3 mm wide.

The average cost is 420 rubles.

- reliable;

- durable;

- comfortable to use;

- little return;

- There is a convenient packaging for storage and carrying.

- not identified.

Sturm SC 38013 CRT-52

votes 0

A distinctive feature is high performance and low vibration. In the manufacture of the structure, high-quality metal was used, which underwent preliminary heat treatment. An efficient lubrication system makes it possible to optimally distribute it over the groove.

The product is sold at a price of 430 rubles.

- tire and chain wear resistance;

- minimum fuel consumption;

- high performance;

- efficiency;

- ease of use;

- chipper teeth.

- missing.

Patriot 91VS–45E

votes 1

The device is equipped with 45 links with a pitch of 9.3 mm. The groove is 1.3 mm wide. Suitable for 30 cm tires. Chipper plan teeth improve performance.

The price of the product is 440 rubles.

- slight vibration;

- performance;

- ease of use;

- packaging in the form of a compact durable blister;

- excellent technical characteristics.

- not identified.

Models of the middle price segment

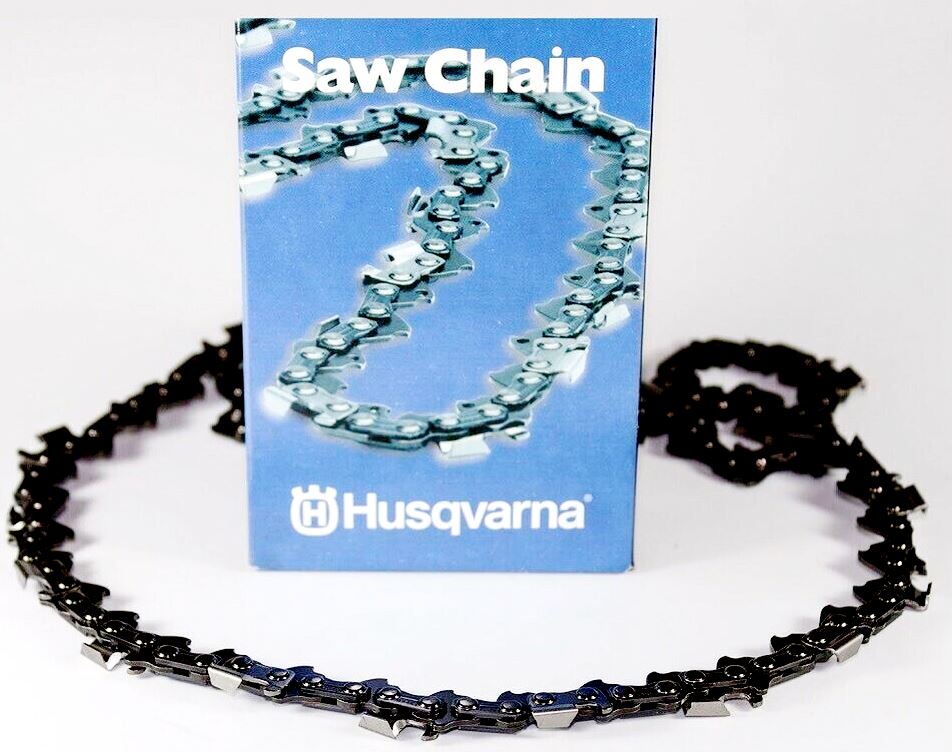

Husqvarna H42

votes 1

The device is manufactured in Brazil. Belongs to the category of spare parts. It is used to equip chain saws with a bar length of 45 cm. It is produced exclusively for units of this brand. In the manufacture of high-strength metal was used. Rectangular teeth allow you to work with wood of any hardness. There are 68 teeth, the groove width is 1.5 mm.By production the LowVib technology was used.

The product is offered at a price of 1099 rubles.

- reliability;

- high build quality;

- durability;

- performance;

- copes with any material;

- reduced vibration level;

- the optimal combination of price / quality.

- not suitable for chainsaws of other manufacturers.

DDE 73 LP 3/8” – 92 249 – 884

votes 0

The Chinese company - the manufacturer produces high-quality products, providing a one-year warranty. It is widely used for chain saws with a gasoline engine of 100 cm3. The length of the edge is increased. In the manufacture of teeth, high quality alloy steel was used. The uniqueness of the design lies in the fact that it allows for minimal impact and high performance.

The average cost is 1199 rubles.

- build quality;

- durability;

- strength;

- reliability;

- ease of use;

- excellent combination of price and quality.

- missing.

Bosch F 016800489

votes 0

The product is manufactured in the United States of America. A replaceable attribute for a Bosch chain saw with a small tire of 20 cm. To increase the resource, the company used metal with additional heat treatment in the manufacture of teeth. Lubrication occurs through holes and recesses at the bottom of the driven link.

The average cost is 1199 rubles.

- quality;

- functionality;

- performance;

- excellent lubrication system;

- long service life;

- convenient;

- minimum fuel consumption.

- missing.

Makita 528086672

votes 0

Products of excellent German quality at an affordable price.In the manufacture of alloy steel was used. Differs in the increased wear and resistance to deformation. There are 64 links with a pitch of 8.25 mm. The tire is 45 centimeters long. The working area is distinguished by a special design that allows you to quickly and efficiently cut any wood.

The average price is 1850 rubles.

- lack of notches;

- perfectly even cut;

- will master a tree of any hardness and quality;

- equipped with a dense box for easy transportation and storage;

- reliability;

- durability;

- quality assembly;

- ease of use.

- not identified.

Husqvarna H 64

votes 0

Consumable for equipping professional-grade gasoline saws. Chisel teeth allow you to cut accurately and accurately. Features of the working design make it possible to effectively saw the workpieces, making them without nicks and defects. Main characteristics:

- the number of links in the chain - 84 pieces;

- step - 10.2 mm;

- groove width - 1.6 mm;

- tire length - 71 cm.

The price for such a product is on average 1999 rubles.

- convenient in operation;

- reliable;

- long service life;

- the presence of a dense box in the kit allows you to conveniently store and transport equipment;

- in the manufacture of high-quality alloyed steel alloy was used;

- wear resistance;

- not subject to deformation.

- not installed.

Oregon PS52E

votes 2

A high quality consumable is produced by a leading American company. It is purchased by both beginners and professional craftsmen in order to replace chains with a further possibility of sharpening. Universal model, suitable for use with devices from various manufacturers.In the manufacture of the chain, progressive PowerSharp technology was used. The kit includes a special sharpening stone. Some links have a diamond cutter. Sharpening can be carried out without dismantling the cutting surface from the bar. There are 52 links, the groove width is 1.3 mm, suitable for equipment equipped with a 36 cm long bar.

Sellers offer products at a price of 2550 rubles.

- high build quality;

- durability;

- ease of use;

- comfort;

- uniqueness;

- universality;

- perfect value for money;

- the company is a manufacturer with a worldwide reputation.

- missing.

Premium models

Husqvarna H 30 Pixel

votes 0

![]()

The Canadian company filled the market with high quality products, but at a significant cost, which not every owner of a summer cottage can afford. Features of the device - slight vibration and minimal rebound. A successful model, adapted to work with any lightweight Husqvarna H 30 Pixel chainsaws, and the length of the guide bar does not play any role.

Using the tool results in a thin cut, no matter what power chainsaw you use. A perfect result is guaranteed in any case. The pitch of the links reaches 8.25 mm, the groove is 1.3 mm wide. Experts believe that the optimal consumable is suitable for working with chainsaws with an engine of 35 - 55 cc. The chain is packed in a bay.

The average cost of production is 20,799 rubles.

- high quality;

- long service life;

- reliability;

- efficiency;

- universality;

- comfort;

- safety.

- significant price.

Rezer Super BPS - 8 - 1.5 - 1848

votes 1

Despite the country of manufacture - China, professionals argue that the product deserves attention and approval. Implemented in a convenient bay. In the production of the tool, a reinforced steel alloy was used, due to which the service life is significantly extended, without losing the original characteristics. How to fasten the chain? The device is quite reliable and almost completely prevents the possibility of injury to a person.

The number of links is impressive - 1848 pieces, characterized by sharp sharpening. The step between it is 8.25 mm, the groove width is 1.5 mm. The chisel design allows for a neat and precise cut. Moreover, the amount of vibration during operation is insignificant. The file itself is 4.8 mm in diameter.

The product can be purchased at specialized points at a price of 12,999 rubles.

- convenient to use;

- high build quality;

- long service life;

- good combination of price and quality;

- comfort;

- performance;

- efficiency;

- versatility.

- missing.

Sturm SC 38013 CRT-OL

votes 0

The device differs in performance and quality of work. Minimal vibration impresses even seasoned craftsmen. In the manufacture of high-quality metal is used, which is pre-heat-treated to increase the resource and increase strength and reliability. Links in the amount of 1635 pieces have a pitch of 9.5 mm. Groove 0.050” wide. Chipper type teeth.

The average cost of a product is 17,799 rubles.

- performance;

- accuracy and accuracy of the cut;

- practicality;

- universality;

- functionality;

- wear resistance;

- excellent combination of price and quality.

- not detected.

H 25 Husqvarna 5033055-01

votes 0

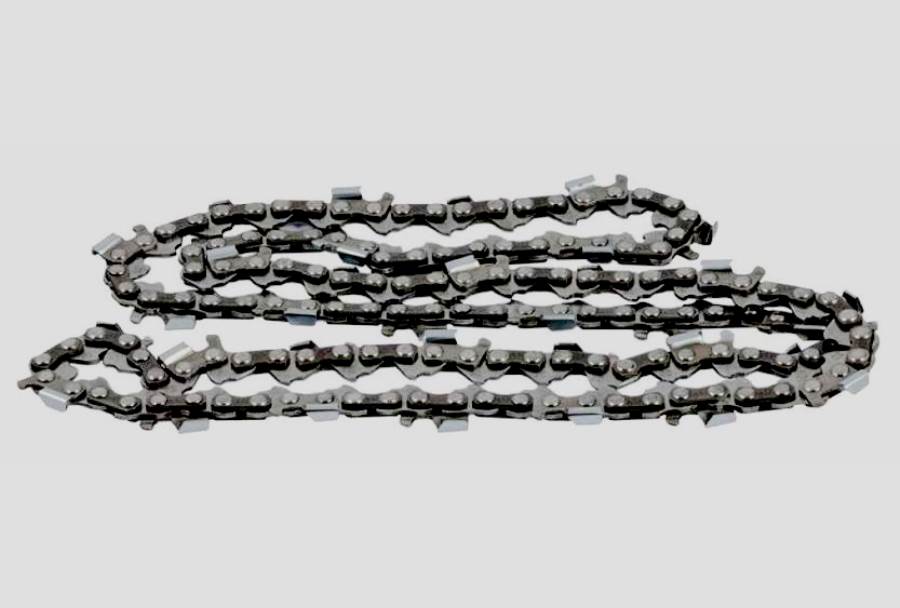

Widely used with petrol saws. It compares favorably with analogues with a minimum level of vibration and a high cutting speed. Delivery is carried out in bays. To obtain a chain of the required length, you simply need to separate the rivets connecting the links. This can be done both manually and using special equipment, such as machines. The total length of the chain is 30 m.

Main characteristics:

- groove width - 1.5 mm;

- chain pitch - 0.325 inches;

- parameters - 250 x 200 x 190 mm;

- weight - 6.16 kg.

The product can be bought at a price of 24859 rubles.

- long service life;

- high quality material of manufacture;

- reliable;

- comfortable;

- universal;

- Swedish quality is worthy of attention and approval;

- functional;

- productive.

- missing.

X - Cut C 85 Husqvarna 5816266 - 01

votes 0

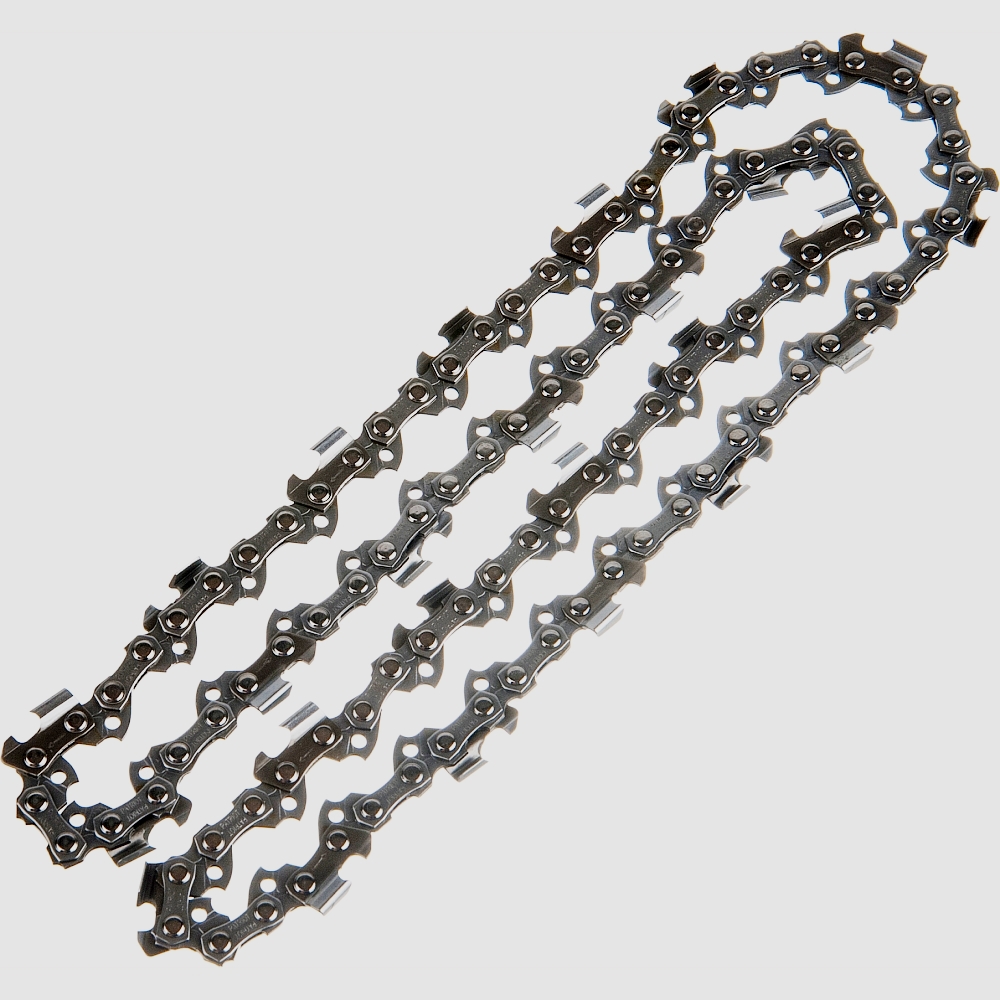

The Swedish company supplies the market with high quality products, which are very popular among professionals. Produced to equip professional gasoline saws. Widely used for felling trees on an industrial scale. Has a low vibration level. Belongs to the category of professional equipment of the highest quality with a huge cutting speed. In order for the chain to work long and productively, it is necessary to monitor the condition of the lubricant.

The device has 1840 links with a 3/8" pitch and a groove width of 1.5 mm. Delivery is carried out in the bay. Weighs 7.96 kg, main parameters: 250 x 200 x 190 mm.

The average cost of production is 25939 rubles.

- comfort in operation;

- minimal vibration and recoil;

- reliability;

- wear resistance;

- optimal combination of price and quality.

- not installed.

Conclusion

The chainsaw chain is considered to be the main consumable. It is of great importance for obtaining the desired result: the cutting speed, the presence or absence of notches and chips depends on the quality and working condition. If you choose the right consumable, then safety and productivity are ensured. Professionals advise not to save on such an important structural element and choose goods from proven global manufacturers. If the chain has fully worked out the established resource, then you should not spend money on replacement or constant sharpening.

Manufacturers produce chains with victorious soldering. But the masters advise to be careful about this option, since the models have both advantages and disadvantages, and the price is not affordable for those who like to put their own garden in order once a year.

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131658 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127698 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124525 -

The best men's sneakers in 2025

Views: 124042 -

The Best Complex Vitamins in 2025

Views: 121945 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114984 -

The best paint for gray hair - top rating 2025

Views: 113401 -

Ranking of the best wood paints for interior work in 2025

Views: 110326 -

Rating of the best spinning reels in 2025

Views: 105334 -

Ranking of the best sex dolls for men for 2025

Views: 104373 -

Ranking of the best action cameras from China in 2025

Views: 102222 -

The most effective calcium preparations for adults and children in 2025

Views: 102016