Rating of the best manufacturers of diamond blades for 2025

Today it is impossible to imagine cutting, grinding and sharpening of hard material without diamond discs. Their main feature is the presence of diamond grit on the cutting part as a spray, which can significantly increase the resource, productivity and quality of surface treatment.

Content [Hide]

What are the options

Thanks to such designs, it is possible to cut all kinds of building materials: stone, concrete, brick, tile, marble, asphalt and much more. The main advantages of the tool:

- accuracy;

- speed;

- noiselessness;

- productivity;

- efficiency.

They differ from each other in a different cutting edge, and therefore are used in various fields of activity.

The main classification is indicated in the comparative table:

| Kinds | Description |

|---|---|

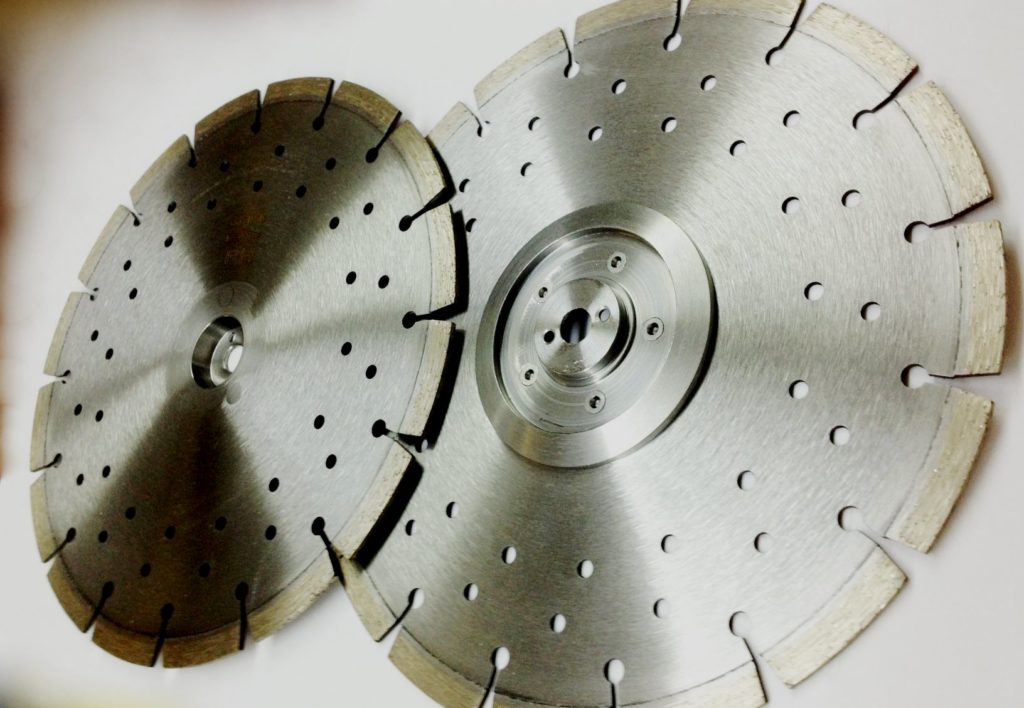

| Segmented | Designed for dry cutting. Quickly cope with brick, granite, concrete, stone. Thanks to the segments, the product is cooled during the sawing process, reducing heat and extending the service life. The recommendations of experts boil down to the following: the continuous duration of work with it should not exceed one and a half minutes. After that, it will be cooled at idle for 25 to 30 seconds. |

| Solid | The main purpose is cutting marble and tiles. Assumes a forced supply of water, which makes it possible to carry out high-quality cooling. The solid construction allows chip-free and even cuts in hard material.There are no restrictions on the duration of operation. |

| Combined | Universal option, suitable for dry cutting and for water supply. Cuts concrete, porcelain stoneware, marble, granite, stone. In terms of functionality, it is slightly inferior to specialized counterparts. |

The best manufacturers have launched the production of special wheels for cutting reinforced concrete, glass, and so on. The list of functions is usually indicated on the packaging. Subject to all operating conditions, the product will last for quite a long time.

Cutting diamond wheels vary in diameter, which ranges from 11.5 to 40 cm. At the same time:

- Small (12.5 - 15.5 cm) and medium (15 - 23 cm) are used for angle grinders. The thickness of the diamond layer is 2.2 mm.

- A circle with a diameter of 35 to 40 cm is intended for use on special equipment.

The advice of professionals boils down to the fact that tiles are best modeled with an electric tile cutter. This device belongs to the special category. During operation, water is constantly supplied, which makes it possible to make the edge smooth and without chips. When repairing a residential building or small technical buildings, you can resort to using a grinder of low power, which is convenient to hold in your hands.

Diamond wheels are also divided into:

- professional;

- simple.

Tools differ in price. If the average cost of a simple disc with a diameter of 23 cm is 550 rubles, then the professional version will cost 2,500 rubles. For domestic purposes, it is worth purchasing an inexpensive high-quality product, which will be enough to complete the work. If you plan to cut in industrial volumes, then you need to pay attention to the best branded tools. Such popular models cannot be budgetary.

Scope of use

Wheels are widely used for sharpening, grinding and cutting metal and hard non-metal surfaces.

They are equipped with:

- petrol cutters;

- angle grinders;

- tile cutters;

- stone-cutting stations;

- wall chasers;

- cutting machines;

- other special equipment.

They are divided into the following categories:

- Sharpening. They have found their application for sharpening carbide tools. They feature a solid working surface and a fine grain size for a high quality surface.

- Cut-off. Flat shape, mainly used for cutting metal products. The working part can be segmented or solid.

- Grinding. Scope of use: removing the old layer of paint, grinding various surfaces, peeling work and so on. Available in plate or bowl shape.

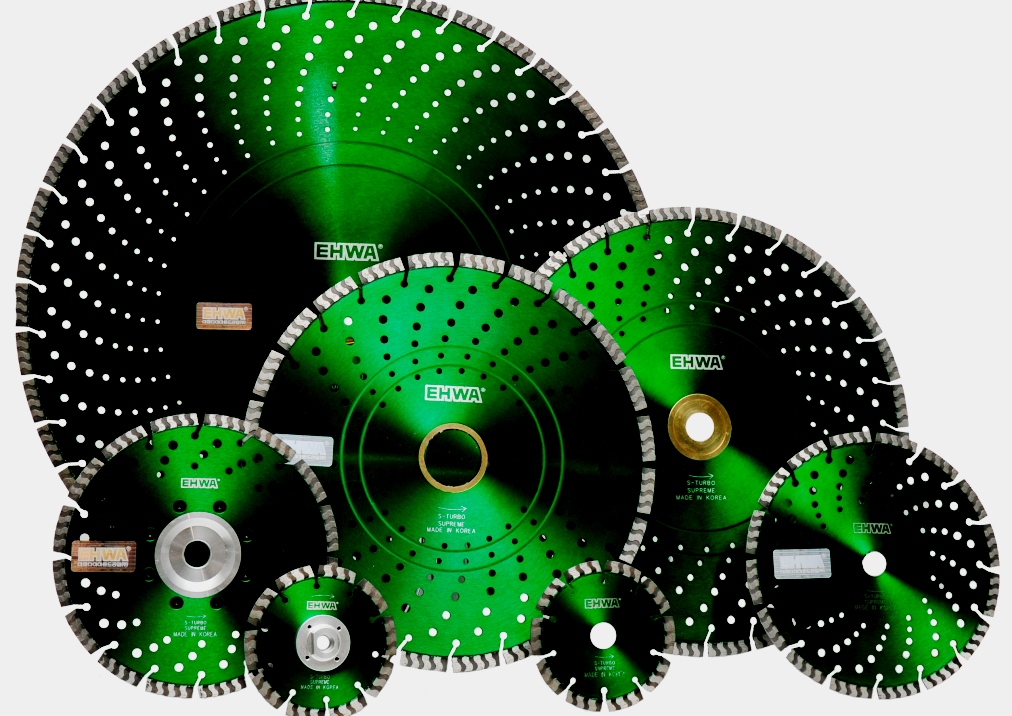

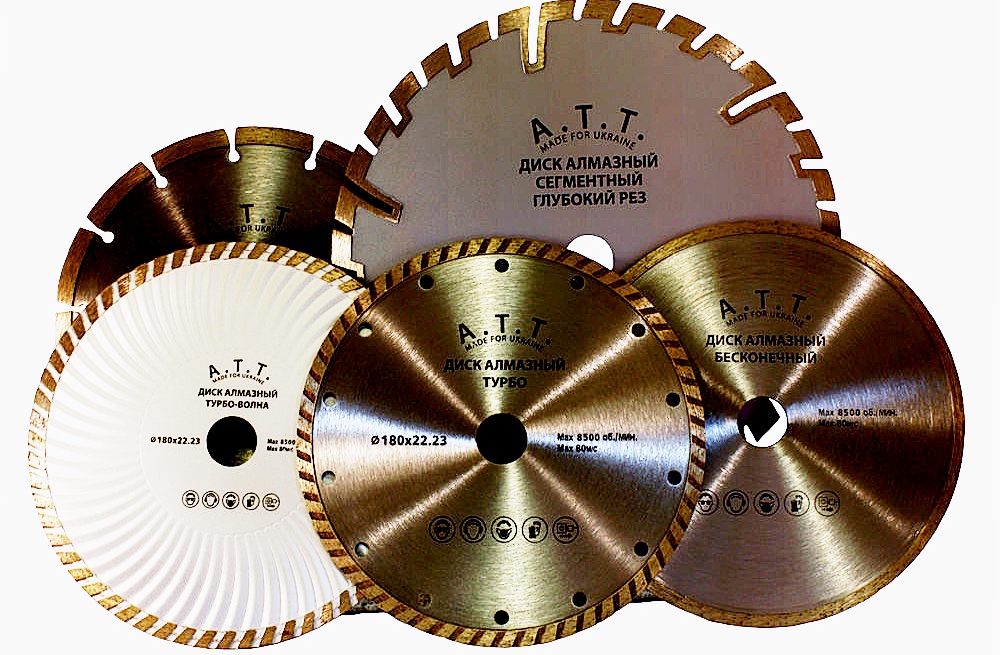

Based on the type of cutting edge, devices are divided into:

- Turbosegment. Notches and notches are aligned.

- Segmented. The cutting surface is equipped with notches dividing it into segments. Differ in a fast cut and quality of work.

- Turbo. The working part is equipped with notches along the edges. Visually resembles a turbine. This improves heat dissipation, thereby increasing productivity.

- Solid. The cutting surface is solid, which makes it possible to make accurate and high-quality cuts, but slightly reducing productivity.

Operating rules

If you follow the rules of use and safety measures when working with diamond discs, then efficiency and durability are guaranteed. Let's dwell on the main points in more detail.

How to choose

The main characteristic that you need to pay special attention to in order to avoid mistakes when choosing is the frequency of rotation of the circle.Slowdown occurs in such cases:

- the device does not have enough strength;

- significant pressure.

The result is overheating of the tool and a decrease in its maximum service life. To achieve high precision and quality of cutting, special equipment is used.

Cutting depth

The indicator directly depends on the diameter of the circle. Working with the tool involves following the rule of "stepped cut": maximum depth is achieved through successive shallow cuts. This makes it possible to increase the service life of the cutting part and reduce friction.

Tool feed rules and optimal pressure

As a rule, working with diamond wheels does not involve significant pressure. The own weight of the cutting machine is sufficient. The feed rate is set by the master independently, depending on the cutting conditions. It is worth paying special attention to the interruption of work in order to cool the equipment, including forced cooling. During operation, lateral friction leads to overheating, which is fraught with deformation of the wheel and damage to the diamond coating. You don't have to work continuously for a long time. It is necessary to give a short rest and ensure that coolant is supplied, if necessary.

How to restore functionality

If you had to cut on various materials, such as reinforced concrete, wood or brick, then the diamond blades become clogged over time. This leads to a decrease in performance. You can restore performance using the grinding method. This will help the use of abrasive material. The result is a complete cleansing of segments and restoration of disk health.

Operating procedure

Before installing a disk, it must be carefully inspected. If deformation is detected, its use should be excluded. The circle is fastened in a certain direction of rotation indicated on the equipment itself. As for the mounting hole and disc diameter, they should be similar to the parameters of the machine.

The disk is installed correctly, excluding distortions. The main point is tight clamping with a nut. Make a few turns in manual mode to understand how correctly you installed the device. Then start the car. The diamond blade is rigid and makes straight cuts. Curvilinear cuts he is not able to perform. Preliminary it is necessary to disperse the tool, not bringing it to maximum speed. When cutting, do not jerk and press hard on the disc.

Precautionary measures

When working with diamond wheels, safety regulations must be fully observed. Carefully read the contents of the pictograms printed on the cutting device. Operate only serviceable goods and consumables for it. Pay attention to the presence of a protective cover on the machines. Manipulations are carried out with gloves and goggles. If necessary, resort to the help of a protective mask, headphones or earplugs. It is advisable to wear protective footwear and clothing. This will help prevent accidents, preserve the health of the master and even his life.

Possible breakdowns

The following errors contribute to a decrease in efficiency and accelerated wear:

- improper use of the product;

- incorrect installation of the disk;

- the circle is selected for the wrong type of work;

- tool is out of order.

There are options when the disk gets stuck.This can happen if there is excessive pressure on the machine. Movements become slow, the edge is smooth. To restore efficiency, any abrasive material must be processed. The edge should restore the bumpiness. With further jamming of the circle, it is worth replacing it with a new, softer one.

If the cutting segment wears out in a short time, then most likely the wrong blade has been selected. If it is too soft, then it will not be suitable for processing hard material. Usually there are aggressive movements, too rapid wear of the segments, which is visible to the naked eye. The height of the segment reaches the body and the disk begins to wedge in the material. Consider purchasing a tighter circle.

How to choose

The main selection criterion is the bore and outer diameters, the configuration of the working part and manufacturer's advice. The outer diameter affects the maximum depth of cut. The most common are 11.5, 23, 18 and 12.5 cm. For a hand tool, the maximum figure is 320 mm. For machine tools, circles of 600 mm diameter are suitable.

Standard bore diameters are 23 and 22mm for 230mm discs, and 25.4mm for wheels 300mm or larger. Product labeling is also important. The speed of the equipment must be equal to or less than the allowable RPM value specified on the disc marking. Be sure to review the direction of the wheel and the recommended material, for example, for asphalt, for reinforced concrete, for working on porcelain stoneware, and so on.

The following factors influence the duration of the operational period:

- At high tool power, the speed does not fall.

- The larger the diameter, the less the load on the work surface.

- It is necessary to observe a rectilinear trajectory of manipulations.

- Take breaks in work, allowing the product to cool.

- Completely eliminate the possibility of overheating.

- Observe the rules for operating the equipment.

- Perform deep cuts in several passes.

Currently, the market is filled with such products. Which tool is better to buy depends on many factors and the preferences of the master. You can choose an expensive branded option used in the construction of a significant facility or become the owner of equipment at an affordable price for a small amount of work.

Before making a final decision, it is worth studying the rating of quality products, popular models, reviews, photos, and new products. According to buyers, it is best to visit specialized construction markets where branded products are sold, which you can visually inspect, touch, talk with a professional seller, and find out what it costs.

As a rule, the question of where to buy is not worth it. If you are used to ordering online, you can use the services of online stores. You must first decide which company is better, pay attention to the advantages and disadvantages of the products offered, see the rating. The average price for a similar product will be slightly lower, but there is no guarantee that in the end a low-quality fake or a product without mechanical damage received during transportation will not arrive.

Rating of the best manufacturers of diamond blades for 2025

For concrete and stone

Inforse 11-01-027

votes 7

Serves for cutting natural and artificial stone, brick and concrete using angle grinders.At release the technology of a hot press was used. Segment height - 12 mm, number of segments - 9, dry cut, fit 22.2 mm. Not suitable for abrasive compounds.

The average price is 548 rubles.

- high speed;

- increased resource;

- durability;

- efficiency;

- acceptable cost.

- missing.

Hilberg Turbo Ultrathin

votes 2

Goods of the Russian brand, but produced in the territory of the Middle Kingdom. It features an X-shaped edge, cuts without the use of liquid. The technology of hot pressing was used in the manufacture. Weight - 0.16 kg, parameters: 215 x 165 x 5 mm.

The average cost is 1086 rubles.

- efficiency;

- performance;

- quality;

- does not leave chips;

- even cut.

- dulls quickly.

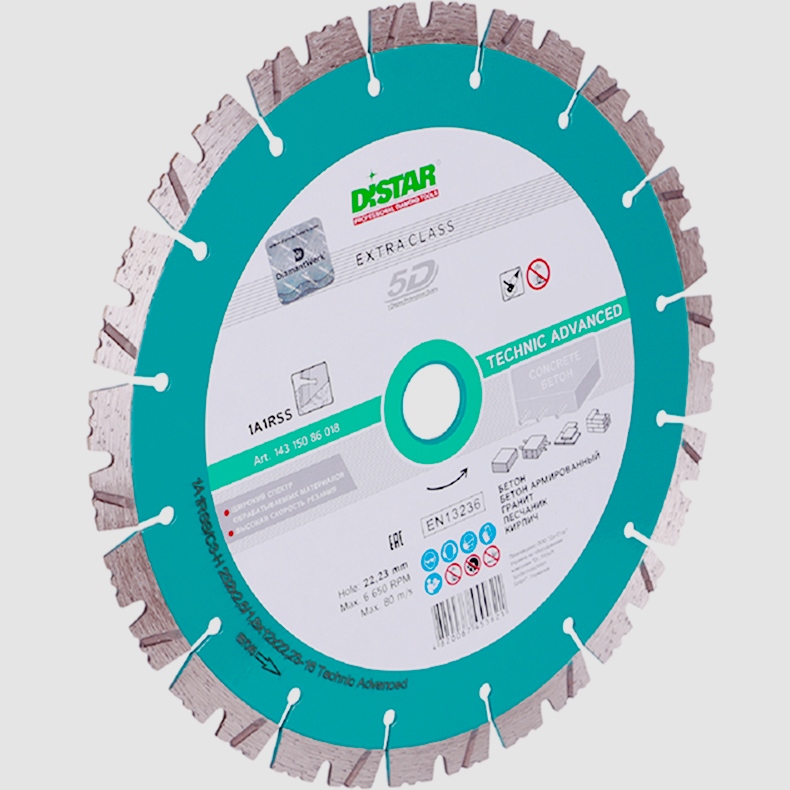

Technic Advanced DiStar

votes 0

It is used for work on angle grinders and cutters of manual type. There are 10 segments, a dry cut is provided. Diameter - 125 mm, thickness - 2.2 mm, weight 0.16 kg.

Unit price - 1049 rubles.

- universality;

- durability;

- performance;

- high speed;

- quality cut.

- missing.

Bison 0512002

votes 0

Universal tool designed to work with brick, concrete, natural stone. Mounted on an angle grinder. Segmented design. The presence of compensation holes allows the cutting edge to strongly contact with the surface being machined.

The price per unit of goods is 242 rubles.

- adequate price;

- minimal wear;

- does not require cooling;

- efficiency;

- performance;

- quality of work.

- not identified.

Bizon turbo, 0515001

votes 1

Turbocharged design, perfectly copes with concrete, artificial and natural stone, brick. Mounted on an angle grinder. High-quality tool steel was used in the manufacture of tooling. The presence of coolant allows you to cut without stopping for a long time.

The average price is 716 rubles.

- compensation holes;

- high performance;

- high-speed processing;

- long working life;

- cut quality;

- convenient;

- excellent value for money.

- not installed.

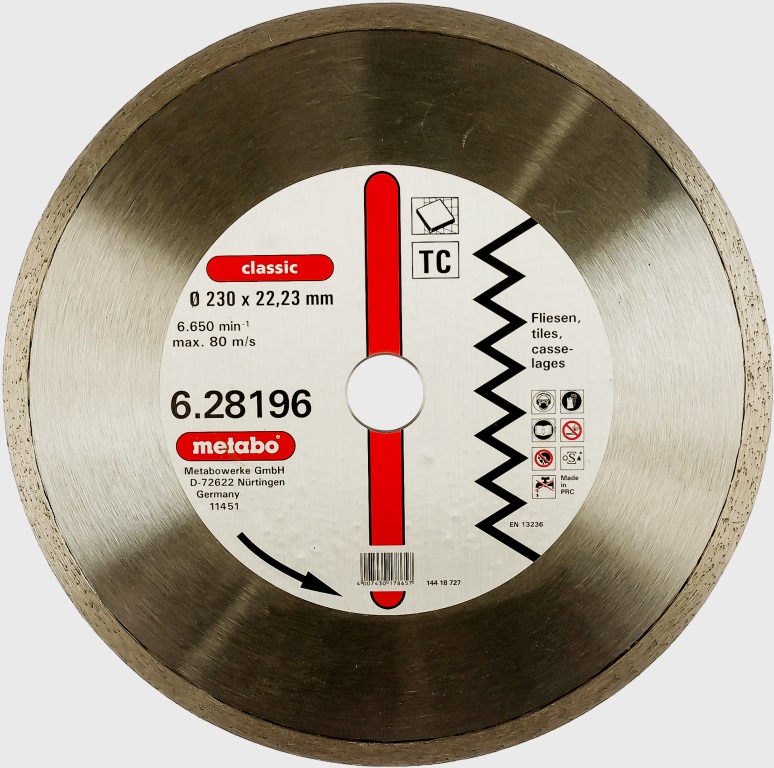

Metabo 628196000

votes 0

The manufacturer produces products for hand cutters and tile cutters. Dry cut available. The height of the diamond layer is 7 mm, it weighs 0.58 kg, the parameters are 260 x 235 x 5 mm. Product of German quality at the best price.

The average price is 1509 rubles.

- convenient to use;

- high performance;

- long service life;

- high-quality manufacturing materials;

- performance.

- missing.

Technic Advanced DiStar 14315086018

votes 0

The products of the Russian brand enjoy well-deserved popularity among professional builders. Attaches to angle grinders and handheld cutters. Dry cutting of concrete, marble, brick, paving slabs, granite and sandstone is provided. Number of segments - 16, diameter - 230 mm, weight - 0.66 kg.

Sellers offer goods at a price of 2199 rubles.

- excellent wear resistance;

- efficiency;

- functionality;

- durability;

- quality of work;

- used for electrical work.

- not installed.

For metal

Messer F/L 125 D - 1.4 T - 3 W - 22.2

votes 0

The product of the Korean manufacturer is distinguished by quality and durability. Main features: solid edge. Works metal efficiently. The manufacturing principle is diamond sintering. Liquid supply is not carried out. Special holes allow you to control the cooling of the work surface.

The average cost is 1160 rubles.

- high strength;

- the presence of holes for cooling;

- during operation, sparks are practically not formed;

- durability;

- ease of use.

- not identified.

Hilberg Super Master 125mm

votes 0

The Chinese company fills the market with quality products, including diamond blades, which are designed to work with plastic, brick, reinforced concrete, reinforced concrete and marble. The edge is segmented with the number of segments - 10, the cutting depth is 20 mm, the type of cutting is both wet and dry. By production the vacuum soldering was used. Mounted on angle grinders and designed to work with steel, brick, marble, non-ferrous metals, plastic and so on.

The product is sold at a price of 890 rubles.

- the edge is segmented;

- vacuum soldering;

- high speed of work;

- excellent cut quality;

- long service life.

- not installed.

F/M Vacuum 125mm

votes 0

The Korean company saturates the market with high quality products with a long service life.Diamond blades with a diameter of 125 mm, a segmented edge, and a mounting hole of 22.2 mm are very popular among the masters of the construction industry. Differs in convenience of processing of metal surfaces. The presence of wide slots makes it possible to operate the device both with water and without it.

The price of products per unit is 2506 rubles.

- the presence of wide slots;

- the edge is segmented;

- copes with metal;

- durability;

- performance;

- excellent combination of price and quality.

- not identified.

Espira SCV Optima 230 x 22.23 mm

votes 0

Russian-made universal tool with a one-year warranty. Easily and quickly processes metal, granite and concrete. Diameter 230 mm, segmented edge height 3 mm. Used for mounting to electrical equipment with appropriate fastening.

The average cost is 2813 rubles.

- fast and accurate cutting;

- works without water and with its presence;

- significant resource;

- performance is noteworthy;

- segments are strong;

- convenient to use;

- durable;

- reliable.

- not identified.

Husqvarna Vari – Cut S 50, 300 – 25.4

votes 1

The universal device of the Swedish manufacturer, there are 21 segments, a 10 mm diamond edge. Available for wet and dry cutting. Handles any hard material. It is possible to change the mounting hole using the Easy-fit system.

The average cost of a product is 7634 rubles.

- compliance with the international quality standard ISO 9001;

- the presence of the Easy-fit system;

- universality;

- functionality;

- performance;

- quality.

- too much cost.

On granite

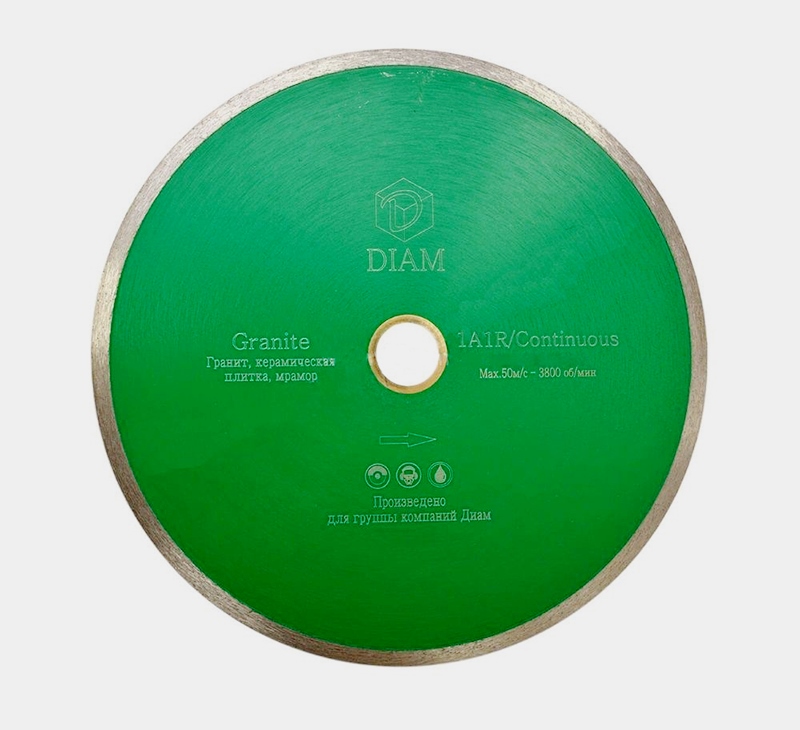

Diam Granite – Elite 250 x 1.6 x 7.5 x 25.4

votes 0

The professional plan device is used for cutting hard ceramics, marble and granite tiles of insignificant thickness. Attaches to electric tile cutters where water supply is provided. Differs in a high resource, quality of a cut, quickly and effectively copes with a hard surface. High resistance to overheating and stress is achieved due to the presence of laser cuts on the disk.

The price of products is 2673 rubles.

- minimal chips;

- high cutting speed;

- performance;

- ease of use;

- long operational period.

- significant price.

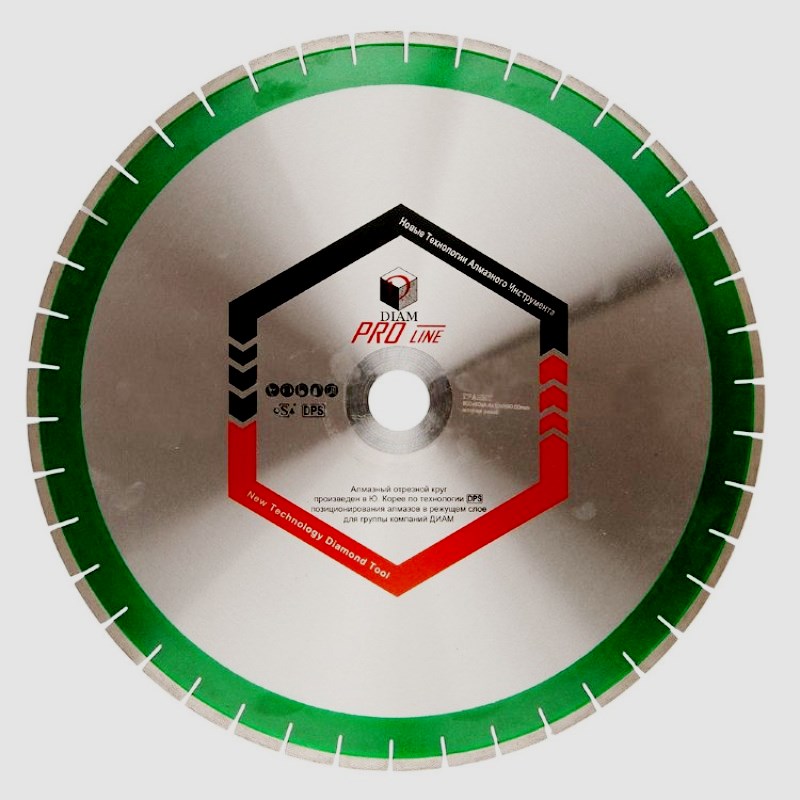

Diam Granite Pro Line

votes 0

The professional grade product has found its application for working with hard sandstones, granite, quartz. The manufacturer has launched the production of eight varieties of the model, which differ in the thickness of the diamond layer and the diameter of the circle. It is mounted in machines and equipment intended for stone processing and the construction industry. It differs from its counterparts in powerful indicators. You can choose the mounting hole.

The average cost is 8374 rubles.

- powerful indicators;

- significant resource;

- performance;

- excellent characteristics;

- in the manufacture of DPS technology was used;

- no need for coolant.

- the price is not affordable for everyone.

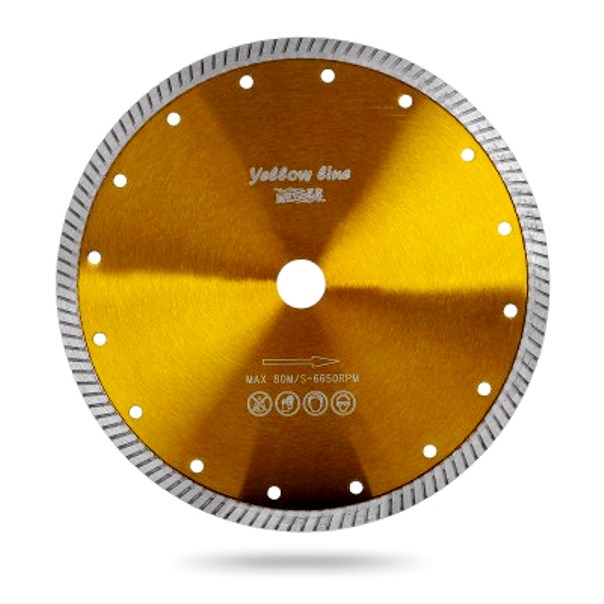

Yellow Line Granite 125 mm

votes 0

The manufacturer produces a special tool for cutting granite. A distinctive feature is an increased resource.It is purchased by craftsmen in case of performing a small amount of work or for the purpose of performing episodic operations. Liquid can be used for cooling, but without it there will be no overheating.

Sellers offer to purchase goods at a price of 627 rubles per unit.

- good combination of price and quality;

- reliability;

- ease of use;

- increased resource;

- powerful.

- chipping may occur when cutting.

Trio Diamond Turbo Hot Press Granite with flange M – 14 80 mm

votes 0

Despite the Chinese production, the product is distinguished by performance and reliability. The main characteristics are as follows:

- cutting depth - 15 mm;

- edge type - turbo;

- diameter - 80 mm;

- edge height - 10 mm;

- thickness - 1.9 mm;

- wet and dry cutting is provided.

Mounted on angle grinders. It is attached to the angle grinder with the help of a clamping flange with M 14 thread. Designed for cutting especially durable materials.

The average cost of production is 826 rubles.

- it is possible to change the cutting angle;

- wide range of disk usage;

- performance;

- strength;

- durability;

- combination of price and quality;

- high speed.

- missing.

For ceramic tiles

Distar, 125 x 22 mm

votes 0

The tool is very popular among professional builders. Thanks to its use, it is possible to quickly and accurately cut porcelain stoneware and tiles. Mounted on a grinder or other special cutting device. The optimum rotation speed is 12250 rpm. It has a solid cutting edge and a bore diameter of 22.2 mm.

In specialized stores, products are displayed at a price of 1298 rubles.

- lack of chips;

- performance;

- guarantees a thin and clean cut;

- dry cutting;

- long service life;

- heating is insignificant;

- convenient to use.

- not installed.

Norton Vulcan Tile 180 x 25.4mm

votes 3

The product features a solid cutting edge. Widely used for cutting stone and ceramic slabs. Leaves no nicks when used on fragile surfaces. The cut is smooth and high quality. In the production of the disc, durable steel, non-ferrous metals and synthetic diamonds were used. Handles hard materials with ease.

The average cost is 1237 rubles.

- slight thickness;

- high accuracy;

- performance;

- quality;

- does not leave nicks and chips;

- high speed - 7650 rpm;

- excellent combination of price and quality.

- missing.

Distar, 250x10x25.4mm

votes 0

A great helper when cutting porcelain stoneware and tiles. It has a significant rotation speed - 3050 rpm. The disc is made of durable steel, 1.6 mm thick and 250 mm in diameter. There is a solid cutting edge. Landing hole - 25.4 mm.

The manufacturer offers goods at a price of 1998 rubles.

- slight heating;

- long service life;

- reliability;

- clean cut;

- a wide range of uses;

- convenient to use;

- wet cutting.

- not installed.

Conclusion

Diamond wheels belong to the category of consumable diamond tools.Are established on manual and automatic (including angular) grinders for grinding, operational development, honing and sharpening. Carbide and hard-to-machine surfaces, glass, ceramics, semi-precious and ornamental stones are easily and effectively processed. Differ in durability, the increased efficiency, self-sharpening and a considerable working resource.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131665 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127702 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124528 -

The best men's sneakers in 2025

Views: 124046 -

The Best Complex Vitamins in 2025

Views: 121950 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114987 -

The best paint for gray hair - top rating 2025

Views: 113404 -

Ranking of the best wood paints for interior work in 2025

Views: 110331 -

Rating of the best spinning reels in 2025

Views: 105338 -

Ranking of the best sex dolls for men for 2025

Views: 104378 -

Ranking of the best action cameras from China in 2025

Views: 102226 -

The most effective calcium preparations for adults and children in 2025

Views: 102020