Rating of the best manufacturers of acoustic drywall for 2025

At the present time, it is difficult to imagine the process of finishing the premises without the use of drywall, but this was not always the case. Buyers were not immediately able to appreciate the benefits of this material. The soundproofing in the room when using it was frankly not very good. Therefore, popular manufacturers have created acoustic drywall, which in terms of soundproofing properties far exceeds the usual one.

Content [Hide]

What is drywall

This is a finishing material that is created from gypsum filler and cardboard. Cardboard, in turn, is impregnated with a special hydrophobic composition. The finished material looks like a rectangular dense sheet with dimensions and color marking. It is often referred to as "dry gypsum plaster", but these are two different materials.

Something similar to drywall was invented back in the 19th century, thanks to Augustine Sacket. He wanted to get something useful by pressing rough grades of cardboard, and between two sheets he made a layer of plaster. However, the material in the form in which we are accustomed to seeing it was patented by the American Clarence Utsman.

Kinds

Drywall is divided into 4 categories:

- GKL is a classic drywall, which can be considered universal. It is used only in dry rooms. This material completely lacks any protection against moisture, dampness, and fire.

- GKLV - plates of this type have a green color, which means high resistance to moisture. Such sheets can be used in the kitchen or bathroom.

- GKLO - this abbreviation stands for drywall with high fire protection.

- GKLVO - this type has the properties of both fire-resistant and moisture-resistant material.

What is acoustic drywall

This type has another name "Soundproof". The discovery of acoustic drywall, which happened relatively recently, was an innovation.

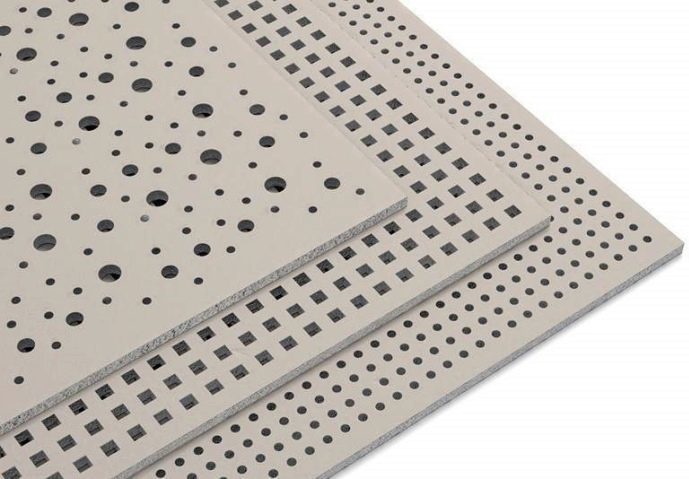

It is used in the decoration of walls and partitions to create good sound insulation of the room. This effect is achieved by perforating the cover structure, the back of which is a special non-woven fabric. Inside the holes, all sounds are muffled.This drywall is available in any color, but most often it is white, gray and black, so the material is easily selected for any color orientation of the room.

Specifications of Acoustic Drywall

If we compare the sizes of the conventional and acoustic options, we can see that their sizes vary greatly:

- The width of the slab for acoustic drywall can be from 188 to 120 cm;

- The leaf length can reach from 199 to 240 cm;

- Weight is from 8.8 to 9.5 kg;

- A drywall sheet, if you do not take into account the canvas, reaches a thickness of 12.5 mm;

- The material has a density of 650-730 kg/m3.

During the tests, it was possible to find out that the greatest sound absorption occurs at a frequency from 500 to 2000 Hz and has an indicator of 0.85. For all drywall panels, it is 0.55. The lowest indicator is drywall with chaotic perforation - only 0.45.

From this it can be understood that the sound absorption coefficient depends on the type of perforation. But with different sizes and weights, it should be 0.2.

The dimensions of the sheets also differ from the dimensions of conventional drywall. The thickness of all panels is 12.5 mm. Other types may have different sizes:

- Panel width: C1 is 1188 mm, C3 is 1197 mm, B1 is 1224 mm. The width of panels B2 and C2 is the same - 1200 mm;

- Sheet length: C2 and C3 - 2000 mm, C1 - 1998 mm, B1 - 2448 mm, B2 - 2400 mm.

Many people know that gypsum does not ignite well, unlike the paper layer. The composition of the drywall sheet uses about twenty percent of the paper. Therefore, there is a certain time limit in which the sheet can protect from fire. Usually it's about half an hour. Therefore, drywall is quite reliable and effective. It should be mentioned that the outer paper layer of the sheet does not burn, but only chars.

Despite all the positive qualities, it will not be possible to completely save a wooden or other flammable structure, but the likelihood of reducing possible damage is high.

Types of perforation

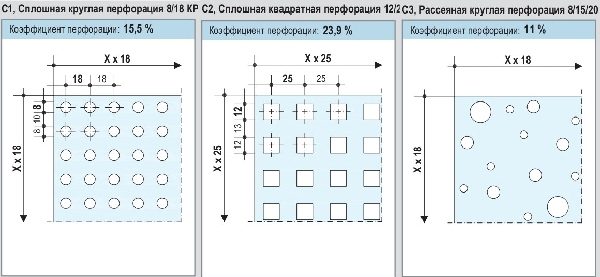

Distinguish pattern and type of perforation. Manufacturer Knauf has only two possible perforation patterns:

- Solid - holes are distributed evenly relative to the sheet;

- Block - holes are drilled in blocks.

The type of perforation has three options, which are characterized by size, shape, distance between holes:

- round;

The holes are 8mm in diameter and the holes are evenly spaced 18mm apart.

- square;

The holes are in the form of squares with sides of 12 mm, and the distance between their centers is 25 mm.

- Scattered round.

Three types of round holes are usually made on the panel with a diameter of 8 mm, 15 mm and 20 mm. And the holes themselves are located randomly.

Where applicable

Due to its properties, namely the creation of an obstacle to the reflection of sound from walls, such a material can be used for cladding:

- rehearsal classes;

- Educational audiences and classes;

- Negotiation rooms;

- musical institutions.

In apartments and private houses, such soundproofing will be useful when creating a home recording studio or home theater.

This material was able to solve several problems at once:

- Removes echo;

- Reduces any background sounds in the room;

- Reduces the level of loudness.

Thanks to sound insulation, it becomes easier to perceive low frequencies and human speech.

How to prepare and install soundproofing

Acoustic drywall is used both for interior partitions and for simple walls. In the case of a wall, certain steps must be taken to prepare for the installation of sound insulation:

- Prepare the wall surface.To cover up all the cracks, if the wall is without cracks, then just wipe it from dust and dirt.

- On the prepared wall, markings are made using a special laser device. It is necessary not only to measure the area, but also to leave markers for attaching the frame.

- A frame is made from an aluminum plate or a wooden beam, which will form the basis. Before installing it on the wall, you need to hang a vibration pad, and then fix the structure. For better sound insulation, the dowels can be treated with a sealant.

- After creating the frame, soundproofing plates should be installed. They must fit very tightly into the structure so as not to leave empty space.

- Then the acoustic drywall is attached. The material has good soundproofing ability, this will make the room as comfortable as possible. Each tile is fixed with a backing and screws.

- In the final part, after installing drywall, all seams must be carefully coated with sealant or putty with reinforced tape.

What to use self-tapping screws when working with plasterboard

All performance characteristics of drywall screws depend on the materials from which they are directly made and their heat treatment. The most commonly used technologies and materials are:

- Carbon steel (GOST 1050) with a protective zinc coating, which is applied by galvanizing;

- Alloy steel (GOST 4543) coated with phosphates or without an adhesive coating of an anti-corrosion layer. Protection against moisture is presented in the form of a simple oiling;

- Brass - this material is characterized by high resistance to corrosion, but low strength;

- Stainless steel grade A2 or A4.

When choosing screws for fasteners, you should pay attention to such factors:

- Dimensions;

The dimensions of the self-tapping screw depend on the thickness of the sheet. When mounting in one sheet, the use of self-tapping screws up to 25 mm long is allowed. The more layers in drywall, the longer the length will be. For example, when mounting in two sheets on a frame, a screw length of 35 mm can be used.

- thread pitch;

The thread pitch is selected depending on the base material. For wooden structures, a screw with a rare thread is used, and for a metal profile - with a frequent one.

- The form.

To select the shape of the self-tapping screw, you need to pay attention to the screw head; when installing drywall, a hidden or semi-hidden one is used.

Rating of the best manufacturers

Knauf

votes 0

Price - 500 rubles.

This is a group of companies that offers the consumer dry mixes for construction, materials for insulation and interior decoration. The company began its activities in Bavaria in 1958, in the city of Iphofen. The branch of the company was built in Moscow in the 70s of the last century.

Currently, Knauf is a major investor in the construction industry in Russia, Ukraine, Kazakhstan, which creates high quality products with the involvement of local resources. In May 2019, a plant was opened at Knauf GIPS, which is capable of producing building modules and panels from the Novy Dom series. Tests have confirmed that the finished modules are recommended for use in the construction of two-story houses in regions with frequent earthquakes.

- Wide range of products;

- Durability;

- Sheets weigh little;

- Certified manufacturer.

- High price.

Gyproc

votes 0

Price - 600 rubles.

Gyproc is one of the most popular drywall manufacturers in the world. The company provides a wide range of products, such as building materials or automotive components.The products of this manufacturer are very popular with consumers throughout Russia. For the production of drywall, the company uses the latest technologies, as well as constantly improving them, which helps to obtain a material that meets all the most stringent standards and requirements.

Gyproc also offers acoustic drywall which is safe for people and can even be used in kindergartens. Such materials are made from 1% binder, 6% cardboard, 93% gypsum.

The company began its journey in the 1990s in Finland. From there, he was supplied to the Russian Federation. However, in 2013 the company launched production in Russia. Among many companies, Gyproc was able to stand out with the creation of drywall with dimensions of 2500/1200/15 mm. Also, one of the distinguishing features of the brand is that only environmentally friendly materials are used in the production, and the company also produces especially light sheets. Their mass is 20% less than that of a standard analogue.

- Environmental friendliness of materials;

- Wide range of products;

- There are drywall models that have less weight than their counterparts.

- Not detected.

Volma

votes 0

Price - 500 rubles.

Volma is a Russian company that is very popular in the market. This company is the first to produce drywall in Russia with an increased level of hydrophobic characteristics. The company's plant is located in Volgograd and is guided by the European quality standard. This allows us to produce high-quality products with the introduction of new technologies.

The main substance in Volma drywall is gypsum.At the beginning, it is crushed, and then fired in a kiln at a temperature of about 180-200C. After that, several protective layers of cardboard are glued to the material. It has the most inconspicuous seams, thanks to the thinned edges, and the product itself has a rectangular shape. Also, to improve product quality, additional substances can be added, for example, cellulose, fiberglass, starch or special antifungal and hydrophobic impregnations.

- Low cost;

- All products of the company are not flammable;

- The sheets have a very dense structure due to the gypsum core;

- High quality products;

- The company focuses on European standards.

- The plates are very heavy (the weight of one plate can reach 35 kg).

Gifas

votes 0

Price - 450 rubles.

Initially, the company developed and mined gypsum stone and quartz sand. But after a certain period of time, the management decided to produce dry mixes and drywall sheets.

Now the Gifas company has a large number of divisions. One of them is located in Russia, to be more precise, in Yekaterinburg. Gifas gypsum board is made in the form of a parallelepiped, and the connecting and supporting sides have a groove and a ridge. Gypsum tongue-and-groove boards are used for interior wall partitions and to reduce noise and echo in rooms.

The company provides a wide range of gypsum boards for any needs.

- Low price compared to other European manufacturers;

- A wide range of different plates;

- High strength plate;

- Strict quality control,

- Not detected.

LaFarge

votes 0

Price - 150 rubles.

This is a French company that produces and sells drywall sheets. It has one of the lowest prices on the market, as it has opened the largest number of factories in other countries. And the quantity does not impair the quality. Such a large number of factories reduces logistics costs. The company has recently appeared on the Russian market, but even so, it is diligently trying to compete with other manufacturers in the field of budget wall cladding solutions. French acoustic material is slightly different in size from its competitors, LaFarge slabs are smaller. And also in color - the plates have a pleasant creamy shade, instead of the classic matte.

- Wide choice of flowers;

- Greater flexibility of the plates, which allows you to make steeper arches;

- The standard package contains fifty sheets;

- Low weight of the plates, only about 10 kg;

- Very low price.

- Before work, the plate must be treated with sandpaper or a rag.

Tips for choosing

You should pay attention to several points.

The best quality acoustic drywall is available at large hardware stores, as they often have stricter storage times and conditions.

If you plan to buy material in a certain place, then you can look at the warehouse and check the humidity in the room. At high humidity, the gypsum base quickly deteriorates, which leads to money wasted.

It should be remembered that drywall is very fragile in inexperienced hands, so it is best to be present in person during loading and unloading.If it doesn’t work out personally, then ask trusted people to control the process and monitor the competence of employees.

A visual check of each sheet is also necessary, as there may be defective sheets in the pack. The most common defects are: broken corners, cracks, scratches, oil stains, etc.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127687 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124516 -

The best men's sneakers in 2025

Views: 124030 -

The Best Complex Vitamins in 2025

Views: 121937 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2025

Views: 113393 -

Ranking of the best wood paints for interior work in 2025

Views: 110317 -

Rating of the best spinning reels in 2025

Views: 105326 -

Ranking of the best sex dolls for men for 2025

Views: 104362 -

Ranking of the best action cameras from China in 2025

Views: 102214 -

The most effective calcium preparations for adults and children in 2025

Views: 102010