Rating of the best air damper actuators for 2022

The damper of the ventilation system (aka air valve) uses a special drive for its opening / closing operations. In order to correctly select this mechanism, you will need to take into account several parameters of the head unit. Most of the dampers on the modern market are equipped with a servo by default, but if one is not in the initial kit, then its installation can be done even when the damper is already integrated into the overall air conditioning system.

Content

General information

The servomotor for the air valve is a controlling mechanism, the operation of which is regulated by automation in the ventilation system. The device itself is mounted directly into the damper structure and ensures its proper opening / closing. In most cases, the actuator must help the valve to correctly eliminate the effect of back draft in the room, but it can also solve other problems, for example:

- Drafts control;

- Prevention of penetration into the room of insects through the ventilation shaft;

- Reducing dust concentration.

In addition, the valve equipped with automatic closing solves one of the most important tasks - the provision of fire safety. A closed damper in time will not allow the fire to spread through the channels of the ventilation shaft.

The considered type of automatic devices can be successfully used in:

- Fire and ventilation systems;

- Cooling and air conditioning systems;

- Heating systems using air valves.

From this we can conclude that the technically considered device is responsible for the automatic function of the movement of structural bladed elements in the ventilation line. These devices differ in silent operation and easy installation. Even if there is a need to permanently fix the servo in a certain, for example, half-closed position, then this can be done even manually. Accordingly, the already small costs of providing energy to this automation will be reduced to zero.

Design parameters and principle of operation

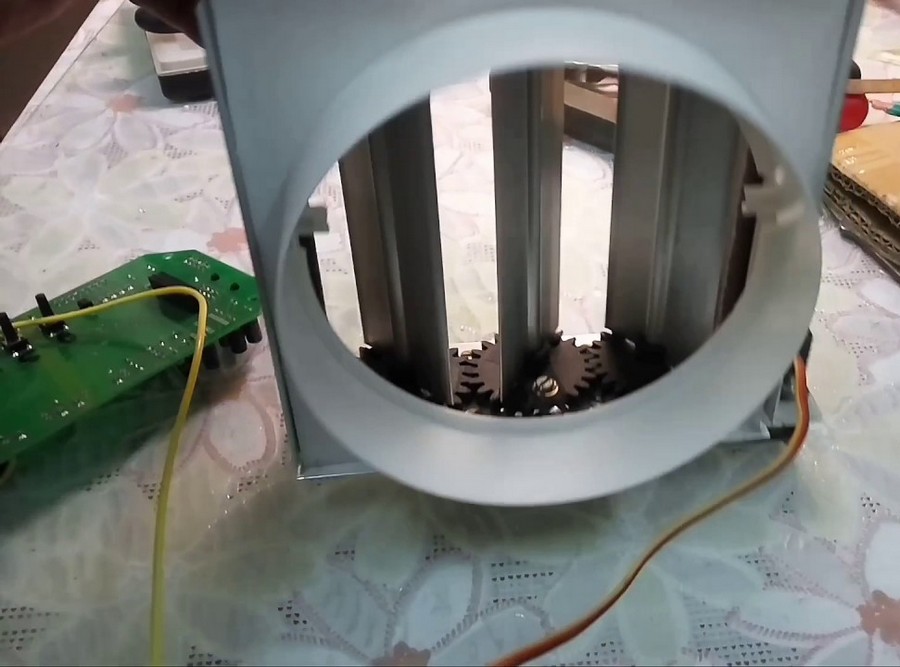

The damper with a drive has the simplest design and in the vast majority of cases it works completely autonomously, without requiring unnecessary settings. Briefly, its functioning can be described as follows. On the body of the head unit, symmetrically to the center, there is a valve, which is ordinary blades or several blades. They are located on a rotating axis, have the possibility of smooth regulation manually or through automation. One axial end passes through the body and ends with a manual control handle (or an actuator for electrical connection). To adjust the volume of the passing air flow, the position of the petals inside the valve changes. In this case, the passage will expand / narrow, which will change the intensity of the flow - from complete patency to a complete stop of air movement. Models of check dampers with a drive operate much easier. During the operation of the hood, due to the influence of the air mass, the valve is discarded and opens the way for air from the room to the mine. In the fully closed position, the blade will be parallel to the plane of the channel section, and in the fully open position, it will be perpendicular.As the fan stops pumping air, the flow pressure will decrease. And under the force of the drive spring, the valve will return to its original position, closing the ventilation channel.

Benefits of Electric Actuators for Air Valves

These devices are primarily used without fail for those climate systems where the amount of air used must change periodically. Electric drives will reliably protect the elements of the air duct from most adverse factors - from the possibility of freezing to power outages. For example, the latter function is generally provided in automatic mechanized mode, because the interruption of the supply of electricity activates the return spring, which returns the servo to its initial position. Accordingly, the valve closes automatically, and this will prevent the water circuit from freezing.

Other advantages of this equipment include:

- Low noise during operation;

- The ability to control the angle of rotation, which is achieved by a mechanical stop;

- Easy installation;

- The possibility of precise fixing, which will prevent possible operating vibrations;

- Low energy consumption.

All these options significantly stabilize the operation of any damper. And when using adapters of a special type, drive mechanisms can also ensure the locking of water channels.

Classification of ventilation actuators

The type of equipment in question may vary in different categories, but specialists usually distinguish six main groups.

- According to the installation method.

They can be mounted both vertically and horizontally. The orientation of the unit will depend (primarily) on the location of the duct itself.Accordingly, for a vertical ventilation duct, you need to use a horizontal-based device and vice versa. If this rule is not applied, then the efficiency of the entire system will decrease significantly. The frame of the servo drive can be built directly into the channel or be laid on. The latter is more convenient to integrate, but the former is considered more practical, because it does not take up much space and is completely hidden in the channel.

- By appointment.

In addition to standard variations, the equipment in question can be specially designed for:

- Fire dampers - they are used to tightly block channels that pass through ceilings, partitions and walls. Their main goal is to prevent the spread of a possible fire flame, smoke and the movement of other combustion products along the ventilation line. Such models are equipped with temperature sensors, which, having received a signal, instantly send a command to the device and it slams the bladed flap.

- Smoke exhaust valves - they are also mounted in smoke ventilation lines, and they are designed to ensure the removal of combustion products and the direction of a fresh air flow into a smoky room;

- Check valves - they have a special spring that can automatically block the wiring of air coming from the opposite direction. Usually, two blades are installed on the central axis of the damper for this, which are driven by a drive. For such a design there is an unspoken name - "butterfly".

- By the number of gates controlled.

The classic valve has a single blade that repeats the body section of the line. However, there are also multi-leaf variations, where the moving parts rotate like a blind, providing overall traction.Naturally, it is desirable to make the operation of the latter by means of an automatic drive.

- According to the principle of action.

The equipment in question can work as follows:

- From manual control - in other words, this is ordinary mechanics and similar devices are marked with the letter "M". Their rotary axis ends with a lever or a specially shaped tip, which can be turned with an ordinary wrench. They may have protractor markings to visualize the indicator of the angle of rotation of the blade in degrees.

- From electrical control - they are marked with the letter "E". Such models are attached to the body of the valve itself and are powered from a standard electrical network, ensuring the movement of the valves. They are used in air ducts with a large pipe section and with a sufficient level of automation.

- From a pneumatic drive - they are marked "P", they work on the principle of the action of air under pressure on the moving parts of the head mechanism.

- According to the density of ensuring closure.

This parameter is purely technical, denoted by the corresponding class:

- "0" - the device is adapted to work in air ducts, where it is not required to observe a special tightness of the shutters;

- "1-3" - the standard level of ensuring the tightness of the closure, which in most cases will prevent the spread of smoke and fire in the ventilation;

- "4" - complete and reliable locking and holding the channel. Closing density is considered maximum and practically guarantees full tightness.

Additional options for electric drives

When selecting an electric drive for a specific air duct system, you should pay attention to its additional option:

- Supply voltage - this parameter must necessarily correspond to the supply voltage of the central control controller.

- Additional switches - they perform some secondary functions, for example, signaling the end positions of the petals or switching the valve to the desired state.

- Speed - this parameter is provided by the design of the equipment itself. The standard value is 0.1 second per 1 millimeter flap movement.

- Maximum operating temperature - some models may have special cooling elements in their housing, which is vital if very hot air is constantly passing through the main channel.

- Stem stroke - for the actuator, it must be equal to or greater than the stroke of the valve itself.

Features of setting and adjustment

The process of setting the system parameters of the air supply system must be carried out simultaneously for all its components. But to set such parameters on your own, without special controllers, is very labor-intensive and not easy. If the drives are controlled from a single control center, then the following operating standards must be set for them:

- First of all, you should determine the settings for those devices that are in close proximity to the fan. Based on the indicators of the intensity of the passing flow, you need to set the maximum level of damper rotation for them.

- By setting the order of operation of the servo drives, it is necessary to form a redirection of the flow to such sections of the network that are least affected by the air relative to the values set in the project.

- When setting the settings, it is required to proceed from the fact that the flow rate error in the exhaust and supply networks is 10%.

IMPORTANT! If mechanical drives or drives with separate control are installed on one of the sections, then it is preferable to mount a separate diaphragm in the channel in order not to engage in constant reconfiguration of individual units.

As a result, automatic control and adjustment, carried out from a single center, is always considered the best option. In this way, it is possible to solve most problems even for climate systems of great complexity, such as branched industrial air ducts or ventilation ducts in high-rise buildings.

Difficulties of choice

Before purchasing drive equipment, you must fully understand the complete set of the system in which it will be used. For example, if the line will pass not only air, but also water, then it is better to purchase a model with a return spring. It is due to this structural element that the valve petals will remain in working condition when a power outage occurs. The spring will close the valve, and very cold air or a large volume of water will not reach the critical areas of the system and will not damage or freeze them. At the same time, the power of the electric drive is also considered an important parameter, that is, it means how large the blades it is able to control. The larger the damper, the more powerful the actuator must be. If the line provides for the possibility of recirculation, then for its full operation it is necessary to use a model with a voltage of at least 10 V. This will be quite enough for a relatively quick opening of the blade by the required 30%.For truly high-quality recirculation, a sample with a voltage of 10 to 20 V will already be required and it will quickly open and hold the sash in a minimum period of 70 percent of its original position. The same models can immediately control two or more blades.

Rating of the best air damper actuators for 2022

Budget segment

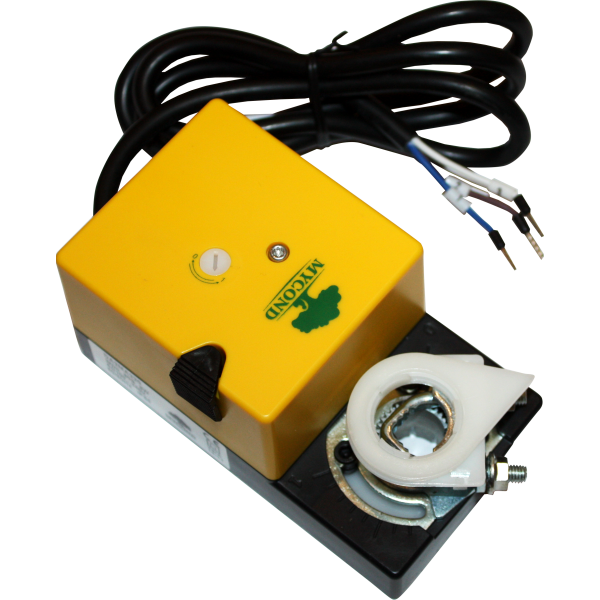

2nd place: "MYCOND DA2MA24" without return spring"

This product does not have the ability to smoothly adjust the air flow, so it is more used to control dampers in simple air conditioning systems. For him, it is imperative that some points of air flow are regulated by mechanical valves. With special adapters, this actuator can be used with water valves. The torque rating is 2.0 Nm, the voltage used is AC 24V, the maximum blade area is up to 0.4 square meters, the time taken to turn the actuator is 30 s. Management - 2/3 position. The recommended cost for retail chains is 3400 rubles.

- It is supplied with a special lock to prevent rotation of the device body;

- There is a mechanical limiter for the angle of rotation;

- Shows low power consumption at finishing position.

- Little functionality.

2nd place: "HOCON" with a return spring, 3N * m, AC 220V"

This sample has a return spring for the "ON" and "OFF" positions and has a general purpose. Used in exhaust and supply ventilation lines for buildings of any number of storeys. Able to provide the opening of the damper with a control signal of 230 V.The return spring can ensure that the valve returns to the "locked" state when the control voltage is removed. Supply voltage is AC ~230V,50Hz, torque is 3Nm, full opening/closing time is approximately <75sec \ <25sec, no limit switches, power consumption is 5W for rotation and 3W for holding. Designed for channels with a cross section of 0.5 m. The recommended cost for retail chains is 5510 rubles.

- Degree of protection - IP54;

- Maximum operating temperature from -20 to +50 degrees Celsius;

- The maximum storage temperature is from -30 to +80 degrees Celsius.

- Not detected.

1st place: "TECHNO 08DNK/24V reversible, accelerated 8Nm, 2/3 positions, 24AC/DC"

The model does not have a spring return and is designed only to control air valves and small dampers that are installed in ventilation systems. Can also be used to control ball valves using a special adapter. The torque is 8 Nm, the rated voltage is 24 V, it has an increased opening / closing speed and a short response time, the control is 2 or 3 positions. It is characterized by low power consumption, can work in groups of up to 10 devices, has a universal adapter for direct mounting on a round shaft up to 20 mm. The recommended cost for retail chains is 6400 rubles.

- It can also be controlled manually, for which you need to activate a special button;

- Possesses the tight case, meeting the requirements of IP54;

- Minimum weight.

- Not detected.

Middle price segment

3rd place: "Siemens" 2 Nm, AC 230 V, spring return, 2P"

This sample is intended for small-sized ventilation dampers (damper area up to 0.3 sq.m.). Provides high control accuracy. Used with controllers with 2-point control signal. The model is dressed in a durable plastic case and comes with a 0.9 meter cable. It is possible to group up to 10 drives in parallel, taking into account the permissible cable length and cross-section. The design uses the patented movement mechanism GQD321.1A. The recommended cost for retail chains is 11,100 rubles.

- The angle of rotation is 90°;

- The presence of a spring return;

- Force - 2 N * m;

- Control signal through two points;

- Degree of protection - IP54;

- Complete with cable.

- Has no limit switches.

2nd place: "Siemens" without spring, 2 N*m, 0.3 sq.m. AC 230 V, 150 sec"

The sample belongs to the group of reversible models - it does not have a spring return, which means that the device returns to its original position by means of an electric motor. This drive is not recommended to be installed on the inflow valve, because when the power is turned off in the ventilation system, the drive will remain in its current position and will not return the damper to the closed state. Its main difference lies in the fact that the control signal in the GSD321.1A drive is the control variability: 2-point control or 3-point control.

- Supply voltage - 230 V;

- Control signal type - variable;

- Cable length 0.9 meters;

- Protection class - IP54;

- Positioning time - 150 seconds.

- Not suitable for all networks.

1st place: "LF230 4 Nm with spring, 230 V, 2-point control"

The model is mounted on inflow and exhaust valves. It is completed with a return spring (“protective function”), which returns the damper to its original position when the power is turned off. This function is in demand in systems in which it is required to close the air inflow inside the ventilation ducts in the event of an accident, which will prevent freezing of the heating section of the ventilation unit. Simple mounting is carried out directly on the damper shaft using a universal grip, equipped with a lock that prevents rotation of the motor housing. High functional reliability: the actuator is overload protected, does not require limit switches and stops automatically when the end positions are reached. When the actuator is moved to the normal operating position, the return spring is charged. When the power supply is interrupted, the energy stored in the spring returns the damper to the guard position. The recommended cost for retail chains is 15,130 rubles.

- Excellent value for money and quality;

- Advanced functionality;

- Easy installation.

- Not detected.

Premium class

3rd place: "Siemens" without spring, 10 N*m, 1.5 sq.m. AC 24 V"

The sample is used in air ventilation systems as part of inflow or exhaust valves. The drive is manufactured by SIEMENS and fully complies with European standards for HVAC systems. It belongs to the group of reversible type actuators, which means that when the power is turned off, the damper remains in its current position.They are not recommended for use in systems where the damper must be returned to its original position (safety function). The force is 10 N * m, which is enough to work with air dampers up to 1.5 sq.m. The recommended cost for retail chains is 16,130 rubles.

- Force 10 N*m;

- Control signal - 0-10 V;

- Degree of protection - IP54.

- Not suitable for all networks.

2nd place: "Belimo NF230A-S2"

The model has a smooth adjustment for controlling air dampers that perform security functions in the ventilation and air conditioning systems of buildings (for example, frost protection). There is a guarantee of six months. The recommended cost for retail chains is 22,700 rubles.

- Fully automated system;

- Durable metal case;

- Smooth adjustment.

- Somewhat overpriced.

1st place: "SIEMENS" at 18 Nm, AC/DC 24 V, spring return, 2P, limit switches"

The sample is used in air ventilation systems as part of inflow or exhaust valves. The drive is manufactured by SIEMENS and fully complies with European standards for HVAC systems. It belongs to the group of actuators with spring return (protective function), which allows them to be used in systems where the damper must be returned to its original position when the power is turned off. The force is 18 N * m, which is enough to work with air dampers with an area of \u200b\u200bup to 3 sq.m. The recommended cost for retail chains is 24,300 rubles.

- Manual control and adjustment;

- Supplied with die-cast aluminum housing and 0.9 meter connecting cable;

- Availability of 2 limit switches.

- Somewhat overpriced.

Conclusion

Installation of an air drive is able to provide full control over the movement of air masses in the system, and this will have a beneficial effect on the operation of any cooling equipment - from a standard fan to an industrial fan coil unit. For the highest quality work, experts advise using samples from foreign manufacturers, because their design is more perfect, and they consume very little energy. It is always worth remembering that the automatic operation of the air valve is able to prevent the spread of fire in time.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131648 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127687 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124515 -

The best men's sneakers in 2022

Views: 124030 -

The Best Complex Vitamins in 2022

Views: 121937 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2022

Views: 113393 -

Ranking of the best wood paints for interior work in 2022

Views: 110317 -

Rating of the best spinning reels in 2022

Views: 105326 -

Ranking of the best sex dolls for men for 2022

Views: 104362 -

Ranking of the best action cameras from China in 2022

Views: 102214 -

The most effective calcium preparations for adults and children in 2022

Views: 102009