Ranking of the best press tongs for 2022

The crimping tool, also known as press tongs, is designed for crimping or crimping not only stranded wires with their contacts, but also for connecting fittings and plastic pipes. It is used in cases where soldering or welding is not possible for certain reasons. Thus, this tool is quite possible to be attributed simultaneously to the category of plumbing and to the category of electrical installation devices. However, it is worth considering in order all the options for its use.

Content

- 1 Wire crimping technology

- 2 Existing types of crimping tools

- 3 Scope of application

- 4 Rules for working with press tongs

- 5 Color marking of dies and sleeves

- 6 Connection of metal-plastic pipes with press tongs

- 7 Preparation of pipe elements for crimping with tongs

- 8 Ranking of the best press tongs for 2022

- 9 Instead of an epilogue

Wire crimping technology

To separate the core endings or wires, various lugs and bushings can be used:

- Forklift;

- Ring;

- Direct.

The crimping itself is used when interacting with multi-core cables with terminal / screw connections, as well as for integrating single-core and multi-core cables with each other and mounting the lugs that will be used to connect to the connector. It is worth noting that the crimping procedure has significant advantages over soldering. This is especially true for situations with electrical circuits and open circuits. A similar situation arises when considering the issue of pipe welding - the pressing method will be more reliable.

At the same time, this method has its own peculiarities.For example, if the work is carried out with copper wires, then the lugs must be made of copper, and if the wires are aluminum, then the lugs for them must be made of the same material.

In the case when the lugs have a bushing cylindrical shape, they are used to prepare the ends of the stranded wire, stripped of insulation, for insertion into a screw-type block. Such tips are made of copper/aluminum, in addition, they are made in the form of a tube with thin walls, which are usually marked with color. For such elements, as a rule, they work with a segmental type tool.

Lugs in the form of a "loop" are used to protect / prepare wires for installation in a screw-type terminal block. Either universal or special pliers will be needed here. Knife tips are used in knife connectors - they are installed in power and automotive electrical circuits, and indeed wherever there is a need for a reliable and inexpensive connection. As well as for the “loop” type lugs, the work can be done with universal or special crimping press tongs.

At the same time, there are special sleeves designed to connect wires to each other. Such sleeves are tubes made of copper or aluminum with thin walls. The ends of the wires are simply integrated into the sleeve and pressed with a crimper or crimping press tongs. In this case, the described sleeves can be used non-insulated / insulated types. A plastic cover with sufficient strength serves as an insulating material.

Existing types of crimping tools

There are two types of crimping tool - press tongs and crimper.The latter type can be produced in a manual or automatic version. It is worth considering each type in more detail.

More about pressing tongs

Their main purpose is to perform crimping of lugs / sleeves for wires and cables. They can vary in types and have a different cross section. There are special models of ticks, which in addition have an amplifier, which can be a hydraulic mechanism or an ordinary lever. Due to this element, the need for additional muscular effort during work is significantly reduced.

Most often, most of the models of the tool in question have a quality control of the produced process, which does not allow the handles to disperse until the whole process is completed. Naturally, to perform quality work, you should use a high-quality tool. The professional grade pliers are equipped with a ratchet mechanism that prevents them from reversing when the job is not completed. Therefore, it will not be possible to quit the process “halfway”, unless the electrician himself interferes with this.

IMPORTANT! The efficiency of the entire circuit will directly depend on the degree of quality of crimping, as well as whether the electrical resistance in the circuit will be appropriate.

More about crimpers

This type can be of two types - manual or automatic. Similar to pressing tongs, the crimper is used for electrical work and is used to connect wires to each other or to connector contacts, directly during operation. The use of this tool helps to completely eliminate the need for welding/soldering.

In cases where the crimper is infrequently used for crimping, it can easily be used as wire cutters or only its calibration grooves can be used. Moreover, some crimper tools have special convex elements with which it is convenient to strip the wire.

If it is necessary to purchase a device only for crimping only one type of wire, then it is preferable to use a crimper with an adjustment function. In this tool, the cutters can automatically adjust to the required diameter by means of a cam/screw that is responsible for the adjustment. Thus, it is possible to greatly facilitate the stripping procedure and the electrician does not have to worry too much about which groove the cable has entered.

Scope of application

Depending on the specific case, the tool must be selected with the appropriate design and shape. For example, for crimping cables of small cross section (from 0.5 millimeters), which have many strands and thin-walled lugs, it is necessary to use crimpers equipped with sleeve pin cable lugs. By itself, the crimping of the wire is carried out until the maximum force is reached, i.e. until the spring mechanism is activated. The need to process a stranded wire arises when it is connected to the terminals of automatic triggers and relays in switchboards or boxes, as well as other devices. The presence of high-quality bushings and the use of a reliable crimping tool will eliminate the fraying of the strands in the wire, because they will be pressed as tightly as possible and at the same time will ensure the continuous transmission of electrical signals.

In the absence of wire lugs and with the subsequent crimping of the ends of the wires, upon completion, it remains only to twist or solder the cable directly to the terminals of the switchboard or distribution devices. And such a connection method can easily lead to frequent breakdowns of the cores, a break in the electrical connection, followed by overheating of the devices or short circuits.

NOTE. In fairness, it is worth mentioning that the soldering option is still acceptable, but only for single-core wires.

For thick-walled ferrules and stranded wires

For the above purposes, a tool of a different type is used, for example, regarding the PK-16 press tongs, there are only five of them. The areas are indicated by special marks on the lips of the device, and the range of possible crimping varies from 1.5 to 16 millimeters. After completion of work, a special stamp remains on the back of the sleeve. Most crimpers, especially PK-16, are designed exclusively for working with stranded wires. If you try to work with them with a single-core cable, then due to the large applied efforts, the core can simply break.

For wires with a large cross section

For such cables, it is preferable to use a special hydraulic press instead of pressing tongs. Such devices appeared long before crimpers, and depending on the dimensions of the press, it is possible to determine which section it is able to compress. In everyday life, such devices are not used, due to their very large size. However, this option can be ideal when installing switching and connecting power cables in electrical panels at the entrances of apartment buildings, etc.

The process itself is not particularly difficult.First of all, to shift the matrix, a large muscular effort should be applied to the operating lever. In the case when the valve is slightly ajar, the stem will be slowly removed. If the valve is fully open, the stem will quickly move away until it stops. When the matrices are fully compressed, blocking is performed. However, excess pressure is not formed, therefore, the possibility of damaging the mechanism itself does not occur. The described hydraulic device itself (due to its rather large size) comes immediately with a cartridge for a certain number of matrices.

Serial crimping of cables

This option is good in that it is possible to prevent the penetration of air into the sleeve. This circumstance is extremely important for cases when it is required to connect alternately aluminum and copper wiring, which may well undergo oxidation when interacting with oxygen.

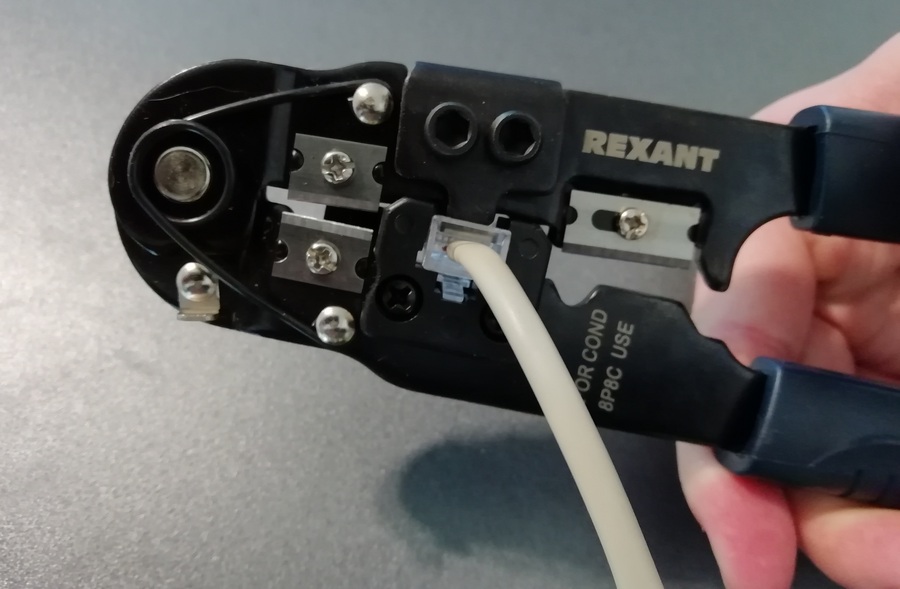

Crimping computer wires

A separate group includes crimpers that crimp the "twisted pair" of a computer cable for a local network. They function in the same way as double-lipped pliers: instead of a metal sleeve, they have a special matrix built into them for the incoming RJ 45 port, with the help of which a telephone or computer wire is crimped. The crimping itself is not performed directly, but with the help of this tool, the contacts are moved, cutting through the insulation on different cores, and fully pressing it to the necessary wiring.

Rules for working with press tongs

The crimping process itself is quite simple and intuitive. The cable is installed inside the tip and jaws of one of the connected elements, then it is clamped with a matrix of tongs, the handles are tightly compressed, forming a high-quality and reliable contact.However, the initial practice may be far from ideal. Loosely compressed or unclenched tongs at the wrong time can show a visually correct result, which, over time, can simply fall apart, depriving the connection made of any contact.

Not maintaining terminal forms

The main reason for this may be incorrect settings for combining / squeezing both jaws of the matrix. The shape and the forces applied to this process must be selected depending on the lugs used and the cables being pressed. Therefore, before starting the whole process, the electrician should have different tools nearby in order to quickly take measurements for different wires and lugs. At the same time, the quality of the work performed will depend on the material (from which the sleeve is made), on the thickness of the sleeve and on the tip. Sealed terminals are very easy to crimp because they can hold shape better than softer materials.

IMPORTANT! Tips for U-shaped sections must always be placed properly to prevent the element from being skewed beyond the limits of the permissible error zone!

Twisting stranded conductors before crimping

Electricians with great experience (and especially the "old school"), who often twisted wires and soldered them, can do this even before crimping. However, such an action is strictly prohibited before crimping multi-wire lugs. The thing is that by crossing two cables with many cores and squeezing them with pliers, the wires will undergo uncontrolled deformation, it is quite possible that they will be completely broken and, therefore, there will be no telecommunications in the current-carrying core.And in the absence of twisting, the wires will be located in parallel, and in case of deformation, the voids will be filled with veins and there will be no squeezing.

Color marking of dies and sleeves

Some manufacturers mark different sizes of sleeves with special colors, as well as special marks are applied to the matrices of press tongs. All this is done in order to more conveniently differentiate them. However, a unified system of brands and colors has not yet been developed, so each manufacturer has its own symbols.

Connection of metal-plastic pipes with press tongs

During the installation of PVC pipes, special connecting elements are used - fittings. They are fasteners or nodal branches - plugs, adapters, tees, crosses. They are also divided into compression and press. To mount the former, you only need a standard wrench, while the latter are mounted using crimping pliers. With their help, crimping is carried out efficiently and quickly, and the result will be a reliable and non-separable connection, almost completely eliminating a break in the switching line. Thus, with the help of pressed fittings, you can get a full-fledged non-separable complex. At the same time, if errors are made during the installation process, then in the future it will not be possible to partially correct them, but it will be necessary to cut out the manufactured fragment and insert a new communication node. It is also worth noting that the cost of press parts is quite high, so repairing communications with their help is not very common.

Preparation of pipe elements for crimping with tongs

The following sequence is mandatory and necessary for any type of tick:

- Using a tape measure, measure the required length of the desired pipe material and make a mark with a pencil where cutting is expected;

- Scissors for metal cut the element with the desired length, while the edge of the cut should be as clear and even as possible, and the cut itself should be made exactly at a right angle;

- In the case when a guillotine tool is used for cutting, its lower edge should be kept strictly parallel to the pipe surface, but still slightly pressing the cutter into the material;

- After trimming, the end edges must be processed using a calibrator. It will correct and compare the shape of the cut itself and chamfer from the inside;

- After that, the sleeve for crimping is removed from the fitting and put on the edge of the pipe, and the fitting is inserted directly into the inside of the cut;

- Then the end elements must be pressed very tightly against each other, while the joint area must be insulated with a gasket. Thanks to it, the material is reliably protected from corrosion, and the overall tightness of the entire system is ensured;

- It is possible to control the placement of the pipe in the sleeve using a rounded cutout in the edge area.

Only after completing all the above 7 steps can the crimping operation begin.

Ranking of the best press tongs for 2022

Budget options

Excellent and inexpensive crimping pliers for working with stranded wires and ferrules. Equipped with a ratchet mechanism to prevent improper crimping, the body itself and the crimping die are made of cold rolled carbon tool steel. At the same time, the design provides for forced unlocking of the ratchet mechanism. Handles are covered with high-strength ABS plastic.

| Name | Index |

|---|---|

| Manufacturer country | China |

| Weight, kg | 0.5 |

| Working section diameter, mm2 | 0,2-6 |

| Additionally | Automatic return |

| Price, rubles | 800 |

- The correct trapezoidal shape of crimping;

- Rugged housing;

- Handle protection.

- Limited application.

2nd place: "BOSI 0.5-1-1.5-2.5-4-6mm2 BS432117"

Multi-purpose crimper for working with different ranges of wires, perfectly copes with the crimping of lugs of standard sizes. The execution mechanism is characterized by the fact that it is able to reduce the load on the hand during compression, while the degree of compression is adjusted accurately and automatically. The existing ratchet mechanism guarantees a quality crimping cycle.

| Name | Index |

|---|---|

| Manufacturer country | China |

| Weight, kg | 0.4 |

| Working section diameter, mm2 | 0,5-6 |

| Additionally | Removable sponges |

| Price, rubles | 930 |

- Crimping jaws are made of alloyed steel;

- Sponges are removable;

- The handles have an anti-slip coating.

- Work only with standard section sizes.

1st place: PKM-6 ZUBR (art. 22654)

This sample is positioned as a multi-range one, although it still works with standard sections. The working surface is made of high-strength steel and is designed for semi-professional use. The manufacturer claims an increased service life, which guarantees high quality electrical work.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Weight, kg | 0.45 |

| Working section diameter, mm2 | 0,25-6 |

| Additionally | Various forms of crimping |

| Price, rubles | 1700 |

- Versatility;

- Can use different forms of crimping;

- Extended service life.

- Not found.

Middle price segment

3rd place: Sparta 177065

These pliers are extremely wear-resistant and can grip both round and flat workpieces, while their accuracy is at the highest level. The edges of the steel jaws are specially hardened to work with high-frequency currents, so they are able to cut even very hard wires. The occurrence of corrosion on the body is prevented by a special paintwork.

| Name | Index |

|---|---|

| Manufacturer country | Germany |

| Weight, kg | 0.55 |

| Working section diameter, mm2 | 0,5-6 |

| Additionally | Not |

| Price, rubles | 1000 |

- Adequate price;

- Reliably lie in the hand;

- There are no backlashes.

- May move slightly as a result of applying excessive force.

2nd place: KVT PKVk-10

This sample is equipped with a special ratchet mechanism that blocks the reverse motion at the end of the crimp. The matrix is self-adjusting, which greatly simplifies the work with tips of different sections. The sample fits comfortably in the hand and is light in weight. The head working part is equipped with a special coating that reduces the likelihood of small cracks and scratches.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Weight, kg | 0.36 |

| Working section diameter, mm2 | 0,25-10 |

| Additionally | Not |

| Price, rubles | 1900 |

- Improved ergonomics;

- Secure grip;

- Pressing speed.

- Overcharge;

- Some inconvenience of working at a maximum cross section of 10 mm2.

1st place: "IEK KO-08E"

The model differs in the strong case made of the tempered steel, is capable to maintain big mechanical loadings.It has a ratchet mechanism and a quick release system. Precisely fitted matrices are responsible for increased accuracy of work. Due to its light weight, this tool is convenient to work for a long time. Anti-slip is implemented in the form of embossed overlays on the handles.

| Name | Index |

|---|---|

| Manufacturer country | China |

| Weight, kg | 0.4 |

| Working section diameter, mm2 | 0,5-6 |

| Additionally | Not |

| Price, rubles | 4000 |

- Increased strength;

- Small dimensions and weight;

- Ease of grip.

- Somewhat short handles.

Professional kits

3rd place: "Radial pliers for manual crimping of press fittings JT-1626B"

This set is specially designed for crimping tube fittings. It is a powerful tool, the set of which is equipped with the necessary number of nozzles. It perfectly copes with the crimping of any fittings-adapters and guarantees a tight scene. Easy to manage.

| Name | Index |

|---|---|

| Manufacturer country | China |

| Crimping force, t | 4 |

| Dimensions of dies for crimping, mm | 16-20-25 |

| Matrix type | TN |

| Price, rubles | 6000 |

- Long handles;

- Ease of use;

- Carrying case.

- Lack of versatility.

2nd place: "Press tongs with a set of nozzles TIM Ф16-32 mm, TH , JT1632"

The manufacturer positions these pliers as a tool that can work with all types of fittings, which ensures its full system compatibility. The press connection speed varies from 5 to 10 seconds depending on the nozzles used. The working part is able to rotate 360 degrees, which means additional convenience in work.The handles are retractable.

| Name | Index |

|---|---|

| Manufacturer country | China |

| Crimping force, t | 4 |

| Dimensions of dies for crimping, mm | 16-20-25-32 |

| Matrix type | TN |

| Price, rubles | 7100 |

- Excellent value for money;

- Telescopic handles;

- Quality manufacturing material.

- Not detected.

1st place: "Universal pliers set UNI"

This kit is designed for cutting, stripping, crimping and integrating wires in complex electrical circuits. The set is universal and suitable for any job (except for working with fittings). The kit is replete with a large number of nozzles, wire cutters are provided separately. All tools are placed in a lightweight and durable case for easy transportation.

| Name | Index |

|---|---|

| Manufacturer country | China |

| Weight, kg | 1.5 |

| Working section diameter, mm2 | Vary |

| Additionally | A large number of nozzles |

| Price, rubles | 8500 |

- Adequate price;

- Extended functionality and versatility;

- Convenient case.

- Not detected.

Instead of an epilogue

Press tongs must be selected, guided by an immutable rule - "For every job you need your own tool." Therefore, it is absolutely not necessary to connect the wires with a simple cold twist. This can lead not only to a break in telecommunications, but also to fire-hazardous manifestations of electric current. It is better to connect the wiring correctly, producing good insulation. At the same time, the connection of PVC pipe lines by crimping is a rather expensive pleasure and is not suitable for everyone. But here everything will depend on the size of the budget of the buyer himself.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131654 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127694 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124522 -

The best men's sneakers in 2022

Views: 124039 -

The Best Complex Vitamins in 2022

Views: 121943 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114982 -

The best paint for gray hair - top rating 2022

Views: 113398 -

Ranking of the best wood paints for interior work in 2022

Views: 110321 -

Rating of the best spinning reels in 2022

Views: 105332 -

Ranking of the best sex dolls for men for 2022

Views: 104370 -

Ranking of the best action cameras from China in 2022

Views: 102220 -

The most effective calcium preparations for adults and children in 2022

Views: 102014