Rating of the best polyurethane varnishes for 2025

The modern building materials market is simply overflowing with various products made on the basis of polymers or from high-tech composites. They rightfully occupy the leading positions in sales. Among finishing varnishes, polyurethane samples are very popular, which are very convenient for finishing wooden surfaces. With their help, wood is easily given a noble appearance, notes of comfort, while protecting the surface.

Content [Hide]

- 1 General information

- 2 Technical features

- 3 Modern look of PU varnishes

- 4 Advantages and disadvantages of PU varnishes

- 5 Areas of use

- 6 Preparation and application of polyurethane varnishes

- 7 Features of caring for a surface treated with polyurethane varnish

- 8 Rating of the best polyurethane varnishes for 2025

- 9 Conclusion

General information

A layer of polyurethane-based varnish will properly help extend the life of the product, while emphasizing the naturalness of its texture and natural pattern, which is especially pronounced on the example of a parquet surface. Unlike other varnishes, the protective qualities provided by the polyurethane layer are higher. They are achieved by the formation of a durable film on the treated surface, which will prevent mechanical damage, prevent the harmful effects of moisture and prevent the spread of fungus or the reproduction of harmful microorganisms. It is worth recognizing that the target material for the types of varnishes under consideration is wood, but it can also be successfully used, for example, for concrete.However, not every composition is suitable for its processing, most of the functional properties will depend on the components included in the structure of the solution. Nevertheless, with the help of PU varnishes it is possible to give concrete additional strength, moisture resistance, resistance to abrasive cleaners, to the negative effects of petroleum products and acids.

Technical features

The considered type of decorative and protective compositions has the following abilities:

- Able to form a tough and clear coating with adequate wear resistance. The treated surface becomes more resistant to irritating oil products, it will more successfully withstand atmospheric precipitation, due to the extreme density of the polymer film created.

- PU varnish perfectly emphasizes the structure of the tree, giving it extra external depth.

- The varnish is not only focused on working on wood, but it can also perfectly process mineral materials, porcelain stoneware, stone and concrete.

Gloss level

These varnishes are usually produced in two types - these are gloss and matte samples. Their variations are also possible, for example, semi-matt or semi-gloss types. It should be noted that the appearance of the formed film does not particularly affect its basic operational capabilities. Accordingly, the gloss level is considered to be purely a matter of aesthetic considerations. However, a glossy surface better reflects possible deep mechanical scratches, therefore, if permanent mechanical stress is expected on the treated surface in the future, then it is better to choose a matte sample for it.

Modern look of PU varnishes

The current industry produces a wide range of polyurethane varnishes for the construction market, which vary in color, consistency, content and degree of gloss. Thus, depending on the preferred final result, any buyer can easily choose the right product - transparent or with the necessary pigmentation, which will give the object being processed the desired shade.

Based on the chemical composition, this finishing material is divided into:

- One-component - a water-based liquid composition that can be applied to almost any object without prior surface preparation;

- Two-component - this composition includes a polymer base and a special hardener. Before work, both of these components are mixed, in accordance with the proportions indicated by the manufacturer in the instructions.

Regardless of the composition, the manufacturer also recommends using a certain type of varnish for certain operating conditions. For example, it is better to polish glossy samples after application and drying with a special polishing paste - they will look more impressive. However, they are not recommended for use on surfaces that will be subjected to increased mechanical stress in the future, because deep scratches are clearly visible on the gloss. If there is no other way out, then it is better to use silky-glossy compositions for such objects. Matte samples are most suitable for rooms where diffused light predominates. With the help of matte shades, it is possible to hide the imperfections of the surface or its unskilled finish as beautifully as possible. From this it is clear that for the described premises, a silky-matt composition will be an ideal option.

Advantages and disadvantages of PU varnishes

Over other types of finishing varnishes, the compositions under consideration have a number of cardinal advantages:

- Excellent for processing any type of wood - from soft to hard, from valuable to the simplest. The most susceptible to processing are oak, pine, birch or larch.

- Easy to apply and, in principle, do not require additional polishing after polymerization.

- The resulting coating is extremely resistant to moisture, calmly in contact with most chemically aggressive detergents.

- The resulting protective film has an increased elasticity, so that, with an appropriate level of operation, the risk of cracking is minimized.

- The treated surface has a wide range of operating temperatures.

- The resulting coatings have a sufficient service life and increased strength.

- The varnish will perfectly protect the object from direct ultraviolet rays.

Of the frank disadvantages, it is possible to note the following:

- Two-component samples have organic solvents in their structure, which indicates their low environmental friendliness, and they have a pungent synthetic odor;

- After a significant time period, the applied layer may turn yellow;

- The highest quality and functional samples are very expensive.

Areas of use

In addition to wooden surfaces, polyurethane solutions can work with other objects. Most often they are used for:

- Additional protection of load-bearing walls, ceilings and floors (regardless of the production material);

- Protection of decorative elements of wooden furniture (stairs, railings) from negative mechanical / chemical effects;

- Formation of a colorless film on ceramic tiles, while impregnating the interstitial concrete spaces in brick bases and slate roofing;

- Creating the effect of "wet" stone;

- Prevention of corrosion on mineral surfaces;

- Improved protection of the visual and aesthetic characteristics of the parquet;

- To provide protection to stone, metal, concrete from rust manifestations.

Varnishes are equally good for indoor and outdoor use, for home and industrial use, and work great with fully synthetic bases (for example, all types of plastic).

Preparation and application of polyurethane varnishes

Most professionals are inclined to believe that ground preparation is still needed, although it is not mandatory. As a rule, it comes down to banal grinding with a special tool. For this, a grinder is usually used, equipped with rectangular blades with rounded edges. It is desirable that the surface become completely even after stripping, but this quality will not negate the fact that finishing stripping with sandpaper is necessary.

At first, such an action is performed with coarse-grained paper, and only then a fine-grained variation is used. Sandpaper is necessary in order to eliminate the slightest cuts and scratches caused by a cutting grinding tool. Grinding itself is recommended to be carried out along the length, because this will help to avoid the formation of large scratches. This rule applies to both wood and metal. A perfectly prepared surface acquires a pronounced matt-gloss appearance, especially under natural light. It should be noted that the metal should be processed according to the spray varnishing method.Before work, the varnish can must be heated using the capabilities of a water bath. This will help reduce the graininess of the application, and the entire course of work will acquire increased accuracy. Naturally, the use of the aerosol method involves the application of several layers, but only after proper drying of each previous layer.

Processing technology

The choice of application method and technology will depend on the qualities and properties of the object being coated and its dimensions. Regardless of the chosen method, all work should be carried out in a well-ventilated area.

Aerosol method

It is better suited for most labor-intensive work, it is better to use it on objects of small dimensions. According to the provisions of the instructions, the spray should be applied evenly to the surface in a thin spray layer, after which the layer must be allowed to go through the initial curing stage. The process of the first and subsequent applications should be uniform and occur at the same speed. With the aerosol method, the consumption of the working substance, of course, will be far from economical, therefore, with a large amount of work, you should stock up on several cans at once, which (preferably) belong to the same production batch.

Roller/brush method

It is typical for the use of both two-component formulations, and for single-component ones. To facilitate the workflow, it is preferable to dilute the one-component solution with a solvent, despite the fact that if the roller / brush acts as the tool, then its volume should not exceed 5% of the total volume of the working material.For two-component samples, it is better to use an exceptionally soft roller - with it the work will be faster, and the prepared, but not applied composition will maintain a liquid state longer. It is always worth remembering that as soon as even the primary polymerization of polyurethane varnish has begun, then any attempt to “refresh” it with a solvent for reuse will fail. A two-component composition on the second layer is not applied immediately, but only after the previous one has completely dried. It should be noted that if the goal is only to protect the object from the negative effects of water, then applying several layers is not required, because one layer will do just fine.

As a result, the choice of work technology directly depends on the object of processing, and on the tasks set, and directly on the PU varnish. For example, a composition with self-leveling properties will not require maintaining time intervals between the application of individual layers. In other cases, the varnished surface may acquire structural irregularities, and it will need to be cleaned with sandpaper. However, such manipulation will invariably lead to a violation of the glossy sheen. At the same time, you need to understand that over time, the applied layer will certainly begin to turn yellow, which should also affect the processing method. In addition, when decorating objects located in children's rooms or in places where people with respiratory diseases permanently stay, it is recommended to use samples of materials that have a sufficient degree of environmental friendliness. At the same time, one should rely on the viscosity indicators of the consistency of the solution - it should usually be 30-75 centistokes (for glossy samples, this indicator is very high).

Features of caring for a surface treated with polyurethane varnish

In order to give specific processed products a maximum operational life, it is necessary that the premises where they are permanently located have special conditions. Without the implementation of this rule, even the most careful care for them will not have the desired effect. For example, if we are talking about parquet, then for its long life in the room you need to create two mandatory conditions:

- Humidity should not exceed 50-60%;

- The temperature should keep the boundaries of +18 ... +25 degrees Celsius.

In the cold period of the year, when the heating is at full power, the air should be moistened, and in the rainy autumn period, on the contrary, it should be dried, for which convectors or fans should be used. In any case, parquet is a porous material, which, if not skillfully varnished, will easily let in and accumulate moisture, which will result in the appearance of mold and fungus. Among the majority of the inhabitants there is an opinion that varnished parquet should be cleaned exclusively with a vacuum cleaner with a soft nozzle. However, this is just a recommendation and not a requirement. The tree, in principle, is even recommended to be washed, but such a procedure should be carried out infrequently, and then only using special detergents. These special compositions will not allow the lacquer polyurethane layer to collapse, and the layer itself will not fade and turn yellow for a very long time, will not be covered with stains. Washing should take place with a wet, but well-wrung out cloth. It should be mentioned that only a completely wrung out rag will not allow water to penetrate between the wooden dice, and after wiping, within a minute after completion, the floor will dry.

Use of detergent chemicals

The best tool in this category, specially adapted for working on polyurethane coatings, are the so-called "cleaners". They are pH-neutral concentrate cleaners that are added to water before washing. The manufacturer indicates the proportions of dilution with water in the instructions. Cleaners may differ in their composition, but specifically for polyurethane surfaces, a separate line is produced, which is absolutely neutral to this type of coating and at the same time is characterized by increased environmental friendliness. However, the first application of the cleaner must occur no earlier than 14 days after the newly applied layer has dried.

Cleaners can be produced both in liquid form and in aerosol form. In terms of application technique, they do not differ much, but aerosol samples clean stubborn dirt or grease stains better, and even help hide traces of slight wear. The spray is sprayed on the desired surface area, after which it is erased with a soft cloth to the required level of reflection.

Special care kits

There is a range of cleaners that not only eliminate pollution, but also form a short-term protective layer on it. Typically, such kits are not cheap, they contain wax inclusions, and to create protection, you need not only to grind the applied substance, but also to polish it. At the same time, their structure includes special antistatic agents, which is important if there are pets in the apartment.

Rags, mops, care brushes

The guarantee of keeping the polyurethane coating clean will also depend on the tool used. If you use a brush, then it should have a special bristle of medium hardness - it is so easy to scrape off dirt, wash the surface, and rub it with high quality.After cleaning operations, the brush should always be cleaned with high quality, removing adhering fragments of dirt from almost every bristle, and then wipe its working part dry. It is preferable that the pile be of natural origin, professionals consider boar bristles to be the best option. If the pile is synthetic, then the bristles should have a medium or high level of softness (this way you can reduce the risk of scratches).

For brush nozzles of vacuum cleaners, the use of synthetic pile in the design is typical. It may feel too rigid to the touch, but it is located in such a way that its work will be more than safe. This is achieved due to the special arrangement of individual bundles of villi, several in a row, and not in a dense mass.

If we talk about the use of rags, then ordinary rags will do, but today's industry already produces reusable thick wipes on a non-woven basis (microfiber). They are easy to rub the base and wash it, and for greater convenience they are easy to adapt to the mop.

Rating of the best polyurethane varnishes for 2025

Budget segment

3rd place: "Vixen aerosol 520 ml VX-24005 LM"

votes 0

Provides protection of wood from biological damage, and also creates a wear-resistant coating that can highlight the natural texture of the material. It is not afraid of exposure to ultraviolet radiation, water, temperature extremes and cleaning products. The composition does not flow from vertical surfaces with uniform spraying and is suitable for application to places with difficult access. The product can be used with any paint and varnish materials. The recommended cost for retail chains is 414 rubles.

- Orientation to difficult conditions of use;

- Good combination with various materials;

- Budget price.

- Small volume.

2nd place: "Premium" colorless Silky-Matte 1 l."

votes 0

This highly durable sample is used to create a transparent coating, silky matte finish. Good for baths and saunas, for parquet and stairs. When completely dry, it forms a transparent, elastic, hard coating. Contains UV filter, non-yellowing. Type of surface to be treated: fiberboard, chipboard, OSB, wood, brick, mineral material, primary drying time - 60 minutes, at a temperature of +20C, complete drying after 48 hours. Application method: roller or brush. The recommended cost for retail chains is 800 rubles.

- Good combination of price and quality;

- Fast drying;

- Antiseptic properties.

- Not detected.

1st place: "Glossy Charm (VD-AK-02-04) - 1l"

votes 0

It is used for furniture, for flooring and other surfaces that experience significant mechanical stress. Emphasizes the texture of wood, giving it additional visual depth and nobility. Wear-resistant varnish creates a very durable, transparent coating. The surface becomes moisture resistant and resistant to oil products, acids and abrasives. The film of polyurethane varnish is very hard, so the coating is durable. It can be used to cover bricks, artificial and natural stone. Well protects wooden furniture from chemical and mechanical influences. Thermally stable up to 90 °C. The recommended cost for retail chains is 890 rubles.

- biological safety;

- Does not have an unpleasant odor;

- Economical expense.

- Not detected.

Middle price segment

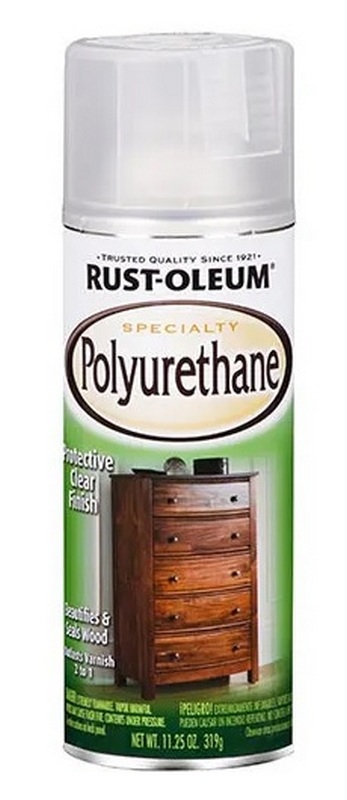

3rd place: "RUST-OLEUM Specialty Polyurethane, Colorless, Semi-matte finish, weight 319 gr."

votes 0

This urethane-alkyd sample is designed to provide a clear protective coating on indoor wood and metal surfaces. Ideal for protecting furniture, doors, shutters, countertops, railings, decorative and wickerwork, as well as door handles, hinges, etc. It exhibits excellent adhesion to wood, metal, plasterboard, concrete, plastered surfaces, as well as to unglazed ceramics, glass, wickerwork, etc. The recommended retail price is 930 rubles.

- Protects against scratches, abrasion, chips, moisture, alcohol and chemicals;

- It is well combined with all types of stains;

- 2 times longer retains shine compared to varnishes from other manufacturers.

- For interior work only.

2nd place: Matte, colorless, polyurethane, odorless SAFORA 600 gr.

votes 0

This super-durable specimen is suitable for furniture and wood for a subtle matte effect. Wet wash is allowed. Colorless, odorless, water-based product. It is highly recommended when working with chalk and is compatible with all water-based paints. Designed for indoor use. Also, it is necessary for any surfaces with increased operational load or if maximum coating strength is required, such as kitchen fronts and aprons, chairs, stools, etc.The recommended cost for retail chains is 1280 rubles.

- Without smell;

- It is safe to use indoors, including children's rooms; it does not have a strong odor;

- Does not stick and does not yellow;

- Creates a noble matte durable and transparent coating.

- Slightly higher consumption.

1st place: "Kleiwer" matte, colorless, odorless, 300 ml.

votes 0

This opaque water-dispersion one-component polyurethane sample has excellent decorative and protective properties. Designed to create a high-strength finish coating after painting furniture and other wooden surfaces indoors of all types of buildings and structures with chalk or acrylic paints. It has high hardness, resistance to abrasion, household stains and washing with detergents. The recommended cost for retail chains is 1425 rubles.

- Eco-friendly, no pungent odor;

- Forms a transparent hard wear-resistant coating with an elegant matte sheen, without yellowness;

- Quick dry;

- Due to its good spreading, it is easy and convenient to apply.

- Not detected.

Premium class

2nd place: "Petri Diamond Hard silky semi-gloss 0.946 l"

votes 0

A similar sample is used for interior work, protects the base from scratches and wear. It is applied to wooden floors (parquet, solid wood, exotic wood floors), furniture, doors, stairs, terraces and other wooden structures. Perfect for use in places subject to heavy loads, harmful environmental influences, heavy flow of people.It can be used for outdoor work, but only in places not exposed to direct sunlight. For maximum wear resistance and reduced consumption, a primer is recommended as the first coat. The recommended price for retail chains is 2440 rubles.

- Possibility of indoor/outdoor use;

- Small consumption;

- Classic clean composition.

- Not detected.

1st place: "Hyperdesmo-D, 20 kg"

votes 1

This product forms a hard and at the same time elastic seamless coating over the entire application area. Easy to use, made on the basis of one component. Polymerizes under the influence of air humidity. High curing speed. Stable over a wide temperature range. Excellent adhesion to most building materials. Absolutely non-toxic after polymerization. After drying, it ensures absolute safety in contact with drinking water and foodstuffs. The recommended cost is 20100 rubles.

- Large volume;

- Fast polymerization;

- Seamless coverage.

- High price.

Conclusion

In addition to polyurethane paints, polyurethane varnish has also become widespread in the construction market. It can be produced in various compositions and allows not only to raise the aesthetic impression of the surface treated with it, but also to extend the period of use of furniture, home interiors and other painted bases.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131658 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127698 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124525 -

The best men's sneakers in 2025

Views: 124042 -

The Best Complex Vitamins in 2025

Views: 121945 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114984 -

The best paint for gray hair - top rating 2025

Views: 113401 -

Ranking of the best wood paints for interior work in 2025

Views: 110326 -

Rating of the best spinning reels in 2025

Views: 105334 -

Ranking of the best sex dolls for men for 2025

Views: 104373 -

Ranking of the best action cameras from China in 2025

Views: 102222 -

The most effective calcium preparations for adults and children in 2025

Views: 102016