Rating of the best polyurethanes for making molds for 2022

Often, in the interiors of office space and residential buildings, natural stone or its imitation fake is used. Of course, a natural mineral looks much more natural and beautiful, but the cost is very significant. At the same time, non-natural material is not worse than natural material either in appearance or quality. For the manufacture of such products, matrices are required into which the hardening composition is poured. They are usually made from polyurethane. Such forms are easy to do on your own at home. This can be a pretty wise investment that will please the eye and last for years to come.

The Russian market has a large selection of products offered by domestic and foreign manufacturers. This review provides basic information about polyurethanes, their properties and characteristics, advantages and disadvantages, as well as the procedure for not making mistakes when choosing the right product.

Content [Hide]

General information

Polyurethane for mold making is a kind of high molecular weight compounds with a polymer structure that have good elastic characteristics, allowing them to be used to create flexible molds.

Applications:

- construction - the creation of interior items, work with artificial stones;

- artistic - decorative elements, sculptures, souvenirs, cladding;

- furniture production - upholstery materials.

In addition, it is widely used to create any complex forms, depending on the specifics of the order.

Peculiarities

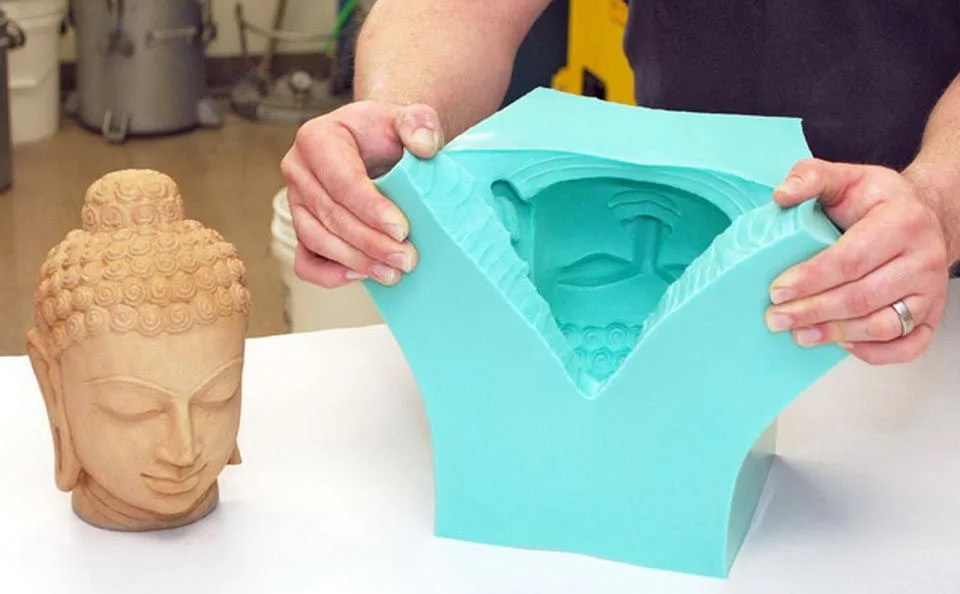

- Easy removal of the hardened product from the matrix without damage and preserving the texture. The plasticity of the material saves time and costs in the production of decorative stone.

- The most accurate transfer of all the features of the relief of the stone, the graphic nature of its surface and the smallest cracks. Such an identity greatly complicates the visual difference between an artificial stone and a natural one.

- The possibility of using combined raw materials for the production of decorative tiles - concrete, gypsum, cement.

- Increased strength, durability, elasticity, resistance to aggressive environmental influences and in contact with abrasive materials.

- Creation of a large range of decorative bricks that mimic the visual effects of aged material, as well as artificial stone, which has a pronounced imprint of a natural surface.

- The ability to change parameters depending on the dye, filler and other additives. The possibility of creating a material capable of replacing rubber in terms of flexibility and ductility, as well as returning to its original form in case of mechanical damage.

- very high elongation, tear and tear strength;

- abrasion resistance;

- strong viscosity and vibration resistance;

- wide range of Shore hardness (indentation method): from 30A (soft) to 99A (very hard) units;

- low wear;

- resistance to high pressure;

- elasticity at low temperatures;

- dielectric properties

- chemical inertia;

- ease of use with the possibility of using at home.

- limitation of use by temperature up to +110⁰С;

- the need for a wax release agent to prevent the polyurethane from sticking to the formwork and model.

Compound

Oil is used as the main raw material for production. The composition contains various components, including polyesters, reagents, emulsifiers. In terms of the number of variations, polyurethane is ahead of such materials as polystyrene, PVC and polyethylene. To create matrices, an injection molding product is used, which has many varieties depending on the properties.

The polyurethane compound includes two types of solutions. Each component has a different type of polyurethane base.

When mixing the two compositions, a homogeneous fluid mass is obtained, which solidifies at room temperature. Due to these properties, the material can be used to create matrices.

Types of two-component raw materials:

- cold casting;

- hot casting.

Among the two-component brands stand out:

- vulcoprenes and adiprenes;

- vulkollans and poramolds.

Two-component polyurethane requires certain additives to change the quality of the raw material. So, thanks to the use of pigments, the color gamut changes, modifiers accelerate the reaction, fillers reduce the percentage of plastic to reduce costs.

Fillers can be:

- chalk or talc;

- fiber or carbon black.

Criterias of choice

To select the best option for liquid polyurethane, the following factors should be considered:

- material for the manufacture of gypsum or concrete, since the features of the forms affect the quality (exposure to grinding, temperature, etc.);

- the possibility of application in various industries, both small and large;

- practicality of execution, for example, pouring or brushing;

- choice of polymerization method;

- work with both vertical and horizontal planes;

- sizes and parameters of matrices;

- the desired degree of circulation resistance: for large-scale work, expensive polyurethane with a high index is needed, for small ones, a less serious option is suitable.

Where could I buy

Popular compounds can be purchased at specialized building departments or stores, as well as from official representatives or dealers of leading manufacturers of such products. As a rule, low-quality or counterfeit mixtures from unknown companies are not allowed on the shelves there. At the same time, you can get useful advice from consultants - which ones are, which company is better, how to mix, how much it costs.

In addition, a suitable polyurethane is available for ordering online in an online store or on an aggregator page, such as Yandex.Market. The product cards contain description, performance parameters, price, ratings and customer reviews.

The best polyurethanes for making molds

The rating of quality mixtures is based on the opinions of users who have left reviews on the Internet. Popularity is due to the basic parameters, operational properties, customer ratings and cost.

The review includes ratings among the best materials at a budget price, in the middle price segment and premium products.

TOP 3 best budget polyurethanes

Vytaflex-20

votes 0

Brand: Vytaflex.

Manufacturer - Smooth-On (USA).

A new generation of two-component resin for making molds used in the production of sculptures, facade elements, wall panels, artificial stone, etc. Best suited for stained/pigmented concrete casting. The components are mixed by weight and volume in a ratio of one to one. By adding So-Strong pigments, additional color brilliance can be achieved.

Price - from 3,096 rubles.

- fluid composition;

- slight shrinkage;

- without deformation of the appearance when removed;

- vacuum degassing is not required;

- prolonged use;

- quality performance.

- when working, strict observance of safety measures is required, the use of a respirator and gloves is mandatory;

- overpriced.

How VytaFlex-20 works:

Silagerm 5055

votes 0

Brand - "Silagerm" (Russia)

Seller - PolyFormat (Russia).

A two-component, cold-curing monolithic potting compound for the manufacture of technical products and elastic molds up to 100 cm in size. It is well suited for the production of paving slabs, artificial stones, as well as various artistic and architectural models from concrete or plaster. Material processing is carried out at temperatures up to 31 ° C by machine or manually. Depending on the material used, it can reach up to 500 working cycles. The warranty period without opening the factory packaging is 6 months.

Price - from 1,790 rubles.

- simple processing technology;

- slight shrinkage less than 0.1%;

- exact copy of the sample;

- creating models with a negative slope and complex terrain;

- room temperature curing;

- accelerated molding when the temperature rises to 70°C;

- a large number of work cycles;

- light coloring in mass.

- not always strong packaging.

Filling four forms with Silagerm:

PolyPlast 70

votes 0

Brand - PolyPlast.

Seller - PolyFormat (Russia).

Liquid monolayer of two-component composition for the formation of a monolithic, fast-curing polyurethane. It is used in the manufacture of architectural products, furniture elements of decor, advertising and souvenir products by pouring into open molds. Processing is carried out manually or with the help of special equipment. The long pot life and low viscosity are excellent for producing complex decors in small batches. Components are stored in a closed original container for up to 3 months.

Price - from 1,250 rubles.

- high strength characteristics;

- light weight;

- excellent tactile reproduction of natural wood;

- resistance to temperature changes;

- durability;

- finished products are easily painted and well machined;

- reliable container;

- nice price.

- unpleasant chemical smell;

- short shelf life;

- requires protection from moisture.

comparison table

| Vytaflex-20 | Silagerm 5055 | PolyPlast 70 | |

|---|---|---|---|

| Life time, min. | 30 | 45-100 | 2-3 |

| Curing time, hour | 16 | 24 | 0.21 |

| Total density, kg / cu. m | 1000 | 1050-1150 | 1000-1100 |

| Hardness, Shore | 20A | 50A | 70B |

| Tensile strength, MPa | 1.38 | 2,5-5,0 | 30 |

| Specific impact strength, kJ/sq. m | ? | 30-40 | 35 |

| Weight, kg | 0.9 | 1.5 | 0,99 |

TOP 3 best polyurethanes in the middle price segment

Vytaflex-40

votes 0

Brand: Vytaflex.

Manufacturer - Smooth-On (USA).

Two-component system with high performance and physical properties of cream color for use in various industries in the creation of forms of architectural elements, sculptures in concrete and plaster. Conforms to strict standards for products that come into direct contact with these materials for a long time. The ratio of components when mixed in a ratio of one to one by volume or weight. All measurements and priming are performed at room temperature.

Price - from 3,999 rubles.

- high strength with a tensile strength of 3.6 MPa;

- good viscosity 2000 cps;

- convenient mixing;

- degassing is not required;

- the ability to add pigments to increase the brightness of the color;

- slight shrinkage;

- durability.

- mandatory use of a separator;

- use only in well-ventilated rooms;

- protect eyes and skin from possible contact with the mixture.

Vitaflex for forms:

MAXPOL-75

votes 0

Brand - MAXPOL.

Producer - Poly Max (Italy).

Two-component polyurethane foam system with manual processing for large volume castings or decorative products. The ratio of the weight parts of the components is 100 to 107. As the mixing temperature increases, the reactivity increases rapidly, leading to a rapid decrease in the start and gel time. With a decrease in temperature, foaming slows down, curing decreases and collapse (collapse) of the foam is not excluded. With an increase in the mass of the stirred compositions, the time may decrease due to the release of heat as a result of the reaction. The specificity of the product affects the molding time, which ranges from one to three hours.

Price - from 3,990 rubles.

- high strength;

- fast curing;

- the proportion of water is 1.3%;

- filling large volumes;

- convenient container.

- cracking may occur when exposed to UV radiation.

Poly Magic 40

votes 0

Brand: Poly Magic.

Producer - Poly Max (Italy).

Two-component yellowish-white polyurethane system with low viscosity room curing for making stamps and molds poured with gypsum, concrete, plastics, soap, wax, etc. It is used in the manufacture of rubber products. The maximum operating temperature is 35°C.

Price - from 3,490 rubles.

- quality composition;

- high strength and resistance to concrete;

- good elasticity;

- the possibility of coloring in mass;

- no unpleasant odor;

- degassing is not required;

- convenient container.

- long flow time.

comparison table

| Vytaflex 40 | MAXPOL-75 | Poly Magic 40 | |

|---|---|---|---|

| Life time, min. | 30 | 3,5-4,5 | 30-40 |

| Curing time, hour | 16 | 3 | 24 |

| Hardness, Shore | 40A | 75 | 40A |

| Weight, kg | 0.9 | 2 | 2 |

| Color | cream | beige | yellowish white |

TOP 3 best premium polyurethanes

Neukadur PN 9008

votes 0

Brand: Neukadur.

Producer - Altropol (Germany).

Beige two-component product based on polyurethane for rotational casting of parts with hollow volumes. The connection of the components in the required proportion of 100 to 60 is carried out after bringing the composition A to a homogeneous state. The resulting mixture, after intensive mixing, is quickly poured into a mold that rotates. It is required to maintain a minimum humidity in the room.

Price - from 4,100 rubles.

- simple use;

- high physical properties and performance;

- convenient container;

- German quality.

- high moisture sensitivity.

Rotational casting Neukadur PN 9008:

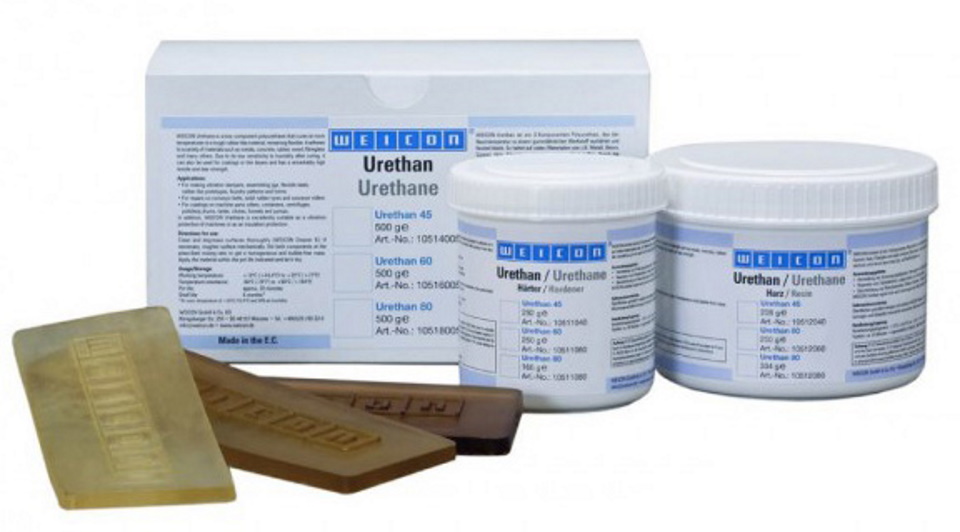

Weicon Urethane

80votes 0

Brand: Weicon.

Producer - Weicon (Germany).

Resin-based repair resin for protective coating and flexible molding providing high wear and impact resistance. It has excellent adhesion to concrete, metals, wood, fiberglass, rubber, and other materials. Together with other branded metal-polymer systems, it is suitable as an elastic coating.

Price - from 6,725 rubles.

- easy mixing;

- simple application;

- calming vibrations;

- "quenching" of vibration;

- creation of flexible gates;

- casting of flexible molds and parts;

- production of rubber-like matrices.

- overcharge.

Video review of Weicon Urethane 80:

Poly Art 70

votes 0

Brand - Poly Art.

Producer - Poly Max (Italy).

Two-component polyurethane system with fast curing, room curing, for the production of technical and decorative products by rotation or open casting. Suitable for advertising, presentation and souvenir production, design, modeling, furniture decor, etc. Keep away from water.

Price - from 5,190 rubles.

- excellent accuracy of detail transfer;

- fast freezing;

- high strength;

- resistance to low temperatures and UV radiation;

- good processing;

- low viscosity;

- easy coloring with pigments;

- simple use.

- insufficient moisture resistance;

- when working, strict adherence to safety rules is required.

Fancy lamp from Poly Art:

comparison table

| Neukadur PN 9008 | Weicon Urethane 80 | Poly Art-70 | |

|---|---|---|---|

| Life time, min. | 5.5 | 25 | 5 |

| Curing time, hour | 1 | 24 | 24 |

| Total density, g / cu. cm | 1.25 | 1 | 1.03 |

| Hardness, Shore D | 78 | 80 | 70 |

| Tensile strength, kg/sq.cm | ? | 41 | 27 |

| Weight, kg | 1.6 | 0.5 | 3.2 |

| Color | beige | beige | Ivory |

DIY polyurethane products

Features of work

Polyurethane is a high-tech material, so when choosing it, you should follow all the manufacturer's instructions on:

- dosing accuracy;

- drying time;

- adding additional mixture;

- maintaining the level of humidity in the room;

- compliance with the temperature regime, taking into account maintaining the maximum temperature of +110⁰С.

To prevent the material from sticking to untreated surfaces, pre-lubricate them with silicone or wax compounds.

Due to a small shrinkage within 0.5-2%, in order to achieve the exact size, it is necessary to carry out a preliminary calculation of this parameter.

What you need

The main components of the technological process:

- two-component compound;

- natural stone (quality imitation);

- material for the frame (formwork) - MDF, chipboard, plywood;

- self-tapping screws, screwdriver, liter container, spatula;

- kitchen scales;

- mixer;

- sanitary silicone and separator.

Step-by-step instruction

- Lay out stone tiles on a horizontally located sheet of plywood or MDF. The gap between the tiles is 10-15 mm, the central dividing part and the edges of the mold should be thicker. After choosing the most successful layout of the prototypes, each cell is glued to the base with silicone.

- Make formwork with the expectation that the height exceeds the stone tile by several centimeters. Attach it to the base with self-tapping screws and seal the joints with silicone to prevent leakage of liquid material. Cover the entire inner surface with a separator that forms a thin film.

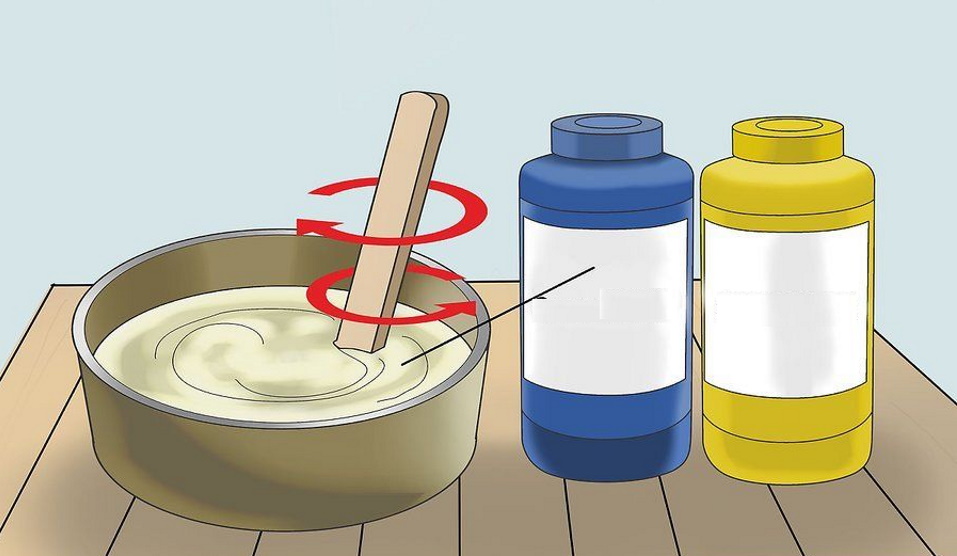

- Mix the two-component compound in a special container in equal proportions using a mixer.

- Pour a homogeneous mass into the corner of the formwork for uniform and dense filling of all voids with air extrusion.

- Leave the product for a day to solidify the mass and turn it into a finished product.

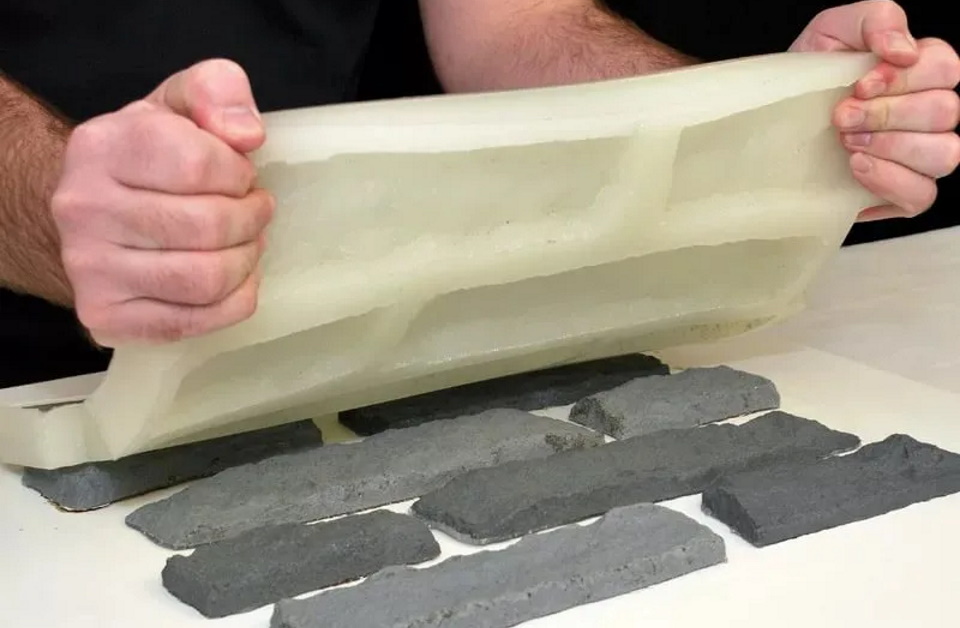

- Dismantle the formwork and separate the form from the prototype, if necessary, cut the polyurethane with a knife. Stone tiles remain glued to the base.

- Wait until the finished product dries, then wipe and leave for a few hours for complete cooking.

Video instruction for making a polyurethane mold.

Good luck molding. Take care of yourself and your loved ones!

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131650 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127689 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124517 -

The best men's sneakers in 2022

Views: 124031 -

The Best Complex Vitamins in 2022

Views: 121938 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114979 -

The best paint for gray hair - top rating 2022

Views: 113393 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105327 -

Ranking of the best sex dolls for men for 2022

Views: 104365 -

Ranking of the best action cameras from China in 2022

Views: 102215 -

The most effective calcium preparations for adults and children in 2022

Views: 102010