Rating of the best polypropylene pipes for 2025

The industrial sector is developing in our time without stopping, so new technologies and materials have become a constant presence in the daily life of a person. Synthetic polypropylene can be attributed to such materials. It is a high-tech basis for the manufacture of various types of pipes. And they, in turn, are used to supply water for irrigation, for drainage, or with their help they equip pipelines and ventilation in residential and administrative buildings. They are also great for moving a variety of fluids, from chemical liquids to pressurized air.

Content [Hide]

- 1 The main properties of polypropylene pipes

- 2 State standards requirements and labeling

- 3 Reinforcement as the preferred protection element for PP pipes

- 4 Advantages of PP-pipes for equipment of hot water circuits

- 5 Ease of integration and installation

- 6 Best Types of Fittings for PP Pipe Systems

- 7 Rating of the best polypropylene pipes for 2025

- 8 Instead of an epilogue

The main properties of polypropylene pipes

The considered material polypropylene is a synthetic non-polar polymer with thermoplastic properties. It was first invented in 1957 and since then the production of sanitary products based on it has been launched, which are characterized by increased strength, an isotactic structure, increased heat resistance and a significant level of crystallization. Polypropylene is extremely resistant to interaction with hydrochloric, alkaline and acid mixtures, as well as with various inorganic substances. It is not fully adapted to the absorption of liquid and can maintain electrical insulation properties over a wide temperature range.

Based on polypropylene, it is possible to produce various advanced materials, for example: high-strength plastic or thermoplastic or other environmentally friendly products. The technological process of recycling the material is not quite expensive, therefore, it easily displaces other non-environmental materials made on a plastic basis from the market.

The main physical properties of polypropylene can be called:

- Bending elasticity - from 6750 to 12000 kgf;

- Tensile failure - from 270 to 470 kgf per square centimeter;

- The temperature of maximum brittleness is from -15 to -10 degrees Celsius;

- Hardness - from 40 to 70 Mega Pascals according to Brinell;

- Melting point - from +165 to +170 degrees Celsius.

Most of the plumbing products that are on the market today are made from sheet propylene. The production technology is based on the principle of extrusion. Depending on the smoothness and shade, as well as other factors, sheets can be classified into two types: the connection of the first is possible by welding, and the second type is a fitting connection - this method is the most modern and will be discussed in more detail below.

Types of polypropylene pipes

To designate this material, the international abbreviation "RR" is adopted, the spelling of which is carried out in Latin. Thanks to the constant improvement of PP production technologies, piping systems from it can be used in hot heating or water supply. The material itself is characterized by excellent tolerance to the chemical effects of the heat transfer fluid. However, in terms of the quality of strength and thermal resistance, unequal types of PP can differ from each other, and significantly.

Thus, pipes made of PP material are classified into three main types, each of which has its own designation:

- PP-N - the initial type, resistant to chemical substances, however, is poorly able to withstand elevated temperatures. It is most often used for the installation of cold water supply and / or sewage systems. It can also be successfully used in drainage or ventilation, i.e. wherever the presence of substances of high temperatures is not expected. In practical terms, this category is most easily encountered on industrial processing lines, where there is also a need for resistance to high internal pressure.

- PP-B is the middle type, which has all the positive qualities of the previous type, but in addition, it is able to withstand temperatures with a small amplitude. Usually they are found on separate sections of the "warm floor" highways. Also, they are easy to meet in the circuits of (closed) hot water supply, provided that the transferred coolant does not exceed a temperature of +50 degrees Celsius. At the same time, a product of this type is preferable to use in sewer systems, because the properties of their base material have a sufficient degree of heat resistance and impact strength;

- РР-3 (РРРС or РРR) is the third and most advanced type, adapted to work in hot water / heating circuits, i.e. wherever the usual temperature easily exceeds the standard +50 degrees Celsius. Their increased heat resistance, coupled with mechanical strength, is achieved through certain manufacturing processes, during which ethylene molecules are directly introduced into the propylene molecular lattice.

State standards requirements and labeling

Any PP pipe, in addition to type marking and having reinforcement, must have certain limits on the maximum withstand production pressure. This parameter has the abbreviation PN and limits ranging from 10 to 25 units. The diameter is indicated by the outer borders. Moreover, the greater the pressure index, the greater the thickness of the pipe wall. For a better presentation, the following examples can be given:

- Diameter 16-20 millimeters - plumbing in a private house or apartment;

- Diameter 25-32 mm - pipes for the riser;

- Diameter more than 32 millimeters - piping systems on main networks, sewers and in multi-apartment buildings.

On the surface of products, the manufacturer sometimes applies a red or blue stripe, which is not a technical characteristic, but only serves as a way of signaling the purpose of the pipe. Everything is intuitive here: blue color - the pipe conducts cold water supply, and red color - is laid in the heating circuit and carries the hot coolant in the DHW system.

In addition to the colored stripes on the tubes, there may be a marking of letters, which will just say about the technical characteristics for installation in the necessary heating systems and water supply systems. For example, it can be mentioned that the alphanumeric marking PN-20 is suitable for a heating system, but a pipe marked PN-25 would be preferable, because it will have a pronounced resistance to high temperatures, as well as to pressure, and even with a significant reserve.

Reinforcement as the preferred protection element for PP pipes

In modern production, there are two types of reinforcement using aluminum foil - perforated and solid.Moreover, the latter option is considered the most economical way of reinforcement. In it, aluminum is located in a thin layer between the propylene layers, as a result of which the overall structure is significantly enhanced. However, such a design still has limitations in operation:

- The temperature of the coolant should not be higher than +60 degrees Celsius, otherwise deformation may occur and the product will simply burst;

- Before soldering, all joints must be cleaned, which makes it possible to significantly reduce the time period for the installation of the entire system;

- It is forbidden to turn off the heating in such pipes in winter, because they freeze at a temperature of -5 degrees Celsius, and this can damage the entire system as a whole;

- In such systems, it is not recommended to frequently change the coolant from hot to cold, because over time, due to temperature differences, the aluminum layer may collapse.

In aluminum perforation, a mesh with small holes is used. During the extrusion of PP pipes, a viscous material penetrates into the perforation, thereby ensuring the adhesion of the metal and polymer.

Thus, by means of aluminum reinforcement, the coefficient of expansion due to heat is significantly reduced. However, some problems may immediately arise during the integration of engineering systems. For example, when welding a socket, it will be necessary to remove the aluminum sheath, as well as strip the tube to a distance that will correspond to the depth of its insertion into the fitting.

At the same time, there are types of PP pipes that do not require the dismantling of the outer layer during the work. But they also have certain disadvantages:

- Only the outer layer can be attached to the fitting, whereby it is equal to the wall thickness;

- To work, you will need a special nozzle for the welding machine;

- After cutting the pipe, it will need to be trimmed.

fiberglass reinforcement

Pipes marked PPR-FB-PPR include two-layer polypropylene, between the layers of which there is glass fiber. Such products are often called fiberglass pipes. Nevertheless, samples with this type of reinforcement compare favorably with their "aluminum" counterparts:

- Their installation does not require cleaning and additional calibration;

- Both time and financial costs will be reduced due to the fact that the soldering process is similar to the connection of all-plastic pipes (as well as other polymer objects with protection);

- Fiberglass reinforcement will not allow the pipe to delaminate due to its same type of structure;

- With the help of fiberglass, the overall rigidity will be increased.

However, the disadvantage of fiberglass reinforcement is that during thermal expansion, its diameter increases by more than 6%, which is not observed with aluminum reinforcement.

Internal PP reinforcement

Samples with a similar reinforcement method are almost full-fledged metal-plastic pipes, in which only the outer layer is made of polypropylene. They are characterized by high resistance to elevated temperature ranges. Their disadvantages include:

- Layering - the presence of a coupling of two dissimilar materials based on glue;

- Only the outer layer of the sample is attached to the fitting;

- The reinforced part is in full contact with the transported substance.

PP-pipe metal-polymer

This type is characterized by a traditional five-layer metal-polymer construction and is used for heating systems and water supply systems. Their main difference is that they use PEX or PP-PT polyethylene as a polymer base, and not simple polypropylene.

Advantages of PP-pipes for equipment of hot water circuits

For hot water systems, it is preferable to use polypropylene pipes for the following reasons:

- PP has a pronounced low weight, which qualitatively simplifies its transportation to the installation site and, in general, the work itself, because this does not require special devices or technical means;

- It is very easy to learn all the required welding techniques, and if you have the right tool, installation will not present any difficulty;

- The production material is environmentally friendly and harmless to residential buildings, because it is not able to change its composition even with strong incandescence, especially since it does not emit toxic substances into the air;

- Stabilizers, which are part of the PP, endure water hammer and various thermal loads (even internal freezing of water will not cause a rupture);

- The circulation of the coolant occurs without noise, without turbulence and evenly, which is facilitated by internal smooth walls;

- Pipes are presented on the modern market with a wide assortment range, besides, the price for them is not very high;

- A circuit made on the basis of these products can last at least 20-30 years (subject to proper installation and integration);

- The appearance of the products is aesthetically pleasing and is not able to spoil the interior, and the contour itself does not require periodic painting or updated decoration.

Thus, PP-pipes with reinforcing layers will be an excellent basis for autonomous and central heating systems in their circuits. Among other things, the integration of these samples is easy and not difficult even for non-specialists.

Ease of integration and installation

Most experts on this issue agree that single-layer pipes are the lightest in this regard. To work with them, just enough:

- Cut the selected sample to the desired length with a pipe cutter (hacksaw);

- Clean up the existing burrs along the edges;

- Connect all structural parts with a fitting (or with a special glue - “liquid welding”).

In principle, multilayer pipes are also installed using the same method, unless cold welding is generally unacceptable in this case, because it will only fasten the outer layers, which will not provide a proper connection. This shows that it is better to connect multilayer products by hot welding or using special fittings (threaded for multilayer structures).

IMPORTANT! Do not attempt to thread the fitting/pipe yourself! In such cases, there are high chances that the resulting threads will not match, which will lead to a violation of the tightness of the entire connection. The easiest way out is to purchase fittings with already prepared classic threads.

It should be noted that samples with aluminum reinforcement will require special preparation before work. The aluminum foil adheres to the polypropylene by means of an adhesive, which means that it can be delaminated, unlike, for example, fiberglass pipes practically “bite” into each other. In order to prevent this negative situation, before welding PP pipes with aluminum reinforcement, a small section of foil should be removed and the outer layer should be soldered to the inner one. Thanks to such a simple operation, the liquid will not be able to penetrate between the layers, and, accordingly, the threat of destruction and deformation of the pipeline system will not arise.

Best Types of Fittings for PP Pipe Systems

Despite the fact that there are many fittings of various shapes and diameters, it is always worth remembering their fitting, which will be an integral attribute of the installation. In general, the configuration of any fitting is completely dependent on the angle of its connection. Most often, the following types of shaped elements are used for propylene products:

- Compensators;

- Tees;

- corners;

- adapters;

- Couplings.

For a better understanding of the installation features, you should consider in more detail the functionality of each element:

- The simplest type of fitting is a coupling. Visually, it is a small barrel with a hole inside. Using it, two elements of similar diameter are attached.

- Adapters are also a simple type, but unlike a coupling, they have different hole diameters at both ends, as a result of which it is possible to connect pipes of different diameters.

- The corners are mounted in the pivot points of the pipe, which creates the required angle of rotation, while the pipe itself does not require deformation. Corner bends can be 45 and 95 degrees. They may also have a metal thread on the outside, with which they can be attached, for example, to faucets in the bathroom (or other plumbing).

- Tees are designed to provide the connection of several PP pipes in the wiring. Tees can vary in diameter and relief inside. However, universal tees (plastic fittings) are also on sale, capable of connecting to various pipe samples, or able to attach different types of products.

- Compensators are designed to absorb temperature changes, damping pressure surges in water supply and heating systems.Thus, they ensure the safety of the entire system and extend the service life of plastic products. Compensators can be made from various materials, but the most common are metal. They can be divided into: universal, bellows axial, rotary, only bellows and shear. Most often, universal models are used, although they are intended for small structures.

Rating of the best polypropylene pipes for 2025

Universal Models

3rd place: "Banninger WATERTEC Faser PN20 25, DN18 mm"

votes 0

A good sample from a German manufacturer. It is characterized by an extended service life, resistant to pollution, adapted for use in the field of water supply and heating. Inside contains a reinforcing layer based on fiberglass, pressure limits are set at 20 units, the maximum heating temperature is up to +70 degrees Celsius. Passing water can be both industrial and drinking. The average retail price is 250 rubles.

- Ease of installation;

- Withstands elevated temperatures;

- Reinforcement based on fiberglass.

- The market is oversaturated with Asian fakes of this brand.

2nd place: "Kalde Orange (3202-tfr-500000)"

votes 0

A quality sample from a Turkish company. The model is positioned as high-strength, with increased wear resistance and quality. It has low linear elongation, which means little deformation even when exposed to high temperatures for an extended period. It has thickened walls by 8.5 millimeters, the maximum operating temperature is up to +75 degrees Celsius, and the maximum pressure is set to 25 units.The recommended retail price is 330 rubles.

- Reduced linear stretch;

- Ease of installation;

- Resistant to deformation.

- Does not tolerate exceeding the recommended operating parameters.

1st place: PILSA BASALT SDR7,4 25, DN18 mm

votes 0

Another Middle Eastern Turkish example. Perfect for setting up heating or water supply systems. Wear resistance and margin of safety - increased due to the use of innovative technologies (there is a complete absence of the need for repairs in the first 10 years). Installation is convenient even when integrating into branched systems. Maximum heating is possible up to +90 degrees Celsius, and the maximum pressure is 25 units. The wall thickness is 3.5 millimeters when reinforced with basalt fiber. The recommended retail price is 550 rubles.

- Basalt reinforcement;

- Reliability and quality;

- Increased strength.

- Overcharge.

Models for heating systems

2nd place: "VALTEC PP-FIBER PN 20 Vtp.700.FB20.25, DN18 mm"

votes 0

This sample is a representative of the European sanitary market. Their products, as a rule, are of high quality, resistance to temperature extremes and extended service life. Any type of coolant can be used, up to chemically aggressive. The maximum heating temperature is +90 degrees Celsius, the maximum allowable pressure is 20 units. The pipes have walls 3.5 mm thick, the reinforcement is made on the basis of fiberglass. The recommended cost is 100 rubles.

- budget cost;

- Adequate price-quality ratio;

- There is an extended warranty period.

- No control strip to simplify the installation process.

1st place: "FV Plast Faser 20"

votes 0

A rather rare and high-quality sample from a manufacturer from Eastern Europe, which has very high operating temperature limits. The material is directly positioned as the best option for arranging thermal circuits and setting up local heating systems. Its installation is not difficult, a long service life is declared without cases of deformation or any changes in the direction of reducing technical characteristics. The operating temperature can reach a limit of +95 degrees Celsius, and the maximum pressure can be up to 20 units. The recommended retail price is 330 rubles.

- Environmental friendliness and hygiene;

- Successfully resists aggressive chemicals;

- It has high bending stiffness.

- Practically unavailable in retail chains (order from abroad is preferred).

Models for water supply systems

3rd place: "Valfex Aluminium, SDR 6 PN25 50, DN 33 mm"

votes 0

A sample of Russian manufacture, completely and only intended for arranging a water supply system. The manufacturer positions it as a high-strength, anti-deformation and wear-resistant sample. It is mounted easily, serves for a long time, while the performance characteristics do not change (subject to proper and competent operation). The maximum thermal temperature is allowed within +90 degrees Celsius, and the allowed pressure can reach 25 units. The reinforcement is made on an aluminum base, the wall thickness is 8.3 mm.The recommended price for sale is 280 rubles.

- Excellent compatibility with many types of fittings;

- Extended service life;

- A long warranty period has been established.

- During installation, the smell of burnt plastic may briefly appear.

2nd place: "RosTurPlast SDR6 PN20 20, DN13 mm"

votes 0

Another representative from the Russian manufacturer. According to thematic publications, the sample is particularly durable, easy to install and extremely resistant to mechanical damage. It can be included in the system of almost any water supply system, including drinking water. Experimental studies have shown that even with not very careful and careful care, a leak does not appear in the pipe for a long time. With rather high maximum pressure and temperature values (25 units and up to +95 degrees Celsius, respectively), there is no reinforcement at all in the sample. The wall thickness has a limit of 3.4 mm. The recommended price is 60 rubles.

- budget cost;

- Mass production - easy to find in retail;

- Ease of installation.

- There is no reinforcement.

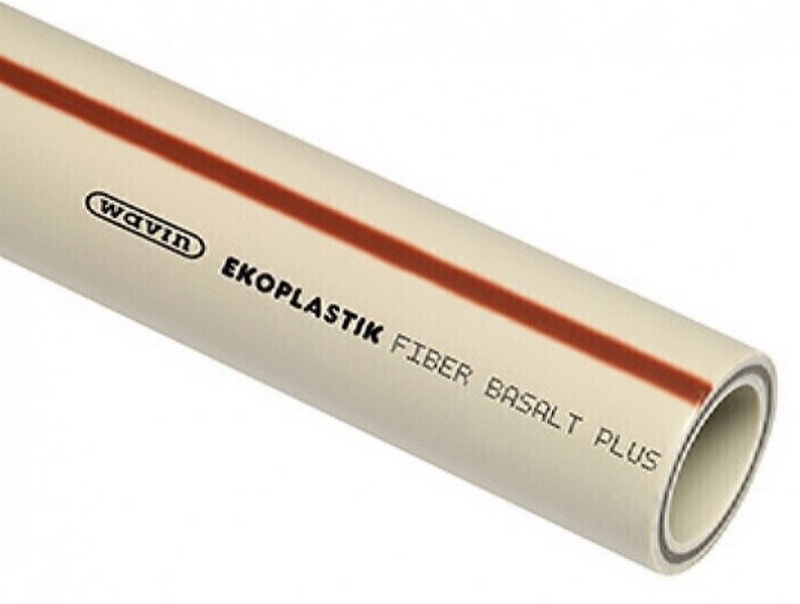

1st place: "Ekoplastik Fiber Basalt Plus 20, DN14 mm"

votes 0

An economical sample from Czech manufacturers. It can be used for both drinking and technical water supply. Leaks do not appear for a long time, durability is guaranteed. The model is designed for a maximum pressure of 25 units, with a wall thickness of 2.8 mm. The operating temperature limit is up to +85 degrees Celsius. The recommended price is 150 rubles.

- Guaranteed long service life without leakage;

- High temperature limit;

- Adequate price.

- Thin walls.

Instead of an epilogue

When choosing a polypropylene pipe for installation or integration of any system, you should always rely on its technical characteristics (so that they correspond to future tasks), as well as on the reliability of the manufacturer. The current situation in the domestic market shows that Russian manufacturers are able to produce pipes of good quality and at reasonable prices. Among the popular Russian enterprises, Welfax and Rosturplast can be distinguished.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131655 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127696 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124522 -

The best men's sneakers in 2025

Views: 124040 -

The Best Complex Vitamins in 2025

Views: 121943 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114982 -

The best paint for gray hair - top rating 2025

Views: 113399 -

Ranking of the best wood paints for interior work in 2025

Views: 110323 -

Rating of the best spinning reels in 2025

Views: 105333 -

Ranking of the best sex dolls for men for 2025

Views: 104371 -

Ranking of the best action cameras from China in 2025

Views: 102220 -

The most effective calcium preparations for adults and children in 2025

Views: 102014