Rating of the best window sills for plastic windows for 2025

A high-quality and reliable window sill will always be a wonderful interior decoration and a convenient stand for indoor plants, which does not exclude its most important function as part of a window unit. Its importance lies in the fact that, together with the sashes and the window frame, it is designed to ensure a long service life of the plastic window. You should not think that window sills only from the same material are suitable for plastic windows. Their diversity is quite large and they can be made from:

- Plastic (PVC);

- Wooden array;

- Natural or artificial stone;

- acrylic compounds.

Content [Hide]

- 1 Modern models of window sills

- 2 Existing types of structures

- 3 Choosing the right size

- 4 Caps for window sills

- 5 Useful tips when buying

- 6 Installation of window sills

- 7 Rating of the best window sills for plastic windows for 2025

- 8 Instead of an epilogue

Modern models of window sills

Plastic

This type of window sill is most often chosen for plastic windows, because they are perfectly combined with the main texture of the window. If the frame has a colored film imitating some kind of decor, then it can also be applied to the window sill. The wide distribution of plastic models can be explained not only by the variety of design, but also by other advantages, which include:

- Simple manufacturing and low cost of production itself;

- Ease of installation;

- Unpretentiousness to care procedures;

- Optimally smooth surface without irregularities;

- Resistance to ultraviolet radiation (yellowness does not appear on the surface and it does not fade);

- Durability;

- The windows themselves do not need to be painted in the color of the window sill and vice versa.

However, plastic samples have not only positive, but also several negative qualities.Among their disadvantages, it is possible to identify the low thermal stability of the entire structure (it is forbidden to place overheated objects on them to avoid melting the base), low maintainability (if dents, cracks and chips appear, it is easier to replace the window sill). Thus, knowing about these significant disadvantages, it will be easier to comply with safety measures when handling, which will clearly extend the life of the structure.

At the same time, most of the questions may lie behind the quality criteria of the plastic itself. The chambers of the product should not be very thin, and it is also preferable to use models with the smallest possible distance between the walls - it is the chamber structure that is responsible for the overall strength of the structure. It is very easy to check the strength - just press on any part of the product and make sure that strong deflections do not appear and there is no characteristic crack.

Thus, plastic models are perfect for those who pursue practicality, do not want to clean up and repaint often. Also, they are suitable for lovers of unusual decor - with the help of a special adhesive film, it is possible to decorate the window sill under a stone or tree.

Wooden

These models are in second place in popularity after PVC models. Wooden window sills should be selected based on several criteria - color, thickness, dimensions and wood used. The oak base is considered the most durable, but also the most expensive. Alder and pine are slightly cheaper, but this material is too soft. A beech base is considered the best option, because this type of wood is strong enough to resist mechanical stress, looks great, and its price is very reasonable.

Wooden models have their own advantages:

- They are very pleasant to the touch, one feels contact with living material;

- Durable in operation;

- Increased strength - the array has a solid structure that can withstand a lot of weight, and such products are subject to restoration when chips and scratches appear, as well as when fading;

- External elegance - the wooden base looks good in almost any interior;

- A wide range of shades and the possibility of painting the surface.

Again, there are certain disadvantages to such products. First of all, these include weak moisture resistance. This quality can be improved through the use of hydrophobic compounds, however, without sufficient processing, the tree will constantly gain moisture from the air. Another disadvantage is the need for care. Wood surfaces require regular maintenance, and their coating needs to be updated at some intervals. The third disadvantage can be called the average level of resistance to mechanical stress (if softwoods are the basis of the window sill, then dents and scratches will become commonplace). And the final minus is usually denoted by a fairly high cost.

For wooden products, the class of wood will be of great importance (the best is “A”, but in classes “B” and “C” there are too many eyes from branches). It is better to give preference to hard varieties. Also, you should check in advance for factory flaws and chips. However, with a greater desire, you can purchase a fairly budget version of the window sill and bring it to mind on your own.

Stone

Their main positive properties are increased strength and durability.They practically do not wear, they do not run the risk of getting dents with careless handling, they do not need to be regularly covered with paint or varnish. Their undoubted advantages include:

- Excellent ability to withstand temperature extremes and high humidity;

- They have a massive and stylish appearance;

- On sale there is a wide range of colors and textures.

Of their disadvantages, first of all, it is worth designating too large a mass, the possibility of chipping, the maintainability of which will be very doubtful. Also, these products are not cheap at all stages of their "life" - production, delivery, and installation will be expensive. They will be the best choice for those who appreciate classic design and massiveness.

Window sills can be made not only from natural stone, but also from artificial, based on acrylic. This material is distinguished by an abundance of textures, colors and shapes.

Window sill-tabletop

This model can be made from various materials as described above. His idea is to combine the surface of the window sill with the table, which is used to save space in the room or to free up additional work space in the kitchen. At the same time, the material is selected in direct proportion to how the work surface will be used further. Artificial or natural stone is suitable for kitchens, and plastic or wood will look good in a living room. And if it is planned to additionally mount a sink into the countertop, then its surface must be strong and thick, plus resistant to moisture manifestations.

Existing types of structures

To date, this range is quite wide and starts from traditional and standard, and ends with exclusive options. The latter include curly structures, which can have any complex shape that can be suitable even for windows with non-standard geometry. On the product it is possible to perform all kinds of curls, bends, monograms - this is just a matter of taste. There are also radical design solutions in which there are raw edges of a wooden board - their natural uneven edge will perfectly complement the interior of a summer house or a country house.

Arc-shaped structures have become popular in the wake of the construction of new types of residential complexes, which use semi-circular window blocks. Bay windows also apply to rounded windows, but they will have corners at the seams. Although, the design, if desired, can always be increased if the wall thickness allows. Then it can be used for a desktop or a tea table. The dimensions of the window sills can also be adjusted for maximum comfort. However, it is worth remembering that the width limit is the protrusion from the wall to the cornice (the distance from the window sill to the curtain / curtain must be at least 2 centimeters). The heating battery should be covered by no more than half in order to ensure the circulation of warm air in the upward direction.

Constructive color schemes may be different, but glossy or matte textures are more popular. The gloss is visually quite impressive, but the dirt on it is very noticeable. The matte surface is less soiled and unpretentious in the process of care, but loses in aesthetic terms.

In order to avoid condensation on the window, the design of the window sill must have the proper length and width of the surface, as well as be correctly placed relative to the battery. If it is not possible to achieve half the opening size for the battery, then ventilation grilles will have to be used.

Choosing the right size

The width of the window sill surface directly depends on the wall thickness and the installation depth of the window in the block. To do this, it is necessary to measure the distance from the PVC guide under the window frame to the end of the wall inside the room. It is not the draft level itself that should be considered, but the finish - tile or drywall added to the wall thickness. Further, the length of the protrusion beyond the wall edge is added to the measured width.

It is possible to provide air circulation from the battery not vertically upwards, but into the interior of the room. This type of arrangement will allow you to distribute heat evenly. If the protrusion is too small, then the heated air will pass along the window block and heat the glass, which will lead to condensation. At the same time, a window sill that is too wide will interfere with the heating of the walls near the window. Thus, the recommended protrusion should be 50-60 millimeters.

As a rule, as a standard, the window sill should extend beyond the slopes by 50-80 millimeters, so the length of the window sill itself should be calculated with a margin of 100-150 millimeters.

The window sill can also be equipped with a complex window structure - a semicircular or U-shaped balcony. In this case, a separate product is placed under each window included in the block and all elements are fastened with special connectors.

In any case, in order not to be mistaken with the sizes, it is preferable to use the services of a professional.

Caps for window sills

The considered element of the window interior will not have a finished look and will look aesthetically ugly and rough if it is not provided with appropriate plugs. A little thing like that can make all the difference. Through the plugs, the part will acquire a finished appearance, and dirt and dust will not settle in its end part. Among other things, the latch-stub will provide:

- Preservation of heat (will stop cold air);

- Full tightness of the structure;

- Easy and strong fixation of the product.

Plugs are selected taking into account the shape, thickness, width and length of the product. It is recommended to purchase plugs immediately directly with the window sill so that they fit a specific model. If a separate purchase is planned, then it is first necessary to measure the ends of the window sill. Naturally, the best plug is made by the supplier who produced the window sill itself, and their shapes can be quite different. Existing types of stubs:

- Form - they can have various bends (called kapinos) and are selected individually by the buyer for the plank shape.

- Colors - as a rule, they have the same color as the board itself. However, there may be decorative options made in a different color scheme. Thus, it is possible to symbolically place accents on individual parts of the interior.

- Length - this standard parameter is 700 millimeters. This value may vary depending on the dimensions of the window sill for which the cap is selected.

Window sills provided with plugs will last much longer, give the main product a complete look and easily fit into the overall design of the room. In addition, with their help, the product itself will be securely fixed in the window unit.

Useful tips when buying

Most buyers naively believe that the main function of window sills is only an aesthetic component. However, they are an important part of the entire window system, protecting the room from the penetration of cold air currents, maintaining the proper level of microclimate. Accordingly, during the acquisition of a window sill board, careful attention should be paid to the following properties:

- Appearance - the goods should not have scratches, chips and other defects, because then they will have to be constantly hidden behind a curtain.

- The material of manufacture - its selection will depend on the financial capabilities of the buyer and general preferences in design. Plastic options that are resistant to moisture and can withstand sufficient mechanical damage and various kinds of deformations will cost the least. The most expensive options are made from natural stone and they are able to visually add a touch of nobility and some luxury to the overall interior.

- Slices - when choosing a window sill, you need to pay attention to its ends. Plastic products have stiffening ribs, with the help of which the structure is provided with resistance to various loads. The more of them, the higher the reliability of the product;

- Installation method - the most unpretentious installation - PVC models. Their installation can be carried out by different methods, but the easiest way is to install them on cement or an adhesive base. Wooden window sill blocks are characterized by hygroscopicity, which means that their installation on a wet base is prohibited. The best solution for them is installation on foam pads or on iron brackets.

Installation of window sills

Installation of a window sill for plastic windows will require the installer to have maximum knowledge of construction processes. Before the start of the entire procedure, it will be necessary to carry out a full preparation of the window block, remove debris from the opening, and ensure dust removal. Due to the fact that the window sill needs to be deepened into the wall in the area of \u200b\u200bthe slopes, cutting is performed in their plane using a perforator. Further, it will require masking during the fine finish. The fastening method should be selected depending on the material of the product and involves several different solutions:

- On the adhesive composition - for starters, marking is made for the placement of the canvas relative to the window frame, after which the structure is superimposed on the adhesive base or sand-cement mortar, and then the height is adjusted in such a way that the panel fits snugly to the mounting point in the frame.

- With the help of iron brackets - a wooden block-type gasket is installed on the window, which is fixed with a sand-cement mortar or screws. Further, iron brackets are screwed to the canvas, after which the panel is installed in the window block and screwed to the wall under the window by means of self-tapping screws. The gaps between the bars are filled with mounting foam, and the joint between the frame and the canvas is reinforced with sealant.

- With the help of linings - the window sill is mounted in the opening, after which the free space under it is filled with blocks or wedges that serve as gaskets, until the canvas goes under the frame, reaching the level of maximum density.

IMPORTANT! Regardless of the chosen type of fastening, the board is installed with a small slope of 3-5 degrees in relation to the interior.This condition is necessary in order to ensure the flow of condensate from windows or from water that can flow onto the surface when caring for indoor plants.

Rating of the best window sills for plastic windows for 2025

plastic models

3rd place: "Construction yard PVC white 300x2000 mm"

votes 2

A good and budget option with a sufficient set of stiffeners, easy to operate and install. It is made of high-quality plastic, the width of the canvas is 300 millimeters with a length of 2 meters. Excellent adhesive backing. Country of origin - Russia. The recommended cost for retail chains is 880 rubles.

- The presence of a large number of stiffeners;

- Quality plastic;

- Economic cost.

- The absence of "native plugs".

2nd place: "Construction yard PVC white 300x3000 mm"

votes 0

Aesthetic and comfortable model for installation in a window unit. Excellent resistance to temperature changes and is not subject to color changes over time. The internal structure is made in the form of honeycombs, which provides protection against excessive mechanical stress. Completely moisture resistant. Country of origin - Russia. The recommended store price is 1400 rubles.

- Easy installation;

- Aesthetic appearance;

- Matte color scheme.

- It is forbidden to use in rooms with a high temperature background.

1st place: "Construction yard PVC white 600x1500 mm"

votes 0

Another representative made of high-quality plastic. It is characterized by high resistance to ultraviolet rays. Easy and simple to install, unpretentious in maintenance.Installation is recommended on an adhesive base with subsequent strengthening of the slopes. There are "native" plugs available. Country of origin - Russia. The established retail price is 1,500 rubles.

- Yellowness does not appear over time;

- Rugged housing;

- UV resistant.

- Not detected.

Wooden models

3rd place: "Pro and Hobby"

votes 0

This product is made from coniferous trees, and with a spliced composition. The applied material belongs to the category "AB". Able to withstand humidity levels of 8-10%. The packaging is made of shrink film. Installation is carried out exclusively with metal fasteners. Dimensions 250-2500-40 millimeters. Country of manufacture - Russia. The recommended cost for store chains is 980 rubles.

- The structure uses an innovative two-component composition (spruce and pine);

- Adequate cost;

- Aesthetic appearance.

- Afraid of high humidity.

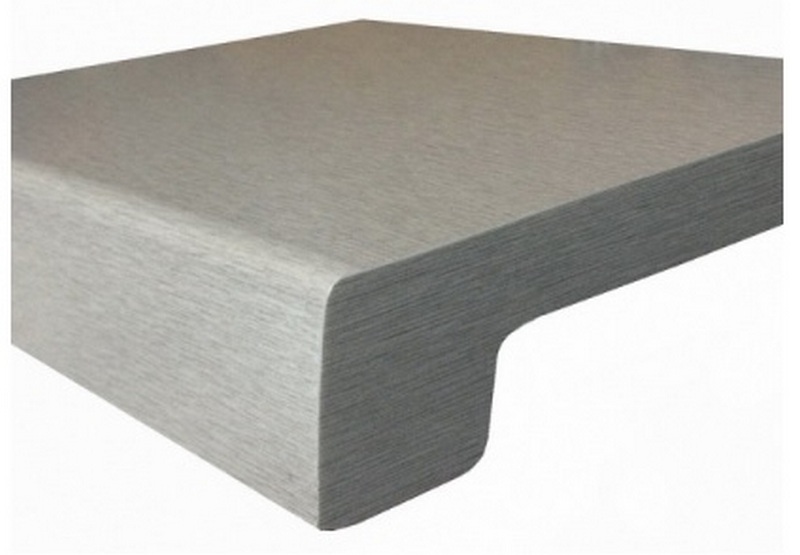

2nd place: "Werzalit Exclusive metallic 100 mm"

votes 0

This product belongs to the category of design and is made and chips combined with synthetic resin. It has certificates of conformity, confirmed by Russian regulatory authorities. It is a monolithic slab, unpretentious to manifestations of high humidity. Quietly withstands temperatures from -50 to +80 degrees Celsius. The color scheme of execution is metallic. Country of manufacture - Germany. The recommended cost for retail chains is 1600 rubles.

- 6 layers of strength in the body;

- Large operating temperature limits;

- Aesthetic appearance.

- Not detected.

1st place: "Werzalit Exclusive light marble 100 mm"

votes 0

Another representative of the line of exclusives. Possesses the increased water resistance since. the structure used polymer glue, coupled with wood shavings. It is extremely convenient in processing, which can be carried out with any available tools. It can be combined with other products from this range without compromising the integrity of the interior. The color scheme used is light marble. The country of origin is Germany. The recommended retail price is 1700 rubles.

- Innovative performance structure;

- Can withstand temperatures of +180 degrees Celsius for a short time;

- Easy installation.

- Not detected.

stone specimens

3rd place: Maple Red

votes 0

A fairly budget option for its segment, at the same time having all the necessary characteristics for a stone window sill. Production material - granite. It can be an excellent replacement for a simple brick window sill in the case when it is necessary to declare massiveness and durability. The reddish hue of the material gives the product a special aesthetics. Fastening involves only using metal screws. Country of origin - Russia. The established cost for shops is 3200 rubles.

- Production material - red granite;

- Massive and durable product;

- Damage resistance.

- Not detected.

2nd place: "Bella White"

votes 0

This sample is intended for interior decoration in a strict executive style.Dark tones are not used in these models, so they are easy to fit into the interior with office furniture. The product is made of natural stone. The strength of the base and its weak susceptibility to any negative manifestations of the environment make the product popular. The quality is fully consistent with the declared price. Country of origin - Russia. The established cost for the retail network is 4380 rubles.

- Good ratio of indicators "price-quality";

- Weak susceptibility to negative loads;

- Good office solution in terms of design.

- Not detected.

1st place: "Emperor Dark"

votes 0

A very original solution, made in a figurative style of natural marble. It is intended exclusively for design decoration of the room. Mounting on large windows with connection of separate parts of a window sill is possible. It has an extremely large mass, so in addition to standard mounts, the manufacturer recommends using additional props. The country of origin is Germany. The set price is 9500 rubles.

- massiveness;

- Aesthetic qualities;

- The material is high quality marble.

- High price.

Instead of an epilogue

Despite the wide range of existing models of window sills for plastic windows, it is better to purchase these products from trusted brands. Firms that honor their reputation will always be able to provide quality certificates for their products. In addition, when buying, you should pay attention to the conditions under which the product is supposed to be used - the density of the material, susceptibility to ultraviolet radiation will be important properties.Thus, a competent approach to the purchase and high-quality installation of the product will become the key to the durability of operation while maintaining the visual and quality characteristics of the material.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131660 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127698 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124526 -

The best men's sneakers in 2025

Views: 124042 -

The Best Complex Vitamins in 2025

Views: 121946 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114985 -

The best paint for gray hair - top rating 2025

Views: 113401 -

Ranking of the best wood paints for interior work in 2025

Views: 110327 -

Rating of the best spinning reels in 2025

Views: 105335 -

Ranking of the best sex dolls for men for 2025

Views: 104374 -

Ranking of the best action cameras from China in 2025

Views: 102222 -

The most effective calcium preparations for adults and children in 2025

Views: 102017