Rating of the best sandblasting guns for 2025

Those who are constantly faced with the need to clean metal surfaces know that this task can be solved in various ways. The most time-consuming, lengthy and exhausting is the use of hand tools. To minimize the time spent and improve the efficiency of actions, sandblasting devices are used.

Content [Hide]

Machine Description

These tools differ in characteristics and principle of operation. However, they contain identical structural elements:

- compressor;

- nozzle gun;

- abrasive tank;

- control device;

- connecting hoses;

- storage receiver.

The most important element is the compressor, which serves to pressurize the air flow. Divided into units of low power, medium power and high power. The operation is controlled by automation, turning the device on and off, adjusting the pressure indicator.

The best and most expensive models are equipped with compressors and a special system that allows you to turn off in the event of a breakdown, as well as in the event of power surges.

The advantages of automation are as follows:

- Full stop of the device in case the operator's hands missed the nozzle.

- The ability to transfer the device to working and idling.

- Management of additional functions.

- When the sand level drops, it starts signaling.

What to look for when choosing a model? On the build quality and dimensions of the hoses for air and sand, as well as for the withdrawal of the abrasive component. It is from these parameters that the power of the device and performance, as well as the quality and duration of work, directly depend.

Features and principle of operation

Sandblasting aggregates are used to remove various kinds of contaminants from surfaces.Manufacturers produce several types of installations similar in principle of operation: thanks to compressed air, abrasive or sand flies out of the nozzle at great speed, crashing into the dirt and effectively removing it. These devices are used to clean buildings, metal structures from rust, old paint, dust and dirt.

Sandblasters are divided into types, depending on the type of action and power. Thus, there is a division into the following devices:

| Kinds | Characteristics |

|---|---|

| Low power | The volume of the container does not exceed 30 liters. Scope of application - hard-to-reach places and when working at a significant height. Unable to function for a long time, you must regularly let the device rest. |

| Medium power | Tanks from 50 to 140 l. Distinguished by the absence of a powerful compressor. Used in medium and small industries. |

| high power | The presence of a container of at least 20 liters. Used for large volumes of work. Huge contaminated areas are treated with this stationary device. |

Based on the type of action, devices are:

- Pneumatic (pressure). Quickly and efficiently cope with heavy dirt or a thick layer of rust. Ready to cope with any amount of work, thanks to which they are well-deservedly popular in large enterprises. A distinctive feature of these devices is as follows: compressed air is supplied not only to the installation, but also to the abrasive dispenser, which significantly increases the speed of the air jet released.

- Vacuum. The principle of operation is as follows: the abrasive substance is supplied to the contaminated base, immediately picked up by vacuum and again thrown into the contaminated area.Can be used for certain activities that may damage nearby surfaces.

- Injection. Distinctive feature: air and abrasive mixture is supplied through different sleeves. The power of the unit is small, so the device is not able to cope with significant pollution in large areas. However, for delicate cleaning, this is the most acceptable option.

Sandblasting options

Thanks to these settings, surfaces of various types can be put in order using:

- Easy cleaning - removal of minor rust and scale. The result is a clean base, but minor contamination may remain in hard-to-reach places.

- Medium cleaning - provides for more thorough measures to remove paint, dirt and rust. Bottom line: there are dotted areas covered with corrosion.

- Deep cleaning, providing perfect cleansing from all kinds of contaminants. It is used in the event that the next stage of work will be the application of paintwork.

Installation types

Sandblasters are available in two types, the differences between which are indicated in the comparative table:

| What are | Description |

|---|---|

| open type | Used in open space: under awnings, on the street and so on. Inexpensive, mobile, with insignificant parameters. The main disadvantage is that a lot of dust appears during operation, there is no way to collect and reuse the abrasive mixture, too much sand is left. Working with the tool is quite dangerous, so the operator must wear full protective equipment. |

| closed type | They are used in a closed space - a special chamber with different dimensions: from a small box to a large room. The machines have considerable power, with the circulation of the abrasive mixture, allowing it to be reused. It is widely used in the construction of large facilities and rarely - at home. Application is safer. The main disadvantage is the significant size, difficulties in transportation and the obligation to connect to ventilation systems. |

Popular models can also be:

- Stationary. Mounted in production shops. Equipped with a built-in filtration system, connected to powerful ventilation systems, they are used for processing individual objects and parts, as well as minor surfaces.

- Mobile. As a rule, small-sized or home-made, made independently at home, using the step-by-step instructions set out on the Internet. They can process tanks, large equipment, building facades and so on. They move to a specific place, depending on the need.

Fields of application for sandblasting devices

The most common industry is body repair. This technique helps to quickly and effectively free the surface from old paint, rust, grease and other contaminants. Often the device is used in the repair of discs: if the part is peeled off, wrinkled or damaged, then before proceeding with its restoration, they first perform high-quality cleaning, and then painting.

What are the advantages of a sandblasting machine? The result of metal grinding with this tool is unique, which cannot be achieved in manual mode.This method removes even the most point elements of corrosion, "hidden" in pits, small pores and microcracks, which minimizes the rusting process of the metal base. Products cleaned in this way last much longer and are less susceptible to corrosion. As for the surface, it turns out surprisingly smooth. In the absence of scratches, the primer and paint perfectly cover the parts.

In addition to car repair, sandblasting device is widely used in:

- furniture production;

- ship repair and shipbuilding;

- during the overhaul of construction projects;

- woodworking industry;

- when cleaning the bases from brick and concrete;

- in the process of metal engraving;

- creating intricate patterns on glass;

- preliminary processing of products before applying thermal spraying and the use of electroplating operations;

- when matting ceramics and glass.

Powerful devices made of high-strength material and endowed with special functions through the use of various nozzles are used to drill holes, grooves and grooves. Design fantasies using such a unit allow you to process the surface in such a way that the material “ages” and takes on a vintage look.

Sandblasting expert advice

It doesn’t matter which company is better to buy a product, and whether it is in the rating of quality products, Russian or Chinese production, budget or at a substantial price. The main condition of work is the observance of safety regulations.A branded tool can be harmful to human health, causing serious lung diseases, or cause injury due to the significant speed of abrasive ejection from the nozzle.

To avoid unpleasant situations and maintain your health, you need to listen to the following recommendations:

- Before work, wear closed shoes made of thick material.

- Do not forget to put on a high-strength special overalls.

- Wear a protective helmet.

- Protect your hands with leather gloves.

Some "daredevil" outdoors wear only a regular respirator, but the best option would be to have a helmet with autonomous air supply. If the actions are performed indoors, then this attribute is required.

It is worth considering that powerful units are not silent, therefore, in order to avoid damage to the hearing organs, it is worth putting on headphones with sound-absorbing functions under the helmet. They can also be built into a helmet.

Features of premises for working with the unit

The effectiveness of any work directly depends on the correct organization of the workplace. The sandblaster will function safely and reliably in a room with a normal humidity level. Otherwise, the process may be significantly delayed, and productivity may decrease. If the humidity is too high, measures are taken to reduce the indicator. For these purposes, special dryers are installed at the facility. The best manufacturers produce popular models equipped with such functionality.

Air purity is of great importance. This is achieved through the use of filtration systems. As a rule, they are already built into the devices, which makes it possible to free the air from particles of dust, dirt, oil.If the device operates in a closed space, then the object must be able to quickly and efficiently be cleaned of sand. The best option is the complete tightness of the room, where the remaining sand will fall into special tanks through holes made in the floor. After preliminary sieving, it can be reused.

How to choose a device

According to buyers, it is necessary, first of all, to pay attention to the weight of the goods. The design should not be heavy. In addition, it is desirable to equip it with a chassis to facilitate transportation. As for the tank, its characteristics must meet international safety standards. When buying, you need to ask the seller for a certificate of verification.

Which product is better to buy depends on the preferences of the master. But there are certain selection criteria that must be considered. Moreover, the brand and rating are not fundamental. The piping system is of great importance. It should be borne in mind that the simpler it is, without fittings and bends, the more powerful the unit. You need to pay attention to the diameter of the hole. The optimal indicator is 32 mm or more.

In order to avoid mistakes when choosing, it is necessary to review the products, read the reviews. You need to pay attention to the following points:

- possibility of functioning with different granular material;

- high assembly reliability;

- the presence of an automatically closing filling valve or damper;

- the presence of a feeding container;

- equipment with a dispenser of abrasive material, shut-off valves for air inlet and outlet;

- the presence of an inspection hatch.

For a powerful compressor, a nozzle with a large diameter is expected. This is the only way to increase productivity.To choose the right air gun, you should pay attention to the following recommendations:

- processing of wood, brick or concrete is carried out by a unit with high productivity, but low jet power;

- metal and glass are best cleaned with a strong jet of abrasive.

There are several ways to buy a device of this type: through one of the many online stores (online order) or delivery directly from China using the Ali Express Internet resource. You can also contact a specialized store, where you can then purchase the selected equipment. The latter option is beneficial in that the sales manager will help you make the right choice, talk about new products, give specific recommendations, and provide quality certificates.

A person with certain skills and tools can make a device with their own hands. How to build an author's version, the Internet will tell. Let the unit not be too powerful, but will provide significant assistance in carrying out repairs.

Rating of the best sandblasting guns for 2025

hose feed

Sorokin 0.9

votes 3

One of the most popular author's brands in Russia. Engineer Sorokin is the author of a large number of special equipment, including sandblasting guns connected to the compressor. The model differs in that it is produced with an upper tank for abrasive, which makes working with it more convenient and simple. Reservoir with a capacity of 0.9 liters. Designed for cleaning small surfaces. It is especially popular with home craftsmen.

The average price is 3000 rubles.

- performs subtle actions;

- light weight;

- comfortable to use;

- durable;

- functional.

- significant cost.

Patriot GH 166B

votes 0

Products are made in China. The main difference is the lack of capacity. The abrasive is supplied through the pipe that comes with the kit. It is immersed in a container of sand, after which the gun is connected to the compressor. Despite the low cost, the product is quite functional and allows you to process significant surfaces.

Price - 550 rubles.

- reliable;

- operational period;

- cleaning hard-to-reach areas;

- insignificant weight;

- a budget option.

- not identified.

Wester SSP-20

votes 0

The Chinese manufacturer has tried to create an amazing assistant for home craftsmen. Despite mediocre technical characteristics, the device is able to clean small surfaces with high quality. Equipped with a small compressor, considered "quiet".

The average price is 1300 rubles.

- compactness;

- ease of use;

- reliability;

- operational period;

- good value for money;

- doesn't make much noise.

- lack of high technical characteristics.

Matrix 57328

votes 0

It is distinguished by the absence of a tank for abrasive and low weight - 1.2 kg. The gun is made of high quality metal, which is not afraid of mechanical damage. Time of continuous operation - from 8 to 12 hours (maximum). Equipped with a standard tank, but sand can also be taken from a bucket. Handles car body cleaning quickly and efficiently.

The product can be purchased at a price of 1119 rubles.

- light weight;

- easy to operate;

- comfortable;

- affordable cost;

- cleaning quality;

- the nozzle is made of durable steel;

- functional;

- suction efficiency of sand into the hose;

- equipped with branded fittings;

- the throughput channel is not clogged;

- can be improved.

- lack of maneuverability;

- short intake hose;

- it is desirable to equip a powerful compressor.

Rock Force RF-HSB-II

votes 3

Produced by a leading Belarusian company, using modern production facilities in Taiwan. In the manufacture of the case, high-strength plastic is used, which completely prevents corrosion. The tank for abrasive material is mounted at the top. Sand filling is carried out through the neck in the back, which is closed with a swivel lid. The flow regulator is located at the front.

The average cost of production is 4510 rubles.

- resistant to overheating;

- the possibility of non-stop operation for 8 hours;

- the rapid connection makes it easier to connect to the hose;

- durable;

- multifunctionality.

- weight in 2 kg;

- may break if dropped.

- due to the large top tank, the operator's view is minimal;

- the price, but the device is worth it.

barrel feed

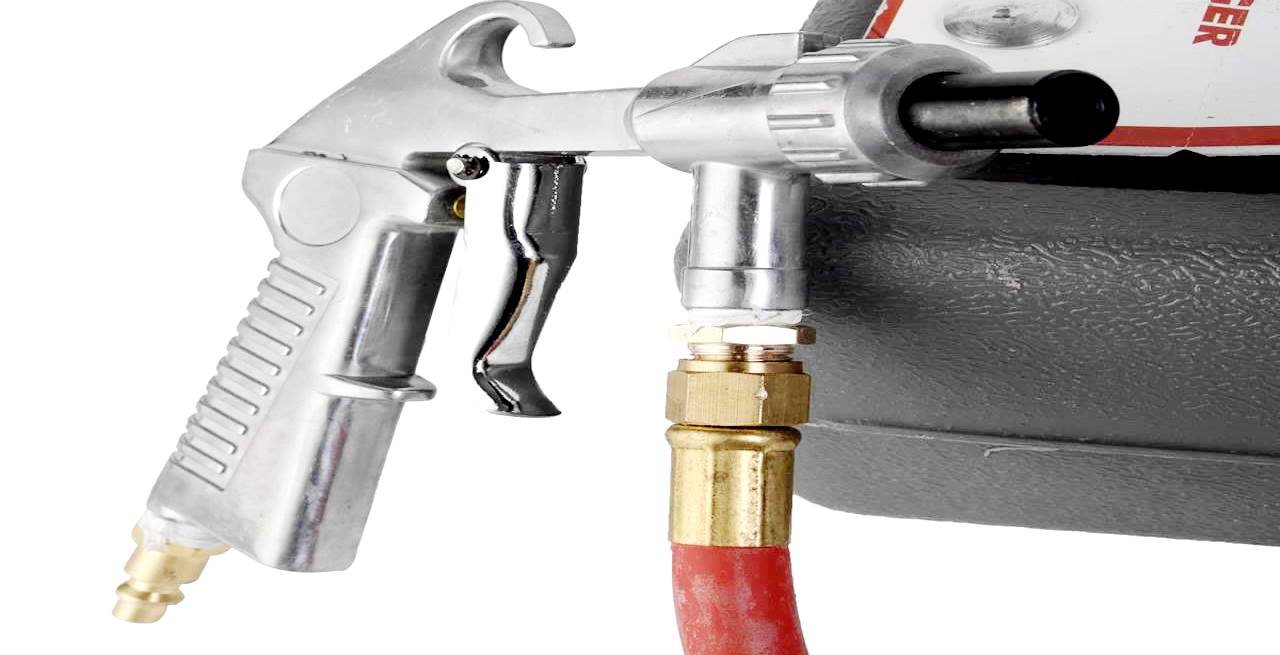

Kraftool Expert Qualitat 06583

votes 1

The German manufacturer launched the production of goods in China, which made it possible to make the price minimal, and the quality worthy of attention. The model consumes 340 liters of air for one minute. The inlet fitting is ¼ inch in diameter. The hose from the compressor is attached by means of threaded connections. Qualitatively held in the hand thanks to the embossed handle. To avoid pinching the trigger of the ring finger, the handle has a separator. The device is easily suspended on a hook by a loop, thereby freeing the operator's hands. Water can be taken from the tap.

The average cost is 1509 rubles.

- there is a hole on the case for hanging;

- secure grip;

- handle ergonomics;

- comfortable use minimizes fatigue;

- not damaged when dropped;

- lack of plastic components;

- performance;

- quality nozzles;

- full visibility at the operator thanks to the bottom tank.

- appearance may deteriorate over time;

- twisting the hose leads to a deterioration in the air supply;

- the threaded connection does not allow you to quickly connect the hose to the compressor.

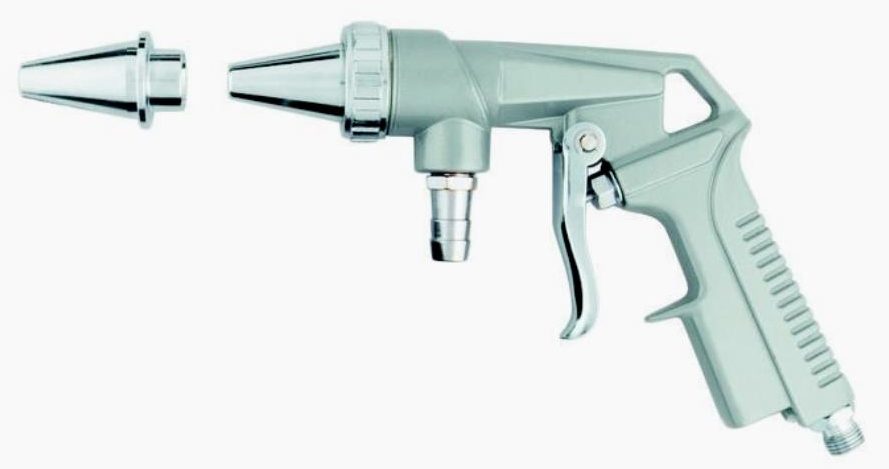

Mighty Seven SX-3102

votes 0

The product of the American brand has a lot of advantages. It is equipped with a 700 ml bottom tank and a stainless steel tube through which small particles pass. Although the gun is plastic, this does not detract from its merits. It has an unfolded shape with an angle of 110 degrees. This allows you to comfortably hold the device during operation.

Sellers offer high quality products at a price of 3430 rubles per unit.

- ease of use of the trigger;

- even distribution of the load on the hand;

- reliable grip due to the relief of the handle;

- weight 350 g;

- the possibility of continuous operation;

- can function with large fractions;

- suitable for weak compressors;

- compact;

- possibility of use at height.

- performance;

- will not cope with the paint;

- overcharge;

- may receive mechanical damage if dropped.

Metabo SSP 1000

votes 0

The German manufacturer offers its admirers a high-quality device with a built-in bottom tank for abrasive. The body is made of metal and covered with paint. Thanks to the presence of a loop, it can be hung on a hook.The straight-through nozzle is made of hardened steel. The raised tip makes it easy to remove. Product weight - 700 g, fitting with a diameter of ¼ inch, air consumption - 300 l / min.

The average cost is 1879 rubles.

- convenient to use;

- cleans not only smooth surfaces, but also ribbed ones;

- ergonomic shape;

- can interact with various compressors;

- the hose is quickly connected to the compressor;

- quality work.

- over time, the appearance becomes unattractive.

Abac 756062

votes 0

The main difference of the model is an aluminum tank with a capacity of 1 liter. Joins with just one touch. The weight is small - 590 g. Convenient for cleaning areas. It enjoys well-deserved popularity among craftsmen due to its ease of operation. The case is completely metal, structural elements made of plastic are completely absent. The product can withstand bumps and drops. Designs are not afraid of scratches and other mechanical damage.

The average cost is 2120 rubles.

- simplicity and endurance of the device;

- the operator's view is not obstructed by the lower tank;

- quickly connects the hose to the compressor;

- tank volume;

- the presence of a hook for hanging;

- operational period.

- slip in hand;

- the metal casting of the body is not done very neatly.

Walmec 50316

votes 0

The manufacturer has focused on a fully metal body covered with rubber, which significantly increases its usability. There is a bottom container for abrasive. The trigger is pressed with two fingers.Thanks to the protruding limiter on the handle, there is practically no possibility of pinching the remaining free fingers.

The tank is made of aluminum, which prevents its mechanical damage during the fall. Product weight - 920 grams, air consumption - 500 l / min. For efficient operation, it is worth connecting a powerful compressor to the device. The presence of a hook on the back allows you to quickly free your hands.

If you study user reviews, then the characteristics of the product are good. It allows you to quickly and efficiently free the surface from rust, dirt, paint layers, make the metal coating completely clean and shiny. Excellent performance is provided by a 6 mm nozzle, which makes it possible to use the unit for professional activities.

The average cost of production is 3589 rubles.

- copes with dirty areas;

- continuous work;

- operational period;

- reliable;

- quality;

- multifunctionality;

- shockproof body;

- tank volume - 1000 ml;

- the weight;

- convenient to use;

- safe if you follow the rules of working with it.

- it is recommended to connect to the compressor;

- sometimes the locking mechanism of the air line is clogged with sand;

- Not available in all outlets.

Conclusion

Sandblasters have long been used in different countries for cleaning all kinds of surfaces. At first they were primitive, but every year they are improved. Global manufacturers pay great attention to such key indicators as power, service life, reliability, safety, convenience, efficiency, functionality.The device must cope even with the most dirty areas, and not only on a flat surface.

Everyone has their own selection criteria. It all depends on the amount of work performed and its complexity. For a small workshop, it is enough to purchase a low-power unit at a budget cost. The main thing is that the device is able to perform the designated functions.

For major repairs at large facilities, you should pay attention to powerful installations. Although these are more expensive, they allow you to effectively and quickly achieve the desired result, saving time and labor. It is worth constantly remembering that working with sandblasters requires strict adherence to safety regulations and the availability of special equipment.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131650 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127689 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124518 -

The best men's sneakers in 2025

Views: 124031 -

The Best Complex Vitamins in 2025

Views: 121938 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114979 -

The best paint for gray hair - top rating 2025

Views: 113394 -

Ranking of the best wood paints for interior work in 2025

Views: 110318 -

Rating of the best spinning reels in 2025

Views: 105328 -

Ranking of the best sex dolls for men for 2025

Views: 104365 -

Ranking of the best action cameras from China in 2025

Views: 102215 -

The most effective calcium preparations for adults and children in 2025

Views: 102011