Rating of the best pellets for 2025

In today's world, pellets are an excellent alternative to gas and other fuels used for space heating. Compared to gas, pellet heating will cost 3-4 times cheaper. However, modern technology for the manufacture of this type of biological fuel is not able to fully replace the gas system. And yet, most potential users have already appreciated the positive qualities of pellets.

Content [Hide]

Pellets - general information

Pellets are a type of fuel based on a solid composition and are produced in the form of cylindrical pellets. Production is carried out from compressed industrial waste from the woodworking or agricultural industry. Fuel pellets are mainly made from the following materials:

- From various types of wood (i.e., these are bark, sawdust and chips of coniferous and deciduous trees);

- From peat;

- From charcoal;

- From husks of grain crops (cake, sunflower, rapeseed, corn, etc.);

- From combustible household non-toxic waste.

At the same time, a substance of plant origin, lignin (a natural polymer found in almost any plant culture), is used as the main binding substance. It is able to plasticize during the granulation process when exposed to elevated production temperatures.

Differences between pellets and other types of fuel

Differences can be found in many parameters, but below it is worth considering only the most basic ones:

- They can be produced automatically, with somewhat less industrial resources being spent;

- They have an increased calorific value, which qualitatively distinguishes pellets from lumpy wood (firewood) or tree bark;

- During combustion, they practically do not leave behind ash that could clog the air duct or boiler burner (which cannot be said about coal or wood);

- They have an increased bulk capacity, which is convenient for their packaging and subsequent transportation in almost any container;

- Unlike firewood, it takes up less space during storage;

- They are not very explosive and cannot ignite if handled carelessly, which distinguishes them from any type of liquid fuel or fuel oil.

If we consider the economic side of the issue, we can distinguish the following differences:

- Prices for pellets are stable and little dependent on fluctuations in world currencies;

- Due to their properties, they cannot damage the equipment that is used for their combustion (for example, clog the boiler air duct), which means a reduction in the cost of not only repairs, but also preventive cleaning of such equipment.

- Speaking about the environmental component of the issue, the following differences can be noted:

- Pellet fuel can be stored in close proximity to residential buildings, because it does not emit harmful emissions and cannot harm human health;

- Granules of this fuel contain only a natural product and are not capable of causing allergic reactions;

- Pellets are completely safe for the environment.

The technical differences can be expressed in the following example, considering how many tons of granular matter is required to release 5000 kW of energy:

- For diesel fuel - 500 liters;

- For wood (firewood) - 1600 kilograms;

- For fuel oil - 685 liters;

- For gas - 475 cubic meters.

Production technology

The production process for pellets is based on pressing pre-prepared and dried to a certain moisture level, and then sequentially crushed to the required fraction, waste from various industries under a pressure of about 300 atmospheres. At the same time, the use of glue and other synthetic additives is prohibited (although some manufacturers, in order to speed up the production process and increase the mass of the granular substance, may add some substances, for example, sand and other low-flammable impurities, and synthetic-based polymers to increase adhesive properties) .

Basic production steps:

- Grinding - raw materials are fed into a special crusher, where they are crushed to the desired level.

- Drying - the resulting raw materials are dried to the percentage of moisture established by the technology, which ranges from 8 to 10%.

- Pressing - after drying, the raw material is fed into a pressing granulator, where the substance is pressed in the form of granules to a given length and diameter. In the production of compression, adiabatic processing, friction, the temperature can rise to 100 degrees Celsius, which causes the formation of thermal energy that softens the lignin, and the fractions stick together into a granular form. This process is called pelletization.

- Cooling - at this stage, the strength of the granular substance is ensured and, after acquiring a shape, it must be cooled.

- Packaging is the final stage of production technology.

In some cases, prior to pressure testing, water treatment and the regrinding stage can be carried out, which is necessary when using certain types of raw materials and their qualitative properties.Crimping is carried out in special molds, annular dies using rotary rollers (rollers), which compress the substance into cone-shaped fillers mounted on a matrix. On the reverse side, the released granules are cut with special knives. Upon completion of the cooling stage, the resulting pellets are sieved and too small fragments are recycled. This technology is, in principle, waste-free, because only low-combustible impurities are removed. Thus, to release a ton of a substance, three to five cubic meters of wood waste will be required, because. compaction occurs approximately three times. Energy consumption for the above process can be from 30 to 50 kW per hour.

Modern types of granules

For boiler equipment that burns pellets, the following types of pellets are used:

- White (wood) pellets - are the highest quality and highly effective option, made from sawdust of coniferous trees. They can be easily distinguished by a uniform and light shade, devoid of dark blotches. Accordingly, the cost of this substance, as a rule, is above average and ranges from 7 to 8 thousand rubles.

- Modifications with the addition of tree bark are a rather economical option, in which, in addition to the wood itself, bark is also added. In principle, it is not much inferior to the one described above, but there is a certain condition - only peeled bark should be used in production technology. In most cases, there is some sand on the bark, so the quality of the fuel can be noticeably lower. Colors range from dark gray to brown.

- Sunflower husk granulate is the most budget modification, which is produced in areas where there is a production network involved in the processing of sunflower seeds. In terms of efficiency, such granulate is inferior to analogues based on wood, and when it is burned, slightly more ash is created.

- Peat option - has good heat transfer performance and is produced where there are large peat deposits. The main drawback is the increased ash content, however, this circumstance is more than offset by the low price - from 5,000 rubles. The color of the substance is black.

- Straw pellets are a rather unusual solution, most often used in areas with small wood supplies. In terms of its effectiveness, it is very much inferior to all the above options.

Difficulties in choosing quality pellets

In principle, to choose the most suitable option, you should focus on the following points:

- The length and diameter of the granulate - the most common diameter is from 2 to 8 millimeters, and, as practice shows, the diameter with a smaller size is more often a foreign product. Larger variations are produced by a domestic manufacturer (usually they use equipment that was previously used for the production of granulated feed). However, the dimensions of the pellets used should not differ too much from each other, so the simultaneous use of different types of fuel is undesirable.

- Surface - the quality of a substance can be determined by its appearance. If the surface is smooth and shiny, then this means that the production process took place at the proper temperature in compliance with all the rules.If there are a large number of cracks on the granules, then their heat transfer may be questionable.

- Hardness - the harder it is to break a single granule, the better. This also speaks to fuel efficiency and helps to eliminate risks during storage and transportation. Situations often arise when, in the process of moving, most of the substance crumbles into dust, which qualitatively reduces the positive heat transfer during combustion, and, accordingly, a large mass of the substance is spent on heating.

- Color - it will depend on the production raw materials used. If there are too many dark inclusions on the wood granulate, then this indicates a sufficiently high presence of sand in the composition, which will impair heat transfer.

- Liquid solubility – A water solubility test can be an excellent quality check. A small handful of pellets are dropped into a container with liquid, where it remains for several hours. Water should completely dissolve them, turning them into a dark wet mass. When this does not happen, this indicates that polymeric substances were used for gluing, which is highly undesirable. To determine the amount of sand in the composition, you need to shake the container and the sand will sink to the bottom of the container.

IMPORTANT! It is preferable to purchase pellet products in bags, but not in bulk. Such a loose version is more easily damaged and is not able to retain its useful properties for a long time, while a plastic bag can protect against the negative effects of moisture and other negative environmental phenomena.

Pros and cons of granulate

The main positive qualities of this type of fuel include:

- Ecological purity - when burning such a substance, the volume of carbon dioxide emitted is equivalent to the volume that is formed during the natural decomposition of various wood waste;

- Low fire hazard - pellets are almost not subject to spontaneous combustion, which distinguishes them favorably from other fuel substances;

- Proper humidity - it is from 8 to 10% versus 30-50% for conventional firewood, which makes their storage more reliable;

- Excellent heat transfer - with the help of one ton you can get 3500 kW of energy (which will depend on the type of pellets);

- Permanent and high density - this quality has a positive effect on the logistics, loading and transportation of pellets;

- Uniformity - the same structure of sizes and shapes makes it easy to automate loading / unloading procedures, as well as incineration.

Significant disadvantages include:

- The overestimated cost of fuel in modern conditions;

- To burn pellets, you will need to purchase a special boiler, which is equipped with automation and has a rather expensive cost;

- The small volume of offers on the market - there is hope that this situation will improve soon, but most potential consumers have to buy in reserve, which entails the need to find storage rooms in conditions where there is no excessive humidity.

Standardization of granular pellets

At the legislative level in the Russian Federation there is no standardization of them. As a rule, manufacturers independently establish the features of the production technology in relation to both the quality of the raw materials used and the quality of the final product.But the main reference point for them is the foreign technologies of those countries where the pellet market has been formed for a long time and where this fuel is very popular.

There is also a similar trend in the market for pellet burning boilers. Each manufacturer in their instructions independently dictates the requirements for the fuel used. Guarantee obligations are also directly dependent on the fulfillment of these technical conditions, which makes the direct producers of granulate focus on them. At the same time, the processes must be strictly maintained so that the products are in demand among potential buyers.

This shows that the Russian market in this direction has not yet been fully formed, and many product indicators have not become common to everyone.

Packing and packing of pellet granulate

There are many ways to package and package the type of fuel in question. This circumstance contributes significantly to satisfying the majority of customer requests. The substance can be sold in bulk in a completely free form or in standard bags (“big bags” - from the English “big bag”), which can hold from 500 to 1200 kilograms.

In bulk, as a rule, fuel elements are shipped to large thermal power plants. However, bulk shipping is also possible for higher quality pellets. They are purchased by enterprises that carry out further retail sales to private consumers or small stations, while packaging the material in bags of smaller volumes. A regular bag is a soft container made of synthetic polymers, and it is supplied with special reinforced slings to automate the loading / unloading work.Materials transported in synthetic bags fully retain their flowability and maintain the proper level of humidity. It should be noted that the loose method of purchase for the end consumer is much cheaper than the packaged version.

Transportation of packaged goods in "big bags" is carried out by special vehicles on platforms loaded by forklifts. But the packaging in bags from 10 to 20 kilograms is completely loaded and transported using manual power and small-capacity trucks. This is because private buyers do not always have the need for large volumes due to problems finding storage space. Also, pellets of higher quality are supplied in small volumes.

Rating of the best pellets for 2025

Budget segment

3rd place: "Gardener's Empire (Conifers)"

votes 1

Very convenient and high-quality pellets designed for space heating. Made from high quality sawdust of coniferous wood. Extremely economical and easy to use. Their efficient combustion occurs due to the increased density of the granules. Application is possible only on special boiler equipment. The length of the granule is 6 millimeters, the production is carried out on foreign equipment. The product is packaged in elastic bags weighing 15 and 30 kilograms. Country of origin - Russia. The established cost for 15 kilograms is 280 rubles.

- Convenient packaging option;

- Economical use;

- Ecological purity.

- Afraid of excessive moisture.

2nd place: "Kuzmich 24 (pine)"

votes 0

This type of fuel is of high quality, as evidenced by their uniform white color.The diameter of individual granules may vary (from 6 to 8 millimeters), but these differences are acceptable for joint use. Greater heat transfer is achieved through the use of a single species of wood - pine without bark impurities. Packed in bags of 25 kg. Country of origin - Russia. The recommended retail price is 450 rubles.

- Environmental friendliness;

- Homogeneous composition;

- High heat dissipation.

- Not detected.

1st place: "Fuel pellets 2025 (oak)"

votes 0

These pellets are made from wood waste on the basis of oak. The composition does not contain any synthetic impurities and even bark elements. The composition provides for increased heat transfer. They do not have an unpleasant odor and have the properties of efficiency. In addition, they can even be used as cat litter. Country of origin - Poland. The recommended retail price is 625 rubles per 15 kilograms.

- Application variability;

- High heat dissipation;

- Homogeneous production material.

- Not detected.

Middle price segment

3rd place: "Grillkoff Pellets (aspen, spruce, pine), 30 kg"

votes 0

This product is made on the basis of different compositions of wood - in the structure there are pine, spruce and aspen. They also added elements of the peeled bark of these trees. Their efficiency is somewhat lower than that of homogeneous options, but this is more than paid off by their cost - only 625 rubles per 30 kilograms. Packing is made in large bags, which reliably prevent the risks of unauthorized saturation of the substance with moisture. The country of origin is Latvia.

- Possibility of use as a filler for a cat's toilet;

- Large packaging at the current price;

- Environmental friendliness.

- Strong smell of pine needles (not everyone will like it).

2nd place: "Gardener's Empire (hay)"

votes 0

This is a fairly economical version of the granulate, which is widely used due to the large packaging dimensions at a fairly adequate price. Due to the fact that the granules have a small length - about 4 millimeters, they can be used both for heating and as a fertilizer at the same time. The product is made from environmentally friendly straw. Storage under maximum dry conditions is required. The standard packaging option is 30 kilograms at a price of 640 rubles per bag. Country of origin - Russia.

- Eco-friendly raw materials;

- Double purpose of goods;

- Standard heat dissipation.

- Requires special storage conditions.

1st place: "Wood technologies"

votes 0

This type of granulate is made from a combined hodgepodge of various types of wood - from coniferous to hardwood. The standard diameter is from 6 to 8 millimeters, but variations up to 10 millimeters are also provided. They have sufficient thermal conductivity. Packing can be any at the request of the customer, or it can be sold in bulk. Country of origin - Russia. The recommended cost for 30 kilograms is 680 rubles.

- Various delivery options;

- Variation of diameters;

- Available storage conditions;

- Low ash content - about 0.5%.

- The heterogeneous composition somewhat reduces heat transfer.

Premium class

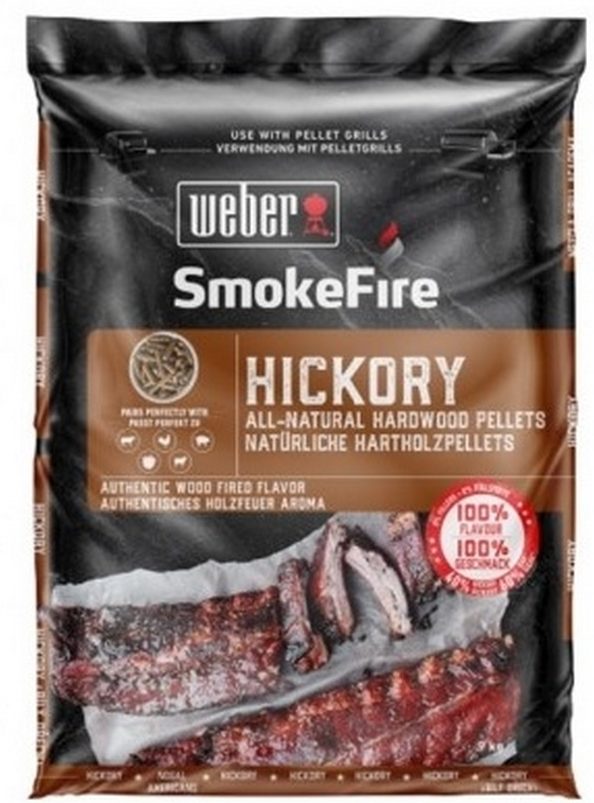

3rd place: "WEBER Wood Pellets, Hickory 190102"

votes 0

This type of fuel is designed for dual use. They can be used as a high-quality ignition for grill operation, and as a heating material. They have a pleasant smell and do not cause allergies. Supplied in a convenient and sealed package of 20 kilograms. One package is enough for the full operation of the boiler for 10-15 hours. The country of origin is Germany. The established cost for the retail network is 1800 rubles.

- Dual purpose item;

- Do not have an unpleasant odor;

- Increased heat dissipation.

- Too high price.

2nd Place: Oklahoma Joe's

votes 0

Another representative of dual-use products. Suitable for use in pellet boilers and for use on the grill. They do not have an unpleasant odor. It is supplied in packages, although their volume is extremely small for the set price of 1900 rubles. The country of origin is the USA.

- Dual purpose product;

- High heat transfer - 5500 kW;

- Convenient packing.

- High price.

1st place: "Mesquite, 9.2 kg, BROIL KING"

votes 0

Completely environmentally friendly product, completely devoid of inorganic impurities, fillers and binding adhesives. Has a spicy hypoallergenic fragrance. Can be used for both cooking and heating. They have a small diameter and are conveniently packaged in sealed packaging. Able to maintain a given level of humidity even in cramped conditions. Standard packaging weighs 9.2 kilograms at a price of 2000 rubles.

- Full environmental friendliness;

- Dual purpose;

- Pleasant spicy aroma when burned.

- High price.

Instead of an epilogue

The analysis of the Russian market of the goods under consideration found that the middle and budget segments are fully occupied by the domestic manufacturer. However, such a product has a single and direct purpose - only heating. At the same time, affordable prices and variability of supply speak of the sufficient quality of products. The premium class segment, as a rule, is fully represented by foreign (primarily European and transatlantic manufacturers), is characterized by a high level of environmental friendliness and can be used in various fields. It is worth mentioning that the price of this quality is very high and multitasking is very high, so the Russian consumer is unlikely to purchase premium samples for heating. Ideal for grilling and other outdoor cooking tasks. In addition, it should be noted that the market for the goods in question in Russia is just beginning to develop and there is hope that domestic firms will soon begin production of multitasking granules, while its prices will not be too high.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131653 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127693 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124520 -

The best men's sneakers in 2025

Views: 124035 -

The Best Complex Vitamins in 2025

Views: 121941 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2025

Views: 113396 -

Ranking of the best wood paints for interior work in 2025

Views: 110320 -

Rating of the best spinning reels in 2025

Views: 105331 -

Ranking of the best sex dolls for men for 2025

Views: 104369 -

Ranking of the best action cameras from China in 2025

Views: 102217 -

The most effective calcium preparations for adults and children in 2025

Views: 102012