Rating of the best pastes for polishing car headlights for 2022

Real car enthusiasts on an ongoing basis take care not only of the external and internal (salon) beauty of their "iron horse", but also carefully treat working parts and mechanisms. To a greater extent, the safety of movement by car will depend on the serviceability of lighting devices - headlights, which will help to keep a special substance - polish in proper condition. Vehicle headlights should always be clean and clear.

Content

- 1 Headlight care: general information

- 2 Properties and consistency of polishes

- 3 Causes causing damage/contamination of lighting fixtures

- 4 Compliance with preventive measures

- 5 The right choice of cleaning agent

- 6 Polishing with pastes

- 7 Polishing and grinding process

- 8 Features of polishing glass lanterns

- 9 Rating of the best pastes for polishing car headlights for 2022

- 10 Instead of an epilogue

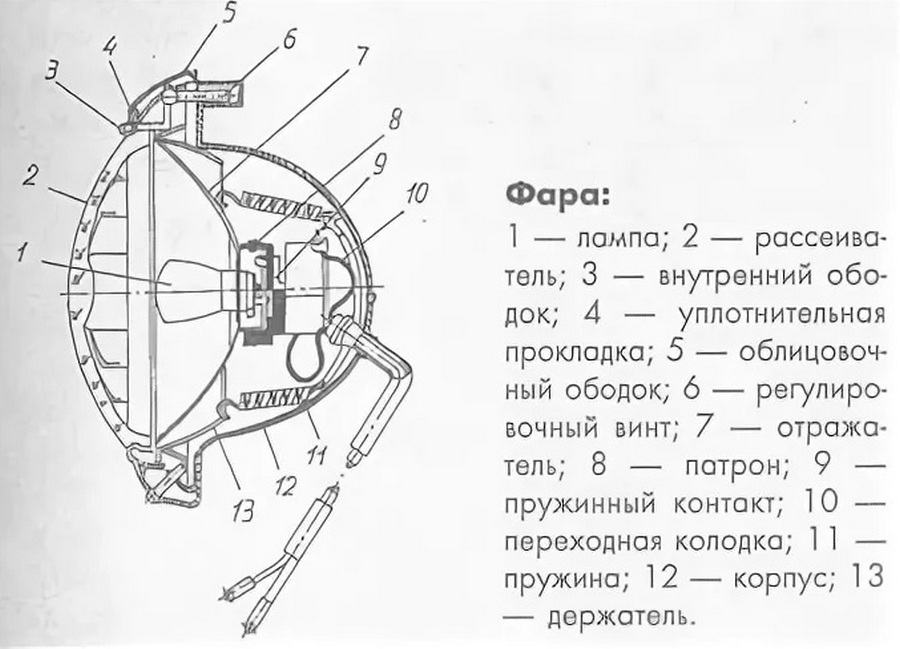

Headlight care: general information

All car headlights need proper care. Plastic or glass lanterns are extremely afraid of the aggressive effects of the external environment, they can also be affected by the costs of the road itself (roughness and potholes). The outer surface of the lighting devices under consideration is highly susceptible to pollution by dust and wet earth, and is also poorly protected from mechanical shocks and chemical attack.

In order to keep the lamps clean, you should use the appropriate care products for these working elements. The assortment range of such substances offered by today's market is very wide, and it is easy to get confused in it. And for the purposes of the right choice, you need to rely on the degree of contamination of the lanterns, on the material from which they are made, and also on whether there are any contraindications for cleaning them from the manufacturer.

Particular attention should be paid to the process of processing lamps with abrasive substances - before starting the operation, you should carefully study the composition of the cleaning substance and possible side effects from its use. It is worth remembering that a well-chosen paste (or tool) can quickly restore lost brightness to car lamps, equip them with a special protective layer, and extend the overall life.

Headlight polishing services are provided by almost any service station and at their level it is possible to restore even those lighting elements that have been seriously damaged. However, the cost of such manipulations can be extremely high.

In principle, it is possible to learn and polish the headlights yourself. For example, it is easiest to do this with plastic samples - the risk of damaging them is relatively small. It will be enough to rub them with a special polish. With glass lamps, everything is a little more complicated, however, you can even walk on them with a grinder. In this case, it is preferable to use a grinding tool with adjustable speed and power. So, by setting the optimal rotation mode, you can prevent overheating of the surface to be cleaned.

IMPORTANT! In some cases, polishing only the outer surface is not enough, because the condensate of dirt can also accumulate inside. This will require additional internal cleaning.

Properties and consistency of polishes

Polishing pastes belong to the cosmetic care products for automotive light fixtures. They can be divided into the following types:

- Restoring action - return lighting devices to their original properties, such as transparency, brightness, lighting range;

- Protective properties - used to form a special film on the surface of devices that will protect them from ultraviolet light and minor mechanical damage;

- Dual purpose - used for cleaning and protection at the same time.

The consistency of polishes can be of two types - either emulsion or paste.

Causes causing damage/contamination of lighting fixtures

Factors that cause pollution or damage to lanterns can be different:

- Dust, dirt, sand;

- Increased exposure to direct sunlight;

- Mechanical shocks;

- Encounter with insects (in large numbers);

- Hit fragments of the road surface.

As a result of the impact of all of the above factors, both glass and plastic headlights get scratches and microcracks, yellowness and turbidity form on their surface. With such light fixtures, driving onto the road is not only ugly, but also unsafe. Moreover, the shortcomings described above can reduce light transmission by at least 30%. From this it can be seen that in order to maintain full performance and attractive appearance of the car, it is necessary to periodically polish the lighting devices. This will both avoid a possible accident and improve the presentability of the car (for example, for a pre-sale situation).

After identifying problems with lighting, transparency and light transmission of lanterns, you need to carefully assess the level of damage caused. It can be nominally divided into three degrees:

- Severe damage in the form of large chips, deep scratches - in this case, it is unlikely that one polishing will be enough, it would be preferable to replace the body, diffuser or reflector.

- Moderate damage appears as small chips, small scratches and moderate cloudiness. In this case, polishing and grinding can help.

- Light damage - with them there is only insufficient light scattering and clouding. Here it is quite possible to polish the lamp yourself.

Compliance with preventive measures

Professionals recommend not to bring the level of pollution / damage to the lighting devices of the car to extreme limits, but to carry out preventive measures on an ongoing basis and periodically remove the detected minor flaws. This will save money on professional polishing, which will have to be done by the service station masters, when the degree of contamination already becomes such that it cannot be eliminated on their own.

At its core, preventive methods are straightforward and come down to the fact that the headlight, from time to time, is wiped with a clean rag, with abrasive or finely abrasive substances applied to it. Such substances include various pastes, creams, and even any improvised means, such as standard toothpaste or tooth powder (by the way, it is powders, according to experts, that do a very good job of this task due to the large fragmentation of their composition). The use of such simple methods will allow you to keep the optics of the machine in excellent condition, and therefore significantly increase its service life.The application process itself does not present any difficulties - the outer surface of the headlight is simply wiped with a soft rag with a cleaning agent in circular, versatile movements.

The right choice of cleaning agent

To make the right choice of polishing agent for automotive optics, a number of important parameters should be taken into account:

- The material from which the headlight is made - some compositions are suitable only for plastic models, while others are intended exclusively for glass ones. At the same time, there are universal multifunctional options.

- The severity of damage - from serious chips and scratches, from which the pastes will not save, to small cracks and clouding, which are calmly eliminated with a polish.

- The level of conformity of a particular headlight model to the cleaning agent used - in this case, the manufacturer's recommendations should be taken into account - this usually indicates the best composition of the polishing agent with which its product will perfectly contact.

Polishing with pastes

A similar polishing method, as a rule, is performed by motorists on their own and for this it is possible to use:

- Ordinary dental toothpaste (powder) - it is perfect for the most common type of lamps - made of plastic (plexiglass), which did not suffer serious damage during wear. It is extremely easy to polish them, so it makes no sense to purchase professional cleaning products - it is quite possible to get by with a widely known tool among the people. Toothpaste contains tiny particles - abrasives that do an excellent job with minor scratches and help restore the original shine of all optics.However, for full-scale work, you may need more than one or two tubes, but rather three or four, along with soft, clean rags or old towels. The paste must be rubbed into the surface in a circular motion for 15 - 20 minutes, then rinse off the applied composition with clean water, and then wipe the surface dry. Also, you can use tooth powder, the abrasives in which are somewhat larger than those of toothpaste, which means that it is able to cope with denser dirt. In any case, brushing with toothpaste/powder is an emergency solution, will not help much with severe contamination and, of course, cannot be compared with professional polishing at the service station;

- Paste GOI - is referred to by the name of the "State Optical Institute", where it passed its first test, as a cleaning agent that has chromium in its composition. The substance has a characteristic green tint, a dense microstructure and is used as a professional tool in workshops and by ordinary motorists. Its excellent performance and cleaning properties allow you to polish/grind the surface of headlights and glass, car body, and in general various objects that need transparency or shine. The tool is made in the form of bars and purchased by weight. To work with it, you need a felt rag. It is always worth remembering that due to its characteristic green color, GOI paste should be quickly removed from the surface being cleaned (using clean water and a rag) immediately after polishing in order to avoid hardening;

- Special automotive polishing pastes - there are a sufficient number of them on the modern market, they can vary in purpose, features of use and quality of processing.The process of their application may also vary, but only slightly. The possibility of using each sample of such a paste should be considered in the context of each specific case.

Advantages and disadvantages of using paste

The undoubted advantages of using paste-based polishes are:

- The relative cheapness of the method - a rare tube will exceed the price of 1000 rubles, and no more than 4 will be needed to polish all the lighting fixtures.

- Economical consumption - a small amount is enough to process a relatively large area;

- Efficiency - with its help it is possible to achieve the desired level of transparency and brightness of the lighting device without spending extra money on paying for service stations;

- Temporary savings - it is quite possible to carry out the processing on your own, without spending time visiting the service station, and the whole procedure will take no more than an hour.

The real disadvantages of the above method include:

- The need to apply sufficient muscular and physical effort;

- The fragility of the effect - however, this drawback applies only to the facts of the emergency use of toothpaste / powder. Specialized substances - GOI paste or special automotive polish paste have a long-term effect.

Polishing and grinding process

The preparatory stage must necessarily include manual washing of all optics. It is carried out using a special car shampoo or any other non-aggressive detergents (technical alcohol is also quite suitable for degreasing surfaces). Then the lantern must be thoroughly dried, and it is better to insulate the adjacent surface of the body with adhesive tape (preferably construction tape) so that cleaning agents cannot get inside.

IMPORTANT! The best way to clean car optics is to dismantle the headlights themselves and clean them separately from the body.

The process of grinding and polishing can be conditionally divided into four stages:

- At the first stage, a coarse-grained cleaning substance should be used. If there is a grinder with adjustable speed, then manual circular rubbing is not needed - this way you can save both time and effort;

- In the second step, a cleaning agent with a medium grain fraction should be used;

- At the third stage, it is necessary to use the highest quality and finely abrasive composition - GOI paste or special automotive paste. With their help, traces of the incompleteness of the previous stages will be destroyed;

- The final step will be the use of polishes - they cover a completely cleaned surface in order to consolidate the result.

IMPORTANT! If a car enthusiast has vision problems, then it is better to entrust the polishing process to professionals, because you can miss small contaminants, which, when the light scatters, will form a blind spot.

Features of polishing glass lanterns

While it is better to use paste-like substances for plastic headlights, it is better to use diamond polishing for real glass. This shows that this will require more serious material, and the work itself will be laborious and complex. The reason for this is that the plastic layer is easier to clean/remove than the glass layer. Thus, for glass, diamond paste is used, which includes the smallest diamond particles no larger than 3 microns. Although glass lighting fixtures are recommended to be cleaned with a grinder (electric grinder), for safety and economy reasons, cleaning work is often done by hand. And this is due to the fact that when using an electric tool it is very difficult to monitor the degree of heating of the surface to be cleaned. If the surface is overheated, it can easily crack. The very process of using diamond paste, in principle, does not differ from the standard one, however, it does not tolerate the processing of dirty surfaces and a piece of foam rubber is used to rub such a polish. The agent should be rubbed until a positive result becomes clearly visible (for example, transparency increases qualitatively).

Benefits of diamond polishing glass headlights

Naturally, if the headlights are not polished on time, then this fact is unlikely to affect, for example, the car's cross-country ability. However, its appearance will leave much to be desired, and the risk of an accident will actually increase. Thus, the advantages of diamond polishing include:

- A qualitative improvement in visibility at night - a clean surface will transmit light much better, the light spot will be scattered in the required diameter, and headlights will not interfere with oncoming cars;

- Financial savings - regular and competent care of the condition of automotive optics will significantly save on service stations;

- External presentability of the car - periodic care of the "eyes" of the car will embellish the appearance in general, so the car will not seem to the potential buyer to be purely visually hackneyed or faulty;

- Optimal smoothness - perfectly smooth headlights without roughness and scratches will become shiny and beautiful;

- Shine of novelty - a smooth and uncontaminated surface of the headlights will provide excellent light refraction, from which they will shine better and further.

Rating of the best pastes for polishing car headlights for 2022

Budget options

3rd place: "Doctor Wax Metal Polishing Paste"

The composition is made in the USA, it is distinguished by its versatility. Despite the fact that the word “metal” sounds in the name, the annotation to it directly states that the tool may well be applied to objects made of plexiglass. This is where the positives end.

| Name | Index |

|---|---|

| Manufacturer country | USA |

| Capacity tare, ml | 150 |

| Achievable improvement in illumination, lx | 20 |

| Price, rubles | 170 |

- Multifunctionality;

- Sufficient capacity;

- soft substance.

- One jar = one application for all machine optics.

2nd place: "Doctor Wax Clear Plastic Polish"

This cleaner contains nano-components that instantly penetrate the surface to be cleaned, which ensures the fastest effect. The container is provided with a special dispenser, the paste is squeezed out evenly. The process of polishing and grinding is quite convenient. The substance perfectly fights against microcracks and turbidity.

| Name | Index |

|---|---|

| Manufacturer country | USA |

| Capacity tare, ml | 300 |

| Achievable improvement in illumination, lx | 40 |

| Price, rubles | 300 |

- Increased capacity;

- Innovative technology applied;

- Quality North American brand.

- Not detected.

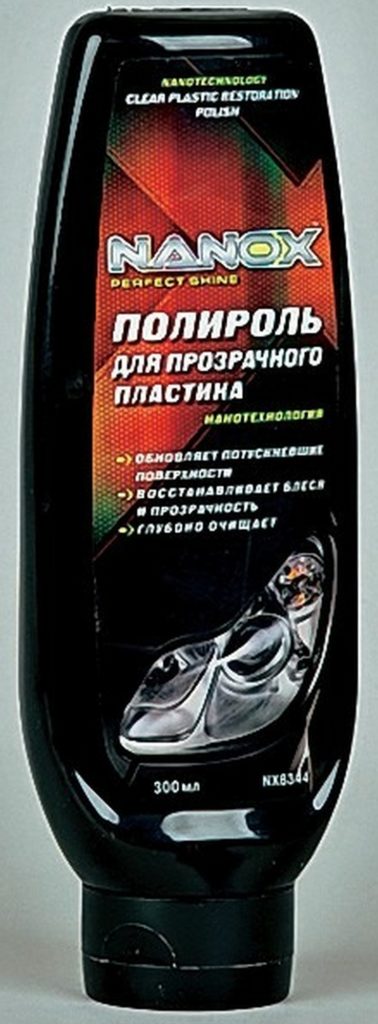

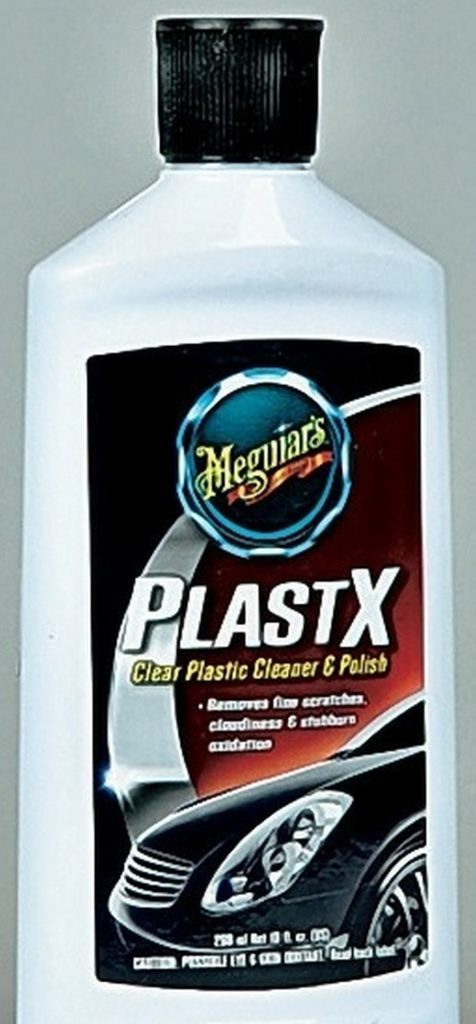

1st place: "PlastX, Clear Plastic Cleaner & Polish"

Cleaning agent dedicated exclusively to plastic products. The container has a convenient dispenser, the supplied mass in one bottle is enough for two times use. He successfully copes with the withered tasks - polishing transparent plastic.

| Name | Index |

|---|---|

| Manufacturer country | Netherlands |

| Capacity tare, ml | 300 |

| Achievable improvement in illumination, lx | 30 |

| Price, rubles | 350 |

- Adequate price;

- Corresponds to the declared functionality;

- Dutch brand.

- There is no Russian abstract.

Middle price segment

3rd place: "AREXONS Abrasive Paste"

It copes well with serious scratches, it can even remove a small layer of dried paint. It can be used in the first stage of polishing, after which it is required to fix the result with waxed products. It will take no more than 40 minutes to process all the lights of a car, with proper skill.

| Name | Index |

|---|---|

| Manufacturer country | Italy |

| Capacity tare, ml | 150 |

| Achievable improvement in illumination, lx | 25 |

| Price, rubles | 370 |

- Excellent result at the initial stage;

- Versatility;

- Does not have a strong odor.

- Requires significant muscular effort.

2nd place: "TURTLE WAX Metallic Car Wax + PTFE"

An excellent representative of a budget brand, in which the equality of “price / quality” indicators perfectly converged. When rubbing does not require much muscle effort. Provides the treated surface with protection against ultraviolet rays and mechanical shocks.The composition uses both wax and abrasive components, it can be used at all stages of polishing, as the only tool.

| Name | Index |

|---|---|

| Manufacturer country | Spain |

| Capacity tare, ml | 300 |

| Achievable improvement in illumination, lx | 35 |

| Price, rubles | 400 |

- The composition contains wax and cleaning abrasives;

- Ease of application;

- Versatility.

- Processing efficiency is achieved only indoors.

1st place: Farecla G3

It is positioned as a high-quality gloss enhancer for any surfaces. However, it is able to cope only with pollution and moderate cracks. Dilution with water is required during application. It performs well in both manual and machine processing. Application is recommended to be carried out with a microfiber cloth.

| Name | Index |

|---|---|

| Manufacturer country | Great Britain |

| Capacity tare, ml | 250 |

| Achievable improvement in illumination, lx | 50 |

| Price, rubles | 450 |

- Enhances the effect of shine;

- Possible both manual and machine work;

- It is possible to consolidate the results with means from the brand line (cosmetic milk).

- Requires dilution with water.

Professional Samples

3rd place: "Koch Chemie F6.01"

The well-known German brand positions this substance as “a smart substance that can get rid of any scratches.” The basis for such an advertising message was the applied formula - it includes a fine-grained mass that does not contain silicone oil. Thus, this paste is subject to the correction of scratches and cracks of high complexity.At the same time, the paste can be applied by machine - especially for this purpose, this brand has a line of grinding materials and fur sponges.

| Name | Index |

|---|---|

| Manufacturer country | Germany |

| Capacity tare, ml | 250 |

| Achievable improvement in illumination, lx | 35 |

| Price, rubles | 920 |

- Supply capacity variability;

- Ease of application;

- Availability of related materials.

- Not installed (for your segment).

2nd place: Menzerna 400 Heavy Cut Compound

Another cleaning substance from a well-known German brand that easily copes with complex dirt and scratches. The formula uses an innovative composition that gives the treated surface an extra shine. Recommended for use at the final stage of processing. Both manual and machine use is provided.

| Name | Index |

|---|---|

| Manufacturer country | Germany |

| Capacity tare, ml | 400 |

| Achievable improvement in illumination, lx | 40 |

| Price, rubles | 1700 |

- Does not require dilution with water;

- Ability to remove small glass/plastic residues;

- Processing speed.

- Weak protection against moisture.

1st place: "3M 80349NF"

Oddly enough, but the first place goes to the representative of the Russian industry. This paste has become very popular due to its excellent technical qualities and properties, as well as due to its low price (relative to the purchased volumes - it can be found both in milliliter bottles and in large containers). Perfectly destroys dirt and cracks of any degree of complexity, applies a protective layer against moisture and mechanical damage, perfectly polishes both light and dark surfaces.Application is possible both manually and on a grinding machine.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Capacity tare, ml | 250-10000 |

| Achievable improvement in illumination, lx | 50 |

| Price, rubles | 650-3900 |

- Not afraid of any weather conditions;

- The composition does not contain silicone;

- Economical expense.

- Not detected.

Instead of an epilogue

A car enthusiast should always remember that the use of non-specialized products, such as toothpaste, powder or micellar water, can only take place in emergency cases, because such products are not able to provide a long-term effect. In addition, on a dirty road, the headlights, after such cleaning, will quickly return to their deplorable state. At the same time, professional headlight cleaning in a workshop is not available to every driver due to its high cost. From this we can conclude that the best solution would be the independent use of special automotive pastes for cleaning headlights. And the conducted analysis of the market showed that among the cleaning pastes there are more foreign samples, although the only domestic brand "3M" overtakes them in all respects.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131651 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127690 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124519 -

The best men's sneakers in 2022

Views: 124033 -

The Best Complex Vitamins in 2022

Views: 121939 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114980 -

The best paint for gray hair - top rating 2022

Views: 113395 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105329 -

Ranking of the best sex dolls for men for 2022

Views: 104366 -

Ranking of the best action cameras from China in 2022

Views: 102216 -

The most effective calcium preparations for adults and children in 2022

Views: 102011