Rating of the best parquet varnishes for 2022

By definition, parquet is a respectable flooring that is characterized by aesthetic beauty and increased practicality. However, over time, parquet tends to become sensitive to mechanical damage and high humidity, and can also simply turn black and lose its attractive appearance. To avoid such problems in the future, to preserve the original appearance of the parquet board, it will be possible to treat it with a special varnish, which will give not only decorative beauty, but also increase the operational life of the coating.

Content [Hide]

Types of varnishes for parquet

Modern lacquer coating for parquet boards is a process of final application of special compositions to the wood, which, after hardening, form a hard film, thereby increasing the wear resistance of the parquet. Varnishes can vary in composition - they can be based on oils or polymers, and it is also possible to include special inclusions or pigments in them.

Varnishes for parquet differ among themselves in the following parameters:

- Technological characteristics - fluidity, volatility, viscosity of the mass itself;

- Color - tinted or colorless;

- Gloss level - gloss / semi-gloss or matte / semi-matte;

- Completeness - consisting of one or two components;

- The base used - the base can be polyurethane, water, formaldehyde or oil resin.

Before painting the parquet, it is necessary to pay great attention to the composition of the varnish base, which must be selected in accordance with the purpose of the room where the painted parquet is located. It is also necessary to take into account the future load on the painted flooring (permanent, periodic). To date, varnishes on the following bases are especially popular:

- Water;

- Alkyd;

- Acrylic;

- polyurethane;

- Formaldehyde.

Each of the above foundations has its own characteristics, which are worth considering in more detail.

Aquatic

Such a varnish coating is most popular among the general consumer masses due to the fact that it dries quickly and does not have sharp / unpleasant odors.The base for such varnishes is ordinary water, which is simply mixed with emulsifiers or solvents at a concentration of 5 to 15 percent. The undoubted advantages of such a varnish will be:

- A high degree of adhesion to the treated surface, which allows them to be used both on fragile and expensive types of wood, and on rough massive boards;

- Increased moisture resistance;

- Maintaining environmental cleanliness.

However, such varnishes have a big problem with wear resistance, which directly indicates a short service life. Moreover, they are very picky about the application process itself - the processing of a wooden surface must be carried out only with a special tool (a roller with a large pile), and upon completion of the entire procedure, a mandatory primer of the treated area is required.

Alkyd

They are based on resins, which are obtained by random mixing of oils and acids, rosin and various organic substances. Due to the fact that organic oils are included in the composition of the varnish, the wood treated with it will be reliably protected from mechanical damage or moisture penetration. This effect is achieved due to the deep penetration of oils into the structure of the tree. Alkyd coating has a pronounced gloss and matte sheen. The main positive qualities of this mixture include:

- Giving the treated surface an attractive appearance by deep penetration into the structure and texture of wood;

- Hanging viscosity, due to which the varnish tightly closes all the voids between the parquet slabs, which eliminates its creaking;

- High resistance to temperature extremes and increase / decrease in humidity in the room.

Among the shortcomings of the acrylic base, one can name the fact that after processing it requires special drying conditions (creating a cool temperature in the room). At the same time, if the alkyd coating is applied too thickly, then at the end of drying, wrinkles may form, which will be a big problem to eliminate. Among other things, varnishes based on this base do not have a long life and constantly need to be updated.

Acrylic

These varnishes are based on resins from methacrylate synthetics. This suggests that after the completion of the drying process, the surface treated by them will be extremely resistant to increased mechanical stress, and will also be able to easily endure temperature fluctuations. The very texture of such a varnish has a characteristic color, which, after processing, can give aesthetic appeal even to inexpensive types of wood. The completeness of these mixtures can also be two-component, which means the presence of polyurethane in the composition.

Polyurethane

They are the best solution for rooms in which there is a permanent high traffic load. Highly recommended for use in public institutions, hotel lobbies, restaurants, spa facilities. It is worth noting that these varnishes have a fairly high cost, however, their consumption is low, which will compensate for the high cost of paintwork. A special solvent may be included in the kit, which will help to cope with the wrinkles that arise after drying. It is clear that the main advantages of polyurethane samples will be:

- Environmental friendliness and safety for human health;

- Resistance to high humidity;

- Increased operational resource;

- Resistance to mechanical stress (scratches or impacts).

The problem may be that the varnish, having increased adhesion, can glue parquet slabs, which then one by one (for example, in case of a fracture) cannot be replaced. However, this only applies to special types of wood, such as Canadian maple or pink beech.

Formaldehyde

Such a coating for parquet is truly considered the most reliable of all of the above. It is based on an acidic or other formaldehyde-based hardener, which provides strong adhesion to any type of wood and protects it from any negative external influences. It is worth mentioning that the formaldehyde coating will have a sharp unpleasant odor after drying, which, however, will disappear after a few days.

Competent selection

This process will directly depend on the type of parquet that will have to be processed, i.e. it will be necessary to take into account what kind of wood the parquet is made of, its type (mosaic or solid wood, shield or single), you must first decide on the method of painting. If the varnish is one-component, it can be applied immediately, and the two-component varnish will have to be mixed with the hardener on its own. Other parameters requiring special attention include:

- The level of occupancy of the room - it would be wiser to choose a wear-resistant brand for a hallway or a hall, and for, for example, a nursery or a bedroom, choose something more decorative.

- The service life of the coating - it can be calculated according to the manufacturer's information. First of all, varnish is a solution, which includes a certain amount of varnish and a solvent. The amount of varnish is indicated as a percentage and can range from 5 to 35 percent. This number is called the "dry residue". So, the higher this residue, the more durable the solution itself.

- Gloss level - this parameter is purely individual and depends directly on the consumer. Today you can choose the degree of gloss from dark matte to sparkling gloss. Here you just need to successfully combine the levels of gloss, while remembering that the varnish tends to wear off, so the frequently used "paths" should be updated in time in order to avoid the appearance of "bald spots".

- Drying speed - again, it all depends on the consumer himself. There are samples that can dry in a few hours, but they will have to be applied in several layers. And there are samples that dry from a day to two, but lie down in one layer. Thus, it all depends on how much time the consumer has.

- Colors - special inclusions can be added to the varnish, which can directly change the color of the treated wood. Here it is important to observe the color scheme and not to cover the parquet in a bright room in “burnt” matte tones.

- Safety and environmental friendliness - in fact, all varnishes throughout their "life" emit harmful vapors into the surrounding atmosphere. Naturally, they are unlikely to be able to cause any significant harm to human health, but to create a feeling of discomfort is quite. In this regard, water-based formulations are considered the most harmless.

IMPORTANT! And most importantly: before applying the coating, you must make sure that the selected varnish is compatible with the type of wood being processed!!!

Rating of the best parquet varnishes for 2022

water base

3rd place: Tex Profi Aqua

votes 3

It is used for processing planed wooden surfaces, which means that it is compatible with parquet processing. In the course of drawing disinfects the processed area. It is perfect for covering parquet in places of permanent mechanical stress.It can be applied to the surface with both a brush and an applicator.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Consumption in liters per square meter | 5 to 15 |

| Drying time in hours | 12 |

| Diluent | Water |

| Price, rubles per liter | 229 |

- Relatively short drying time;

- Suitable for both windows and railings;

- Application variability.

- Poor gloss retention.

2nd place: Luxens

votes 0

A sample from a French manufacturer, is a branded product of the Leroy Merlin network, is not distributed at other retail outlets. It has good adhesion, slightly yellowish over time, the second coat can be applied as early as two hours after the first.

| Name | Index |

|---|---|

| Manufacturer country | France |

| Consumption in liters per square meter | 10 |

| Drying time in hours | 2 (between layers) |

| Diluent | Water |

| Price, rubles per liter | 500 |

- Does not have a strong odor;

- Suitable for almost all types of wood;

- Has a good grip.

- Works poorly with unprepared surfaces.

1st Place: Tex Profi Waterborne

votes 0

Universal mixture that works with any wood elements. It copes well with processing even if inserts from other materials (for example, natural stone) are provided on the parquet area. It has an extremely economical mode of spending.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Consumption in liters per square meter | 8 to 9 |

| Drying time in hours | 3 (between layers) |

| Diluent | Water |

| Price, rubles per liter | 1700 |

- There are both matte and glossy blend options;

- Long operational resource;

- Handles minor scratches/bumps very well.

- Doesn't handle loads well.

Polyurethane base

3rd place: Dufa Expert D333

votes 0

Economical option for high traffic areas. The use of polyurethane in the mixture allows you to increase the service life. The material itself has neither color nor smell, therefore it is suitable for processing wood species that have their own “color”. Excellent contact after hardening with various aggressive detergents.

| Name | Index |

|---|---|

| Manufacturer country | Germany |

| Consumption in liters per square meter | 8 |

| Drying time in hours | 12 (between layers) |

| Diluent | Polyurethane |

| Price, rubles per liter | 1200 |

- You can even wash with abrasive products;

- Colorless coating;

- Increased operational resource.

- Takes a long time to dry between layers.

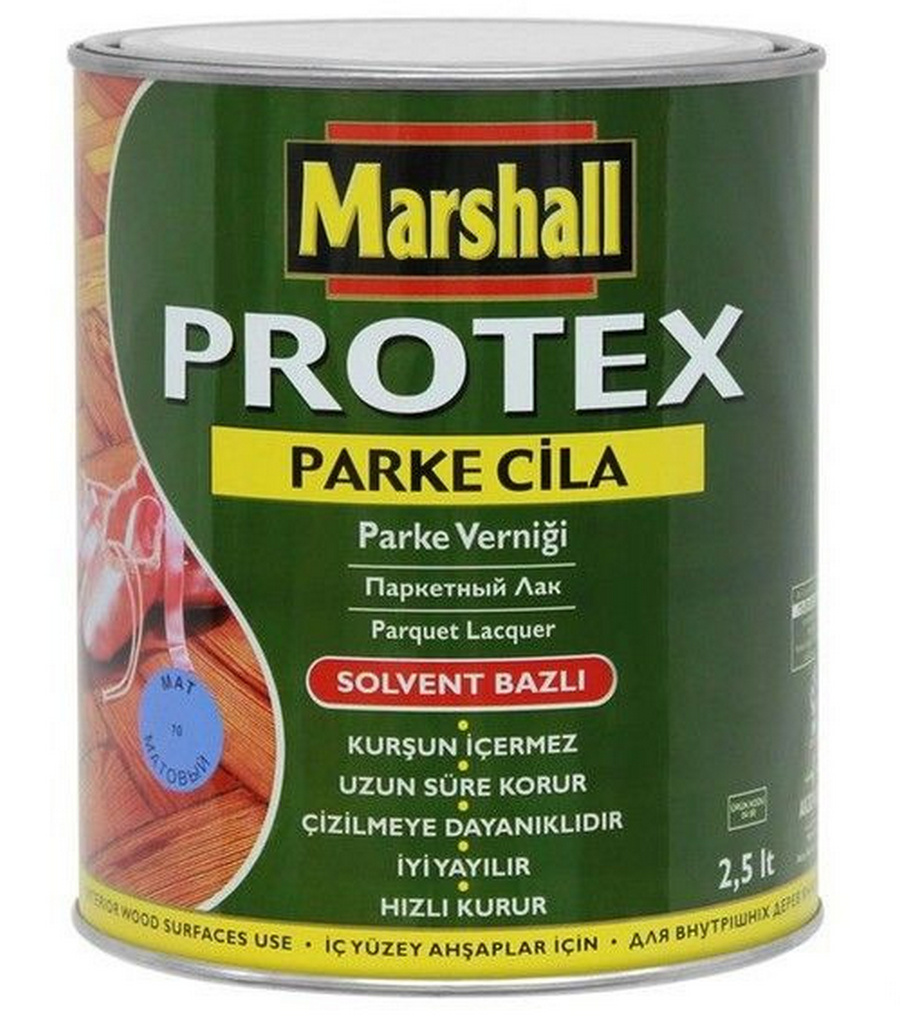

2nd Place: Marshall Protex Parke Cila 90

votes 0

This sample contains special inclusions that categorically increase the wear resistance of the coating. However, at the same time, you will have to sacrifice drying time - as much as 96 hours! It should be noted that as a result, an extremely reliable processing result will be obtained, and the ingredients present will color the parquet in a noble matte color.

| Name | Index |

|---|---|

| Manufacturer country | Estonia |

| Consumption in liters per square meter | 7.5 |

| Drying time in hours | 96 (general) |

| Diluent | Polyurethane |

| Price, rubles per liter | 1000 |

- Economic consumption;

- The presence of additional ingredients;

- Low cost.

- Long curing period.

1st place: 3V3 Vitrificateur Protection

votes 0

This French mix is able to work on almost any surface (from parquet to simple plank flooring or flights of stairs). You can work with a brush or with a roller. It is characterized by an extremely short drying period “to touch”, for applying the next layer - only 30-40 minutes. However, for this you will have to sacrifice a rather large consumption of liters per square meter.

| Name | Index |

|---|---|

| Manufacturer country | France |

| Consumption in liters per square meter | 12 |

| Drying time in hours | 0.3-0.4 (between coats) |

| Diluent | Polyurethane |

| Price, rubles per liter | 2500 |

- Short curing period;

- You can work with any tool;

- Blotches provide additional gloss.

- High price;

- Uneconomical expense.

Decoupage mixes

Decoupage is a method of decorating parquet, which consists in attaching an ornament (as a rule, these are cut-out applications) to the surface and further coating the resulting composition with varnish.

3rd place: Taika Glow Tikkurila

votes 0

It is used for fixing applications on parquet, walls, and other surfaces. It has additional inclusions that provide a glow of the treated surface in the dark. It is characterized by a fairly fast curing period.

| Name | Index |

|---|---|

| Manufacturer country | Finland |

| Consumption in liters per square meter | 8 |

| Drying time in hours | 6 (between layers) |

| Diluent | Acrylic |

| Price, rubles per liter | 3500 |

- The presence of a matte / luminous effect;

- Fast drying;

- Excellent adhesion between parquet and appliqué.

- High price;

- Requires serious skills to apply.

2nd place: Biofa 2050 Universal

votes 0

This varnish is made from natural raw materials. It can be applied to parquet made not only from wood, but also from cork. Penetrates deep into the structure of the tree. Providing excellent adhesion of the ornament to the bearing surface. Resistant to mechanical damage.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Consumption in liters per square meter | 12 |

| Drying time in hours | 4 (between layers) |

| Diluent | Acrylic |

| Price, rubles per liter | 1000 |

- Excellent value for money;

- Versatility;

- Full processing requires only two layers.

- Sensitive to high humidity.

1st place: Pinotex Lacker Aqua 70

votes 0

This solution is absolutely odorless, therefore it is ideal for decoupage when decorating rooms intended for children (children's bedrooms, playrooms). Differs in extremely fast process of hardening "to touch". In the process, it can give a milky whitish tint, but eventually becomes colorless.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Consumption in liters per square meter | 12 |

| Drying time in hours | 4 (between layers) |

| Diluent | Water |

| Price, rubles per liter | 1000 |

- The presence of anti-fungal / anti-mold ingredients;

- Does not darken over time;

- Does not have a strong odor.

- Not identified (for their segment).

Instead of an epilogue

To date, choosing a varnish coating for parquet is not a big deal. Both online stores and retail outlets offer a wide range of options for every taste and budget.Prices for this material vary very little from store to store, the difference can reach a maximum of 50-100 rubles. The main difficulty is the question of finding the necessary form of packaging - most stores try to sell varnishes in containers with overall volumes, but what if the buyer needs only a small amount for renewal? That's why you need to study the information from its official website on the Internet before visiting the store and find out in which container the desired varnish is sold.

Among the popular manufacturers of these mixtures, there have not been any significant changes over the past 20 years - Western brands are in the lead almost everywhere, and the domestic manufacturer has occupied a niche slightly below average.

Speaking of buying "for the future", preference should be given to samples with a long shelf life and a universal scope.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131650 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127689 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124517 -

The best men's sneakers in 2022

Views: 124031 -

The Best Complex Vitamins in 2022

Views: 121938 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2022

Views: 113393 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105327 -

Ranking of the best sex dolls for men for 2022

Views: 104365 -

Ranking of the best action cameras from China in 2022

Views: 102215 -

The most effective calcium preparations for adults and children in 2022

Views: 102010