Rating of the best crimpers for 2022

Hydraulic test pumps are indispensable equipment during construction and repair, ensuring that there are no leaks in water supply, heating, fire protection systems. They ensure that pipelines will work successfully under pressure.

In our review, we will provide recommendations: what to look for in order not to make a mistake when choosing a product, which company model is better to buy. We will get acquainted with popular manufacturers, a description of their brands, we will orient you at an average price.

Content

Types of "crimpers", how to choose them correctly

A qualified person uses the functionality of a hydrostatic unit to pump liquid at high pressure into a water supply system. The test provides confidence that the components have been assembled correctly, after which you can install bathroom fixtures or other equipment.

Testing takes place at the lowest point in the system. Inspectors visually inspect pipes, connections and fittings for leaks, monitor pressure gauges. The readings must not deviate from the allowable test pressure readings. Sometimes significant drops indicate a faulty pressure gauge or equipment, but can also potentially reveal a major problem with system integrity.

Pressure testers are used to test a variety of water systems in residential and commercial buildings, from sprinklers to plumbing lines. The basic features are the same across all test units, but power, durability, portability, and handling can vary greatly by variety.

- Most standard plumbing pressure test pumps are electric. They produce less power than gas appliances, but they have enough energy for most systems. Many experts note the convenience of connecting electrical equipment, no need to mess with fuel, this explains the popularity of this model. Electric units do not generate steam during use, which is essential indoors. You can buy models that run on car batteries. This allows them to be used in unfinished buildings without operating voltage.

- Powerful gas appliances quickly pressurize the system, filling it with water.They are typically used for large diameter pipe work, testing risers in tall buildings.

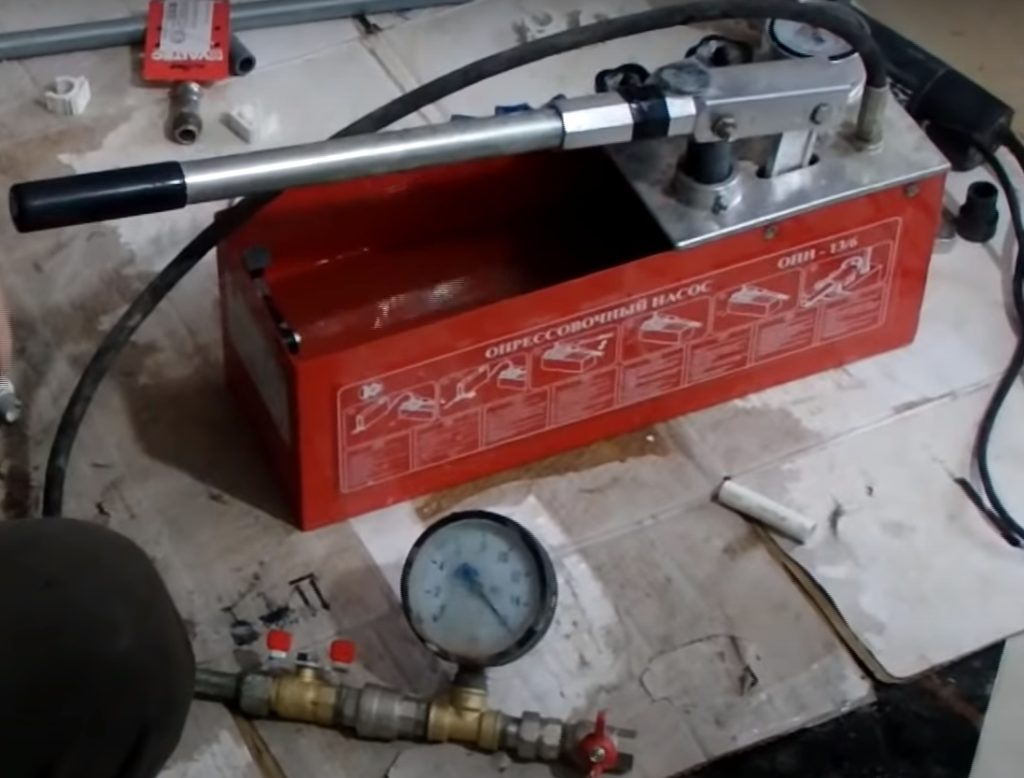

- Manually operated equipment pumps no more than 8 liters of fluid per minute into the system. It is less common among experts. Many contractors avoid the inconvenience associated with the need to pump water on their own, with their own hands, to wait longer.

- Crimpers for cables.

The natural pressure in the system influences the choice of apparatus for testing. There are other important criteria that inspectors should consider:

- It is important to note the diameter, length of the tested pipe. A small residential system is tested quickly, it is not difficult to reach the test pressure, so manual units can be used.

- The type of system is another important factor influencing the choice of equipment. Filling a dry riser will take longer than a wet one.

- The size and height of the building is also an important selection criterion, due to gravity.

Weight plays an important role during equipment acquisition. It affects the speed of movement of the contractor on construction sites. As a rule, the more powerful the machine, the more it weighs. Large units may require two people to move and are often mounted on wheels. The lightest machines use aluminum components, which are significantly lighter than parts made from other materials.

The best machines made of "flying" metal are more resistant to damage from corrosion, freezing. It is known that the casings of old models made of cast iron and other metals crack during vibration at low temperatures. Brass components can also help reduce weight and improve equipment rust resistance.

You have a choice between cheap low pressure brass troughs, to 316 stainless steel pumps from well-known brands. They will all do their job. Where to start in order to choose the best machine that suits your needs and budget, here are some tips:

- It is necessary to understand what kind of liquid and pressure in the system. This is a very important question. The pipe can be filled with mineral oil, fuel, water, brine, synthetic hydraulic fluids, and a variety of other chemicals. The pressure can vary from fractions of a bar up to 1000 bar.

- Budget, "industrial" manual hydraulic machines are versatile, meet high requirements, they can easily handle oil pumping. As for the fuel, which has a lower viscosity, other equipment designs are possible. We would advise looking at a more specialized unit with poppet check valves, they eliminate leakage. No need to use metal ball valves for low viscosity liquids.

- Inexpensive machines with a chute are used for water, which can be a problem. It is corrosive, so you need to look for an apparatus that can withstand pressure and not corrode.

- Whatever your budget, it is important that the device performs accurately from day one. Typically, pressure pumps run into trouble when they are left filled with water for long periods of time before being reused.

- The construction of stainless steel, bronze solves the problem of corrosion, but its price is quite high. Compounds successfully resist rust, their disadvantage is the low strength of the unit.

Be aware of hidden device maintenance costs.Some users will buy cheap machines to do one test. Always strive to minimize corrosion, use quality parts during repairs.

Where could I buy

Budget novelties are purchased in specialized supermarkets. Managers will tell you the points you are interested in: how much the model you like costs, what they are. The product can be viewed in the online store by ordering online.

Rating of quality crimpers for 2022

Our top list is based on real reviews, it takes into account the opinions of buyers who are familiar with the product, its functions, features. Here you will find photos and tables of characteristics.

Inexpensive

Zitrek TH-25

The manual device "Zitrek TH-25" is a high-precision bench tool used for hydrodynamic testing of pipeline structures, communications service. "Zitrek TH-25" is used to certify equipment after installation, repair work in the field of construction and housing and communal services.

The device is capable of pumping water, antifreeze, oil. The kit for the device includes: pressure gauge, sleeve. "Zitrek TH-25" is used as a hydraulic mechanism as part of more complex units.

Technical indicators:

| Options | Characteristics |

|---|---|

| Maximum fluid temperature | 80 °C |

| Volume of the tank | 5 l |

| Type of | Manual |

| View | Specialized works |

| Test head | 30 bar |

| Connection to pipeline | External G1/2 |

| Working fluid | Water, oil |

| Rotor | Dry |

| The weight | 3 kg |

| Dimensions | 320x200x260 mm |

| Permissible fluid temperature | from +5 to +80 °С |

| Series | TH |

| Weight of packed goods, kg | 1.99 |

| Packed goods dimensions, mm | 321x192x122 |

- designed to increase the pressure in pipelines (functions only as a test tool that checks for tightness);

- manometer;

- small dimensions, weight;

- comfortable handle;

- can act as a hydraulic drive for various devices.

- not detected.

HSY30-5

The test device "HSY30-5" is able to quickly and fairly accurately test the tightness of sewers, pipelines, and other closed circuits. The mechanism is suitable for servicing solar batteries. Constant pressure is generated due to the robust design of the apparatus. It includes an ergonomic valve that regulates the opening of the valves, a brass piston and a casing.

Due to the filter located at the inlet, the HSY30-5 is protected from breakdowns associated with the ingress of dirt into the system. The mechanism stands out for its small dimensions, mobility, manual drive allows you not to look for a power source on the construction site. The set complements the container made of metal with anti-corrosion coating.

Technical indicators:

| Options | Characteristics |

|---|---|

| Volume of the tank | 12 l |

| Type of | Manual |

| Test head | 60 bar |

| Connection to pipeline | External G1/2 |

| Working fluid | Water |

| Rotor | Dry |

| The weight | 7.8 kg |

| Dimensions | 500x190x140 mm |

| Series | HSY |

| Housing material | Steel |

| Item unit | Thing |

| Weight of packed goods, kg | 7.5 |

| Packed goods dimensions, mm | 520x200x310 |

- pressure gauge data is read during operation of the equipment;

- brass piston, valve body ensure long service life;

- efficiency 45 ml / cycle;

- compact, lightweight, ideal for mobile use;

- unique valve system maintains a constant head

- the inlet filter increases the reliability of operation.

- not detected.

Rotor Test Mini

The manual tester "Rotor Test Mini" is used to test the tightness of water-bearing communications with a pressure of up to 25 bar, the device has a metal reservoir with a capacity of 5 liters. The device is able to quickly "pressurize" the heating system. "Rotor Test Mini" is used to test leakage inside air circuits, refrigerators, oil and sprinkler structures, and other closed installations. The pressure gauge included in the set is easy to read. The holder has a rubber lining that allows you to more comfortably carry the device.

Technical indicators:

| Options | Characteristics |

|---|---|

| Max fluid temperature | 60 °С |

| Volume of the tank | 5 l |

| Type of | Manual |

| Test head | 25 bar |

| Connection to pipeline | External G1/2 |

| Working fluid | Water |

| Rotor | Dry |

| The weight | 7 kg |

| Dimensions | 320x210x260 mm |

| Permissible fluid temperature | from +5 to +60 °С |

| Housing material | Steel |

| Weight of packed goods, kg | 3 |

| Packed goods dimensions, mm | 32x21x26 |

- compactness;

- metal casing (reservoir);

- comfortable rubberized handle;

- high-precision pressure gauge that controls parameters;

- The piston is made of strong brass resistant to corrosion.

- not detected.

Medium

Rothenberger RP 50

The manual German unit "Rothenberger RP 50" is used for accurate, quick testing of the working pressure, tightness of water supply structures, tanks, heating, sanitary equipment, compressors, steam, cooling, oil units.The device generates pressure in the test space, after which the operator closes the shut-off valve and observes whether the pressure gauge readings are falling. This establishes whether the water supply structure or container is airtight.

Constant pressure inside the unit is ensured by 2 valves, stainless steel spherical spindles. "Rothenberger RP 50" has a reliable tank with a capacity of 12 liters made of galvanized sheet steel, which can successfully withstand mechanical damage, the harmful effects of the environment, freezing, and does not rust. The machine has a piston made of metal, a pressure gauge 0-60 bar, the set includes a connecting fitting with a 0.5 inch nut.

Technical indicators:

| Options | Characteristics |

|---|---|

| Max fluid temperature | 50 °C |

| Volume of the tank | 12 l |

| Performance | 0.045 l/min |

| Type of | Manual |

| Test head | 60 bar |

| Connection to pipeline | Internal G1/2 |

| Working fluid | Water, oil |

| Rotor | Dry |

| The weight | 8 kg |

| Dimensions | 720x170x260 mm |

| Permissible fluid temperature | 50 °C |

| Series | RP50S |

| Housing material | Steel |

| Weight of packed goods, kg | 7.91 |

| Packed goods dimensions, mm | 535x195x357 |

- meets the high requirements of German workmanship;

- frost resistance;

- wear resistance;

- tank volume 12 l;

- consumption about 45 ml / cycle;

- connector R 1/2”;

- control hose with fabric braid;

- reduced risk of measuring errors due to hose quality;

- the possibility of using a pressure gauge with an accurate scale (0.1 bar) for testing up to 16 bar;

- high performance;

- fast filling with long stroke;

- ergonomic handle;

- The gauge pointer accurately indicates the set pressure, so head loss is easy to determine.

- not detected.

HP-60

The testing hand-held device "NR-60" was manufactured by a Russian enterprise, the device is equipped with a container and is used to check the tightness of pipes and tanks. The unit is able to withstand pressure up to 60 bar (6 MPa). The HP-60 is a multi-tasking tool, its measuring devices are located conveniently for the operator, who controls the readings of the main parameters.

The casing of the device is resistant to rust, it is convenient to carry it from place to place, in case of long-term storage it can be packed. The device is capable of pumping water, mineral oil, antifreeze. The HP-60 set includes: a tank with a capacity of 12 liters, a high-precision pressure gauge, a hose that can withstand increased pressure, 1.5 meters long. The unit will be needed in case of certification of various buildings and structures.

Technical indicators:

| Options | Characteristics |

|---|---|

| Brand | Reference |

| Working environment | Water, oil |

| Performance | 15ml/tact |

| Working fluid pressure, MPa | 6 |

| type of drive | Manual |

| Installation method | Outer |

| Tank capacity, l | 12 |

| Weight, kg | 11.04 |

| Overall dimensions, mm | 615x205x315 |

- rust resistance;

- works with water, oil.

- not detected.

Rekon

The manual tester "Rekon" is used for testing work. Due to the generation of water pressure, factory and home-made closed circuits are checked for leaks (heat supply, sewerage, solar batteries, refrigerator compressors. The device is capable of pumping oil, it is used during the production of boilers, compressed gas cylinders; pressure tanks, testing sprinklers.

Technical indicators:

| Options | Characteristics |

|---|---|

| Max fluid temperature | 60 °С |

| Volume of the tank | 12 l |

| Performance | 3 l/min |

| Type of | Manual |

| Test head | 60 bar |

| Connection to pipeline | External G1/2 |

| Working fluid | Water |

| Rotor | Dry |

| The weight | 8 kg |

| Dimensions | 500x190x290 mm |

| Minimum liquid temperature | -30 °C |

| Housing material | Metal |

| Weight of packed goods, kg | 8 |

| Packed goods dimensions, mm | 510x200x310 |

- rugged, comfortable metal construction for harsh environments;

- corrosion-resistant metal tank with powder coating;

- lever with an ergonomic handle used during carrying;

- wear-resistant brass construction with one-piece shut-off valve and pressure gauge with an accurate scale for reading changes in parameters;

- 2-valve stainless steel ball system increases reliability;

- high performance during the long stroke of the lever and accuracy with a small one;

- flexible reinforced high-pressure braided hose increases reading accuracy.

- not detected.

Expensive

Rothenberger RP Pro 3

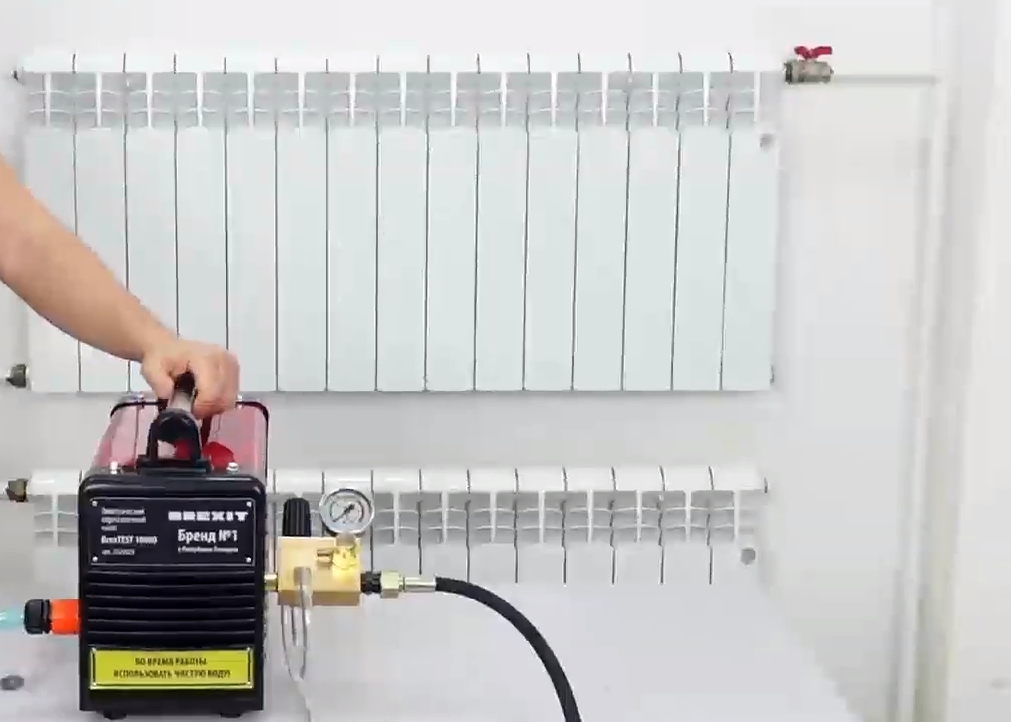

Your attention is an automatic crimping machine for testing "Rothenberger RP Pro 3", powered by electricity. It is used during testing of pipelines, water supply tanks, heating, air conditioning, fire extinguishing, sewage, irrigation structures, solar panels, other hydraulic and pneumatic systems, in the manufacture of pressure tanks, industrial boilers. The machine can withstand up to 40 bar.

Technical indicators:

| Options | Characteristics |

|---|---|

| Voltage | 220 - 240 V |

| Frequency | 50 / 60 Hz |

| The weight | 16 kg |

| Power | 1300 W |

| Current strength, A | 6 A |

| Pressure | 0 – 40 bar, scale division 1 bar |

| Dimensions (L*W*H) | 380*290*300mm |

| Threaded connection | R 1/2' |

| Performance | 6 l/min |

| Protection class | IP 32 |

| Noise level | 90 dB |

| High pressure hose length | 1.2 m |

| Engine oil | SAE 15W/40 |

| Supply hose length | 2 m |

| Maximum fluid temperature | + 40°C |

- compact, durable plastic housing, convenient to use on any construction site;

- strong, reliable single-phase four-stroke electric motor with a power of 1.3 kW;

- thermal switch prevents overload, damage to the pump;

- the test hose has a steel braid, preventing leakage during measurements;

- glycerine pressure gauge compensates for pneumatic shocks, making it easier to read readings during dynamic loads;

- pressure control valve with precise markings on the handle;

- automatic filling, leak testing of pipelines and tanks;

- free choice of liquid supply type: self-priming or pumping;

- quick overview of functions;

- used for water, oil, glycol, "typhocor".

- not detected.

OGS-100 EP-40

"OGS-100 EP-40" device with electric drive for testing water-bearing structures. It is used for pressure testing of tanks of various volumes, pipelines. "OGS-100 EP-40" operates in the Russian climate, in the ambient temperature range from 10 to 35 degrees. This series has category "U", GOST 15150-69.

The machine has the following features:

- checking the strength of pipes, engineering structures after installation or repair;

- applied during the commissioning of heating networks;

- detects leaks in heaters;

- used during the installation of tanks under pressure.

Precautionary measures:

- avoid contamination of the unit, hydraulic fluid;

- use only clean drinking water or VMGZ, I-12A, I-20A oils;

- periodically check and clean the inlet filter.

- after work and prolonged storage, always remove water from the hydraulic system by pumping it in a waiting order for a few seconds;

- do not work with water at temperatures below 0 degrees;

It is important to pay attention to the presence of lubrication in the built-in grease fittings and on each of the machine's three piston cavities.

Technical indicators:

| Options | Characteristics |

|---|---|

| Max head | MPa (kgf/cm²) 10/100 |

| Productivity, l/min | 40 |

| Overall dimensions LxBxH, mm | 730x400x650 |

| Overall dimensions of the water tank LxBxH, mm | 390x310x150 |

| Tank volume, l | 15 |

| Mass of the pressure tester, kg | 50 |

| Rated power, W | 2200 |

| Voltage, V/Hz | 220÷240 / 50 |

| Water supply | Pure drinking water, max. temperature 40°C |

| Length, mm | 2500 |

| Inner diameter, mm | 18 |

| High pressure hose dimensions: | |

| Length, mm | 1500 |

| Connecting hose to the system under test, inches | 1/2" conical male |

| Drain hose, mm | 2000 |

- 12 months warranty;

- electric drive;

- power 2200 W.

- not detected.

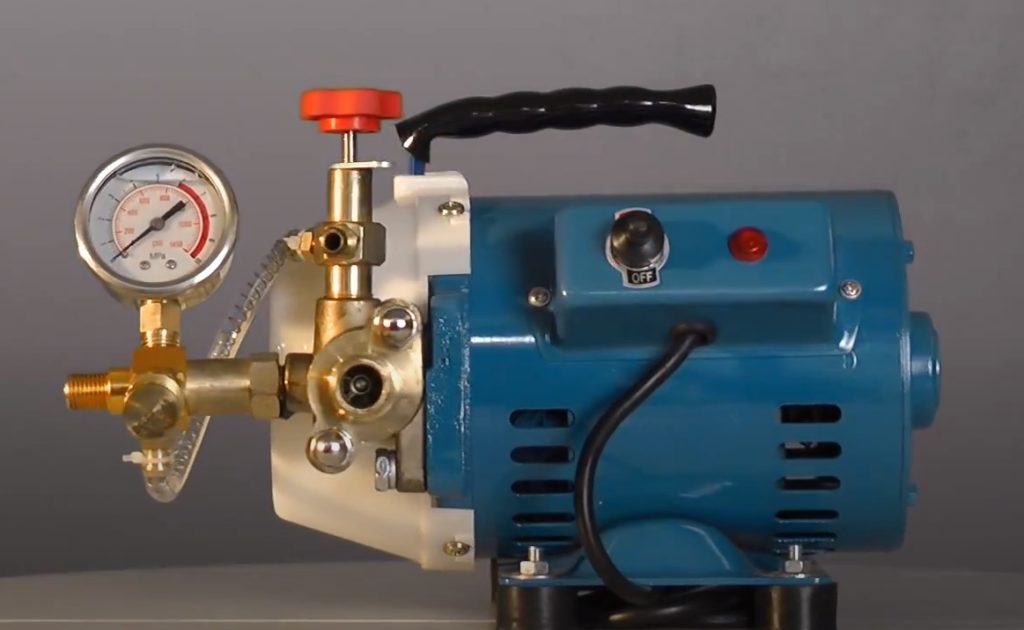

MGF Compact 60 905200

"MGF Compact 60" works thanks to the electric drive, withstanding up to 60 bar. The unit was created by an Italian company for pressure testing, filling, pumping liquids and non-acidic substances inside hydraulic structures. The increased pressure is generated by the powerful pistons of the mechanism. A reliable device can successfully resist rust, has a strong motor. Advantages of the MGF Compact 60 electric apparatus:

- the small mass of the device contributes to its faster transportation;

- reliable motor with power reserve;

- universal (EN 837) glycerine manometer with 3 different scales in basic units of measurement guarantees correct readings;

- no need to connect to a compressor;

- fittings made of stainless steel, brass;

- there is a filter element at the inlet, which reliably protects against dirt ingress;

- insulation class IPX5, work S1.

Technical indicators:

| Options | Characteristics |

|---|---|

| Gross weight | 15.2 kg |

| pressure gauge | + |

| Max. pressure | 60 bar |

| Voltage | 220 V |

| Performance | 7 l/min |

| Power, W | 1750 |

| Producing country | Italy |

| Current frequency, Hz | 50 |

| Overall dimensions, mm | 200x440x320 |

- accurate manometer;

- overheat protection;

- The convenient holder provides comfortable carrying.

- not detected.

Messer ТН 400Р

The Messer TN 400P unit, powered by an electric motor, is used to test various heating, water supply designs, pumps antifreeze, oil. If the device is additionally equipped with a high-pressure nozzle, a hose, it is possible to convert the Messer TN 400R at home, thanks to the increased volume of pumped liquid (7.5 l / minute), into a household or industrial device for washing cars, window glass, external elements of air conditioners.

Another way to use "Messer TH 400P" is the spraying of agricultural agrochemicals. The machine is sold in a cardboard box, the kit includes: water intake hoses 2.5 m long, high pressure 1.2 m and discharge; primary filter, pressure gauge, stopcock.

Technical indicators:

| Options | Characteristics |

|---|---|

| Max liquid temperature, °C | 40 |

| Power, W | 370 |

| Productivity, l/min | 7.5 |

| Type of | Electric |

| Test pressure, bar | 30 |

| Working fluid | Water |

| Rotor | Dry |

| Dimensions, mm | 358x288x261 |

| Permissible liquid temperature, °С | 40 |

| Voltage, V | 220 |

| Series | TN |

| Housing material | Aluminum |

- accurate manometer;

- the regulator makes it possible to easily and quickly change the pressure;

- the device can spray agrochemicals;

- coarse filter;

- convenient holder for carrying;

- can be used as devices for washing cars, window blocks, and other surfaces.

- not detected.

We hope the step-by-step instructions described above answered your question: “How to choose the right crimping machine?”

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131654 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127694 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124521 -

The best men's sneakers in 2022

Views: 124037 -

The Best Complex Vitamins in 2022

Views: 121942 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2022

Views: 113398 -

Ranking of the best wood paints for interior work in 2022

Views: 110321 -

Rating of the best spinning reels in 2022

Views: 105332 -

Ranking of the best sex dolls for men for 2022

Views: 104370 -

Ranking of the best action cameras from China in 2022

Views: 102218 -

The most effective calcium preparations for adults and children in 2022

Views: 102014