Ranking of the best fire retardant paints for 2022

The power of fire is not easy to control, it is more profitable for a person to take preventive measures than to solve problems after a fire. To ensure the prevention of building fires, there are appropriate means: from paint coatings to extinguishing systems. Fire retardant paint will be the first step to ensure the greatest safety of the premises.

The owner, who is not familiar with the elementary basics of safety, assumes that the role of the coating is insignificant in matters of preventing the spread of fire. Such beliefs lead to trouble, because you should not neglect the basics. A person interested in protecting a building from fire is advised to familiarize himself with the most important provisions regarding the principle of operation of specialized paint.

Content

Fundamentals of fire prevention

It is important to understand that a specialized coating does not have the function of extinguishing a fire. The agent protects the treated surface from the destructive action of the flame. More specifically, a fire that has arisen inside the building is not able to destroy the walls on which the funds are applied, as well as things treated with fire retardant paint.

The tool received a similar property due to its constituent components, which provide a momentary hardening of the substance upon contact with an irritant. The coating is made (traditionally) from a fire retardant filler, coloring pigment elements and a silicate product.

In addition to their direct purpose, refractory agents can have the effect of conservation for the working surface. For example, there are brands of coatings for metal that will also protect it from corrosive and other harmful influences. There are also products for wood products that have an additional function for the material being processed.

Protection of metal products

A fire can also have a harmful effect on a metal surface, so the owner of a building that houses functional elements made of this material should think about protection.The market offers a wide range of coatings for the protection of metal products, a potential buyer should consider in detail the most popular positions.

Fireproof paint from Plumcore-4

Paint from Plumcore includes cement (Portland), fillers with fibers, and a foaming agent. Upon contact with an open flame, it produces a protective cushion, which prevents the painted structure from igniting. The tool is allowed for processing both in civil and legal buildings, as well as in public places. Complies with legal regulations, licensed, average consumption is approximately 0.5 liters per m2.

- Additionally, it has an insulating effect on noise, and also retains heat inside the room;

- Resistant to moisture and vibrations;

- Facing work is allowed, but only with materials that are resistant to combustion;

- Nice color and texture.

- Not the most economical position.

Review:

“I painted the load-bearing poles in the trading pavilion with this tool, the color is pleasing to the eye. It is easy to apply, unpleasant odors disappear quickly. I recommend it to anyone who is looking for a reliable refractory mixture for metal structures!”

Solution from Teksoterm for metal (enamel)

The manufacturer guarantees decent protection of metal structures, thanks to a well-thought-out balance of the components of the composition. It is usually used for the protection of steel products in the construction of legal and civil buildings. It is popular due to the quality of the paint.

Remarkable increased adhesive performance, which means a strong compatibility of the paint with the metal surface. Despite the strong adhesion, the primer should not be neglected.The manufacturer assures that the coating is resistant to mechanical damage. It should be borne in mind that with a temperature drop (it becomes hotter by more than 10 °), the material produces minimal swelling, which does not affect the quality of further use.

- Dries in a short time;

- Large amounts of work per approach are acceptable;

- Does not require specific preparations before staining.

- Mixed reviews.

Review:

“I isolated the gazebo in the yard just in case with this paint. It dried quickly, no unpleasant odors were noticed, there were no difficulties in the work. Would recommend to anyone looking for fireproof paint for metal at an affordable price!”

Refractory mixture from Defender Ak 121 25

Paint from the company Defender brand Ak 121 consists of components related to organic, in addition to the refractory properties, it gives resistance to corrosion and other harmful factors. It is applied with a minimum layer on the structure, does not contain toxins, meets the requirements for environmental friendliness.

The paint produces a protective layer in the form of a film based on carbon, which prevents the spread of fire on the surface of the structure. Carbon protection is resistant to the destructive effect of fires, therefore it is able to ensure the safety of the treated object for a long time.

- Reliable blend;

- Eco-friendly composition;

- Brand reputation.

- Not the cheapest paint on the market.

Review:

“The workshop was treated with this paint, because acquaintances spoke of the brand extremely flatteringly.During operation, there were no difficulties, the mixture was diluted and the supporting pillars were processed. There are fewer reasons to worry about the safety of the workshop building. Would recommend to anyone who is looking for a fire protection paint for metal!”

Protection of wood products

The tree is extremely popular among the people as a building material due to its low cost and ease of (relative) installation. Wooden buildings are able to provide the owner with relative durability, resistance to frost and the reliability of the structure as a whole. There is one significant drawback in the construction of wood - this is its increased flammability. Although according to the construction technique, the processing of material from combustibility, pests and other factors is mandatory, and in the case of buying lumber in a store, the buyer receives a deliberately prepared product, it should be borne in mind that it is not worth saving on the issue of fire safety and wood.

Since ancient times, the issue of fire resistance of wood has been given utmost attention. Products from this material (from military equipment to residential buildings) were subjected to the application of a protective layer of a mixture of salts with acetic extracts. Such measures gave impressive results, but modern technologies are an order of magnitude superior to the methods of their ancestors.

The solutions presented on the modern market include complexes of components, and the balance of the composition is carried out at the level of licensed professionals. Current impregnations concentrate protection on the surface layers of wood, providing strong protection to the main layers.

Titan D (for wood)

The paint contains components that form a massive protective layer upon contact with an open fire. It does not affect the texture of the work surface.The manufacturer took care of the environmental friendliness of the product, which eliminates toxicity, so the buyer should not worry about the purity of the air inside the painted room.

The product complies with legal requirements, is licensed. Standard can - ¼ l. Popular, easy to use.

- Acceptable cost;

- Positive reviews;

- Ease of use.

- Not always available.

Review:

“Treated the summer cottage with this remedy, now there are less worries about fires. It is applied without problems, the main thing is to prepare the walls for painting with appropriate means (non-combustible). I recommend it to anyone who is looking for fireproof wood paint of acceptable quality at an adequate price!”

Refractory composition from Neomid (for interior)

The mixture from Neomid is designed to protect objects inside the building: furniture, cabinets, chests of drawers and other accessories. With the help of this paint, the buyer will not only protect the internal utensils from the harmful effects of a fire, but also give it a pleasing look, get rid of the destructive effects of parasites and moisture, and strengthen the wooden product as a whole.

In the basic configuration, the buyer receives a white tint paint, which is combined with additional tone changers. Users note that the paint is best combined with additives that create creamy shades. It is important to keep in mind that additional funds can only be used in a proportion not exceeding 5% of the volume of the main paint.

- Pleasant appearance;

- Adequate cost;

- Additional functions.

- Not found.

Review:

“I use this paint not for the first time, when I used it on the previous object, I was pleased with the overall look and ease of use. I recommend it to anyone who is looking for compositions of pleasant shades for fire protection!”

Ecofire on wood

The mixture from Ecofire is notable for its increased plasticity properties. Also, the dried paint appears as a monolithic coating without roughness, cracks and bumpy granules. In terms of appearance, the product from Ecofire is not inferior to decorative type paints.

Most of this product is used to provide protection in legal, industrial, private buildings, as well as in common areas involving metal structures. It should be noted that the consumption of the product is moderate, which reduces the cost of bulk purchases, if it is necessary to color impressive volumes. No thick layer is required to achieve a consistent level of protection, which also reduces costs and downtime. The packaging from the store initially carries the prepared solution, which means that the master is freed from preparatory work, including dilution of the material. The product does not contain components that can significantly clog the application device, which saves time on cleaning the tool. The material has strong adhesion, due to which it is combined with an impressive number of surfaces (it is not recommended to neglect the primer).

For application, it is necessary to prepare the surface by means of a primer, then prepare the tools. In the absence of pneumatic tools, it is necessary to turn to classic rollers or brushes.The package contains advisory instructions on the method of staining, if the master doubts his own technology, it is recommended to consult the manufacturer's advice.

- Strong adhesive properties;

- manufacturer's reputation;

- Nice color and texture.

- Not the lowest price tag.

Review:

“We painted the load-bearing beams in an industrial building, we were satisfied with the color. Although the price is not the cheapest, you should not save on safety. I recommend it to anyone who is looking for paint in aesthetic colors and textures to protect metal structures!”

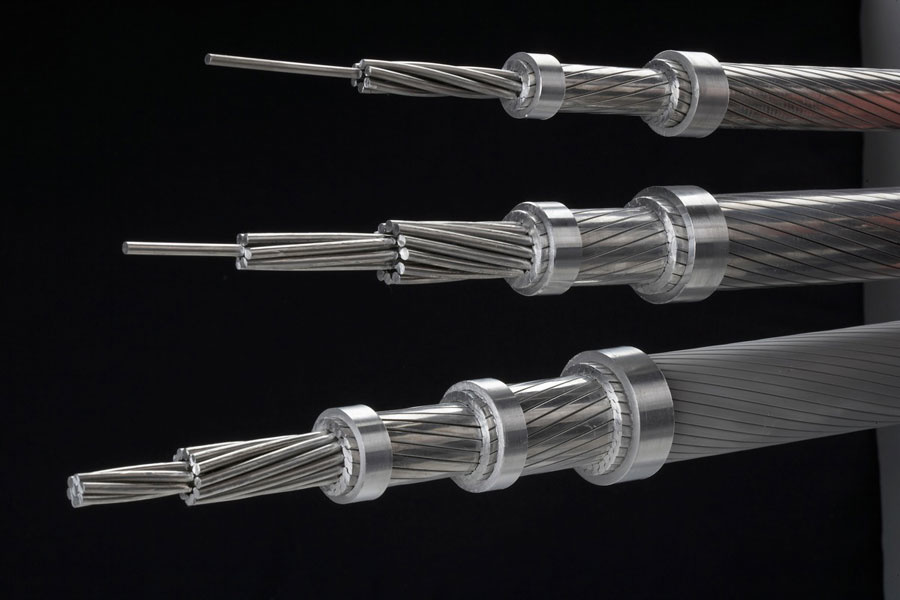

Cable protection

Such compositions are necessary in wiring places that do not allow factory insulation. Cable protection due to paint is necessary to stop the spread of fire over the wiring area. The composition of specialized mixtures includes elements that, reacting with open fire, take the form of a foam pillow, due to which the painted wires increase in size several times.

If there are unprotected sections of the building's wiring, the owner undertakes to insulate the surface of the cables using refractory mixtures. To carry out such work, it is necessary to resort to the help of licensed professionals; it is not allowed to independently produce insulation.

For cable insulation Neomid 030 Professional

It is necessary to degrease the wires before proceeding with the application. It is important to ensure that there are no defects in the basic insulation. It is allowed to dilute the solution by means of water, to interfere only at low speeds. The addition of water is permissible until the most convenient consistency for application is obtained, but it is forbidden to cross the line of 1/10 of the total volume of the composition.

Degreasing and cleaning of the working area must be carried out exclusively with non-flammable means. It is forbidden to use gasoline, alcohol and alcohol-containing compounds for the primary processing of cables. Also, tools that pose a danger to the integrity of the cables are unacceptable. When interacting with the paint, it is necessary to wear protective equipment (eye protection, work overalls, specialized gloves). In case of contact of the solution with the mucosa, it is necessary to use water to cleanse the damage, in severe cases, it is necessary to go to the hospital without delay.

- Acceptable cost;

- Ease of use;

- manufacturer's reputation.

- Not found.

Review:

“I treated the cables in my house with this paint with the help of a professional firm. According to the masters, there were no difficulties during application. They diluted it with water, and the work went effortlessly. I recommend it to anyone who is looking for insulation for wires at an adequate cost!”

For insulation of cables Fire Vd-K

The mixture from the company Ogneza has gained a reputation for reliable insulation for unprotected sections of cables. Suitable for standard wiring categories, convenient to use. In addition to the main function, it will provide protection from small pests, such as rodents.

- Adequate price tag;

- Additional protection against pests;

- Ease of wiring.

- Not found.

Review:

“I use this composition all the time to isolate cable sections that require it. There are no difficulties in the work, in addition, the mixture provides additional protection against pests. Would recommend to anyone looking for reliable wiring insulation!”

Outcome

Firstly, the owner needs to cover the main elements of the building, which are required by law. Usually, these are load-bearing elements, pipe lines, electrical communication points, fire safety elements. Depending on the specifics of the building, additional individual requirements are imposed. After processing the main parts, it is worth taking up the walls. To obtain the best fire resistance, it is recommended to cover as many surfaces as possible that are at risk. If the owner is interested in the safety of fragile things (small souvenirs, documents), it is worth placing them in a safe, and the safe is inside a box painted with a refractory composition.

It is recommended to entrust fire safety finishing to specialists whose services are presented on the market in a wide range. Self-painting of surfaces is allowed, but to get the best effect, this should be entrusted to specialists. In addition, buildings for which a legal status is assigned (state institutions, commercial organizations, entertainment centers) are not allowed for self-processing. Finishing work on the part of security in such premises is carried out exclusively by professionals with a license for the relevant activity from the Ministry of Emergency Situations. The above requirements are supported by legislative norms, so do not neglect this recommendation. In addition, experts offer quality and guarantees that the owner will not receive during self-processing.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131662 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127701 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124527 -

The best men's sneakers in 2022

Views: 124044 -

The Best Complex Vitamins in 2022

Views: 121948 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114986 -

The best paint for gray hair - top rating 2022

Views: 113403 -

Ranking of the best wood paints for interior work in 2022

Views: 110330 -

Rating of the best spinning reels in 2022

Views: 105336 -

Ranking of the best sex dolls for men for 2022

Views: 104376 -

Ranking of the best action cameras from China in 2022

Views: 102224 -

The most effective calcium preparations for adults and children in 2022

Views: 102019