Rating of the best sewer check valves for 2025

Clogged drains are an extremely annoying problem, often leading to very dire consequences in terms of home comfort. The reason for the occurrence of such circumstances may be improper installation of the sewer system or a gross violation of its operating conditions. To prevent blockages and the formation of traffic jams (along with the occurrence of persistent stench), the equipment of the check valve complex (stop valves or OK) will help.

Content [Hide]

- 1 Check valve - purpose and principle of operation

- 2 Mounting methods for certain types of OK and additional options

- 3 Standard Mounting Procedure for Check Valves

- 4 Basic rules for operating OK

- 5 Difficulties of choice

- 6 Rating of the best sewer check valves for 2025

- 7 Conclusion

Check valve - purpose and principle of operation

The main purpose of the shut-off valve system is to block the passage of sewage in the opposite direction in the pipeline. The main scope of the considered devices is not limited only to their installation in private houses - the installation of OK will also be relevant for residents of apartments on the ground floors in multi-storey buildings. Among other things, this equipment will also prevent small rodents from entering the apartment, often using sewer access. The most popular diameter for check valves is 110 millimeters. It is this size that allows you to combine the device with various pipelines. The node itself is installed on a common sewer outlet from an apartment / private house. The design of shut-off valves consists of the following components:

- Body made of plastic/metal;

- Sealing disc, whose job is to block the pipeline from the reverse flow;

- A spring made of steel, through which the disk described above is held (it is compressed due to water pressure);

- Forced opening element.

The principle of operation of the device in question is intuitive: the disk, under the influence of sewage, rises, and the flow is directed to the sewer line. As the drain is completed, the disk closes the cavity of the outlet pipe, and this will prevent the return of sewage water. The closing / opening process is provided by a spring.

Modern Types of Check Valves

They can be classified according to many technical features, but their design features will always be the main ones.

- Ball

The action of OK data is based on the movement of the ball, which is pressed against the "saddle" by the spring. The design is considered quite reliable and is used, as a rule, in highways with low traffic flow.

- Swivel

The mechanism looks like a flap, which is fixed in a pipe segment. It only deflects if the flow is in a certain direction. If the flow goes in a different direction, then the flap slams shut, and the disk sits in the “saddle”. This design is considered extremely robust for use in highly polluted environments and performs well in lines with a large pipe diameter.

- Spring (lifting)

Their design is somewhat similar to a shut-off valve, the difference lies in the method of unlocking the shutter. It works not as a result of human impact, but under the pressure of a liquid drain. The pressure itself provokes the unlocking of the shutter, from which the drain occurs.As the fluid pressure decreases, the valve lowers into the “saddle”, thus preventing the flow of the drain in the opposite direction. Such OKs perform well not only on horizontal sections of highways, but also work great on vertical risers. However, the design has a significant drawback. It consists in a special sensitivity to the level of contamination of the passing fluid, which often provokes jamming of the mechanism.

- double leaf

This type of OK received such a name due to the presence in its design of two wings, which are installed on the axis of the flow section. These parts are unlocked only with fluid flow in a single direction, which is marked with an arrow on the body of the product. As the fluid movement weakens, the flaps will straighten out and close. This design is not suitable for pumping heavily polluted streams carrying large solid fragments, because this will be fraught with a loss of pressure. However, double-leaf models can handle complex liquid media (eg sea water, oil products, etc.). When mounting such a mechanism, one should accurately take into account the conditions for its future use - this is necessary to select the appropriate seal for the disc (it should not be too susceptible to aggressive environments).

- Wafer disc

The device is a single-leaf disk connected to a rod on a spring. When pressure occurs, due to the force of the pressure of the liquid, the spring will be wrung out, simultaneously opening the passage in the line. And when the flow weakens, the disk gets into the "saddle", sealing the through hole.The advantage of this system is its compactness and light weight along with simple installation (installation is allowed in any position).

Materials for the manufacture of locking equipment

The considered type of shut-off valves can be made of various materials. If we talk about metals, then they can be steel or cast iron. Products from them are usually equipped with excellent fasteners and high-quality rubber gaskets. Synthetic models (this is PVC or plastic) are focused exclusively on modern versions of sewer pipelines. If they are mounted on old metal pipes, then special adapters will be required. Other popular materials include:

- Polypropylene;

- Stainless steel;

- HDPE;

- Brass;

- Bronze.

The last two positions belong to the category of elite plumbing and are very expensive.

Mounting methods for certain types of OK and additional options

According to the method of installation, the considered valves can be divided into:

- Flanged method - installation is carried out by using appropriate flanges, and tightness is achieved by using special sealing gaskets.

- Wafer method - usually used for home networks and is the use of the most standard outdated technology from the late USSR.

- Welded method - it is used to form especially tight couplings, where the strength of the connection is put "at the forefront". The main advantage of this method is that the valve will not require third-party maintenance and is suitable for any pipeline. Use in home sewer networks is allowed.

- The coupling method is the most modern type of installation, in which the device is fastened by screwing the valve onto pipes that are equipped with a coupling with a seal.

For the latter method, different connection types can be used:

- BP / HP - internal thread with external thread (the so-called "butterfly");

- HP / HP - only on the external thread;

- BP / BP - only on the internal thread.

Conditional (average) pressure

This parameter must be taken into account when choosing an installation method and means the pressure of the working fluid medium. Can be 10, 16, 25 or 40 bar.

Presence of a filter

Some OK products have a special filter. In most models, this role is played by a regular mesh, which is mounted in front of the outlet, but the presence of a filter will better prevent possible clogging of the equipment. However, the filter will have to be periodically cleaned from large fecal fractions stuck in it (during the passage of the flow).

Water seal (siphon)

This component is highly desirable for any device that is installed on a sewer system. It is a simple piece of equipment made in the form of a curved outlet fitting that holds a small supply of water. The device is designed to perform the function of cutting off the environment (odors) of the sewage system from the internal microsphere of the room. It usually looks like a bowl with an outlet. The device is connected to the drain hole as an independent component. This type of installation facilitates both initial installation and subsequent replacement in case of wear or damage.

Standard Mounting Procedure for Check Valves

The installation of shut-off valves will consist of the following steps by default:

- Performing a visual inspection of the installed product. It should not contain any internal or external scratches, cracks, chips and other deformations.

- Checking the performance of the valve itself, by supplying water from both sides to the nozzle of the device. So you can quickly identify and eliminate possible minor defects in the form of a slight leak of liquid, or immediately return the product under warranty.

- Determining the direction of installation of the device, which is marked with an arrow on its body. With this marking, you can accurately orient the device in relation to a common collector or drain well.

- Before starting the direct installation process (if we are talking about an apartment building), you should block the riser, having previously notified the residents about this. The use of water during the installation period will not be possible.

- If the materials (as well as the diameters of the branch pipe and pipe) of the manufacture of the OK and the line itself are different, then special adapters should be prepared and installed in advance.

- The installation process itself consists in sequentially connecting the corresponding holes to the sewer pipes, with the obligatory complete fixation of all joints.

- When connecting, each joint is subject to mandatory sealing.

- After completing the installation and unblocking the riser, it is necessary to check the overall performance of the system for tightness, for which it is necessary to perform several consecutive drains. All identified deficiencies are subject to immediate elimination.

Basic rules for operating OK

Check valves, like any shutoff equipment, will require some maintenance. Timely replacement of worn-out elements will help to avoid unexpected flooding of the room.For private houses, the frequency of cleaning valves from debris is 3-4 times a year, for an apartment building a little less often - 1-2 times a year. If during the operation of the valve an uncharacteristic rattle or creak is heard, extraneous noise, then it must be immediately checked and an unscheduled cleaning should be carried out. It should be noted that the wear resistance resource of each component in the device under consideration must be indicated by the manufacturer in the instructions for it. Most parts can be replaced under warranty, and if it has expired, then it is better to change the entire device.

Difficulties of choice

Before buying a check valve, you should pay close attention to the following technical points:

- Pipe diameter - i.e., the size of the diameter of the pipe to which it can be connected. Most models on the modern Russian market have a connection by bells.

- Material of manufacture - most manufacturers today are focused on the production of plastic products that are supposed to be used for sewer lines from the same (or related) material. If the line consists of cast iron pipes, then it is better that the valve is cast iron. Naturally, current technologies also involve the insertion of polymeric devices with the implementation of a connection based on a special transition cuff, but a homogeneous material is preferable. At the same time, professionals note that high-quality metal models are equipped with stainless steel dampers.

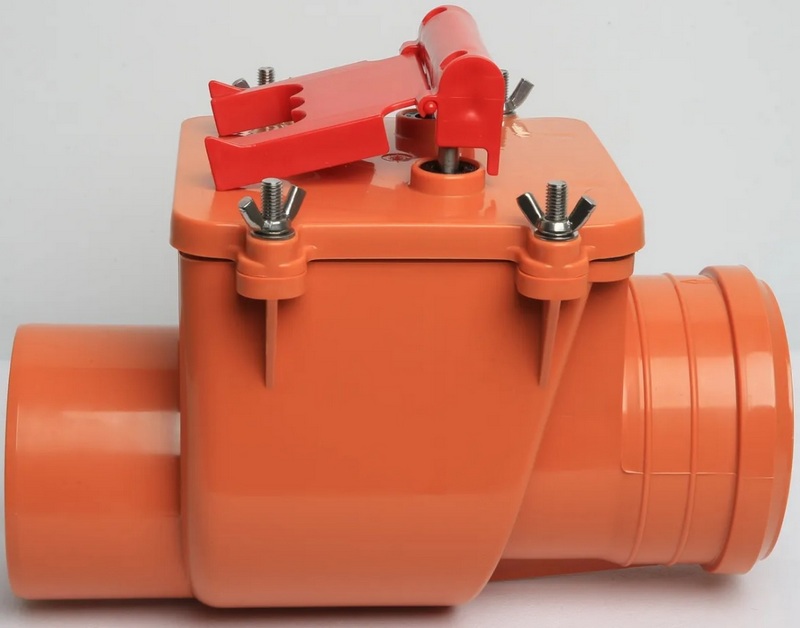

- Place of installation - there are samples that are recommended for installation only indoors, they have a classic gray color. Orange products are allowed to be placed both inside and outside the building.They are called universal and they are made of more durable materials that can withstand significant mechanical loads and significant temperature fluctuations.

- Working capabilities - the technical information for each product indicates the possibility of its work either only with liquid effluents, or it has the additional ability to pass some fecal matter through itself. At the same time, a recommendation is given regarding the spatial position of the installation (it can be strictly defined or universal).

- Dimensions - special attention should be paid to them, which will be relevant if installation must be carried out in a limited space.

- The maximum allowable working pressure - it should not be less than the working pressure in the pipeline of the sewer network where the installation is planned.

- The option of forced closing of valves - this option will become more justified for private houses, where the pipeline does not have a special length.

- The reputation of the manufacturer - before buying, you should get as much information about the manufacturer's brand as possible, while at the same time paying attention to the presence of the company's warranty obligations and their duration.

Rating of the best sewer check valves for 2025

Internal

4th place: "SantekhMir" OK sewer internal horizontal "

votes 0

The model is equipped with a locking damper made of profiled stainless steel, has a reed seal, an inspection cover with connecting outlets for PP, PVC socket pipes. It is possible to lock the damper in the closed state using a manual lock with a safety lock against spontaneous closing. Production material - ABS plastic. The recommended cost for retail chains is 876 rubles.

- Modern material of manufacture;

- Cheap price;

- The simplest installation.

- Not detected.

3rd place: TATpolymer OK 50 mm

votes 0

The sample has a horizontal outlet and is used in internal sewage systems. The valve prevents the reverse flow of flows in case of clogging of sewer pipelines, and also serves as an obstacle to the penetration of insects into the room. The body is polypropylene. The recommended cost for retail chains is 926 rubles.

- Maximum operating temperature - +60 degrees Celsius:

- Light weight - 117 grams;

- The feed direction is one-sided.

- Pass only liquid medium.

2nd place: "Miano 50 mm (M0601)"

votes 0

The product is used to protect the premises from sewage, to eliminate unpleasant odors in the event of an emergency. This fitting is indispensable when installing the sewerage system of a private house. The case is made of shock-temperature-resistant plastic, is not subject to corrosion and rotting. There is a handle for emergency shut-off of the drain with the possibility of cleaning. The snug fit of the inner lid (stainless steel) prevents the penetration of odors and small rodents. Minimal installation/operation costs. The recommended cost for retail chains is 1526 rubles.

- Durable manufacturing material;

- Socket type connection;

- Stainless steel disc.

- Not detected.

1st place: "ZB horizontal, grey, version A, "Karmat ZB50-AS"

votes 0

The model is intended for installation in a horizontal position.It is mounted on pipes with a diameter of 50 mm, which are fixed to the wall with fixing clips. The product is able to create reliable protection for several plumbing fixtures at once, if they are connected to a single installation. The device is equipped with a manual lever. It makes it possible to completely block the passage, preventing the reverse flow of wastewater.

Additionally, the valve does not allow unpleasant odors from the sewer to enter the room. An important advantage is the presence of a self-cleaning function. The valve has a perfectly smooth surface from the inside, on which dirt and fats do not settle. The polymer belongs to environmentally friendly materials that do not emit toxic and harmful substances for human health and the environment. Valve fasteners are stainless steel type 0H18N9. All gaskets and sealing materials are made of flexible polymer. Gaskets are not afraid of wear, designed for a long service life. The recommended cost for retail chains is 2880 rubles.

- Extended service life;

- Opposition to the settling of fats;

- Quality foreign brand.

- Not detected.

Universal

4th place: "110 mm" DAVETI "

votes 0

The sample is designed to effectively protect the premises located on the lower floors of buildings from flooding by the regressive flow of sewage or rainwater. Back pressure can be caused by intense precipitation, thaw or flooding. The location can be both external and internal. Clear drawing instructions for installation are included. The recommended cost for retail chains is 1925 rubles.

- High-quality manufacturing material;

- Dense rubber gasket;

- Work with various types of liquid.

- Not detected.

3rd place: "RUVINIL" 110 mm for external sewerage"

votes 0

The model is designed to automatically block wastewater in the event of a backflow, which can be caused by sewer blockage, pump shutdown or rodent intrusion. Connection diameter - standard, production material - polypropylene. The recommended cost for retail chains is 2126 rubles.

- Vertical/horizontal installation;

- Adequate cost;

- Durable manufacturing material.

- Not detected.

2nd place: "FLEXTRON" for external sewerage 110 mm"

votes 0

The sample is recommended for installation in private houses, apartments, office premises, in production, etc. Designed to protect against the flow of drains in the opposite direction. The principle of operation is mechanical: with the correct direction of water flow, the damper deviates and ensures unhindered passage of the flow, with the opposite direction of water flow, the damper completely closes the pipe section and does not allow the flow to pass beyond the valve. Horizontal mounting only. It is mounted in places that allow separating the internal sewerage from the external one (for example, in the basement of the house, in the pit outside the building, at the outlet of the sewerage from the apartments and offices of the lower floors into the common pipeline of the building). The inlet/outlet fittings of the valve are designed to be connected to any sewer socket pipe made of polypropylene or PVC with a diameter of 110 mm. It is possible to work through adapters.The recommended cost for retail chains is 2700 rubles.

- High tightness;

- Durable manufacturing material;

- Warranty - 50 years!!!

- Not detected.

1st place: "ZBK horizontal exhaust "Karmat ZBK110"

votes 0

The product is intended for installation on sewer pipes with a diameter of 110 mm. The valve does not depend on power sources and operates in automatic mode. The design of the device is made of modern polypropylene. The composition of the polymer includes a special stabilizer, which gives the material special properties. The stabilizer increases the resistance of polypropylene to ultraviolet radiation, temperature extremes (up to +95 degrees Celsius). The polymer is completely safe and non-toxic for the environment and humans. Polypropylene is not affected by chemically aggressive compounds. The manufacturer used a unique connection system in the device. Thanks to this feature, the valve can be installed on drainage or corrugated pipes. The design is equipped with modern gaskets patented by the brand. The valve has a blocking brass ring. The gasket guarantees the reliability and tightness of the connection several times better than similar devices provide. The seal is made of ethylene propylene rubber. Also, the product is equipped with a chromium-nickel damper and casing. Due to this, rodents and insects will not penetrate into the premises through plumbing fixtures. The valve is installed at the end of a sewer pipe that discharges wastewater into a collection well, cesspools, rivers or reclamation ditch. The recommended cost for retail chains is 4700 rubles.

- Stainless steel disc;

- Blocking ring made of brass;

- Increased tightness.

- High price.

Conclusion

The type of protective fittings under consideration has long become almost an indispensable element of the sewer system in any home. Its main purpose is to prevent the uncontrolled return of drained / waste fluid from the sewer, protecting the room from flooding with fecal water. Most modern models can successfully perform this task, however, for their effective application, some of their technical features should be studied.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131653 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127694 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124521 -

The best men's sneakers in 2025

Views: 124036 -

The Best Complex Vitamins in 2025

Views: 121942 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2025

Views: 113398 -

Ranking of the best wood paints for interior work in 2025

Views: 110320 -

Rating of the best spinning reels in 2025

Views: 105331 -

Ranking of the best sex dolls for men for 2025

Views: 104369 -

Ranking of the best action cameras from China in 2025

Views: 102218 -

The most effective calcium preparations for adults and children in 2025

Views: 102013