Rating of the best scissors for cutting polypropylene pipes for 2022

While it is possible to use any improvised tool for cutting pipes for domestic purposes, for example, various saws and grinders, such devices are unlikely to work for cutting a main pipe made of polypropylene (PP). There are two reasons for this: in the resulting cut, the vertical angle of the butt is more likely to deviate from the standard of 90 degrees, and the inner and outer walls of the pipeline will be replete with burrs. For this reason, the installer will have to spend additional time to eliminate such defects, which, with a large amount of work, will take more than a few minutes or even several hours. At the same time, overall productivity will decrease and time costs will increase. Therefore, it is more logical to use specialized tools, for example, scissors, which will completely avoid these problems.

Content

Scissors for polypropylene pipes

This device is one of the main tools that are used in the process of installation / dismantling of pipes made of polypropylene of small diameter. They can be used both for domestic purposes and for laying long trunk lines, which include internal water supply systems and other plumbing lines. In all modern modifications of scissors, in order to ensure a cut at a right angle, a semicircular platform of small width with a slot is located below, into which the pipe and the cutting blade (descending from above) are conveniently placed and which sticks into its shell.

Most scissors have a lever-type design with a blade that will naturally dull quickly during use. However, this situation should not become a problem, because replacement blades are often supplied immediately in the kit, and in extreme cases, a worn cutting element can always be sharpened again.

Modern types of scissors can work with polypropylene pipes with a diameter of up to 75 millimeters, but the standard limit for most models has a maximum of 63 millimeters. However, practice shows that pipes with a diameter of more than 42 millimeters are rare.

Thus, polypropylene pipe shears have the following working qualities:

- Allow to achieve high cutting speed;

- By themselves, they are compact, convenient in the process of storage and installation of pipes, able to perform their functions in a limited space;

- Their wide range of modifications and relatively inexpensive cost allows you to choose the right tool for almost any type of work.

However, they also have a couple of drawbacks. These include:

- Spring options load the operator's hand very heavily, forcing him to exert significant muscular effort (this drawback is especially felt when performing a large amount of work);

- Spring scissors do not allow you to make a one-time cut with one hand more than 25 millimeters;

- In cases where the blade is poorly sharpened, burrs and other traces of excessive deformation will inevitably appear on the walls of the pipeline.

In this regard, scissors with a ratchet mechanism are significantly superior to spring ones, because their mechanism on the teeth allows you to make not one single long cut, but several small ones, by repeatedly pressing on the handle. The return of the cutting element to its original position occurs either by pressing a special button, or by turning a special lever, or by simply spreading the handles.

Due to the fact that it is not required to apply significant muscular efforts on ratchet devices, the operator’s hand does not get tired much, however, the time of the cutting procedure will still increase. It is worth noting that repeated pressing and step-by-step eyeliner are the key to maintaining a neat cut line, moreover, with step-by-step cutting, it is more convenient to keep the workpiece in a completely perpendicular position with respect to the tool, which means that the cut will always have the required 90 degrees vertically. However, both ratchet and spring scissors have the only problem - when working with a poorly ground cutting part, there is a high risk of jamming the inner / outer walls of the propylene pipe.

Tool for cutting pipes made of polypropylene with an increased diameter

In order to lay water supply lines for indoor use in public utilities and households, products with a diameter exceeding 42 millimeters are extremely rarely used, and most scissor models are designed for this diameter. For polypropylene models with a diameter of 50 and 110 millimeters (such circles have classic sewer lines), they use a different type of toolkit that guarantees quick and convenient cutting.

pistol type

This cutting device visually resembles a pistol in shape. To make a cut, the pipe is located on a semicircular platform in front, and the cutting element is brought to it from the side by repeatedly pressing the handle (again, a ratchet mechanism is used in the design). The return of the blade to its original position is carried out by pressing a special button.And here it should also be noted that the ratchet method again wins over the spring one, since it involves the application of less effort on the part of the operator. In the pistol type, the cutting parts may be replaceable or may be re-sharpened.

Roller type

The main element for cutting in this tool is a rotating roller with sharp edges. The classic roller device for propylene pipes is enclosed in a semicircular body with a handle in the form of a regular platform with a roller mounted on a retractable pulley. During operation, the pipe is located on a special seat (which is sometimes equipped with a built-in cylindrical roller for the purpose of convenient turning of the pipe), and a special wheel is brought to it to make an incision. Further, the workpiece rotates around its own axis in several revolutions until the desired fragment is separated from the main part. In some cases, it is possible to remove the workpiece and simply break it off along the notch.

The roller type is the most preferred when working with plumbing and external sewer products, as its models are specially made to process specific diameters. In the body of the tool itself there are through holes where you can insert the workpiece. At the same time, the roller can cut through it independently, or the workpiece, passing by rotation along the roller, will cut itself off.

Features of roller tools include:

- Ability to cut polypropylene pipes with a large and specifically set diameter;

- During the cutting process, the risk of jamming the walls of the processed object is minimal;

- The forces applied for operation are significantly lower than those of the spring or ratchet type;

- To carry out the work, it is only necessary to accurately calculate and adjust the force of the roller “on the clamp” in order to obtain a smooth and completely matching cutting line.

Guillotine type

This standard tool has a rather simple design, which consists of a blade moving along guides and a figured platform for placing the pipe. With this device it is possible to cut polypropylene products in diameter from 50 to 350 millimeters. The cut of the guillotine type is extremely even and at the same time the requirement for a cut angle of 90 degrees is observed. The device can be operated either manually or with an electric motor.

With the manual method, the blade is lowered by applying muscular force to the screw rod. This method improves the quality of the cut edges while reducing the risk of jamming. However, the mechanical option will clearly increase the time spent on the production of a large amount of work. This shows that for cutting polypropylene pipes on an enlarged scale, it is preferable to use a device equipped with an electric motor.

Some features of the use of scissors

For any scissor models, both manual and electric, the manufacturer always provides detailed instructions. Strict implementation of its provisions is simply necessary not only to perform quality work, but also to comply with safety regulations by the operator. However, there are principles that are common to all models. A vivid example is the requirement to keep the pipe in a vertical position during the cutting process. At the same time, a clear angle of 90 degrees must be observed between the ends (this is especially true for the working process on welded or fitting pipes).You should also keep the entire workflow under constant control - for this, the tool handle, which is responsible for pressing / bringing the blade, must be set in motion smoothly in order to exclude deformation of the object being processed.

Difficulties of choice

When buying scissor / cutting tools for polypropylene pipes, you need to pay close attention to the following factors:

- Classic PP shears, as well as pistol-type devices, are used exclusively for pipes with a diameter of up to 42 millimeters. For cutting products with a large circumference, it is better to use a roller or guillotine type.

- The vast majority of models of domestic or Chinese production have a body made of cheap material - silumin (an alloy of silicon and aluminum) or duralumin, which means reduced ductility and strength. It is extremely rare to find models whose body is made entirely of steel. Although they have more weight, they are less susceptible to mechanical damage than aluminum-based alloys. The best option can be called a device whose body is made of light alloy steel.

- When buying, you need to pay attention to the thickness of the cutting element. If the blade is very thin, then the likelihood of it going to the side will definitely increase. And the consequence of this will be getting a cut with an angle that does not correspond to 90 degrees.

- The best option for the blade material is stainless steel with an increased hardness factor. In such models, the edge, as a rule, has the form of an obtuse angle with a sharp point in the middle.

- The device itself must have a comfortable support with a width of lips on opposite sides of the future incision by 15 millimeters. The bottom line is that at a similar depth, the PP pipe is standardly immersed in shaped elements during soldering.Thus, by accurately marking the length and drawing the line to the edge of the support platform, it is possible to obtain a more accurate size of the object after cutting, while maintaining its future immersion depth.

- Despite the fact that ratchet shears cut longer, they are easier to cut the workpiece at an accurate right angle. This is achieved by gradually bringing the knife to the surface and clamping it with a stop. Then its more precise location at 90 degrees is carried out with a smooth pressing on the handles of the mechanism. For the spring type, the cut is carried out in one motion, which, with the slightest mistake, will mean a deviation from the desired right angle. And it will be very difficult to correct such a mistake later.

- During the buying process itself, it is best to have a sample of the polypropylene pipe that is going to be cut with you. It is easier to try on the selected tool to the pipe in the store than to go through the tedious procedure for returning the purchased goods.

- You should not purchase a device with handles that are too small - they will be uncomfortable to work with, and their shortened lever will require the application of large muscular efforts. For roller and guillotine types, the main guideline will be their comfortable placement in the palm of your hand, while the grip must be secured with a relief or anti-slip (rubberized) coating.

- Due to the fact that PP scissors are considered professional tools, it is necessary to pay attention to the manufacturer's brand. Products from Rems, Gross, Valtek, Rotenberger and Milwaukee have proven themselves to be excellent qualities in practical work.

- In cases where it is planned to produce a large amount of work on cutting PP pipes, it is better not to save money and purchase an automatic model, or a model equipped with an electric drive. Although more money will be spent, the effort and time saved will be worth it.

- Separately, it is worth mentioning Asian devices - you do not need to completely trust the technical data indicated in their instructions regarding possible diameters for the cut. Experience shows that they can often only handle pipe circumferences up to 25 millimeters. For larger diameters, you need to purchase a tool from a manufacturer that is completely trustworthy.

Rating of the best scissors for cutting polypropylene pipes for 2022

Budget segment

3rd place: "VALTEC - 40 mm"

This budget option of the tool differs in durability of service and special reliability. In confirmation of these qualities, the manufacturer has installed a 2-year warranty on the device. The case is made of an alloy of silicon and aluminum (silumin), which reduces the total weight of the device to 400 grams. The average blade life is 5,000 cuts. These scissors can even be used to cut polypropylene pipes with a reinforced layer up to 0.6 mm thick. The device has a ratchet mechanism and a spring system for distributing handles. The recommended retail price is 670 rubles.

- Small dimensions and light weight;

- budget cost;

- Spring wiring system.

- Weak body elasticity.

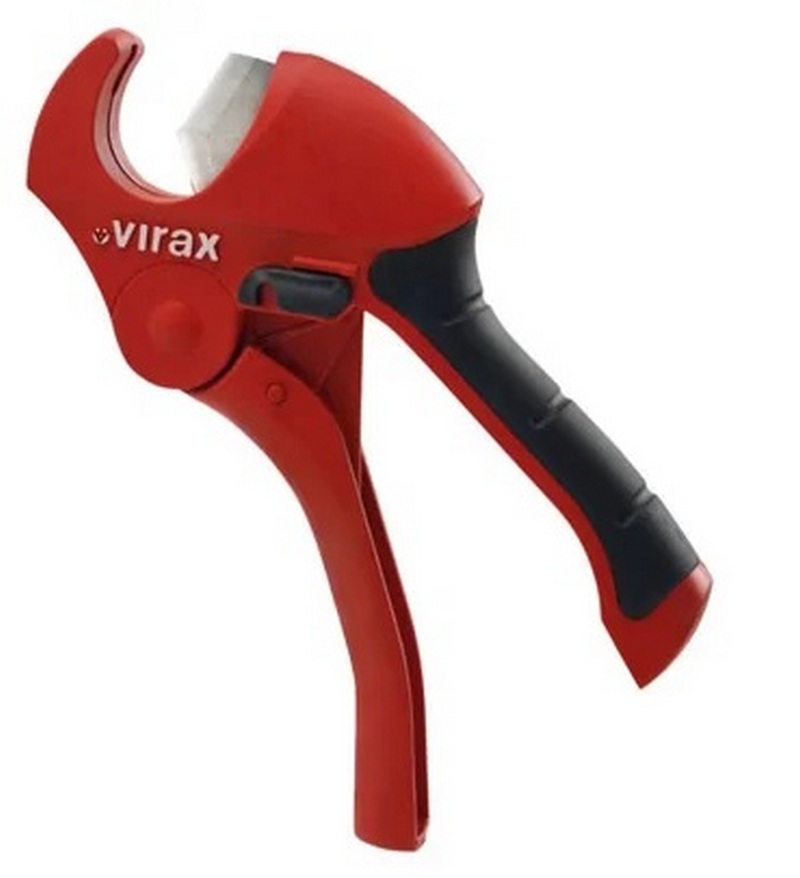

2nd place: Virax RS-32

A good sample that does an excellent job of cutting PP products up to 32 millimeters. Differs in the special accuracy and comfort in work.The design uses a special V-shaped profile of the cutting element, which is made of stainless steel, which implies a high-quality cut in the absence of side deformations. The second handle has a unique shape and is very comfortable for working grip. Soft touch pads do an excellent job of anti-slip function. The opening of the jaws is carried out due to the spring, and the cutting element is securely fixed in a certain position with the help of a special latch. The total weight of the device is very small and amounts to 200 grams. The recommended cost for retail chains is 1800 rubles.

- Cutting accuracy;

- Anti-slip pads;

- Special blade shape.

- Do not try to work on large diameters.

1st place: "Fit-63mm"

A budget category model, but it is able to work through pipes with a circumference of up to 63 millimeters. Great for many models made on a plastic base. The device is manufactured in China under a Canadian license, therefore, its cost is very attractive for a domestic buyer. The main structural parts are made of aluminum alloy, and reliable, made of light tool steel, cutting elements make it possible to process even those polypropylene pipes that have reinforcing inclusions. The recommended retail price is 2700 rubles.

- Lightweight body;

- Tool steel knives;

- Extended range of machined circles.

- Constant working control over the indicators of an even cut is required.

Middle price segment

2nd place: "Rothenberger Rocut 42 TC"

This model of scissors will be able to provide maximum cutting accuracy of a polypropylene product, and it can also be used to work with metal-plastic. The set maximum working diameter is 42 mm. This device can be operated even with one hand. The cutting edges of the knives provide maximum precision cuts, which is complemented by a reinforced mechanism. The supply of the applied forces is carried out by a ratchet mechanism based on a rack and pinion. There is a lock on the handle, through which the tool is brought into a position that is safe for transportation and storage. Replacing the blades with new ones (the problem of finding them on sale) is not a particular difficulty. The established store price is 4530 rubles.

- Possibility of one-hand operation;

- The presence of a latch to protect the components in the non-working position;

- Changing knives is not a problem.

- Not detected.

1st place: "Ridgid 1442N"

This sample represents a fairly well-known and high-quality Japanese brand. These scissors are easy to use and easily cut through polypropylene pipes, as well as other artificial materials from among the products of the PVC industry. The sample is the "standard" of the American industry, which means the selection of high-quality aluminum for the body. A full and durable ratchet mechanism will prevent the formation of burrs after notching. Comfortable work is ensured by grips made according to the ergonomics system and located in the lower part. It is especially worth noting the presence of a ruler for marking accuracy. The recommended cost for retail chains is 5600 rubles.

- Precise cutter;

- The presence of a ratchet mechanism;

- Comfort grips.

- Large weight - more than 700 grams.

Premium class

2nd place: "MGF UNIQUE 63"

This sample is freely capable of working for polymer products with a diameter of up to 63 millimeters. It has a serious 1080 alloy blade, which means easy cutting of PP, PVC and PE based polymers. The use of this unit is to obtain a high hardness of the gaps. The manufacturer has set a locking hook, which is responsible for the safe movement and storage of the device. The built-in beveler ensures proper cutting, and the well-placed linkage only confirms it. In general, the instrument is labeled as a low-effort tool, and most experts have no doubts about its performance and durability. The established price for shops is 6200 rubles.

- High hardness cutting edge;

- The level of work of the professional direction;

- Very powerful ratchet.

- Not detected.

1st place: "REMS ROS P 42P"

This device, by right, is the best among the models from the German manufacturer in this line. Its accuracy can reach 1 millimeter, and when handled in the skillful hands of the operator, even less and more correct. Practice shows that with traditional functionality - neither a burr nor excess chips remain. The device is able to work on any metal-plastic blanks. The set includes replaceable blades, which are hardened according to an innovative method. Upon completion of the cutting stage, the blade automatically enters the protective groove. The quality of this device is determined at the European level.The established cost for retail chains is 6,700 rubles.

- European quality;

- Excellent function to eliminate (fence) chips;

- Improved accuracy.

- Not detected.

Instead of an epilogue

The established analysis of the market of the devices under consideration determined the following: most of the objects of study (namely, the scissors indicated in the rating) cannot fully ensure the fulfillment of tasks at the required level. From this it is clear that spring devices are “last day”, while “ratchet” devices can still support competition. Accordingly, a set of designated devices, devoid of an electromotive drive, is akin to a “hammer and chisel”, used in the most extreme cases. Regarding the modern brands of the devices in question, it can be noted that the domestic manufacturer is poorly represented. And even more so, he (the Russian manufacturer) focuses on Western counterparts, but without trying to comply with their standards. Bottom line: the choice of scissors should be based only on essentially specific tasks. Otherwise, the choice of an expensive device may turn out to be complete worthlessness and a waste of money “for nowhere”.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131650 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124517 -

The best men's sneakers in 2022

Views: 124031 -

The Best Complex Vitamins in 2022

Views: 121938 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2022

Views: 113393 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105327 -

Ranking of the best sex dolls for men for 2022

Views: 104363 -

Ranking of the best action cameras from China in 2022

Views: 102215 -

The most effective calcium preparations for adults and children in 2022

Views: 102010