Rating of the best knives and discs for trimmers for 2022

The trimmer (aka lawn mower) is a popular household appliance that, in its functionality, is more like a lawn mower. The tool itself has a certain compactness and lightness, with its help it is enough to simply mow rather small areas of grass, including thickets near tree trunks, fences and other inaccessible places. The trimmer is perfect for cutting young growth and dead wood (including high weed cover), as well as for processing well-groomed and soft grass on the lawn. The main thing in all this business is to choose the right disc for this tool.

Content

- 1 Varieties of trimmers

- 2 Using Trimmer Discs

- 3 Disk selection issues

- 4 DIY knife making

- 5 Difficulties in choosing between fishing line and knife

- 6 Advantages of discs over fishing line

- 7 General rules for safe handling of metal trimmer knives

- 8 Proper sharpening of trim discs

- 9 Rating of the best knives and discs for trimmers for 2022

- 10 Instead of an epilogue

Varieties of trimmers

According to the type of energy supply source, the considered instruments are divided into:

- Petrol - it is convenient to process quite large areas with them, because they have increased power. In addition, it is possible to install various additional nozzles on them, which help to loosen the soil, cut small knots and branches, and they can also process tree crowns and give a neat appearance to shrubs. The disadvantages of such equipment include their increased weight, noisy operation and poor adaptability to functioning in humid conditions (for example, mowing grass covered with morning dew).

- Electrical – these devices are easy to use due to their low weight. However, their range is short and will always depend on the location of an electrical outlet nearby.

- Rechargeable - probably the most mobile and maneuverable option, because it is able to work far from a power source. But here everything rests on the amount of electric charge of the battery - even the latest models produce a full charge in a maximum of 20 minutes. But recharging them can take several hours.

Using Trimmer Discs

As mentioned above, petrol models have higher mowing power, so they prefer steel or heavy plastic discs. For other samples, light paddle knives or light plastic knives are often used. Such cutting devices will not greatly burden a low-power electric or battery-powered apparatus.

However, the use of one or another type of knives will not always depend on the power of the equipment. Not the last role in this case will be played by the transmission mechanism, which can be either rigid or flexible. In devices in which a rigid mechanism is installed, rotation is carried out by means of a shaft, and in models with a flexible mechanism, this process passes through a steel cable. Thus, if you install a heavy steel disk in an apparatus with a flexible cable, then extreme loads will occur on it, and the whole structure will quickly become unusable. Therefore, in a lawn mower using a flexible transmission, only plastic discs or even fishing line are installed. To find out the type of transmission, just look at the instructions. However, it can also be determined “by eye” - if the trimmer has a curved bar, then it uses 100% flexible transmission.

IMPORTANT! It is imperative to decide on the type of transmission before buying a knife!

Disc material

Steel discs often use either alloy tool steel or its carbon tool form. It can also have soldering from wins on the blades and teeth. Steel knives are often installed on professional equipment that can mow any grass, young growth, and even small trees with a trunk no more than 70 mm. Plastic knives are suitable for household specimens, they can mow low weeds, but are better suited for ordinary lawn mowing.

IMPORTANT! It is worth remembering that plastic cutters are not suitable for young shoots!

Knife design

Bladed - they have 2-4 blades, but sometimes there can be more. They are lighter in weight than gear ones, have a lower inertial moment and load the engine, coupled with the transmission mechanism of the apparatus, extremely little. They have specific areas of use:

- Hay preparation.

- Lawn mowing.

- Removal of small weeds.

It is highly desirable to work with paddle discs only on the same type of soft grass, because the grass flies away from the knife when mowing. When using three-blade models, the trimmer will grind the grass more finely, respectively, this option can work on tall grass. The four-bladed version will already do an excellent job with a small hayfield.

Bladed knives are more often used in practice in summer cottages and small household plots - an electric trimmer with a plastic or small steel knife can be called the best choice for such purposes.

jagged - they will find their application if you need to frequently mow young shoots and small trees. The teeth on the disk are arranged in the form of small pointed protrusions. Their number can range from 20 to 80 pieces.This shows that the more teeth on the disk, the more complex the operation it is able to perform (for example, the more teeth, the easier it is to cut down a tree).

Disk selection issues

In cases where it is necessary to mow the lawn and standard weeds (no more than once a month), then the 8-tooth disc will be the best choice. If it is supposed to process tall grass, a disc with 24 teeth is optimal (mowed plants are practically not wound on them). Still, professionals advise having several different discs in stock, each of which will be intended for a specific job. In addition, when using an electric tool, it is preferable to use knives with holes - they are lighter in themselves, which, accordingly, load the equipment's electric motor less.

For daily work in the professional segment of activity, it is better to use discs made of alloy steel and having victorious soldering. The ideal option is when the entire circle is made directly from the winner. Regarding the price tag: the disks themselves are not complex devices, and therefore even a Chinese model for 400-700 rubles can last a couple of seasons. But branded models, the cost of which starts from 1,500 rubles, will last more than one five-year period (subject to proper care for them).

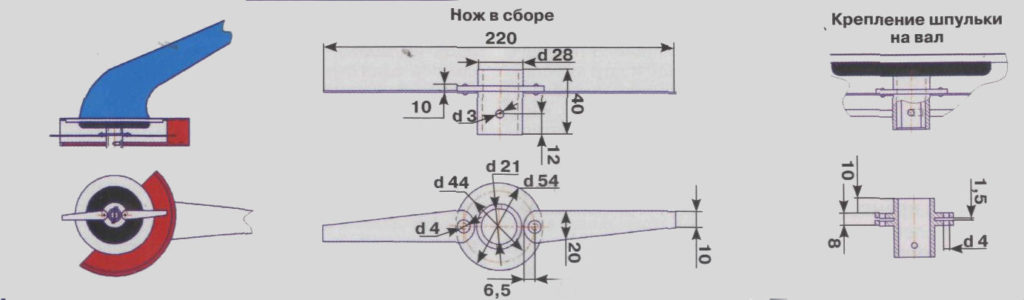

DIY knife making

The easiest way is to pile a trimmer disc in its bladed design. For this you will need:

- A part of a pipe (preferably copper rather than steel) with a suitable diameter - an adapter sleeve for the output of the flexible shaft will be made from it.

- Steel sheet with a thickness of not more than a millimeter (for the manufacture of washers).

- Standard cotter pin (GOST 297-66) (mounting the base in the shaft).

- Stainless steel strips (thickness from 1 to 1.2 mm) (knife blades themselves).

- Fastener (it is preferable to use rivets rather than nuts/screws, despite the fact that even if they come as spare parts with the machine).

Manufacturing sequence:

- To begin with, it is necessary to mark the overall dimensions of the fixture so that when cut out, they do not go beyond the protective casing. After that, you can proceed to the manufacture of the bushing from the pipe.

- In order to improve the fit, the sleeve is made split and seated along the outer surface of the trimmer shaft. Due to the fact that the diameter of the washer can only be determined by the dimensions of the available space, it is also possible to select the washer from the most approximate standard sizes.

- The washer must be welded to the sleeve so that the formed leg along the seam takes up a minimum of space.

- It is better to make blades on a milling machine, paying special attention to taking into account sharp edges and corners - they should not bend excessively during their subsequent sharpening.

- Rivet fasteners, which have a slight vertical play, will allow high-quality cuts, especially from dead wood.

- In order to prevent rubbing of the blades in case of their possible expansion from heat, it is necessary to carefully check the presence of gaps (at least 1.5 mm) between the blades and the pipe.

- The last step will be to securely fasten the entire structure to the shaft with a cotter pin.

Difficulties in choosing between fishing line and knife

The fishing line is used for low and soft grass, for taller grass, with obviously hard and old stems, it is better to use a knife. In a set of branded trimmer models, these two cutting tools are usually included in advance.Depending on the frequency of use of a particular element, brand models, as a rule, serve at least 5 seasons.

Proper selection of fishing line

The fishing line is considered to be not a very reliable cutting tool, because it can easily catch on glass, stone, a thick branch and break. Therefore, before choosing a fishing line, you need to decide on its thickness. Usually, the thickness is written in the instructions, which also outlines its functional features. A standard fishing line has a diameter of 1-1.4 mm, but its competent selection will always depend on the power of the mowing machine itself. As a rule, a normal package contains 15 meters of wood material. It is enough for 5-10 applications. At the same time, there are also enlarged coils, in which the length of the wire is about 200 meters.

IMPORTANT! It is necessary to pay close attention to the date of manufacture of the fishing line, because the older it is, the faster it will break!

Forms of the forest section

This parameter will depend on the type of grass. Round fishing line is characterized by increased strength and is suitable for almost all types of vegetation. But it is quite noisy during operation, therefore, in order to work with it in relative comfort, it is necessary to use earplugs or construction headphones.

The wood material can be figured, and be made in cross-section in the form of a star, square or polyhedron. Such a thread should be used in the course of clearing the ground cover from thick and hard stems, especially since the noise from it is quite small. At the same time, it is worth mentioning that its increased efficiency lies in the fact that it has sharp corners, hence the ability to cut dry grass with high quality. However, such a thread breaks much more often.

Correct choice of line diameter

For different softness / freshness of the grass cover, you will need a special diameter of the fishing line. However, this does not mean that a thick cord (fishing line) can be installed on any mower, regardless of its power limits. Before such installation, be sure to familiarize yourself with the recommended characteristics that are indicated in the instructions. As an example, the following situation can be indicated: an attempt to wind a 2-mm cord on an apparatus that is designed to work with a thread of no more than 1.2 mm will invariably lead to a breakdown of all equipment, because. the engine will inevitably overheat.

According to the thickness of the diameter, the cord can be divided into the following sizes:

- 1.2-1.6 mm - thin. Perfect for small lawn care, including infrequent mowing. The power of mowing equipment can be from 0.5 to 0.7 kW.

- 2-2.4 mm - the most popular version of the material. It is used in medium power equipment, which is extremely common among avid summer residents. It copes equally well with withered grass and young shoots.

- 3-3.2 millimeters - is considered the choice of professionals, it is usually installed on powerful gasoline braids, it copes with rough dead wood and weeds without any problems.

- 4 millimeters is the thickest of the existing ones, it even has a little aluminum added in order to strengthen the material. It has very clear restrictions on engine power, which is why it is rarely used and only against weeds with a strong root system.

IMPORTANT! As a rule, the manufacturer paints the fishing line in certain colors (from softer to more aggressive, for example, from green to red), so that it is visually easier for a potential buyer to understand the thickness of the cord.

Line material

The standard cord material is nylon, which is extremely flexible and strong and able to withstand temperature fluctuations and load volumes. Also, there are threads with a metal core - they are stronger than nylon by about 30 percent and are less prone to wear. Great for tall grass. Regarding price variability: nylon will cost about 100 rubles, and material with metallic inclusions - from 800 rubles.

Advantages of discs over fishing line

The indisputable positive advantages of disks, in comparison with cord, include:

- Work with a variety of vegetation - it can be small grass, and thick-stemmed plants, and long deadwood. The fishing line, in turn, can hardly cope even with medium-sized plants, not to mention plants with a thick stem. The cord will either quickly get tangled when trying to work on such herbs, or wear out extremely quickly, which indicates a clearly low economic efficiency.

- The speed of achieving the desired result - the disc is quite capable of qualitatively cutting the grass surface in one pass, without leaving the so-called "roosters". It is impossible to say the same about mowing with a cord, especially since the use of a circle purely physically speeds up the entire mowing process.

- High wear resistance of the cutting wheel - yes, knives or parts of the wheel can become dull, but they can always be re-sharpened. But if the fishing thread breaks, then it will not be possible to fasten it in any way - there will be one option - a complete replacement.

However, it is worth mentioning the disadvantages that are inherent in the cutting circle:

- It often causes the motor to overheat.

- In a collision with a very hard obstacle, there is a high probability of complete damage to the cutting edges, which cannot be restored.

- Transmission mechanisms break down more often, even though a disk is used that matches the installed mechanism, whether on a flexible shaft or on a rigid one.

General rules for safe handling of metal trimmer knives

- Such knives should only be installed on machines with a straight shaft. This circumstance is due to the design features of the cutting element.

- In the event that the disc hits a very hard obstacle during mowing (such as a stone), it will usually bounce back towards the operator's feet. For units with a straight bar, the distance to a person’s legs from a rotating head is quite safe.

- Standard trimmers have U or J handles for safer operation. If the design uses a D-shaped handle, then the unit is equipped with a special restrictive plug, which rests against the operator's leg and ensures that the leg does not come into contact with the cutting parts.

- Even if the cutting wheel stumbled upon a solid obstacle, as a result of which it was bent, then this situation can be corrected with a simple hammer. To do this, you just need to straighten out all the bumps with a few strokes. However, this circumstance applies only to expensive branded models, the disks of which are made of high-quality metal. Even the very flexibility of the knives was specially incorporated by the manufacturer into the design of the device in order to reduce the load on the transmission and engine when colliding with hard objects.

Proper sharpening of trim discs

If the cutting discs are used for a long time, they may become dull. This phenomenon is considered normal, but you should not continue to use such a circle - there is a possibility of injury to others and the final breakdown of the device itself. In addition, dull blades have reduced performance, which leads to poor mowing results, and it is also possible for the motors to overheat, which can lead to complete wear of the gearbox. The easiest way to sharpen knives and even buying new knives does not look economically justified against this background.

IMPORTANT! You can sharpen any steel knife, including those equipped with victorious overlays. However, to sharpen them, you will need a special diamond-coated wheel.

Step-by-step instruction:

- First of all, the cutting part is removed, because it is not safe to sharpen the disk directly on the unit itself.

- It is necessary to inspect the disk for further operational suitability. Do not sharpen the cutting part if it has signs of extreme deformation, cracks and chips - in this case it is better to replace the element.

- Sharpening itself can be done using a conventional file or grinder. It is also worth trying a sharpener, but in this case, certain skills will be required from the operator. Still, experienced gardeners prefer the simplest and safest way - using a file. To do this, you just need to fix the disk in a vice and turn it at an angle of 30 degrees.

- In the case when a large emery or "grinder" is used, then this method will require special care. During sharpening, redness and heating of the metal should not be allowed, otherwise it may be tempered.And this will later serve as the basis for accelerated wear and rapid abrasion of the cutting edge.

- The ideal option for an inexperienced operator would be to use a file. With its help, you can sharpen the cutting element as efficiently as possible, while not reducing its future performance in any way.

- Some difficulty may be sharpening a circle with numerous teeth (30-80 pieces) - in this situation, you should use a “grinder” with a refined abrasive wheel.

At the end of all operations, you need to install the disk in the trimmer and check the mowing efficiency. This will literally take 5 minutes. Care must be taken to ensure that the machine does not overheat and that the cut grass does not remain on the cutting parts.

Rating of the best knives and discs for trimmers for 2022

Economy class

3rd place: SIAT Blade 10002

A good sample from Italy, characterized by simplicity and efficiency. The thickness of the blade approaches the average values, which indicates the everyday orientation of the tool. The product is able to integrate with most modern models of lawn mowers. Special care is not required, engine overheating is not observed.

| Name | Index |

|---|---|

| Manufacturer country | Italy |

| Material | Plastic |

| Number of knives (teeth) | 2 |

| Thickness, mm | 3 |

| price, rub. | 220 |

- Good value for money;

- Strong base;

- Democratic pricing.

- Few blades.

2nd Place: PATRIOT "Promo" TBS-3

Excellent replacement blade compatible with all standard models. It will cope with both tough weeds and perfectly mow the grass in small areas in hard-to-reach places.The body of the sample is made of hard grades of plastic, which means increased wear resistance. It can become a reliable replacement for even expensive fishing line.

| Name | Index |

|---|---|

| Manufacturer country | China |

| Material | Reinforced plastic |

| Number of knives (teeth) | 3 |

| Diameter, mm | 230 |

| price, rub. | 250 |

- Increased strength;

- Versatility;

- Good alternative to cord.

- Weak distribution in the territory of the Russian Federation.

1st place: Huter Blade 3T-GDT

The disk-blade is intended for processing small household plots on an ongoing basis. The tool itself has a protective coating that prevents premature wear and corrosion. Great for sharpening at home. The mass of the element does not overload the engine.

| Name | Index |

|---|---|

| Manufacturer country | Germany |

| Material | Alloy steel |

| Number of knives (teeth) | 3 |

| Diameter, mm | 255 |

| price, rub. | 350 |

- Possibility of re-sharpening;

- Can be used permanently.

- Not suitable for low power trimmers.

Middle segment

3rd place: AL-KO 112405

The sample has a standard fit diameter, which means that it can be installed in various types of mowers. The manufacturer made the cutting blade from high-quality tool steel, in addition, equipped it with anti-corrosion protection. Additionally, the possibility of re-sharpening is provided. Copes well with daily loads, he is not afraid of collisions with hard objects.

| Name | Index |

|---|---|

| Manufacturer country | China |

| Material | Tool steel |

| Number of knives (teeth) | 3 |

| Diameter, mm | 250 |

| price, rub. | 430 |

- Able to endure permanent loads;

- Withstands collision with stones;

- It has additional protective coatings.

- Not found (for its segment).

2nd place: ENIFIELD 40T-EN

Suitable for harvesting both dead wood and young growth. Does not leave "roosters", the haircut is extremely fast and even. The form is based on stainless steel, which indicates high anti-corrosion qualities (work in conditions of morning dew). It has 40 cutting teeth, which maintains high productivity.

| Name | Index |

|---|---|

| Manufacturer country | China |

| Material | Stainless steel |

| Number of knives (teeth) | 40 |

| Diameter, mm | 255 |

| price, rub. | 550 |

- Smooth haircut;

- Stainless steel applied;

- Variety of working material.

- A large number of teeth - re-sharpening is best left to a professional.

1st place: Fubag Four Blade 38740

Non-standard 4-bladed knife, rarely found on the territory of the Russian Federation. It showed itself well in work on dense vegetation, the stems do not wind on the petals, after cutting, an even and neat cover remains. Re-sharpening of the blades is possible, however, does not interact well with solid objects.

| Name | Index |

|---|---|

| Manufacturer country | China |

| Material | Steel |

| Number of knives (teeth) | 4 |

| Diameter, mm | 255 |

| price, rub. | 720 |

- Re-sharpening;

- Democratic price;

- Rare 4-blade design of the cutting wheel.

- The disk may warp if it hits a hard object.

Professional Samples

2nd place: CHAMPION C5157 HT48 "Maxi-Cut"

A wonderful solution for avid gardeners. The model has three movable knives made of heavy-duty plastic, which work perfectly both on wet grass and weeds.Despite the high strength, the sample does not have an overweight, which favorably affects the operation of the engine. Easy to maintain and dismantle.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Material | Reinforced plastic |

| Number of knives (teeth) | 3 |

| Diameter, mm | 255 |

| price, rub. | 950 |

- Versatility;

- Strength;

- Light weight.

- Not detected.

1st place: Husqvarna 5784445-01

A powerful sample designed for powerful trimming units. It is advisable to use it in branded devices that have a liquid fuel power source. Differs in high quality of sharpening and long service life.

| Name | Index |

|---|---|

| Manufacturer country | Norway |

| Material | Alloy steel |

| Number of knives (teeth) | 3 |

| Diameter, mm | 300 |

| price, rub. | 1750 |

- Ease of use;

- Western quality;

- Long service life.

- Not found.

Instead of an epilogue

Summing up, it is worth noting that the quality of grass mowing will directly depend on the competent and correct selection of a knife / disc for a trimmer. If the budget allows, then it is better not to save on the model of the lawn mower itself and take a universal sample that can work with both fishing line and discs. At the same time, it is preferable to purchase both the cord and discs in several versions at once in order to correctly use the cutting element, depending on the work to be done. But the power source (electric motor, battery, liquid fuel) must be selected based on the tasks that are to be performed most often.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131650 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127689 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124518 -

The best men's sneakers in 2022

Views: 124032 -

The Best Complex Vitamins in 2022

Views: 121938 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114979 -

The best paint for gray hair - top rating 2022

Views: 113394 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105328 -

Ranking of the best sex dolls for men for 2022

Views: 104365 -

Ranking of the best action cameras from China in 2022

Views: 102215 -

The most effective calcium preparations for adults and children in 2022

Views: 102011