Rating of the best bench lathes for 2022

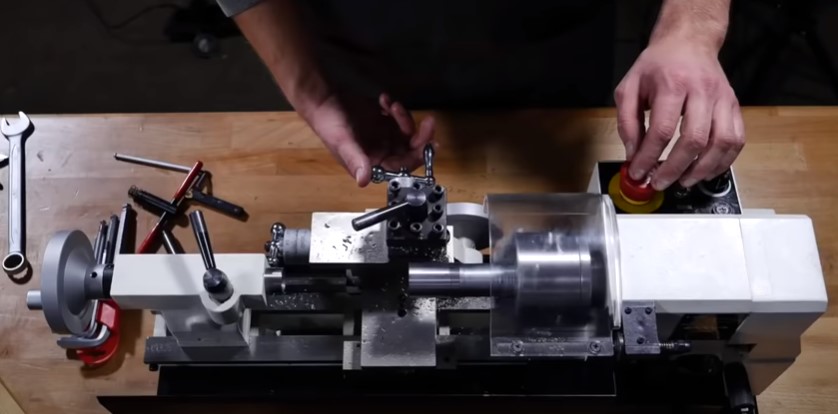

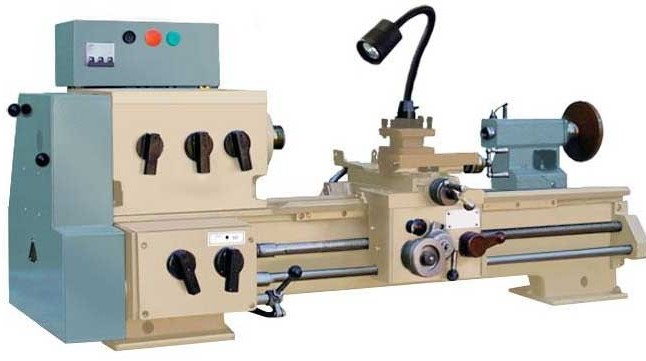

Often at home there is a need for turning parts of varying complexity with optical accuracy: to make a non-standard automotive spare part, a useful device for the home. An indispensable assistant comes to the rescue - a desktop lathe. The best manufacturers offer many models that differ in price and quality. Where to buy a reliable device, which company is better, what to look for when choosing? We will try to answer these and other questions, as well as present a rating of the most popular models of desktop lathes for 2022.

Content [Hide]

How to choose a bench lathe

Before mastering the work of a turner at home, it is advisable to find out what machines are, their characteristics and functions.

Mini-analogues of industrial equipment are of the desktop type, as they are easily placed on any work surface. Such devices are multifunctional and designed for the manufacture of small parts at minimal cost. The processing material can be any: steel, wood, any kind of plastic.

Criterias of choice

To purchase a reliable model for the home workshop, garage, service station or training lab, it is appropriate to consider a number of parameters:

- appointment;

- distance between centers;

- bed type;

- bed material;

- allowable voltage;

- power consumption;

- spindle speed;

- degree of automation;

- retrofit possibility.

By appointment It is possible to distinguish devices that work with blanks from different materials: wood, metal, plastic, less often glass, diamond.

Distance between centers is considered the main criterion, because it determines the maximum possible length of the machined parts. The average value of this value usually corresponds to a workpiece length of 800 mm. Important numerical indicators are the length and width of the desktop. They indicate the maximum possible dimensions of the workpieces.

From the type of bed depends on the stability and rigidity of the structure and the reduction of vibration: stationary and portable. In any modification, the fastening of their guides must be of high quality and durable.

The most preferred bed material is cast iron, which can withstand any load and effectively dampen vibration, thereby achieving maximum precision in operations. Most models have a weight of 10-15 to 500-100 kg. However, there are devices weighing up to 260 kg. Separate modifications are produced without a frame. In this case, its role is played by attachments to the working surface.

Permissible voltage for a powerful high-performance machine used on an individual basis, it is most often 380 V. In cases of using a device without a frame with a manual operating principle, the allowable voltage is 220-230 V. For efficient and safe use of a one- or three-phase machine, there must be appropriate electrical wiring.

Power consumption. Lightweight models without a bed consume a small amount of electricity - 0.3 - 0.7 kW. Most often these are devices for working with soft materials (plastic, wood). However, most desktop metal models with a cast iron bed have an average power consumption of 1.5 kW.

Spindle speed determines the quality of work and productivity of the machine as a whole. The lower the engine power, the lower the number of revolutions per minute the spindle will make. The minimum spindle speed is usually 150-400 rpm, the maximum speed reaches 2500-3500 rpm. In a higher class of devices, a speed controller (mechanical or electronic) is provided, which provides the optimal depth of cut for various types of processing.

By degree of automation machines are manual, semi-automatic and electronic (CNC). This is reflected in the cost of the product.When buying a device, it is appropriate to think about which principle of operation will be more convenient.

Possibility of retrofitting greatly facilitates work, improves quality and productivity. Additional equipment may be different, based on the needs of the master:

- a set of cutters;

- lunette;

- milling head;

- tool holder;

- scroll chuck;

- collet;

- revolving center.

Recommendations when choosing

A few tips to help you choose the right machine:

- The best purchase option is to first familiarize yourself with the characteristics, reviews about the advantages and disadvantages of the proposed model, and order online in the online store.

- Take into account the dimensions of the product when making a delivery method: will it be possible to independently deliver the ordered cargo if it has an impressive size and weight.

- Based on what materials it is supposed to work with, choose a model with a certain number of speeds and a convenient speed control system.

- If mass production of the same type of parts is foreseen, then it is advisable to buy a machine with the function of a copier that guides the cutter along a certain path.

- For turning as a hobby, it is better to choose devices with low power. They are also characterized by low noise levels. When using a device for large-scale work, it is advisable to purchase a device with a powerful engine, given that expensive models from well-known manufacturers have special noise protection even at high power. Powerful machines of a lower cost class will be very noisy.

- Try to choose the model that has the best ratio of price, functionality and quality. In this case, the machine will last for many years without failures and breakdowns.

- For beginners, models with a horizontal axis of rotation and a small length of the desktop are preferable.

Rating of quality desktop machines for 2022

We offer you to get acquainted with the best desktop lathes in each price segment from domestic and foreign manufacturers with a description of the main technical characteristics. The popularity of models, according to buyers, is determined by their demand in 2022 and the largest number of positive reviews.

Budget (from 10,000 rubles to 50,000 rubles)

Proma DSO-1000

votes 5

| Characteristics | Values | |

| Voltage, V | 220 | |

| power, kWt | 0.4 | |

| Rotation diameter over bed, mm | 350 | |

| Workpiece length, mm | Up to 1000 | |

| Maximum rotation speed, rpm | 1250 | |

| Weight, kg | 35 |

A compact turning machine of a well-known Czech brand is designed for processing wooden surfaces in the form of a cylinder, a cone. Widely used in construction, home furniture making and small scale manufacturing. Equipped with a copier, which makes it easy to produce a large number of blanks of the same shape. Thanks to its light weight and small size, it can be installed on any table or workbench in just a few minutes. The kit includes all the necessary fixtures and tools. The device is easy to use, long and trouble-free. In the event of a breakdown, there are no problems with repairs.

Average price: 12,500 rubles.

- cheapness;

- easy to use;

- wear-resistant design;

- easy to install;

- high processing accuracy;

- work with wood of any hardness;

- with copier function;

- good equipment;

- easy to buy online.

- does not process metal and plastic.

Belmash WL-300/450

votes 0

| Characteristics | Values | |

| Voltage, V | 230 | |

| power, kWt | 0.55 | |

| Rotation diameter over bed, mm | 305 | |

| Maximum length of the workpiece, mm | 1000 | |

| Maximum speed, rpm | 2800 | |

| Weight, kg | 30 |

A Chinese-made model from a young Belarusian brand will be of interest to those who are actively involved in woodworking: internal and external turning, facing, cutting, grinding. The cast iron bed, which accounts for the largest part of the total weight, ensures the immobility of the structure when installed on a countertop or workbench. Components are made of durable wear-resistant materials. Factory-set parameters ensure smooth caliper running and high accuracy. A console is located on the left side of the bed for convenient placement of the required tools. The device is equipped with five spindle speeds, to switch which it is enough to move the drive belt from one to the other motor pulley. For convenient control on the device, there are only three buttons:

- inclusions;

- shutdown;

- speed switching.

There is a device for extending the working surface, which allows you to process workpieces up to one meter long, and not just standard ones up to 455 mm.

The only drawback, according to buyers, is the lack of engine protection against overheating. Therefore, it is advisable to work on the machine with short breaks.

Average price: 27,800 rubles.

- easy to use;

- mobile;

- convenient change of speeds;

- stable;

- inexpensive;

- tool console.

- overheats quickly.

Anchor Corvette-73

votes 1

| Characteristics | Values | |

| Voltage, V | 220 | |

| power, kWt | 0.4 | |

| Rotation diameter over bed, mm | 350 | |

| Workpiece length, mm | Up to 1000 | |

| Maximum rotation speed, rpm | 1250 | |

| Weight, kg | 35 |

The woodworking machine of the Russian trademark, small in size and power, is convenient for domestic use. There are no complex parts in it, the materials from which the components are made have high wear resistance and durability. The machine is useful for carpentry, with its help you can make dishes, rolling pins, candlesticks, coasters, handles and furniture legs. It can be easily transported in a car to a garage, workshop or cottage. A low-power motor will not cause an overload of the home electrical network, however, if it is continuously turned on for more than half an hour, it overheats. The belt drive regulates four spindle speeds, however, the principle of operation is inconvenient: it is necessary to open the shield, loosen and flip the belt manually and close the shield again.

Average price: 11,700 rubles.

- easy to operate;

- transportable;

- reliable fixation;

- several processing modes;

- profitability;

- durability;

- detailed instructions.

- engine overheating;

- inconvenient speed control.

Average in price (50,000 - 150,000 rubles)

Zentech MD 250-550 vario

votes 0

| Characteristics | Values | |

| Voltage, V | 220 | |

| power, kWt | 0.75 | |

| Rotation diameter over bed, mm | 250 | |

| Workpiece length, mm | 550 | |

| Maximum rotation speed, rpm | 2500 | |

| Weight, kg | 120 |

Model of Ukrainian manufacturer, country of manufacture Taiwan. The small size allows it to be used in everyday life for working with metals and alloys. The device is manufactured in accordance with the highest European quality standards from the best materials with a large margin of safety. After preparatory manual adjustment, the cutter can work in automatic mode.For reliable installation of a rather heavy machine, its legs are covered with rubberized material that does not scratch the surface of the workbench.

The powerful motor is equipped with an efficient air cooling system, so it can work for a long time without the risk of overheating. Impressive cast-iron bed headstocks reduce the possibility of vibration to a minimum, securely fix the parts. The minus of the model is sufficient noise during operation.

Average price: 135,000 rubles.

- cooling system;

- automatic control;

- hardened components;

- legs on rubber pads;

- complies with European standards;

- processes any metal;

- does not require special wiring;

- stable;

- good set.

- noisy.

Stalex SBL-250/550

votes 0

| Characteristics | Values | |

| Voltage, V | 220 | |

| power, kWt | 1.1 | |

| Rotation diameter over bed, mm | 250 | |

| Workpiece length, mm | 550 | |

| Maximum rotation speed, rpm | 2000 | |

| Weight, kg | 120 |

The model of the domestic brand is characterized by a modern design, a convenient control system with digital display and information tables on the headstock. It is used for mechanical processing of metal and polymer workpieces of different lengths due to the additional stroke of the quill up to 70 mm. Durable powerful motor and hardened components ensure long life and stable operation. Operator comfort is achieved by equipping with a protective screen, vibration-absorbing bed. The package includes:

- thread indicator;

- protective screen;

- rear apron;

- set of cams;

- cartridge;

- interchangeable gears;

- tool holder.

Average price: 143,000 rubles.

- wear-resistant design;

- automatic control;

- safe;

- quick release button;

- informative tables;

- rich equipment;

- quality ingredients;

- complete absorption of vibration;

- powerful engine;

- profitability;

- little noisy;

- ergonomic design;

- digital panel.

- weak fastening of small longitudinal feed.

JET BD-7

votes 0

| Characteristics | Values | |

| Voltage, V | 220 | |

| power, kWt | 0.59 | |

| Rotation diameter over bed, mm | 180 | |

| Workpiece length, mm | 350 | |

| Maximum rotation speed, rpm | 3000 | |

| Weight, kg | 44 |

A universal model for household and semi-professional purposes with wide technological capabilities. Small dimensions and weight provide mobility of the device. Thanks to the cast-iron bed and powerful stocks, the structure is stable on the working surface and does not vibrate. Ease of use adds the ability to connect to a normal household power supply and low noise levels. Retrofitting is provided to perform a wide range of tasks when working with metals, wood and plastic. The digital display shows all the set operations and the possibility of correcting them.

Average price: 74,000 rubles.

- simple operation;

- reliable design;

- high precision of operations;

- digital display;

- extended equipment;

- low noise level;

- mobile;

- additional functions;

- powerful engine;

- adequate cost.

- plastic gears.

Expensive (from 150,000 rubles)

MetalMaster MML 2870v

votes 1

| Characteristics | Values | |

| Voltage, V | 220 | |

| power, kWt | 1.5 | |

| Rotation diameter over bed, mm | 280 | |

| Workpiece length, mm | Up to 700 | |

| Maximum rotation speed, rpm | 50-2500 | |

| Weight, kg | 202 |

The household appliance from a domestic manufacturer is made in China.The novelty is an improved previous model, it has a number of features and technical characteristics that make it an ideal assistant for working with metal blanks, including cone-shaped, cutting inch and metric threads. The bed, 180 mm wide, is made of vibration-resistant cast iron with high rates of hardening and grinding.

Ceramic-metal bearings and a V-belt significantly increase the service life of the machine, protecting the motor from overheating. The feed box for adjusting the caliper stroke and thread pitch is located in an oil bath, so it does not fail for many years. The lead screw is equipped with telescopic protection against premature wear and the penetration of chips and dust.

There is a possibility of additional equipment of milling installation. For the safety of the operator, a protective screen and a red emergency engine shutdown button are provided in case of an emergency or traumatic situation.

The average price is 202,000 rubles (for a stock, it can drop to 192,000 rubles).

- compact device;

- high precision hardened metal spindle;

- electronic speed control;

- motor protection against overheating;

- rich equipment;

- durable;

- economical;

- low noise;

- mobile;

- safe.

- not available in every region.

Stalex SBL-280/700

votes 0

| Characteristics | Values | |

| Voltage, V | 380 | |

| power, kWt | 1.5 | |

| Rotation diameter over bed, mm | 280 | |

| Workpiece length, mm | 700 | |

| Maximum rotation speed, rpm | 1800 | |

| Weight, kg | 190 |

The heavy overall model of the domestic brand is made in China.Features exceptional power, ergonomic design, stepless speed control, hardened and ground guides. The high price is justified by the exceptional quality of the device, which provides unsurpassed accuracy in mechanical operations with a workpiece of any material. Comes with a metal stand.

Average price: 223,000 rubles.

- durable engine;

- quality assembly;

- automatic feed;

- smoother change in speed;

- lack of vibration;

- universality;

- intuitive operation;

- rich set.

- rarely on sale.

Rustan TV-9

votes 0

| Characteristics | Values | |

| Voltage, V | 380 | |

| power, kWt | 1.1 | |

| Rotation diameter over bed, mm | 220 | |

| Workpiece length, mm | 525 | |

| Maximum rotation speed, rpm | 1000 | |

| Weight, kg | 230 |

Another representative of the Russian mechanical engineering, a three-phase device, characterized by versatility and ease of use. Reliable components, unsurpassed assembly, automatic control allow you to easily perform a full range of turning operations on the machine. The only negative that buyers note is the high cost. For operator comfort and better visual perception of work performed, the device is equipped with a lighting lamp.

Average price: 472,000 rubles.

- multifunctionality;

- power;

- full set;

- high build quality;

- high-precision processing;

- node reliability;

- lamp included.

- high cost.

Which one is better to buy a desktop machine for home use, how much a reliable model costs, with what power consumption, dimensions and functionality, everyone decides for himself.The presented review of popular devices will help to avoid mistakes when choosing an indispensable assistant for the master.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131650 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127689 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124517 -

The best men's sneakers in 2022

Views: 124031 -

The Best Complex Vitamins in 2022

Views: 121938 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114979 -

The best paint for gray hair - top rating 2022

Views: 113393 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105327 -

Ranking of the best sex dolls for men for 2022

Views: 104365 -

Ranking of the best action cameras from China in 2022

Views: 102215 -

The most effective calcium preparations for adults and children in 2022

Views: 102010