Rating of the best floor skirting boards for 2025

Floor plinths are needed not only to maintain the completeness of the interior picture of the entire room, but they are also designed to perform essential applied tasks. Depending on the characteristics of the room itself, you should select the type of skirting board that is suitable for it. In general, this process is not particularly difficult, but it has some features that must be taken into account when choosing and installing the finishing element in question.

Content [Hide]

- 1 Appointment of skirting boards

- 2 Modern types of floor plinths

- 3 Some features of popular models of skirting boards

- 4 Choice of mounting method

- 5 Selecting the height of the floor plinth

- 6 Rating of the best floor skirting boards for 2025

- 7 Instead of an epilogue

Appointment of skirting boards

It is worth noting that initially the plinth had an exclusively aesthetic purpose. With its help, the finish was given a complete look. Over time, through this element, they began to mask the technological gaps between the floor and the walls, which were formed during the laying of the floor covering. It is not possible to completely eliminate such gaps, because they are needed so that the coating can easily narrow / expand with temperature changes or with changes in humidity. If there are no gaps, then due to the occurrence of the previously indicated circumstances, the coating may deform and “go in waves”. On the other hand, if the technological gap is left uncovered, then garbage will accumulate in it, which will reduce the level of external attractiveness of the room as a whole.

There are variations of skirting boards with a special purpose, for example, with built-in lighting.They are suitable for giving rooms and passages soft night lighting. If the light source is installed at a height, then it can "cut the eye", so soft light coming from below is considered more preferable and gentle.

Also, passing technical cables can be masked under the skirting boards. These skirting board models have been very popular lately, given how many wired household appliances are in the modern house today. As a standard, under the plinth it is possible to lay a couple of cables of medium thickness.

Modern types of floor plinths

At the beginning of the use of skirting boards, it was carried out only with the help of wooden dies, the range of shapes and types of which could not be called large. Nowadays, there is already a fairly wide range that allows you to choose the right finishing product as accurately as possible:

- Wooden - they are perfect for a wooden floor, parquet board or parquet. Despite the fact that the breed of plinth wood should preferably match the breed of wood flooring, and the color should match the tone. It is better to buy such skirting boards immediately together with the flooring, a separate selection can be a problem. In any case, wooden skirting boards have never been cheap, and their installation is fraught with certain difficulties.

- Products made of MDF or HDF - these synthetic materials differ only in density. The production takes place as follows: a bar is created from the molten mass, on which a laminating layer of PVC or veneer is applied. These finishing elements should be installed if the floor is covered with linoleum or a wood-like laminate is laid. The color of the skirting board should match the tone of the coating.The same products can be adapted for cashing doorways due to the ease of installation.

- Plastic - these models are considered to be the most affordable and cheapest, which is not entirely true. Indeed, the simplest samples are very cheap, but those that can mask cable channels are much more expensive. Usually, they also have rubberized edges, and they are produced by companies specializing in the production of laminate. It is also preferable to purchase them from the same manufacturer that made the flooring in order to achieve a complete match of color and texture.

- Ceramic - this is a rather exotic type of finishing elements under consideration and it is used exclusively with the same ceramic flooring (may be suitable for wall decoration).

- Metal - this type of product is rarely found in residential areas, however, some of the latest trends in design allow their installation (for example, minimalism, modern or high-tech). Metal variations are perfect for rooms with difficult operating conditions. Most often used in unheated vestibules, terraces, and other semi-open spaces. They are usually made of aluminum, which can be painted, polished, or coated with matte enamel. There are aluminum variations with a laminated finish.

- Foam (polyurethane) - they are ideal for subsequent painting. There is no need to match them to the tone for walls or floors. However, the main disadvantage is their excessive fragility, incl. when operating, you need to be as careful as possible. Installation is possible both on glue and on self-tapping screws.

Some features of popular models of skirting boards

Plinth massive

This category includes the most ancient type of elements under consideration - wooden.They have not lost their relevance so far, despite their venerable age. Massive variations are traditionally used in conjunction with a floorboard, which, in principle, is not surprising: if the owner has the funds for an expensive board, then it makes no sense to install an artificial plinth on it. Massive models are perfect for completely dry rooms - bedrooms or children's rooms. In other cases, their effectiveness falls, because they have poor moisture resistance.

As mentioned above, for a wooden floor, you should choose a plinth made of wood of the same species. The easiest way is to order exactly massive models immediately from the manufacturer: most manufacturers of parquet and wooden flooring immediately introduce skirting boards to their product line.

IMPORTANT! Experts advise to strictly observe the equivalence of the wood species of the skirting board with the wood species of the floor, even if another option seems more appropriate!

On the Russian market, solid oak and beech woods are very popular. The decorative parameters of samples made from cherries are also quite good. The advantages of a massive wooden plinth are:

- strength;

- durability;

- Environmental friendliness;

- The ability to independently adjust the element to the desired size by simply filing it.

However, massive elements also have disadvantages. The main one is overpriced. Although, sometimes, in order to reduce the cost, they can be made according to the “set of planks” method, but such variations do not have the best decorative qualities, because they have a non-uniform texture, which makes it completely impossible to hit “tone-on-tone” with the floor. The second disadvantage is the poor resistance to temperature and humidity changes.When these indicators change, internal stress is created in the wood, through which it is possible for the product to peel off the floor or wall, even with wallpaper and paint. In any case, the installation of a massive wooden plinth should be done using dowels or self-tapping screws with flat heads in order to avoid deformation or cracking of the product.

It is always worth remembering that wood is a natural material, so one should not expect 100% evenness and smoothness from massive skirting boards. It is better to purchase this type of product with a margin, because. some parts will most likely need to be replaced over time.

Plinth veneered

This type of product under consideration is an excellent solution for wooden flooring - parquet and parquet boards, and most importantly - massive floorboards. In addition, it is much cheaper than the massive plinth version. The range of these products on the market is constantly expanding, the list of wood species from which the veneered plinth is made is constantly growing (with the development of technology).

If we compare massive options with veneered ones, then the latter are better able to hold the geometry, they are less at risk of spontaneous deformation and twisting. It was possible to achieve dimensional stability by making the base frame, for which the stacking technology of moisture-resistant wood is used, most often this role is played by pine.

The entire plank is assembled from small pieces of wood, ranging in size from 20 to 50 millimeters, which are glued together using the “lightning” method. A thin layer of veneer (made of valuable wood) or its artificial counterpart, or a specially aged variation, is glued on top.As a rule, the top layer will be bioprotection, which is applied in order to prevent the development of fungus and harmful microorganisms. The overall strength of the skirting board can be increased by creating a basic composition of several layers.

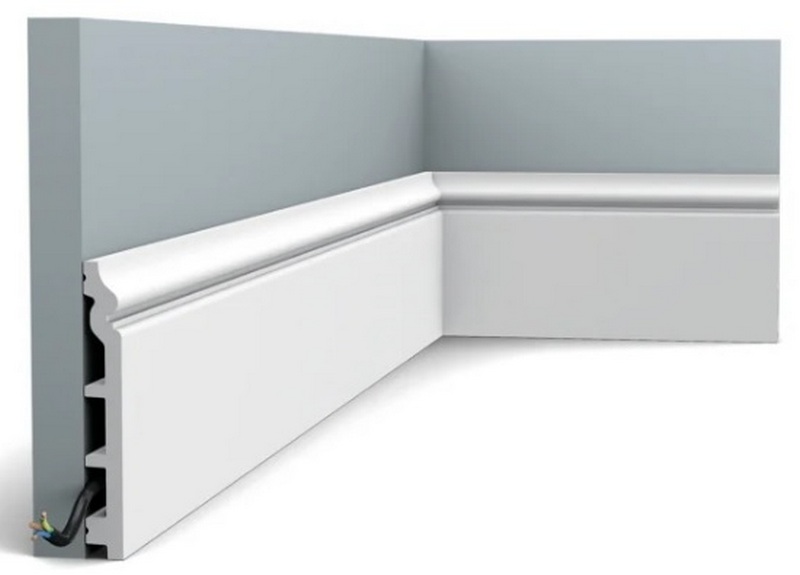

Visually veneered options look very high quality and aesthetically pleasing, as they have tone transitions characteristic of natural wood, there are traces of knots and irregularities, which gives more natural aesthetics, and all this is complemented by a beautiful fibrous structure and sapwood. In general, naturalness is harmoniously combined with external high cost. The shape of veneered products can be straight or embossed, with a height of 40 to 80 millimeters.

However, it is necessary to mention the existing shortcomings. Before buying, you should find out exactly what kind of wood the product is made of. This is necessary in order to correctly calculate how long it will take to re-coat the surface with varnish. Veneer, like any wood, tends to fade. Sometimes it is possible to give a tone to the veneer through tinting impregnation, visually preserving the wood structure, but this will also not be an eternal solution.

Veneered products are attached to special clips - it is on them that the plinth body itself will, as it were, be put on. It is also possible to fasten this finishing element to liquid nails. The undoubted advantage of installation will be that when installing a plinth made of veneer, you do not have to use plugs and corners.

Plinth plastic

These plinth variations are perfect for laminated parquet or linoleum, but are categorically contraindicated for use in conjunction with piece parquet, and even more so with parquet flooring.There are varieties of this product, suitable for carpet - they are made in the form of L-shaped strips. A tape cut from the carpet is inserted into them. As a result, a plinth is obtained from the same material as the carpet.

Not so long ago, a plastic flexible plinth was introduced to the market, the structure of which has undergone a change at the molecular level. Its storage after release is carried out only in special packaging. These products can take the desired shape, smoothly passing along the curved lines of the boundaries of walls and floors, bypassing bends and various decorative elements of the interior, such as columns.

To install a flexible model, it is necessary to fix the carrier profile by preheating it in warm water or hot air. After installation, the element hardens and retains its shape when cooled. However, for the installation of a flexible model, very smooth and even walls will be required so that no gaps and unnecessary gaps are visible.

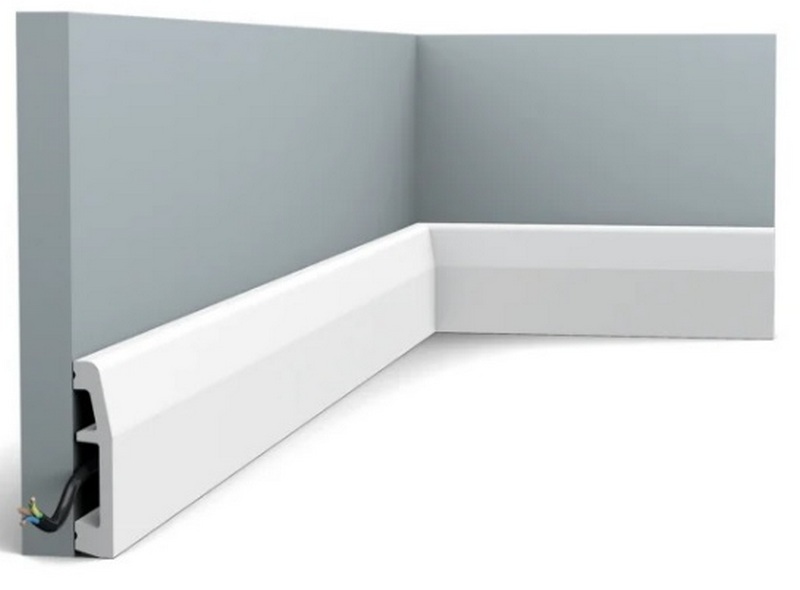

Almost all plastic models for the floor are collapsible: they include a mounting part and a front side. The hollow design of the plastic plinth makes it easy to hide technological wires in it. Plastic samples will be an ideal solution for arranging offices and service premises, as well as buildings with a high percentage of humidity.

The main advantages of plastic models are:

- moisture resistance;

- Resistance to mechanical stress;

- Successful resistance to direct ultraviolet rays;

- Weak susceptibility to deformation;

- The presence of cavities for laying technological cables;

- Affordable cost.

The issue of quick selection of products in tone and relief for any type of flooring based on laminate or linoleum is not a problem.

Some experts believe that plastic options look quite cheap, however, this can be attributed to a matter of taste and a matter of finance. The disadvantages of these products include their obvious artificiality and unnaturalness, the need to use plugs and corners, as well as a clear standout against the background of other decorative elements. In addition, there are size restrictions - the maximum height of this type of skirting board can be no more than 45 millimeters.

Choice of mounting method

The main question that arises when installing skirting boards is where is it better to mount them, to the floor or to the wall? The answer is: with a floor covering made on the basis of a parquet board, parquet or laminate - only to the wall. This is due to the fact that all of the listed materials have significant moisture and thermal expansion, therefore, along the perimeter of the coating (between the wall and the edge of the flooring), it is necessary to leave a technological gap, which is then covered with a plinth strip, while the coating material itself is not subject to fixing, it must have the freedom of space for expansion / contraction.

In order to prevent debris and dust from penetrating under the bar, an elastic sealant must be used. It will be able to remain mobile even after hardening, leaving freedom of movement for the floor covering, which is practical and convenient.

There are several ways to install skirting boards:

- Through - is the simplest and most reliable, but aesthetically unattractive;

- Gluing is also an easy way, but not suitable for all skirting boards, and the walls should be as even as possible;

- Secret - it can be mounted on clips or using guides, or you can fix the main part on dowels and screws, and close everything on top with a decorative strip.

The last fixing method is also not very simple and it is possible only on flat floors and walls. The most reliable and easiest way is to fix the base on the wall, which is typical for skirting models with a cable channel. Clip-on samples and samples with guides will be very dependent on the overall design of the product. It is always worth remembering that after several removals / installations of the bar on the mount, the groove will expand, which will worsen the quality of the fixation.

Selecting the height of the floor plinth

The height parameter will depend on the dimensions of the room and the height of the walls. In some cases, skirting products can visually increase the volume of space, in others - reduce it. For spacious rooms, it is preferable to lay a dark-colored floor with dark skirting boards, although original color solutions can also be used.

Low ceilings look more spacious with light-colored skirting boards against the background of the same floors. As a standard, with walls 2.5 meters high, the optimal height of the plinth will be about 4-5 centimeters. If the ceilings are too high, then you will need high plinth samples, about 5 - 7 centimeters in height (even an indicator of 10 centimeters is allowed). It should be noted that small skirting boards in large rooms are visually "lost" and the room takes on an unfinished appearance.

Rating of the best floor skirting boards for 2025

Budget segment

3rd place: "HiWOOD white floor paintable duropolymer Hiwood D125 1 m.p."

votes 1

This product is made of duropolymer, characterized by high quality, safety, flexibility. It has good impact resistance and water resistance properties. The smooth surface is suitable for painting. It can be used for decoration of external and internal premises, for decoration of sports halls, canteens and entertainment centers. Thus, both commercial and domestic applications are possible. The recommended cost for retail chains is 145 rubles.

- Eco-friendly material;

- Quality manufacturing;

- Versatility of application.

- Not detected.

2nd place: "Cosca floor white duropolymer Decomaster A118 1 m.p."

votes 0

This sample is made from the latest generation duropolymer, free of formaldehyde, solvents, CFCs and other hazardous substances. Fully meets the requirements of sanitary safety. The degree of fire risk is extremely low. Oriented for installation in canteens, children's rooms, hospitals, i.e. will not harm persons with respiratory problems. The recommended cost for retail chains is 200 rubles.

- Affordable price;

- Full environmental friendliness;

- Maximum fire safety.

- Not detected.

1st place: "NMC Belgium floor skirting board for painting polyurethane high duropolymer FB2 1 lm"

votes 0

This finishing element has an aesthetic appearance, has a relief surface, and is made of modern duropolymer.The material of manufacture is characterized by special environmental friendliness, and the design provides for the possibility of laying one small technical cable. Installation is possible with self-tapping screws or on "liquid nails". The recommended cost for retail chains is 230 rubles.

- Installation variability;

- Niche for technological cable;

- Eco-friendly production material.

- Not detected.

Middle price segment

3rd place: "Deartio floor white MDF for painting Pro-Line wide W04-120 1 lm"

votes 0

This figured sample is made of MDF and has a factory white color, which does not interfere with painting it in a different color. The structure is very strong and very easy to install. Installation can be carried out both on clips and on “liquid nails”. The product has one technical channel. The recommended cost for retail chains is 240 rubles.

- Special strength;

- Availability of a technical channel;

- Possibility of re-staining.

- Impossibility of trimming in height.

2nd place: "Perfect floor impact resistant high DD004 paintable FL 1.53.108 duropolymer polyurethane HSP 120 1 m.p."

votes 0

This polyurethane sample is perfect for office decoration. Special impact resistance is useful for rooms with high human traffic. The presence of technical channels will make it possible to convenient wiring from the wires of office equipment. It has an increased height indicator and can be painted to match the color of the interior. The recommended cost for retail chains is 245 rubles.

- High office version;

- Affordable price;

- Resistance to mechanical influences.

- Not detected.

1st place: "Cezar floor high smooth straight Cezar A036 1 r.m."

votes 0

This plinth product is made in a classic simple style. Due to its height, it can visually increase the space in the room. Initially it has an even white color, which can be replaced. The structure is made of impact-resistant duropolymer and is suitable for both home rooms and office rooms. The recommended cost for retail chains is 250 rubles.

- Versatility;

- Classic strict style;

- Quality performance.

- Not detected.

Premium class

3rd place: "100 Progress Profiles 2m. Polished, BTAC 100"

votes 0

This sample is made of high quality stainless steel AISI 304-1, can be equipped with a self-adhesive layer or without it. It has a high aesthetic value and is very easy to install, ideal for use in private and public spaces where hygiene and design requirements are high. Can be used as an original high-tech decor element. The kit comes with inner and outer corners, end caps and fittings for straight runs. The recommended cost for retail chains is 3650 rubles.

- Variety of applications;

- Focus on hygiene and aesthetics;

- The presence of a self-adhesive layer;

- Good set of consumables.

- High price.

2nd place: "Plinth for carpet Dollken (Dolken) TLE55 Brown 132 2500x55x10"

votes 0

This product is made on the basis of ultra-ecological polymers and is intended for furnishing rooms with a floor covering in the form of a carpet. Installation It is carried out using a self-adhesive strip and is not particularly difficult. The closable top is stretchy, easy to remove when needed. Perfect for coatings with a thickness of up to 7 millimeters. The recommended cost for retail chains is 6,700 rubles.

- Practical installation method;

- Elastic cover;

- High level of adhesion;

- Self-adhesive mounting strip.

- High price.

1st place: "Flexible PVC floor plinth Progress Plast BTPFN 62A 50mm 50m black self-adhesive"

votes 0

This model is the latest kind of profile made from vinyl flexible and non-toxic resin with a height of up to 62 millimeters. It is characterized by increased strength and is ideal for the formation of skirting boards around the perimeter of the floor covering with a high degree of aesthetics. From all others, this profile is distinguished by the presence of a lower protrusion, which makes it possible to lay profiles at an angle of 90 degrees. It is also possible to fully mount on a PVC-coated floor. By means of a horizontal protrusion it is convenient to hide the perimeter expansion joint. Installation is carried out by means of glue or mastic (options with a self-adhesive base are available). The recommended cost for retail chains is 15,550 rubles per set.

- Installation variability;

- Possibility of high-quality concealment of the perimeter seam;

- Innovative production material.

- Very high price.

Instead of an epilogue

The analysis of the market of the materials under consideration found that it is dominated by a tendency to popularize the latest technologies, such as flexible skirting boards and stainless steel skirting boards. It is gratifying that most models from the budget and medium price segments are produced in Russia, which makes their price tags affordable. At the same time, all innovative models are exclusively Western products, as evidenced by their excessively high prices.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131654 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127694 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124521 -

The best men's sneakers in 2025

Views: 124037 -

The Best Complex Vitamins in 2025

Views: 121942 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2025

Views: 113398 -

Ranking of the best wood paints for interior work in 2025

Views: 110320 -

Rating of the best spinning reels in 2025

Views: 105332 -

Ranking of the best sex dolls for men for 2025

Views: 104370 -

Ranking of the best action cameras from China in 2025

Views: 102218 -

The most effective calcium preparations for adults and children in 2025

Views: 102013