Rating of the best floor gas boilers for 2022

On the territory of the Russian Federation, climatic conditions are very severe, and winters are quite cold. This dictates the vital need for heating in houses and apartments. If a gas main is suitable for the place of residence and conditions allow, preference is given to installing a gas boiler. The reason is the complete autonomy of the heating system with the least effort and the greatest benefit.

The review describes in detail all the nuances and criteria in order to avoid mistakes when choosing a floor-standing version of a gas unit. Below are the principles and basics of its work, as well as ratings of the best and most effective models with a consideration of the main advantages and disadvantages compared to wall structures. Recommendations from experts and user reviews draw attention to the characteristics and capabilities of heating devices in order to make the right decision before investing in expensive equipment.

Content

General information

A floor gas boiler is a device placed on a special platform or floor that generates thermal energy by burning gaseous fuel for heating objects (premises) and heating water.

The main types of fuel are:

- main natural gas - methane;

- liquefied gas in cylinders - propanobutane mixture.

Changing from one type of gas to another is done by changing the nozzle and adjusting the pressure setting on the valve. However, for a number of operational and economic reasons, mainline fuel is much more preferable.

Design

Despite some differences between the models, the general arrangement of modern units practically corresponds to the classical scheme, taking into account the use of the latest manufacturing technologies and materials. The main components are:

- gas supply control mechanism;

- gas stove;

- heat exchanger;

- control and diagnostic unit;

- frame;

- air intake circuit;

- protection module;

- coolant circulation system with pumps and safety valves.

Principle of operation

- Natural gas from the main through the burner nozzles is fed into the combustion chamber.

- The main burner is ignited by an igniter automatically or by pressing a button using electric or piezo ignition.

- When the set coolant temperature is reached, the burner goes out after the gas supply is cut off, the ignition of the igniter continues.

- When the temperature drops, the gas supply resumes, the burner is re-ignited by the igniter.

- A coolant circulates inside the walls of the combustion chamber (heat exchanger), which, when heated, distributes the accumulated heat energy through the heating system and releases it to the surrounding space through radiators. After cooling, it returns to the boiler.

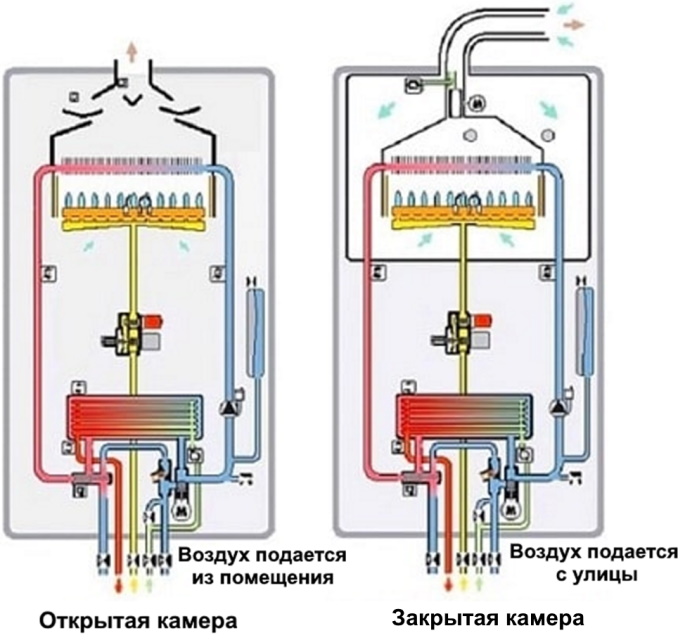

- Oxygen for the combustion process enters through the bottom of the unit. Due to natural draft, combustion products are removed through the chimney.

In turbocharged boilers with a closed combustion chamber, air is forced in to increase combustion efficiency. The combustion product is discharged through a side (coaxial) chimney, which facilitates installation and site requirements.

Classification

According to the principle of action

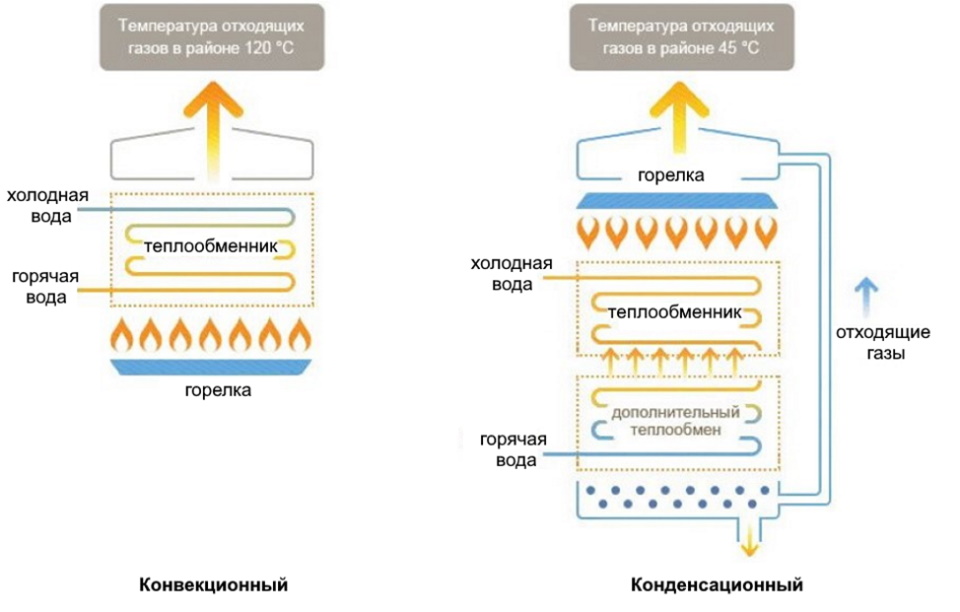

- Traditional (convection) - using the lower calorific value of the fuel by the rapid removal of flue gases along with water vapor to the outside.

- Condensation - using the highest calorific value due to the condensation of the generated steam on the walls of the economizer and redirecting heat to the heating circuit. As a result, while saving fuel, productivity increases significantly up to 114%, but due to the complexity of the design, the price of the unit also increases.

By the number of circuits

- Single-circuit - they heat only the coolant, they have compact dimensions, simple maintenance, economical fuel consumption.If hot water is required, an additional water heater or indirect heating tank will be required.

- Double-circuit - simultaneously heat the premises and heat the water, equipped with automation and a good security system. However, they require an electrical connection.

Type of combustion chamber

- With open - oxygen intake from the room, a chimney with powerful traction, the average price is not very high.

- With closed - oxygen intake from the street, regular removal of soot and soot through a coaxial chimney, energy dependence during operation.

According to the material of the heat exchanger

- Steel - have high strength and ductility with good resistance to mechanical stress and temperature extremes, are inexpensive in production with good maintainability. At the same time, they are not sufficiently protected from corrosion formations; in order to achieve a sufficient degree of inertness, the walls are thickened with simultaneous weighting of the entire device. Service life up to 18 years.

- Cast iron - have a long service life of more than 30 years and are not afraid of corrosion, but are distinguished by an increased price, fragility and weight.

- Copper - have a long service life, low weight and dimensions, as well as corrosion resistance. However, the cost is too high and there is a risk of failure in case of strong heating of the elements.

By type of burner

- Atmospheric - at a low cost, very noisy in operation.

- Inflatable (fan, replaceable, mounted) - are more expensive due to the extended configuration and the presence of a fan, which is also very noisy in operation.

- Single-stage - the issuance of only one level of power.

- Two-stage - the issuance of two power levels.

- Modulation - with smooth regulation of the output power.

By type of ignition

- With electronic - automatic start saves fuel, because.there is no constant burning of the igniter.

- With piezo ignition - it is started by pressing a button manually, does not require connection to electricity.

Advantages and disadvantages

The main advantages of outdoor units include:

- Large power range of various values from 10 kW to more than 1 MW.

- High performance large combustion chamber with special design.

- Possibility of heating several objects of a small area or one room of a large area.

- Economical fuel consumption.

- Ensuring autonomous operation of heating by non-volatile models.

- Rich functionality depending on the equipment and configuration of a particular unit.

- Self-detection of faults when equipped with modern auto-diagnostics.

- Place the instrument in a separate room to minimize noise levels.

- A small amount of harmful emissions into the atmosphere of exhaust gases.

- Long service life.

- High level of security provided by installation in a separate room, diagnostics, multiple fuses.

The cons are:

- the need to allocate a separate furnace room;

- obligatory arrangement of an effective chimney;

- difficult installation with the involvement of qualified specialists and the purchase of strapping elements;

- low productivity for hot water supply and high gas costs for hot water in summer;

- possible problems with electronic control in case of power surges;

- reduction of the service life of steel products due to the formation of corrosion;

- the danger of failure of cast iron units due to careless loading, transportation or unloading, causing the appearance of microcracks;

- increased costs for additional options to expand the functionality.

Criterias of choice

In order not to make mistakes, you need to pay attention to the main characteristics of the heating unit:

1. Required power for the full performance of functions and the principle of regulation: per 10 square meters. m of heating area with a ceiling height of up to 2.7 m is taken as 1 kW (for central Russia) with an increase in heat losses of up to 25%. In the case of higher ceilings, a multiplying factor of up to 1.2 is set. For a two-circuit model, up to 20% for hot water supply must be added to the calculations.

2. Number of circuits: one or two. For a double-circuit, the DHW capacity should be calculated in the range of 2.5 - 17 liters per minute.

3. Type of combustion chamber and burner: atmospheric with an open chamber or turbocharged with a closed chamber.

4. Efficiency:

- up to 90% - non-volatile models with a single-stage burner and a cast-iron heat exchanger;

- up to 93% - turbocharged devices with forced draft and a closed chamber.

5. Heat exchanger material: cast iron or steel.

6. Prominence of the manufacturer's trademark and reviews of manufactured products. The list of the best includes companies from Russia: Wester, Lemax; Germany: Buderus, Viessmann, Vaillant, Wolf; France: De Dietrich; Italy: Biasi, BAXI, Sime; Sweden: Electrolux.

7. A set of additional options in accordance with the wishes and needs:

- circulation pump for pumping the heating circuit;

- electronic pump control;

- automatic switching on of the pump in the summer;

- monitor with push-button or touch control;

- temperature controllers;

- overheat protection;

- gas pressure adjustment;

- gas supply control;

- flame control sensor;

- thrust sensor;

- protection against temperature fluctuations of the coolant;

- protection of the heat exchanger from freezing;

- gas leak alarm;

- additional functionality at the request of the customer.

Where could I buy

Popular models of floor-standing gas boilers should be purchased at specialized sales points for heating equipment or from dealers of manufacturers of such equipment. The best units and novelties are available there for visual inspection and testing of the main controls in practice. At the same time, consultants will help with practical recommendations: what brands are there, how to choose, which company is better to buy, how much it costs.

In addition, good models can be ordered online in the online store or using the popular Yandex.Market aggregator. A separate catalog of this marketplace contains product cards with descriptions, characteristics, photos and customer reviews.

The best floor gas boilers

The rating of high-quality gas-fired heating units was developed based on the popularity in Yandex.Market data and the opinions of users who left reviews on profile pages. The popularity of models is due to technical parameters, functionality, economy, reliability, ease of installation and maintenance, safety and price.

The review includes ratings among the best single-circuit and double-circuit floor products presented on the domestic market.

TOP 5 best single-circuit floor gas boilers

Siberia 11

Brand: Siberia.

Producer - CJSC "Rostovgazoapparat" (Rostov).

Non-volatile convection-type unit for operation in autonomous heating systems of country houses and medium-sized commercial premises. Able to function stably at reduced pressure in the gas line. An innovative patented heat exchanger made of high-quality steel with special thermal insulation is installed.Precise maintenance of the set temperature is achieved by reliable Eurosit gas automation. The Italian burner Worgas from a stainless steel provides full combustion of fuel. The current temperature of the heat exchanger is visually displayed by a capillary thermometer. Easy access to any node makes it easy to repair the device in the event of a breakdown.

Price - from 32,700 rubles.

- efficiency with efficiency up to 90%;

- energy independence;

- quality assembly;

- innovative technologies;

- good maintainability;

- built-in capillary thermometer;

- original Italian components;

- wear-resistant housing;

- seasoned design;

- attractive appearance;

- compact dimensions;

- simple installation;

- easy maintenance;

- acceptable price.

- basic functionality corresponds to the price.

Siberia 11 installation:

Borinsk AOGV-11.6 Eurosit

Brand - Borinskoe.

Producer - OJSC "Borinskoye" (Lipetsk).

Economical non-volatile model of convection type for autonomous heating of residential and commercial premises. Works on methane with a flow rate of up to 1.17 cubic meters. m / h., Providing efficiency with an efficiency of up to 87%. The main parameters are adjusted manually. The built-in thermometer displays the temperature of the coolant to prevent overheating of the unit. Warranty period - 3 years.

Price - from 28,244 rubles.

- work efficiency with average efficiency up to 87%;

- low gas consumption;

- simple operation and maintenance;

- energy independence;

- tubular heat exchanger made of high-quality steel;

- piezo ignition;

- Italian-made gas automation;

- built-in thermometer;

- protection "gas - control";

- easy connection;

- compact dimensions;

- ergonomic design;

- budget price.

- The feature set matches the price.

Protherm Bear 40 KLOM

Brand - Protherm (Germany).

Producing countries - Slovakia, Turkey, Germany, Great Britain.

Convection model of automatic type with an open combustion chamber for heating commercial and residential premises of medium size. Works on liquefied and natural gas, providing high efficiency and efficiency up to 92%. The heat exchanger is made of cast iron with good anti-corrosion properties. Fuel economy is achieved by using auto-ignition according to a given start-up and shutdown algorithm. Thanks to the modulation of the flame, the intensity of the gas supply is smoothly adjusted as needed, reducing fuel consumption. The basis of the control system is a microprocessor that provides smooth power control. The unit is equipped with universal protection in case of various emergency situations - sudden extinguishing of the burner flame, freezing or overheating of the coolant, pump blocking. If a battery is connected, operation is possible even when the electricity is switched off.

Price - from 150,400 rubles.

- efficiency with efficiency up to 92%;

- cast iron heat exchanger with good anti-corrosion properties;

- simple operation and maintenance;

- available accessories;

- automatic control and diagnostics;

- multifunctional protection;

- built-in manometer and thermometer;

- display;

- quality assembly;

- stylish design.

- without remote control;

- overcharge.

Video review Bear KLOM:

MORA-TOP SA 20

Brand - MORA-TOP.

Country of origin - Czech Republic.

Convection unit with an open combustion chamber for inclusion in autonomous heating systems of country houses and cottages.It is characterized by proper operation at low gas pressure. The primary heat exchanger is made of high quality cast iron with good corrosion resistance, reliability and durability up to 30 years of service. The main parameters are adjusted electronically. The built-in thermometer and pressure gauge allow you to control the temperature and pressure of the coolant to prevent the device from failing if the permissible parameters are exceeded. When the flame goes out, an automatic shutdown of the gas supply is provided.

Price - from 49,870 rubles.

- efficiency with efficiency up to 92%;

- fast heating;

- convenient pilot burner with flame modulation;

- power indicator;

- cast iron heat exchanger with good anti-corrosion properties;

- gas-control function;

- built-in manometer and thermometer;

- reliable security;

- simple installation;

- winter-summer mode;

- acceptable cost.

- energy dependence.

Gas boiler SA E:

Lemax Premium-30N

Brand - Lemax.

The manufacturer is Lemax LLC (Taganrog, Rostov region).

Non-volatile convection model for operation in a closed-type heating system in a private house at a pressure of up to 3 atmospheres with the possibility of conversion to liquefied gas. The combustion chamber of open type with a power of 30 kW. The steel heat exchanger complies with Russian GOSTs and international standards. The original Italian components of the gas burner and safety automatics manufactured by SIT, as well as the POLIDORO micro-torch injection burner, were installed. The improved system provides protection against draft interruption, heat exchanger overheating, blowing and sooting. Easy to service due to removable elements of profile equipment and cladding.

Price - from 52,140 rubles.

- effective work;

- maximum efficiency up to 90%;

- ease of use and management;

- convenient service;

- easy cleaning through the removable top panel;

- high quality steel;

- pressure gauge on the front panel;

- reliable protection;

- good anti-corrosion properties;

- excellent value for money;

- strict attractive design.

- no auto-ignition when blowing.

Lemax high-tech production:

comparison table

| Siberia 11 | Borinsk AOGV-11.6 Eurosit | Protherm Bear 40 KLOM | MORA-TOP SA 20 | Lemax Premium-30N | |

|---|---|---|---|---|---|

| Thermal power max., kW | 11.6 | 11.6 | 24,5-35 | 15 | 30 |

| Energy independence | Yes | Yes | No | No | Yes |

| Electrical network | - | - | single-phase | single-phase | - |

| The combustion chamber | open | open | open | open | open |

| Heated area, sq. m | 125 | 90 | 350 | 150 | 300 |

| Control | mechanical | mechanical | electronic | electronic | mechanical |

| Heat exchanger material | steel | steel | cast iron | cast iron | steel |

| Fuel, gas | natural, liquid | natural | natural, liquid | natural | natural |

| Gas consumption: | |||||

| natural, cubic m/h | 1.18 | 1.17 | 4.1 | 1.6 | 3.5 |

| liquefied, kg/h | 1 | - | 3.3 | - | - |

| Heat carrier temperature max., °C | 90 | 40-90 | 45-85 | 35-85 | 90 |

| Comfort | thermometer | thermometer | auto-diagnostics, frost protection, flame modulation, pump blocking protection, power-on indication, auto-ignition, overheating protection, thermometer, pressure gauge | power-on indication, auto-ignition, thermometer, manometer | overheating protection, thermometer |

| Protection | gas control | gas control | gas control | gas control | gas control |

| Connection: | |||||

| gas, inch | ½ | ½ | ¾ | ½ | ¾ |

| heating, inch | 1½ | 1½ | 1 | 1 | 2 |

| Chimney, cm | 12.5 | 11.4 | 15 | 11 | 13 |

| Dimensions (WxHxD), cm | 28x85x56 | 40.3x99.2x46.3 | 50.5x88x60 | 36.5x84.5x52.5 | 47x96.1x55.6 |

| Weight, kg | 52 | 45 | 130 | 99 | 75 |

TOP 4 best double-circuit floor gas boilers

Signal S-TERM 16B

Brand - Signal.

The manufacturer is Signal-Teplotekhnika LLC (Engels, Saratov region).

Non-volatile convection model for creating heating and organizing hot water in residential and commercial premises up to 180 sq. m. with high efficiency up to 90%. It is equipped with high-quality EuroSit automation and Italian-made POLIDORO burner. During operation, there is practically no noise. Thermocouple acts as a source of Thermo-EMF. The use of modern painting technology provides good anti-corrosion properties.

Price - from 31,000 rubles.

- efficiency with efficiency up to 90%;

- low noise level;

- easy access to the gas burner device;

- good maintainability;

- original parts made in Italy;

- innovative coloring technology;

- protection system with flame control sensors, overheating, draft;

- stylish design;

- acceptable cost.

- not identified.

Conord AOGVK - 11.6-1

Brand: Conord.

Manufacturer - Conord Plant LLC (Rostov-on-Don).

Non-volatile convection apparatus for organizing hot water supply and heating at facilities up to 116 sq. m. Work at reduced pressure in the line and the stability of the set temperature is achieved by using multifunctional valves made in Italy. High efficiency is achieved by good thermal insulation of the housing with minimal heat loss.

Price - from 25,690 rubles.

- efficiency with efficiency up to 90%;

- energy independence;

- low noise level;

- gas control function;

- durable cold-rolled metal heat exchanger;

- compact dimensions;

- easy installation;

- simple maintenance;

- great price.

- not identified.

Installing Conord instead of the old AOGV:

ZHMZ AKGV-17.4-3 Universal N

Brand - ZHMZ.

Producer - OJSC Zhukovsky Machine-Building Plant (Zhukovsky, Moscow Region).

A universal non-volatile convection model of a household gas device for operating in heating systems of various types and organizing hot water supply in private homes with an efficiency of up to 88%. Modern technological equipment provides good performance. The main or liquefied gas is used as fuel. The hot water production capacity is 5.4 liters per minute. Mechanical control manually adjusts the main parameters. Equipped with an air vent, excess air is automatically removed from the heating system when the pressure rises.

Price - from 56,300 rubles.

- energy independence;

- average efficiency up to 88%;

- environmental safety with a low content of carbon and nitrogen oxides in the exhaust gases;

- Italian automation EuroSit;

- air vent;

- built-in thermometer;

- advanced design.

- not detected.

Lemax Premium-25B

Brand - Lemax.

The manufacturer is Lemax LLC (Taganrog, Rostov region).

Non-volatile convection type unit for operation in a closed heating system of commercial or residential facilities with an efficiency of up to 90%. The steel heat exchanger meets the requirements of Russian GOST and international standards. Productivity of delivery of hot water makes 7 l/min. The mechanical type of control manually adjusts the main parameters.The built-in thermometer allows you to control the temperature of the coolant. The modern safety system ensures that the fuel supply is cut off in case of a sudden extinguishing of the flame and the burner is turned off when the coolant temperature reaches abnormal values.

Price - from 55,000 rubles.

- efficiency with efficiency up to 90%;

- simple control;

- energy independence;

- durable steel heat exchanger;

- original Italian components of safety automation and gas burner;

- microtorch burner POLIDORO;

- soft start;

- low noise level;

- modern protection against overheating, soot formation, draft interruption, boiler blowing;

- gas control function;

- built-in thermometer;

- convenient service;

- functionality without unnecessary bells and whistles;

- acceptable price.

- not detected.

Premium 25V:

comparison table

| Signal S-TERM 16B | Conord AOGVK - 11.6-1 | ZHMZ AKGV-17.4-3 Universal N | Lemax Premium-25B | |

|---|---|---|---|---|

| Thermal power max., kW | 16 | 11.6 | 17.4 | 25 |

| Energy independence | Yes | Yes | Yes | Yes |

| The combustion chamber | open | open | open | open |

| Heated area, sq. m | 160 | 116 | 140 | 250 |

| Efficiency, % | 90 | 90 | 88 | 90 |

| Control | mechanical | mechanical | mechanical | mechanical |

| Heat exchanger material | steel; copper | steel | steel | steel |

| Consumption of natural gas, cubic meters m/hour | 1.8 | 1.38 | 1.87 | 3 |

| Heat carrier temperature max., °C | 50 - 90 | 50 - 90 | 50 - 90 | 90 |

| Hot water capacity at 30°С, l/min | 7.8 | 3.3 | 5.4 | 7 |

| Functions | overheating protection, thermometer | thermometer | thermometer | thermometer, overheat protection |

| Protection | gas control | gas control | gas control, air vent | gas control |

| Connection: | ||||

| gas, inch | ½ | ½ | ¾ | ½ |

| heating, inch | 1½ | 1½ | 2 | 2 |

| Chimney, cm | 10 | 11.4 | 13.5 | 13 |

| Dimensions (WxHxD), cm | 26x85x47 | 32x95.3x40.6 | 42x105x48 | 55.6x96.1x47 |

| Weight, kg | 41 | 36.8 | 57 | 88 |

Floor gas boilers are characterized by high efficiency, rich functionality, simple operation and maintenance, as well as long battery life. However, obtaining optimal parameters is possible only with the right choice, installation and commissioning of heating equipment. At the same time, it is better to entrust such a complicated matter as installing a boiler to professionals rather than trying to install and connect it to the gas main with your own hands.

Happy heating. Take care of yourself and your loved ones!

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131654 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127694 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124521 -

The best men's sneakers in 2022

Views: 124037 -

The Best Complex Vitamins in 2022

Views: 121942 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2022

Views: 113398 -

Ranking of the best wood paints for interior work in 2022

Views: 110321 -

Rating of the best spinning reels in 2022

Views: 105332 -

Ranking of the best sex dolls for men for 2022

Views: 104370 -

Ranking of the best action cameras from China in 2022

Views: 102218 -

The most effective calcium preparations for adults and children in 2022

Views: 102013