Rating of the best sets of taps and dies for 2022

Taps and dies make up such a special group of tools that may be needed at any time of work. Thanks to their kits, it is possible to repair jammed internal threads and stripped bolts, as well as to restore single samples of nuts and studs, which can be difficult to buy in retail. Due to the fact that dies and taps have different designs, methods of application, areas of use, they should be considered in detail separately.

Content

Tapping

Among the existing detachable connections, threaded ones are considered especially reliable. At one time (before the first use of a screw-cutting lathe in the 17th century), each pair of nut-bolt was made individually and they could not be interchanged. In the 19th century, mankind began to apply special standards for applying internal threads. It can be carried out both with the help of a machine tool and with the help of taps.

Design features

A modern tap without fail has the following design elements:

- Intake (aka head) part in the form of a hollow cone, necessary to start the formation of a cutting profile;

- Several lateral grooves (usually two to six) that will provide lubrication and chip ejection;

- Calibrating element, in the form of an elongated cylinder, which will complete the formation of the profile;

- The shank responsible for fastening the tap in the chuck or turn signal clamp.

When making a cross cut, the shape of the groove will depend on two of its surfaces: the front edge of the cutting tooth of the tap and the back of this tooth.

Chip grooves can vary and be of the following types:

- Single-radius - they are used on calibration tools and are a cross-section in the form of a round arc;

- Rectilinear - used for applying nut threads and their cross section has the shape of the letter "U";

- Mixed - the back groove has the shape of an arc, and the front groove has a straight line (most universal tools are made according to this scheme).

Unique features of taps

The main types of taps have only their exclusive characteristics. Knowing these characteristics, you can always choose the right tap model:

- Threaded pitch;

- Profile and with its height;

- Maximum profile height;

- Thread diameter outside;

- The length of the fence part;

- Backing length;

- Corner of the intake cone.

IMPORTANT! It is worth remembering that any taps are divided into devices with left and right threads.

Types by area of application

According to the area of their use, taps are divided into:

- Locksmiths - they have a shank in the shape of a square, they are used manually. They come with a collar, through which the rotation and threading occurs. The set contains two taps, slightly different from each other in diameter, and where each removes only its share of the allowance from the surface of the hole being machined. Tools in such a set differ in the number of lines that are engraved on the shank or stamped there (especially accurate is indicated by three lines, intermediate by two, and rough by only one).

- Machine (machine) or machine-manual - they can cut both manually and on industrial equipment (for these purposes, drilling / turning machines and even large industrial processing centers are required).In contrast to the above, these taps have a shortened intake element, since the alignment of the axes is provided by the machine. They are made of high-quality tool steel, have heat resistance, and are little susceptible to mechanical pressure.

- spanner - they are used in automatic machines for threading inside nuts. In their design, they are distinguished by a more elongated shank, which has a smooth cylindrical shape. Upon completion of the thread rotation, one after the other, the nuts move to the shank, waiting there for the end of the work throughout the series. After the end of serial production, the shank comes out of the chuck, and all the resulting nuts fall into the receiving tray.

Differences in types according to design features

Taps by their own design can vary greatly among themselves:

- Fluteless - they are used when interacting with soft / viscous materials and therefore have very small grooves (viscous materials can be called light metal alloys and several types of low-carbon and high-alloy steel grades);

- Screw - they have grooves in an upward spiral, through which they carry out threads inside blind holes on production machines / automatic equipment;

- Stepped - the working element is divided into two sectors, the first cuts through, and the second smoothes;

- Combined - a drill is installed right in front of the lead-in element, during one approach a hole is drilled and threading is carried out there;

- Broaches - they are needed for threading in passing holes using a lathe;

- Bell type - they are needed for threading larger diameters (up to 0.5 meters) and include several cutting systems that are fixed in a common frame.

There are also exclusive designs, which are due to special production tasks.

Thread Types

Each thread size and type requires its own taps. They are not interchangeable, like threaded ones. The main types may differ:

- Metric - denoted by the letter "M" is a triangular isosceles profile, where the apex angle is 60 degrees, and its dimensions are determined in millimeters;

- Inch - denoted by the letter "W", its profile is a pointed angle of 55 degrees, and the diameter is displayed in inches and as well as fractions, and the number of turns per inch is used as a step mark;

- Pipe - its difference is a different inclination of the rear / front parts of the profile, which provides a guaranteed connection, and also prevents self-unwinding.

Manufacturing materials

All taps endure large mechanical/thermal impacts during operation, and the tool itself must cut a large number of holes at this time. Accordingly, high quality tool steels are required for production materials:

- Manual models - U10A or U12A - high-carbon steels;

- Machine models - PM5 high-speed steel;

- For automatic machines of increased productivity - hard alloys with increased heat resistance.

IMPORTANT! However, such metals have one major drawback - if damaged, the tap for threading cannot be freely drilled / removed.

Technological process of threading

In total, it includes four main stages:

- The preparatory stage is the selection of a drill of the required diameter and the implementation of drilling, while the drill must not be left behind. Before that, it must be sufficiently sharpened, otherwise the material will overheat, and the reliability of the thread will decrease. The hole is countersunk, and in the case of a blind hole, a small depth allowance must be reported;

- Cutting directly - at this stage, all movements performed are carried out measuredly, clearly and accurately, lines should not be skipped, but all three should be applied in sequence from coarse to precise;

- Cleaning stage - here they clean the passage holes with a wire brush, and the deaf ones - with air under pressure or with a construction vacuum cleaner;

- Check stage - here it is necessary to screw the screw into the existing hole, while the entry should be smooth along the thread, without any extra effort and all sorts of distortions.

Tap Damage - Possible Causes and Solutions

The tool in question, of course, is not entirely durable, prone to banal obsolescence and natural wear and tear. The most common damage cases:

- Warping;

- Too narrow working opening;

- Excessive effort that the operator applies to the gate;

- Failure to follow the reverse half-turn rules at the end of each full scroll.

If any of the above cases occur, then there is no need to rush and try to run the thread faster or try to skip the tap from the set. All this can result in temporary losses, and therefore all extraction actions should be done slowly.

Threading with dies

The connection with bolts can be safely called the most popular type of fastener.However, even super-quality carving will eventually become unusable. And here there are two ways - you can seek help from a professional locksmith or thread yourself. In any case, for this operation, a set of leroks or dies will be needed - this is how hand tools for applying external threads are called. By means of them, it is possible to quickly restore worn-out hardware or make the desired part to an existing stud / bolt.

Classification of lerok (dies) by design

The first characteristic that distinguishes one die from another is the hull design. According to this indicator, they are divided into:

- The dies are rounded - their body is a full-fledged ring, through which the workpiece is passed. Due to the increased rigidity, as a result, a high-quality spiral profile is formed on an excellent thread;

- Sliding dies (lehrs) - they consist of 2 elements and are intended for the manufacture of threaded areas of different diameters;

- Cutting dies - their threaded diameter along the take-off can be from 0.1 - 0.3 millimeters, and therefore they must be used when applying inaccurate threads.

Thread orientation classification

On this basis, the dies can be subdivided:

- Left - rarely used and especially in specific auto parts, rotation mechanisms, and in cases where the right thread can unwind;

- Right - the most popular direction, used on screws, bolts, axles.

Profile classification

According to the profile of the plate can be:

- Metric - have a metric thread, marked with the letter "M", followed by a number indicating the diameter in millimeters.Sizes up to 68 mm are standard, while each standard corresponds to a large or small step (in the Russian Federation this is regulated by GOST 9740);

- Cylindrical pipe - marked with the Latin letter "G", their thread is measured in inches (relative to the metric system 1 inch = 2.54 mm);

- Conical pipe - they will be marked with the letter “K”, they are used to obtain a threaded surface in the form of a cone in especially critical joints that are installed in places where elements work under high pressure (for example, working units of production machines);

- Trapezoidal - their thread section is an equilateral trapezoid. They are used in power pairs, where rotation is converted into translational movements (for example, a nut and a lead screw in a bench and machine vice).

Die holders

In order to cut, one die will not be enough. It is also necessary to use an assistant device for holding and clamping the lehrka - it is called a die holder. One such device is immediately designed for several sizes - from small to large. The plate is installed inside and held by a screw.

Production material

For the production of dies-lerok, high-speed steel R18 or R6M5 is used as standard. They are good in terms of "price / quality", have an extended operating period and do an excellent job with minor repairs and household work.

Thread cutting technology using dies

Basically, the principle of action is quite simple, however, and here there are some nuances:

- At the preparation stage, you need to grind off a small bluntness at the end of the part with a file (the tool will cut better);

- Firmly fix the die in the holder, make sure that it does not rotate;

- Perform two full turns, slightly pressing the handle with your hand;

- After the tool has entered the part, you need to perform 2-3 full turns and one action half a turn back - this way the application is performed more efficiently.

IMPORTANT! It is necessary to constantly control the position of the holder in relation to the element to be processed - it must always be perpendicular in the absence of inclination!

Features of choosing a set of dies and taps

First of all, you need to clearly separate all the tools and navigate the set. There are professional options for kits, and there are amateur ones designed for domestic use.

First you need to decide on the type of dies / taps. For example, which system is supposed to be used more preferentially - inch or metric. In Russia, the metric system is more often used. Here you can visually identify the lehrs of this system on the basis of their conical shape and the established metric thread pitch. It is also worth considering the fact that the threads of the lerka are of a triangular profile - this can be seen from the last turns of the blades. Thus, using a similar tool, the nut can be screwed onto the restored thread.

The accuracy of the desired cutting will be achieved through split dies, and if precise cutting is not needed, then it makes sense to take a set with solid lehrs. Of course, most professionals advise purchasing a set that contains all existing types of cuts.

Separately, it is necessary to mention the cases - the sets can be in convenient plastic or wooden boxes, they allow you to comfortably transport the entire tool. And if necessary, it is easy to use it.

Regarding the material of manufacture - in this case, there is no need to philosophize much - the tool, by definition, is made of high-strength high-carbon steel. However, you should still avoid outright counterfeiting - usually Asian “no-name” manufacturers make their sets from soft metals.

Rating of the best sets of taps and dies for 2022

Hand sets

3rd place: 5545 ERMAK M3-M10

An excellent and inexpensive set of domestic production, perfect for domestic needs. Although the set of tools is small, it is able to cope with the most common household tasks. The case is made of plastic, has foam recesses for tool storage.

| Name | Index |

|---|---|

| Number of items | 14 |

| case material | Plastic |

| Total weight, grams | 600 |

| Producing country | Russia |

| Dimensions, mm | 15x20x15 |

| Price, rubles | 1300 |

- Budget price;

- Durable tool making material;

- Sufficient functionality for everyday tasks.

- Fragile case.

2nd place: Stayer Master 28020-h24

Expanded in functionality kit from a foreign manufacturer. It is quite capable of coping not only with household tasks, but can also be used for simple minor repairs of auto parts. Supplied in a metal case, tool compartments are made of plastic.

| Name | Index |

|---|---|

| Number of items | 24 |

| case material | Metal |

| Total weight, grams | 1200 |

| Producing country | Norway |

| Dimensions, mm | 30x20x30 |

| Price, rubles | 2100 |

- Advanced functionality;

- Adequate price;

- Dual measurement system (inches and meters).

- Inconvenient case.

1st place: "Berger" BG31TDS

In many ways, a universal kit, because it can be used both for locksmith and automotive parts. Most of the dies and taps for standard rifling are present in it. Excellent quality of sharpening allows not to make excessive efforts during the work. The case is made of steel and has a strong key lock.

| Name | Index |

|---|---|

| Number of items | 31 |

| case material | Metal |

| Total weight, grams | 1300 |

| Producing country | Denmark |

| Dimensions, mm | 30x20x30 |

| Price, rubles | 3400 |

- Excellent cutting quality

- Reliable case;

- Durable tool material.

- In practice, there is no M12x1.25 die (it is not in the photo, but it is in the description).

Machine kits

3rd place: ZUBR Professional 28110-H24

Like most professional kits, this one is distinguished by a large number of tools in the kit, a wide range of their application, and the use of several marking systems at once. All tools are made of high-carbon, durable steel and are designed to withstand the highest loads when installed in machine tools.

| Name | Index |

|---|---|

| Number of items | 24 |

| case material | Metal |

| Total weight, grams | 900 |

| Producing country | Russia |

| Dimensions, mm | 30x15x20 |

| Price, rubles | 4700 |

- Uses two systems - pipe and metric;

- Durable metal tool making.

- Not identified (for its segment).

2nd place: SKRAB 33895

This kit is distinguished by a convenient arrangement of items in the case - taps on the bottom, dies on top. To hold the tool under the internal thread, there is a special gate with embossed handles.A universal die holder for all sizes is also supplied. Users note the high quality of cutting both with machine and manual methods of work.

| Name | Index |

|---|---|

| Number of items | 45 |

| case material | Plastic |

| Total weight, grams | 1100 |

| Producing country | Taiwan |

| Dimensions, mm | 30x20x30 |

| Price, rubles | 9700 |

- Convenient arrangement of items in the case;

- Universal holder for lerok;

- Complete set with a special gate.

- High price.

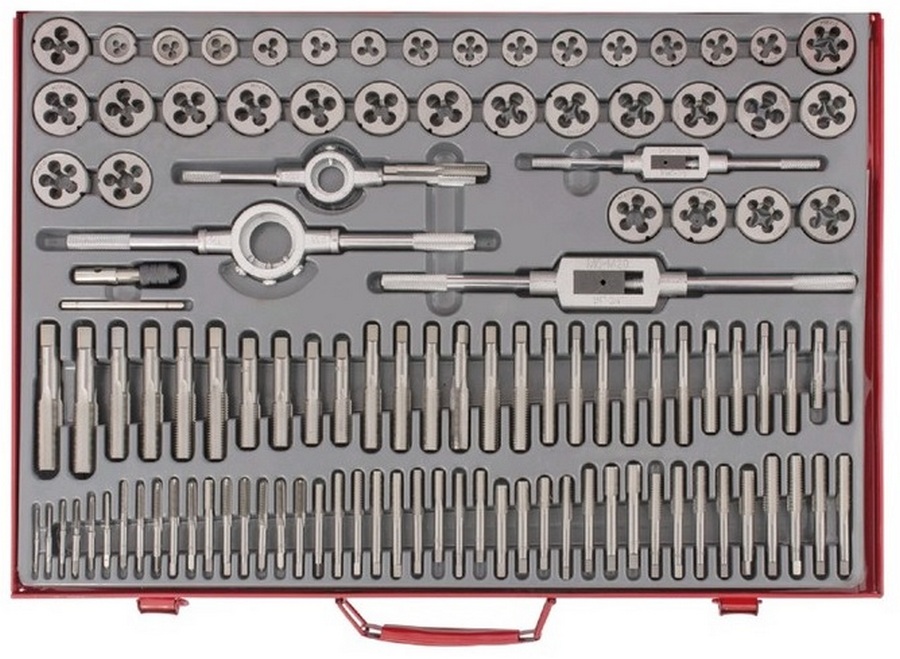

1st place: Matrix 773110

The most professional set for 110 items. Able to perform absolutely any work both in domestic and industrial terms. Fully suitable for machining parts made of any material - aluminium, cast iron, steel and copper. All tools are made of innovative heavy-duty cutting steel 9XC.

| Name | Index |

|---|---|

| Number of items | 110 |

| case material | Plastic |

| Total weight, grams | 1500 |

| Producing country | Taiwan |

| Dimensions, mm | 50x30x50 |

| Price, rubles | 11000 |

- Current price/quality ratio;

- The tool is made of the latest steel;

- Practical versatility and a lot of functionality.

- Not found.

Instead of an epilogue

During the analysis of the market, it was found that the Russian buyer still prefers foreign variants of sets. This is due to their wider functionality, as well as additional equipment. At the same time, users from Russia try to make most purchases via the Internet. The reason for this is the high cost of a really good kit, in connection with which it is necessary to make some financial savings, which allows you to do online shopping.

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131651 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127690 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124519 -

The best men's sneakers in 2022

Views: 124033 -

The Best Complex Vitamins in 2022

Views: 121939 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114980 -

The best paint for gray hair - top rating 2022

Views: 113395 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105329 -

Ranking of the best sex dolls for men for 2022

Views: 104366 -

Ranking of the best action cameras from China in 2022

Views: 102216 -

The most effective calcium preparations for adults and children in 2022

Views: 102011