Rating of the best mounting boxes for 2025

The mounting box is popularly called the socket box. This device is designed to provide isolation and order when placing outlets, switches, and other electrically-based mechanisms.

The appearance of the box is made in the form of a cylinder or a box with round holes. The device is placed in a recess in the wall. The end of the wire from the strobe is installed in the socket. The cable end equipped with protection is joined to the insulating box, then the socket itself is mounted.

Content [Hide]

Mounting box device

Mounting boxes are designed according to common standards. This is necessary to avoid confusion when conducting electricity to the house. The standard socket set includes the following components:

- Socket compartment.

- Switch lever.

- Power regulator.

- Heating and cooling controller.

- Additional regulators.

In the back and side sides of the device there are compartments that can be printed out for the wire. Such a solution is necessary to eliminate unnecessary drilling.

Installation of the components of the socket, switch or other electrical appliance to the box body is allowed in 2 ways:

- With self-tapping screws.

- With the help of universal fasteners (paws, ears, etc.).

The most durable fastener for electrical equipment is considered to be a method using a screwdriver and 2 high-quality self-tapping screws. These self-tapping screws can be screwed both vertically and horizontally (to each other). Most modern boxes have 4 communication compartments, so they have universal compatibility. If the electrical device itself has compartments strictly along the vertical or horizontal axis, it is required to select a mounting box with the appropriate communications.

It is important to consider that if the installation of electrical products (switches, etc.) is allowed using universal fasteners, then the installation of sockets should be done using self-tapping screws. Self-tapping screws will provide a strong connection that will save the structure from breakage if the owner of the house abruptly pulls the plug. Although this method will ensure the safety of the structure, it is still not often used in practice. This is due to the fact that the box must be mounted extremely evenly. When fastening with self-tapping screws, adjustment of the fit is excluded. In this case, the structure remains in the position in which the master fixed the mounting box.

Fasteners using universal fasteners (lugs, paws, etc.) are not able to give the degree of reliability that self-tapping screws give, but this method is more popular. Popularity is due to ease of handling and the ability to adjust the installed box to a small extent, which is enough to achieve the required evenness. A similar method of fastening is suitable for mounting switches and power regulators. The cases of the aforementioned devices have anti-deformation technologies of universal mounts.

Categories of junction boxes by wall material

Socket boxes are also divided into 3 categories depending on the material of the wall. The following sockets are on sale:

- Under a dense wall (plaster);

- Under the plasterboard wall;

- For plinth.

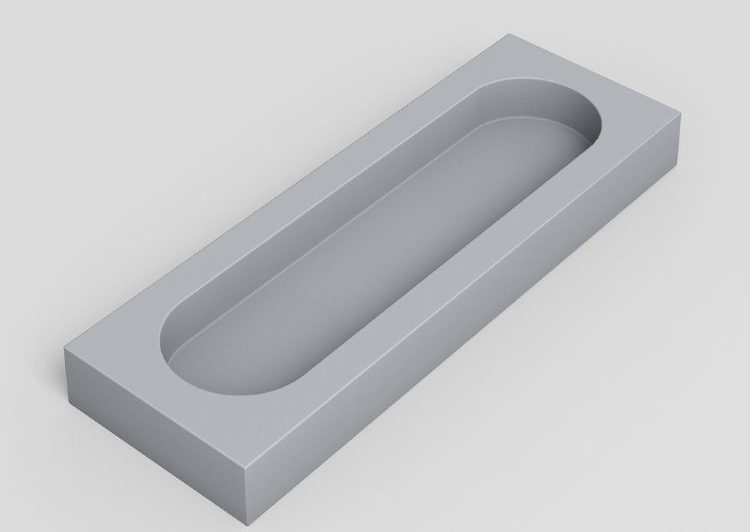

There are devices on the market that allow installation in a plinth. It is important to know that this category of products is only compatible with plastic skirting boards. These socket boxes do not require drilling recesses and strobes in the wall. This type will require embedding the structure in the plinth.The shape of the case provides the most organic joint between the mounting box and the plinth. Wiring is also carried out in a secret manner (under the plinth). This category is not often found, because installation under the baseboard is contrary to building codes. In accordance with the laws, sockets must be placed at a designated height. In addition, such models are not allowed to be combined with switches and switches.

Mounting boxes for complex installation

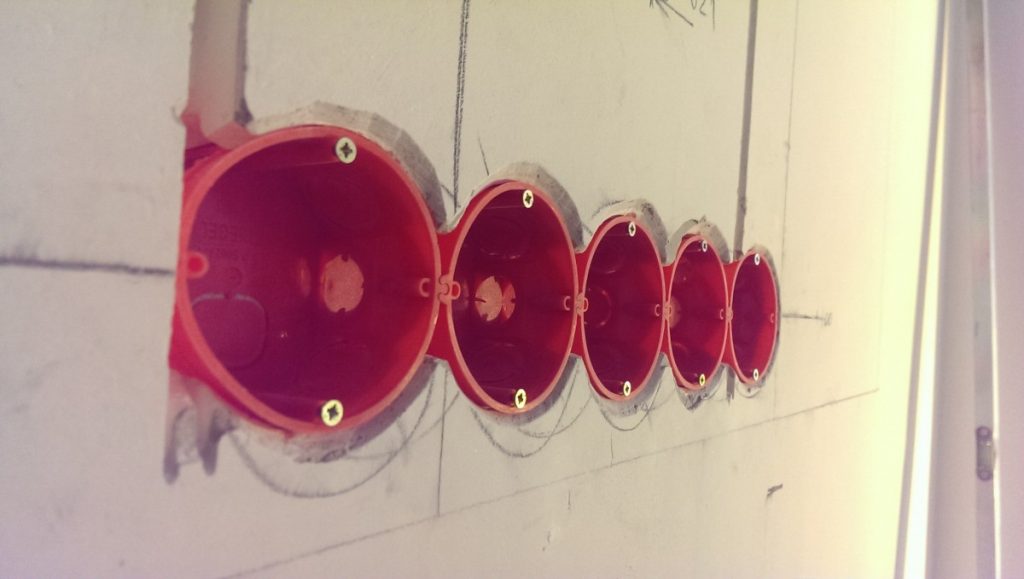

In the case of mounting a complex of sockets or switches in a monolithic housing, the proper distance and spacing between devices must be observed. In order to achieve a uniform pitch between devices, special models are used that are equipped with proper jumpers. Such instances make a single device from a complex of different devices. Using this type of boxes, it is allowed to combine any number of devices, depending on the specifics of the socket.

On sale there are instances whose jumpers are built into the case as a monolithic structure. It is not uncommon to find socket boxes whose jumpers can be dismantled. A subspecies with removable communications allows cabling of devices through jumpers for an ordered connection.

It is not uncommon to find rounded specimens, which involve the installation of many devices under a single monolithic body. This type differs from the previous one by a fixed number of connectors (from 2 to 10), depending on the specifics of a particular instance.

Mounting boxes for brick, concrete, foam block and gas block (plastered surface)

Under the plastered wall are specimens, whose installation involves hiding the body under the thickness of the finishing material.Similar products are usually used for walls made of solid materials (brick, foam block, etc.). To place such a socket, you must use a drill with a special tip. Using a drill, a recess for the body is drilled, then a strobe is hollowed out for laying the cable. The end of the wire is installed in the compartment of the box, then the socket is placed in the recess in accordance with the level. After that, the holes are filled with finishing material, then the master proceeds to the final work.

Junction box Schneider Electric model 203025

votes 1

The Schneider company was founded in the 36th year of the 19th century in France. The company specializes in auxiliary equipment for electrical engineering. Initially, the company produced auxiliary products for large-scale electricity production. In modern times, Schneider is engaged in the manufacture of household appliances.

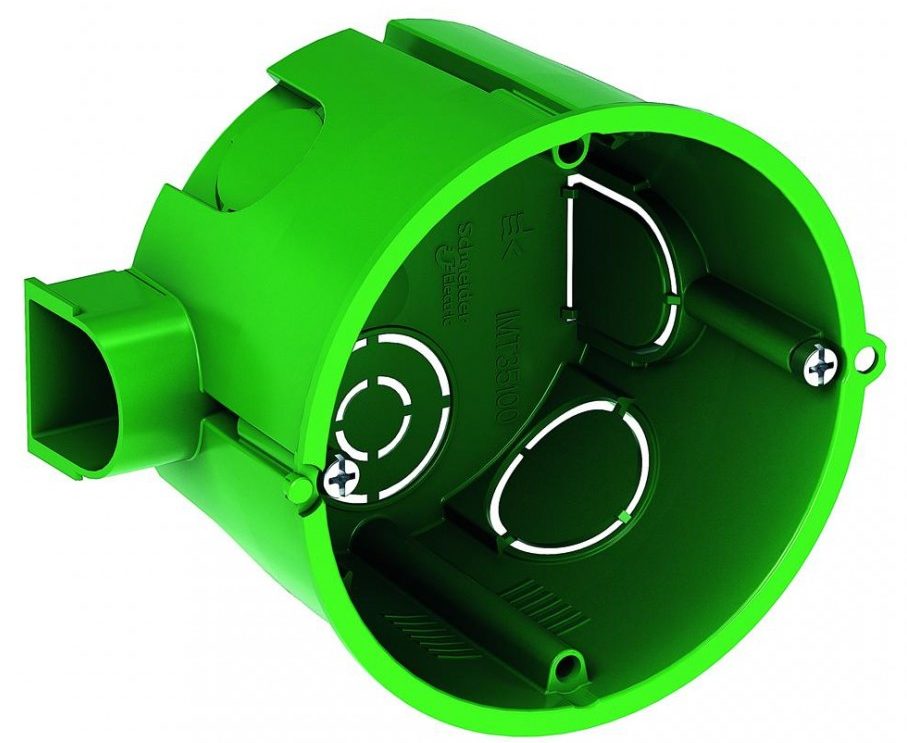

Model 203025 is found on sale at a price of 7 rubles. per piece, the dimensions of the box as a whole are 6.5 by 4.5 cm, the shape is cylindrical, the architecture is for a single network connector. Fastening is carried out both by means of bolts and universal. There are 8 communication connectors, there is also the possibility of rear cable wiring. Made of green plastic, hole diameter - 6.8 cm, length - 8.1 cm, depth - 4.5 cm.

- Low price per piece;

- Company reputation;

- Possibility to pass the cable from the back.

- Mixed reviews.

Review:

“The socket box is of good quality, but I would not recommend it for use in a building with high network loads. This product is suitable for a country house where voltage is not given regularly. I recommend it as an economy option for a country house!”

Junction box Schneider Electric model blnpk000012

votes 0

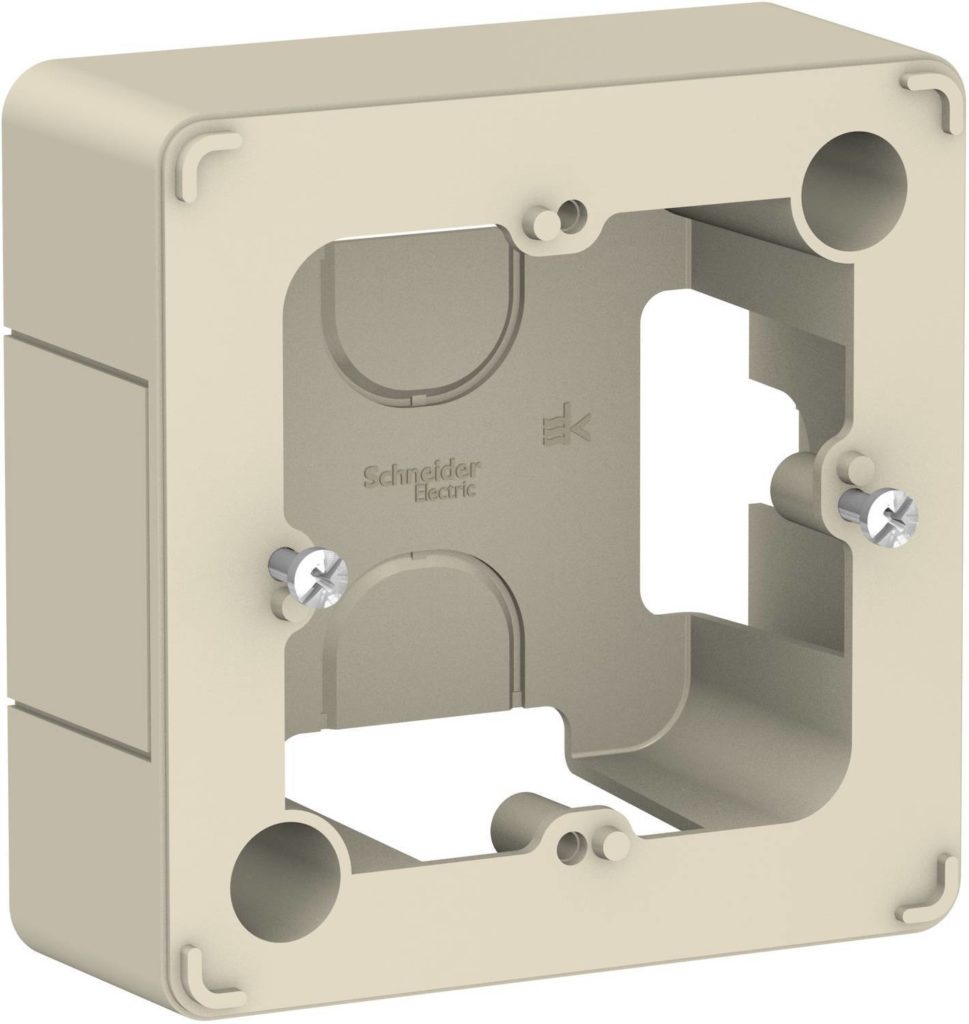

On sale are copies at a price of 60 rubles, white colors, the dimensions of the model are 8.6 by 8.6 by 3.4 cm. A complex connection of models into a single block is allowed.

- Adequate cost;

- Possibility of creating a complex of socket boxes;

- Nice design.

- Not found.

Review:

“This example showed good results in stability, and installation was not a problem. I recommend it to anyone who is looking for a brick socket at an affordable price!”

Mounting boxes for drywall

Placing such a structure in a drywall wall will require a special architecture device. Such a device has 2 mounting platforms, which are fixed with screw fasteners. This fastener uses the entire space of the product body. Screw fasteners fix the socket box like a paper clip on the wall. This category of products will provide a secure fit, but in terms of firm fit, the previous category wins.

Mounting box Gusi model c3e3 sp 68x45

votes 1

On sale is found from 11 rubles. A piece. Fasteners are available both with screws and with lugs. Rear wire routing available, protected to safety standards. Hole diameter - 6.8 cm, depth - 4.5 cm.

- Affordable cost;

- Universal ways of fastening;

- Protected by security standards.

- There are negative reviews.

Review:

“Does the job, but heavy workloads are best avoided. Although the design is protected in accordance with the requirements. I recommend it as an intermediate option for a socket.”

Junction box Tdm model sq1401-0511

votes 0

It is presented on the market at a price of 26 rubles. per piece, the dimensions of the structure are 6.5 by 6.5 by 5 cm. It serves to separate communications and provide additional insulation. The design protects the electrician from mechanical damage, as well as from the negative effects of high humidity and dust accumulation. The product is made from a mixture of plastics.

- Acceptable price;

- Reliable protection;

- Quality manufacturing material.

- Not found.

Review:

“The socket model is excellent, it saves from the effects of dampness, as well as from the negative effects of dust on the electrician. I recommend this model to everyone who is looking for a socket outlet for branching wires with reliable protection!”

Mounting box Era model bs-p-75-75-20

votes 0

It is found in stores at a price of 38 rubles. per piece, the dimensions are 7.5 by 7.5 by 2 cm. The product is used to organize telephone cables with protection from harmful influences, such as physical damage or the harmful effects of moisture.

- Adequate price tag;

- Reliable protection system;

- Appearance.

- Not available in all stores.

Review:

“The main advantage of the model is the appearance and reliability of the design as a whole. This socket copes with its task, there were no failures in the work. Would recommend to anyone looking for a reliable quality copy!”

Mounting box Stekker model ebx10-24-44

Available for sale at a price of 46 rubles. per piece, serves as the basis for the organization of cable communication. It is protected by protection standards, localization in the open air is allowed, the material of manufacture excludes combustion, there is the possibility of communication between the model and other structures.

- Acceptable price;

- Possibility of installation outside the house;

- Easy to install.

- Not found.

Review:

“The socket box of this model from Stecker proved to be the best in terms of protection against unwanted effects of moisture and dust. In addition, there were no problems with the installation of the device. Would recommend to anyone looking for a back box with some serious protection!”

Junction box Ruvinil model 67045

votes 0

On sale is found at a price of 63 rubles. Per piece, the dimensions of the structure are 10 by 10 by 5 cm. The form factor is square, the structure is made of plastic-based materials, protected by a degree of protection in accordance with Ip54 standards. It can be used in any climatic conditions, the case carries 8 connectors for communication.

- Adequate price tag;

- High standards of protection;

- Possibility of use in any climate.

- There are mixed reviews.

Review:

“Not a bad box for the money, given the high degree of protection. There are 8 connectors for communications on the case, so the range of use of the model is wide. Installation of the structure will not cause difficulties, the box is unpretentious in operation. I recommend it to anyone who is looking for a reliable mounting box for an adequate price!”

Mounting box Dx model 53700

votes 0

Available for sale at a price of 70 rubles. Each unit measures 8 cm x 8 cm x 4 cm. Form factor is square, recommended for use as a base for organizing males, protection is of a high standard. The product is made of plastic-based materials, there are 6 connectors for communications.

- Acceptable cost;

- High standards of protection;

- Quality manufacturing materials.

- Not found.

Review:

“An excellent copy for its price range, there were no complaints in operation, as well as in installation. I recommend it to anyone who is looking for a quality socket!”

Soundproof socket boxes

The main task of these mounting boxes is to ensure the integrity of the soundproofing system of the room, because it is in the places where sockets and switches are installed that sound transmission can be observed.

All of the socket boxes listed below are produced for a different number of positions (sockets, switches) that can fit inside the box. As a rule, this number is in the range from 1 to 4.

The cost of the product is higher, the more sockets it is designed for.

The most popular acoustic sockets are:

MaxForte SoundBOX

votes 0

This box is made of high-strength polymer, characterized by fire safety and long-term performance. Inside the product can be placed from 1 to 4 outlets.

It differs from most of its competitors in its small thickness (the required depth index), 34 mm, which allows the box to be used even in thin soundproof systems.

The cost of the product for 1 outlet is 1300 rubles.

- Small thickness;

- Does not complicate further plastering of walls, because. the box rises by only 3 mm and does not protrude beyond the finish layer;

- Fireproof materials of the socket box;

- Long service life of the product;

- The front side is slightly rough, which allows the plaster to lay down well on top.

- Not tagged by users.

Review:

“I chose the box as a replacement for home-made boxes from GVL sheets.The advantages are obvious, in addition to saving time, you get a structure without joints, completely monolithic, which provides additional sound insulation.»

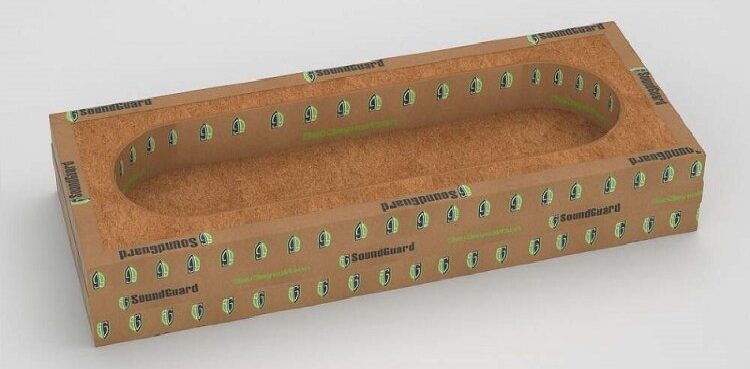

SoundGuard IzoBox

votes 0

Also, like the previous sample, the box is presented in several modifications and can fit inside from 1 to 4 sockets / switches. The cost of a box for 3 positions is 2000 rubles.

The material here is multi-frame cardboard, corrugated, with quartz filler. The product can be installed inside a frame structure, fixed in a layer of sound-absorbing wool and/or a sound-proof panel.

- The general indicator of the soundproofing system of the room is significantly increased with this box;

- Installation does not require special skills and tools.

- Not marked.

Review:

“Good design, easy to install, although there are doubts that the cardboard is still a combustible material.”

SoundGuard IsoBox 4 Standard

votes 0

This acoustic box differs from the previous version primarily in the material of manufacture. Here it is wood chips and resin. This makes the product moisture resistant, which means it can be used in rooms with high humidity, bathrooms.

The option under consideration involves the placement of 4 electrical outlets / switches inside, there are options with a smaller and larger capacity indicator.

The size of the considered acoustic socket: 55 x 115 x 36 mm, cost: 1180 rubles.

- moisture resistant;

- Can be used in wet areas;

- Easy to install;

- Significantly affects the overall sound absorption.

- Not marked.

Review:

“I installed this box when installing soundproofing in the room, the installation did not take much time, the sound through the socket really became less audible.”

Outcome

It is important to take responsibility for the choice of mounting box in order to avoid a number of unpleasant consequences. The appearance of the wall, as well as the safety of the room as a whole, depends on the quality of the socket. To avoid the most commonplace mistakes when choosing a junction box, you should familiarize yourself with the basic provisions on the market for such devices.

There are 2 types of socket boxes on the market, plastic and metal products. Both categories have specific properties that should be researched before purchasing a particular product.

Plastic sockets are more popular than metal ones. Popularity is explained by a more favorable price in combination with useful properties. Plastic products are made according to technologies that provide the product with resistance to burning, which makes it possible to use such specimens as universal ones. The main disadvantage of products made from this material is considered excessive elasticity. If you fix such a socket with universal fasteners, you will not be able to get the proper landing strength. In such a scenario, the owner of the house runs the risk of facing deformation of the outlet when the plug is abruptly removed. When buying a plastic product, it is recommended to pay attention to specimens with the thickest and least elastic body.

A steel junction box is considered the least safe because steel has no insulating properties. Such socket boxes are not popular due to the fact that metal conducts current, moreover, the price is an order of magnitude higher than that of plastic ones.Before. Steel products were popular because of their resistance to combustion. Modern plastic socket boxes are not inferior to steel ones in stability, so the latter have lost popularity. Although metal products require skill during installation, steel boxes still win in structural rigidity, which is important during long-term operation. In addition, rigidity opens up additional horizons in the installation and use of electrical devices, which ensures a strong niche position of steel sockets. One of the main disadvantages of metal products is the inevitable appearance of rust. With long-term operation, this problem will bring a number of difficulties to the owner of the house. In practice, problems are identified as follows: the owner of the house plasters an unnecessary socket with a solution, and after a while, traces of corrosion appear on the plastered surface. Neither paint nor wallpaper saves from this effect. When using a plastic socket, a similar problem is excluded.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131652 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127693 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124520 -

The best men's sneakers in 2025

Views: 124034 -

The Best Complex Vitamins in 2025

Views: 121941 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2025

Views: 113396 -

Ranking of the best wood paints for interior work in 2025

Views: 110320 -

Rating of the best spinning reels in 2025

Views: 105331 -

Ranking of the best sex dolls for men for 2025

Views: 104369 -

Ranking of the best action cameras from China in 2025

Views: 102217 -

The most effective calcium preparations for adults and children in 2025

Views: 102012