Ranking of the best mini circular saws for 2022

Often, professional craftsmen need to perform a large amount of work in the carpentry field, so stationary saws on discs become the best assistant for them in this matter. But for amateurs who infrequently or not on a professional basis are engaged in carpentry, such an expensive device is completely unnecessary, because it is not cheap in maintenance and takes up too much space. Thus, home craftsmen usually choose the best option for themselves, which is classified in the carpentry environment as a “mini-disk saw”. This type of tool belongs to the class of manual circular saws and is specially oriented to semi-professional activities. However, it is worth noting that in many technical parameters such devices do not differ much from their “older” counterparts.

Content [Hide]

- 1 Distinctive features of miniature saws

- 2 Structural elements

- 3 Existing species

- 4 Specifications

- 5 Additional options

- 6 Cutting disc operation

- 7 Outer disc diameter

- 8 Fundamentals of safe work

- 9 Ranking of the best mini circular saws for 2022

- 10 Eventually

Distinctive features of miniature saws

Their main purpose is to work with wooden blanks of relatively small dimensions. In particular, they specialize in the following tasks:

- Sawing wood along and across the fibers;

- Cutting any wooden parts, including MDF, laminate / plywood and chipboard;

- Cutting thin and soft metal.

The devices themselves have several main distinguishing features:

- Small sizes of units;

- Relatively small weight - up to 2 kilograms;

- The small size of the working disk;

- Limited cutting depth.

Based on the above characteristics, a small saw is optimal for soft metal profile operations or for thin wood applications in the home.

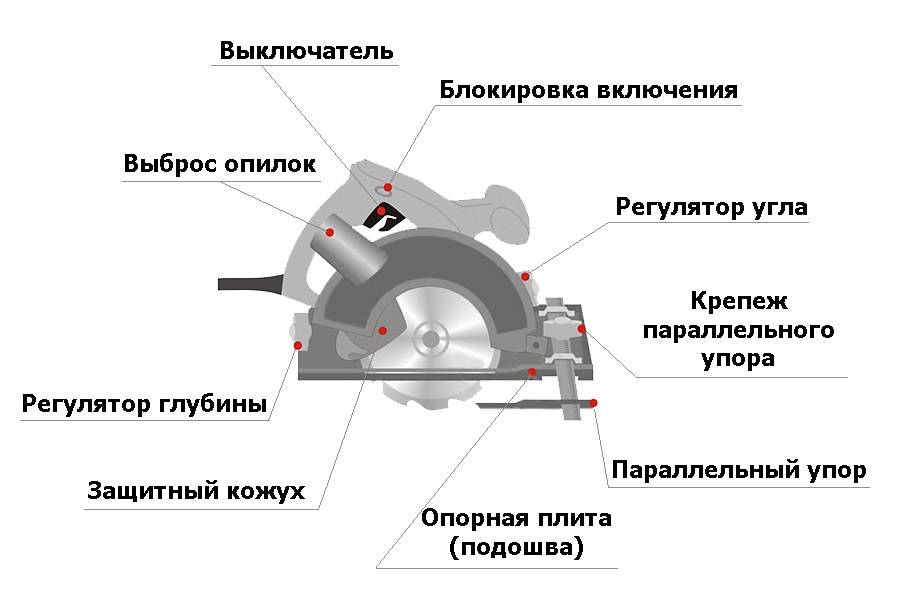

Structural elements

Despite the narrow orientation of the described unit, it has a rather complex device.The main working part in it is a saw blade with teeth, which is driven by an electric motor. Usually, this element is located on the front of the device. Manufacturers also produce a variety of saw blades, the shape of the teeth of which will be specifically designed for a specific task - sawing wood, pressed boards or metal.

In order for the mini-circular to work on hard material, hard alloy soldering is applied to the teeth of its working disk. Therefore, the entire workflow is many times faster, but the cut line may not turn out to be too smooth.

In order to ensure the protection of the operator's hands during the rotation of the saw, the working disk itself is covered with a safety cover. As a rule, the upper part of such a box is securely fixed, but the lower part rises slightly when working on the workpiece.

The electric motor itself is installed in a small case, which, in fact, is also a handle. Smaller specimens are standardly made in a plastic case and can be equipped with rubber elements (for easy holding). The engine start button is located on the body itself. On larger models, the handle for holding is located on top, on smaller models it is located behind the body.

The specified placement of the handles allows you to make the entire tool more mobile and maneuverable. Some samples of small saws can be additionally equipped with a support platform, with the help of which the master, without overstressing, calmly holds the canopy device, which ensures a more stable positioning of the tool during work operations.

Existing species

To date, the market has a fairly extensive range of miniature saws. You can choose the most preferred option for any type of proposed work. Therefore, it is necessary to consider in more detail each variety of small circulars.

Manual models

They differ in a rather complex device and design. Usually, this type of device is intended for operations with pliable and thin material:

Through them, it is permissible to perform the following operations:

- Cutting metal with soft structure;

- Cutting various types of wood (including laminate, chipboard and MDF);

- Sawing wood across and along the grain.

Distinctive features of manual models are considered to be:

- Small dimensions, allowing you to easily transport the tool from place to place;

- Relatively low weight - this indicator rarely exceeds 2 kg .;

- Have a small working capacity;

- The size of the saw blade itself is also quite small;

- The resulting cut is not too deep.

IMPORTANT! Hand saws are suitable for working with certain materials that have a soft base. A small manual circular is unlikely to cope with denser raw materials, especially since an attempt to work with such a tool on it can lead to a breakdown of the apparatus.

Disc models

They are characterized by a complicated design. Again, the main working part will be a saw blade designed for processing various materials. Also, as in hand saws, the rotation of the disk is started by means of an electric motor. However, these tools have several distinctive parameters and are equipped with a number of additional functions:

- Variability of cutting depth adjustment - with the help of a special regulator, it is possible to shift the cutting part of the disc below the tool stop.

- The ability to remove chips / dust - in a number of samples, a special pipe is installed through which you can connect a vacuum cleaner (usually industrial), which will automatically suck chips and remove dust (this option is especially relevant when carrying out large repairs, when it is necessary to prevent dust from settling on the surrounding fittings).

- Protection against accidental on / off - for this, there are two special buttons on the case, pressing them simultaneously turns the device on / off.

- Permanent mode of operation (no breaks) is a very useful option when you need to perform a very long cut, which is clearly time consuming.

Desktop models

Mini-circular saws can also be made in stationary desktop versions, however, such samples are not widely used. It's all because of the fact that the main property of a mini-circular saw should be its mobility and small dimensions, although its functionality is sacrificed. At the same time, if the master has the opportunity to take up a relatively large space under the desktop, then there is no need to choose a small saw - it's easier to take a full-fledged professional desktop model.

Battery Models

Due to the fact that the sizes of the considered saws, in principle, do not provide for the placement of capacious batteries in their cases, they are almost not represented in a number of autonomous devices.

But they still exist, and they are distinguished by ultra-low power. But they are able to work in places where there is no electrical connection.The absence of a power cord allows you to work at height, in the field, etc. The downside is that cordless saws are not designed for a long time of permanent action, but the solution will always be the presence of spare additional batteries. The standard voltage that such batteries support is 18 V. It is worth noting that the battery must be from the manufacturer of the saw itself - universal battery models are almost never found. The same rule applies to the charger. However, some "craftsmen" can also remake the charger for a certain brand of batteries, but it's not a fact that the battery in this case will last a long time.

Specifications

As a rule, small circulars are classified as lightweight tools, so they have rather modest qualities:

- Power - the cleanliness of cutting and overall performance directly depend on this parameter. The nominal value for this category of saws varies between 400-800 watts. This is enough for cutting thin lath and plywood.

- The speed of rotation of the working disk - this characteristic will affect the quality of the cut. At high speeds, for example, cutting plastic will be inefficient, because the material being processed will begin to melt. But when working with wood, the speed can be increased. In the case of metal work, again, a decrease in frequency will be required, because the cut may turn out to be uneven. This leads to a certain conclusion - it is better to have a model in which the speed can be manually adjusted.

- Cutting depth - this property is directly affected by the size of the disk and the very features of the protective cover.It often happens that saws with the same diameter of the working saw blade cut parts with different depths. The nominal characteristics are as follows: with a disc diameter of 65 millimeters, the cutting depth will not exceed 50 millimeters (the missing 15 millimeters will be limited by the casing).

- Cutting angle variability - this function is provided in many models of modern mini-circulars, usually it is set within 0-45 degrees. Although, most masters, both professionals and amateurs, do not often use this option. Therefore, focusing on its mandatory presence when buying a tool seems inappropriate.

Additional options

Modern models of miniature circulars are more than often equipped with many additional options that are a great help in the work of the master. Naturally, such a unit will cost more than the most standard model, but in most cases this will be justified:

- Plunge sawing - there are saws that can start sawing not necessarily from the edge of the sheet, but, for example, from the middle. This design provides for the possibility of lifting the saw blade at any time during operation. This option is very useful when it is necessary to cut a window, a hole for a tube or a socket in a solid sheet.

- Wedging knife - due to the fact that the wood fibers are subjected to excessive stress when interacting with the saw blade, then at the end of the work they can close and the cutting disc will be in a clamped position. However, this situation can be avoided if a riving knife is placed behind the saw blade.In order to ensure the normal operation of this device, its end must be located at a distance of 3 centimeters above the lowest tooth of the cutting wheel.

- Soft start - the presence of this function will allow the cutting disc to gain momentum evenly, without any jerks. The option will provide not only comfortable work for the master, but also create a more gentle environment for the operation of the electric motor.

- Controlled speed during load changes - the undoubted advantage of this option is that in the case of processing hard material, the electric motor independently increases the power output, while maintaining the speed stability parameter.

- Jamming resistance - this function is provided by a special mechanism called a slip clutch. Thus, even at the moment when the cutting wheel jams, the motor will stop its rotation without any harm.

- Prohibition of accidental start - quite by accident, you can turn on almost any tool. In order to prevent this situation, manufacturers simply install another start button on the case. As a result, the start of the entire unit will be possible only if both buttons are pressed simultaneously. In principle, such a structure for operating a small saw may seem difficult to some, but it will prevent many situations that are potentially dangerous for the operator.

- Overload protection - this feature will become especially relevant for light devices and devices with reduced power. The protection will work automatically as soon as the load limit is reached.

- Integration with a vacuum cleaner is an excellent additional option, useful in cases where it is necessary to keep the workplace clean.

- Laser sight (pointer) - with its help, you can carry out cutting operations without the need to apply preliminary markings to the material. However, the constant use of the laser pointer in work is more suitable for professionals, so it is worth adjusting to keep it level. It is used in the production of high-precision cuts.

- Spindle lock - the function fixes the disk, preventing it from accidental rotation, for example, during its change.

- Electrodynamic brake - instantly slows down the rotation of the electric motor after releasing a special key, so there is no need to wait up to 10 seconds until the rotation stops completely.

- Parallel stop - designed for making cuts parallel to the surface of the material from the side. On a special stop ruler, a special graduation is applied to set the width.

- Stationary installation - thanks to special fasteners, some model options can be attached to a table or workbench, while receiving an almost full-fledged likeness of a sawing machine. Such samples have some bevel in the upper part of the body. This option is more common in semi-professional, powerful and expensive models. With such an installation, it is necessary once again to make sure that the fasteners are securely fixed before starting work, because they will bear the bulk of the load.

Battery models may have their own additions:

- Battery capacity - the larger the capacity in mAh, the longer the tool will work (all other things being equal).

- Battery voltage - a higher value of this parameter indicates an increased power of the device, as well as an increased battery life.

- Type of battery - modern models mainly use a lithium-ion type of battery, which is characterized by a high cell capacity, the absence of a "memory effect" (does not require complete discharge to zero before the next charge). However, lithium-ion batteries do not tolerate low temperatures very well, they are quickly consumed in the cold. There is another option in the form of nickel-cadmium batteries, although they are considered obsolete, they have not yet completely disappeared from the market. By themselves, they weigh more than lithium ones, they need to be completely discharged before a new charge, but they can easily withstand any temperature fluctuations.

- The number of batteries in the set is very good when several batteries are included in the cordless saw kit at once - their presence will allow you not to take long breaks in work. Usually, there are no more than two of them, but the best option would be to have three - while one battery is charging, you can successfully work alternating the other two.

IMPORTANT! The best construction tool brands try to make interchangeable batteries for different types of their tools. For example, a battery from a jigsaw of one company can fit a mini-circular, a screwdriver, and an angle grinder of the same brand.

Cutting disc operation

When operating with the described type of saws, you should always remember that they are primarily a tool designed for cutting, and therefore their working circle will certainly become dull at a certain point in time. Only its high-quality sharpening or a full replacement with a new one can correct this situation. Thus, in order to avoid premature blunting, it is necessary to select a working element depending on the density of the material to be processed.

Outer disc diameter

Its choice must correspond to the technical parameters of the material to be processed. Due to the fact that there are a lot of variations of this parameter, the manufacturer must indicate them in the instruction manual.

Nozzle hole diameter

Due to the fact that the circles differ in diameter, their nozzle holes may also be different. All this, again, will be interconnected with other parameters specified in the instructions. Some standard values have a common marking.

Tooth characteristics

Large teeth are used for rough and straight cutting. Their use is characterized by the fact that much less time is spent on sawing, but its (cutting) quality leaves much to be desired. It is worth remembering that circles with large teeth should not be used on pressed material - they will simply tear it. In this case, it is preferable to use fine-toothed discs, so they are ideal for processing wood board or plywood.

IMPORTANT! Experts advise to purchase several types of cutting elements at once, so to speak, for all occasions. Particularly useful are circles that have additional holes in the base - they increase the operational life, because their presence does not allow the circle to overheat frequently during work operations. However, these saws are rarely used with such an intense load.

Fundamentals of safe work

Despite the fact that the mini saw is a lightweight device, it can also cause serious injury if handled improperly. All operations performed will require the utmost care and attention from the master:

- Protective goggles and gloves must be worn during operation.

- Do not turn on/off the saw while it is under load. Always first remove the cutting wheel from the material.

- Visual control over the sawing process should only be carried out from the top position, because the rotation of the working circle occurs from the lower direction.

- In order to obtain more accurate cuts, you need to use a special slot in the base of the platform, which is just designed for precise positioning.

- If it becomes necessary to set up a sight (laser control center), it is better to make a couple of test cuts in an unimportant place on the part.

- Mini-saws do not like long periods of constant work, you should try to work in time periods of no more than 15 minutes.

Ranking of the best mini circular saws for 2022

Economy class

3rd place: PIT PMS89-C

votes 0

This sample will perfectly cut metal and wood, and at low speeds it will easily cope with plastic. The rubberized handle is perfectly located in the hand, does not slip, providing comfort of work. In order to prevent slippage, special notches are located on the start key. The general conclusion about the tool is a good price / quality ratio.

| Name | Index |

|---|---|

| Power, W | 600 |

| Revolutions, min | 5500 |

| Cutting depth, mm | 28.5 |

| Weight, kg | 4.1 |

| price, rub. | 4500 |

- A budget option;

- Protection of discs from overheating through holes in the base;

- Large teeth.

- Big weight.

2nd place: DIOLD DP-0.55 MF

votes 0

An excellent sample from a Russian manufacturer specializing in sawing wood and chipboard. Particularly focused on home use. Able to withstand long-term loads.It has increased power, so it is able to process even hardwoods. The set includes a rich package: a ruler, a key, an additional saw blade, a case.

| Name | Index |

|---|---|

| Power, W | 550 |

| Revolutions, min | 4500 |

| Cutting depth, mm | 25 |

| Weight, kg | 2 |

| price, rub. | 5100 |

- Extended equipment;

- Comfortable handle grip;

- Complete focus on processing any type of wood.

- Not found (for its segment).

1st place: Makita HS301DZ

votes 0

This model is particularly compact, however, it is preferable to use it on materials of medium and increased softness, such as plastic, PVC pipes, softwoods. It has the ability to adjust the variability of the cutting angle - up to 45 degrees. Powered by rechargeable batteries, which are purchased separately.

| Name | Index |

|---|---|

| Power, V | 10 |

| Revolutions, min | 1500 |

| Cutting depth, mm | 26 |

| Weight, kg | 1.6 |

| price, rub. | 6500 |

- No backlash;

- Convenient case for transportation;

- Light weight.

- Small turns.

Middle segment

2nd place: Einhell TC-CS 860/1 Kit

votes 0

A multifunctional sample that copes well with laminate, and with plastic, and even with ceramic tiles, not to mention the main materials - metal and wood. Integration with an industrial vacuum cleaner is possible. The set is perfectly completed - by default, as many as 3 removable disks are immediately included!

| Name | Index |

|---|---|

| Power, W | 450 |

| Revolutions, min | 6000 |

| Cutting depth, mm | 26 |

| Weight, kg | 1.9 |

| price, rub. | 7400 |

- Power and lightness;

- Accuracy when cutting;

- Sufficient equipment.

- Rigid and short power cord.

1st place: BOSCH GKS 12V-26 2/0Ah х2L-BOXX

votes 0

Rechargeable version, characterized by a relatively long operating time. More positioned as a tool for field work in the absence of a permanent power source. Possesses variability of an angular sawing. Equipped with a spindle lock, which provides additional security and simplifies the change of the cutting element.

| Name | Index |

|---|---|

| Power, V | 12 |

| Revolutions, min | 1400 |

| Cutting depth, mm | 27 |

| Weight, kg | 1.4 |

| price, rub. | 9000 |

- Increased time of continuous action;

- Designed for field conditions;

- 2 batteries in the set by default.

- Expensive consumables.

Semi-professional samples

2nd place: BOSCH UniversalCirc 12-0

votes 0

The tool is positioned as an advanced model for amateur home use. Power is supplied from a replaceable battery, which is purchased separately. Guide rail included. It is especially noted that the control of this device is characterized by increased safety due to the many blocking functions (from safe switching to stop spindle).

| Name | Index |

|---|---|

| Power, V | 12 |

| Revolutions, min | 1400 |

| Cutting depth, mm | 26 |

| Weight, kg | 1.4 |

| price, rub. | 9700 |

- High performance;

- Increased security;

- Power and lightness.

- Not detected.

1st place: Makita HS301DWAE

votes 1

A very expensive and productive option, equipped with many additional options. However, this greatly affected the overall cost. Able to process parts from any materials for which miniature circulars are adapted. It has a blocking of accidental activation.

| Name | Index |

|---|---|

| Power, V | 10.8 |

| Revolutions, min | 1500 |

| Cutting depth, mm | 28.5 |

| Weight, kg | 1.6 |

| price, rub. | 12000 |

- Multifunctionality and versatility;

- Ergonomics;

- Lots of options available.

- High price.

Eventually

Despite the fact that mini-saws are inferior in functionality to stationary counterparts, they are more convenient to use and lighter. Thus, for an amateur craftsman who creates at home, they will become indispensable helpers. However, it is always necessary to select a tool depending on future work tasks, respectively, a thorough study of all technical characteristics will be the key to the correct and competent selection of the device. At the same time, when handling the device, all safety rules must be strictly observed and always read the operating instructions before starting carpentry operations.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131652 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127693 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124520 -

The best men's sneakers in 2022

Views: 124034 -

The Best Complex Vitamins in 2022

Views: 121941 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2022

Views: 113396 -

Ranking of the best wood paints for interior work in 2022

Views: 110320 -

Rating of the best spinning reels in 2022

Views: 105331 -

Ranking of the best sex dolls for men for 2022

Views: 104369 -

Ranking of the best action cameras from China in 2022

Views: 102217 -

The most effective calcium preparations for adults and children in 2022

Views: 102012