Rating of the best micrometers for 2025

We often face in production the need to make accurate measurements. Both turners and jewelers can face such a problem. Of course, you can use a caliper, but a micrometer will give a minimum measurement error. And thanks to the low cost, every specialist can easily afford it.

Content [Hide]

What is a micrometer

The measurement of various quantities began in ancient times. Evidence of this are various architectural monuments, which would not have reached our days without precise execution. Previously, measurements were carried out with primitive products, but progress does not stand still. Each product began to change and improve. This also happened with measuring instruments.After all, the more complex the manufactured product, the more precisely it is necessary to measure the details. And one of these meters was the micrometer. So in 1848 in France, the first patent was received for a device that was a screw caliper with an additional circular scale. The additional scale made it possible to obtain more accurate fractional measurements from the main scale. After that, the device began to improve in design, but the basic principle remained unchanged.

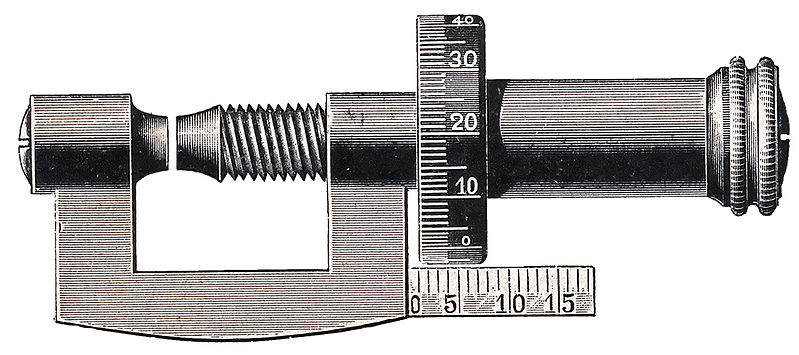

The design of the device is not difficult. It is based on a metal bracket with a heel and a screw mechanism. Between them is placed the object that needs to be measured. By tightening the screw, its width will be displayed on the scale. First look at the stem scale indicator, then at the drum scale. By summing these two values, the exact result will be obtained.

The micrometer is used to measure materials that do not deform when compressed.

Also in the design there is a latch that will not allow the scale to go astray until the result is recorded.

How to use

Before using the micrometer for the first time, it must be adjusted. Also, this procedure may be necessary during operation, if the settings fail. First you need to remove all dust and dirt from the device. After that, unscrew the screw with the drum. Now you need to rotate the screw until the jaws close. Tighten the screw with a ratchet until it clicks. This is necessary to fix the measuring surface. Now you need to rotate the drum, its zero mark should coincide with the reference mark on the stem of the device. To make the match accurate, you need to look at a right angle from the side of the drum. A view from other angles will give a visual deviation from the standard. When the values \u200b\u200bmatched, you should take hold of the cylinder and tighten the nut.

Now you can start measuring. First you need to unscrew the screw to the size of the part to be measured. After the part is placed between the screw and stop. Rotating the ratchet until it clicks, clamp the part. To get the result, the value of the drum scale is added to the horizontal scale. Usually, to obtain a result with a minimum error, several measurements are taken, and their average result will be considered the final one.

Wipe down the device after each use. Dust or dirt particles can cause errors. Also, the device should not receive mechanical impact. This will create irregularities in the details, which will also lead to errors. Store the micrometer separately from other instruments. When storing it, it is better to wrap it in a soft cloth or thin foam rubber, and then put it in a separate box.

Types of micrometers

This product has found application in various fields. To adapt it to various conditions of use, some design features were introduced. Let's take a look at them. The most common instrument is the smooth micrometer. It is used for external measurement of parts. The division step on the horizontal scale is 0.5 mm, and on the drum 0.01 mm. There are also models where the division on the drum scale is 0.005, 0.002 or 0.001 mm. This version of the device is available with both mechanical and digital indication.

To measure the value of the thickness of a sheet or strip, a sheet gauge is used. To increase the contact area, such devices have additional plates on the screw and heel.Since metal sheets are uneven, measuring with a smooth micrometer will result in a large error. The presence of plates helps to avoid this.

A pipe micrometer is used to measure the thickness of pipes. In their appearance, they differ from other models. Here the brace is cut off, and the heel replaces it. For measurement, the heel is placed inside the pipe, after which it is clamped with a screw. In this way, accurate data on the wall thickness of the pipe can be obtained.

A wire gauge is used to obtain wire thickness data. Among all varieties of micrometers, this option is the most compact. It does not have an arcuate bracket, and outwardly it may resemble a metal rod. Its main feature is a small travel range. But it doesn't need anything else for its purpose.

There is also a device with a very thin screw and heel, it is called a micrometer with small jaws. It is used to measure the surface of a metal after drilling or turning. Thanks to this design, it can easily get into thin holes.

To measure the thickness of metal blanks in production, a device for hot rolled metal is used. With its help, data is taken without waiting for the product to cool. So in the shortest possible time it is possible to determine the readiness of the produced part.

In addition, there is a universal device that has removable tips. Such a device is suitable for those who work with various parts and materials. By replacing one tip with another, the device is easily adapted. Budget options for universal products can produce a small error. This is due to the formation of a gap with insufficient compression.

The most convenient is the digital version of micrometers, which has an electronic display. Taking data with such a device takes less time and has high accuracy. They require a battery to function. The durability of digital instruments may be lower than mechanical ones. Since such a device, with careless handling, will easily become unusable. For example, it is easy to damage the display here. Devices from the expensive price segment can have many additional features. For example, memory, the time of the measurement. This functionality will be useful when a large number of measurements should be taken in a short period of time.

How to choose a micrometer

Before buying this measuring device, you should familiarize yourself with its classification, and, based on the purpose of measurement, determine the type of device you need. After that, you should pay attention to several criteria that you will need during operation.

First, you should decide on the measurement range. This criteria will depend on the size of the items you will be working with. The most common are instruments with a range of 0-25, 25-50, 50-75 and 75-100 mm. When working with various parts, all 4 options may be needed, and for narrow specializations, one type will be enough. For example, jewelers won't need long range instruments because they work with fine details. And some industries require accurate measurements of large parts. For such cases, there are devices where the maximum range reaches 600 mm.

The accuracy of the result will depend on the measurement step. This parameter depends on the division scale.This means that the smaller the step value, the more accurate the final result will be. Also, each device has its own error. This value can be seen in the product data sheet.

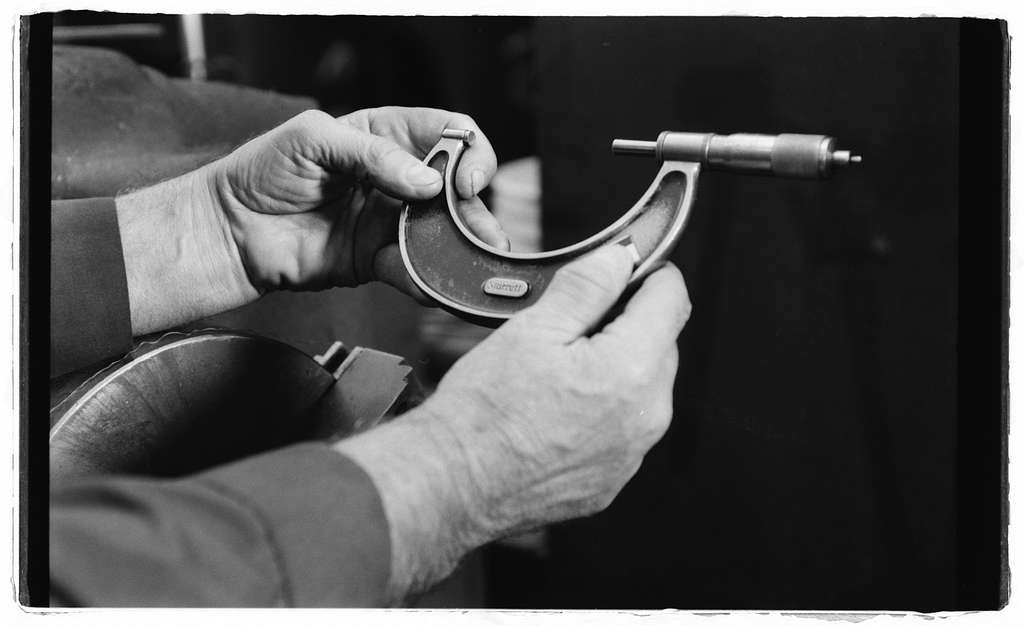

And for convenient use, you should pay attention to the ergonomic design, dimensions and weight. The weight of micrometers can reach up to 2 kilograms. For long periods of use, this may be inconvenient. To appreciate the ergonomics of the device, you should hold it in your hand. The grip should be made with the left hand, and the right should easily reach the adjustable elements. Also, the places where the device is gripped should not slip in the hand and it is desirable to have a relief surface.

It will also be a positive thing if the device is equipped with a case. It will be convenient for transportation and storage.

The best micrometers

Matrix 317255

votes 0

This mechanical micrometer is from the German company Matrix. It is made from high quality tool steel. The tool is made in the form of a bracket. In addition, the bracket is covered with enamel. This design will protect the tool from corrosion, rust and mechanical stress. On the tool there are overlays from thermoinsulating material. This makes operation convenient and practical. The micrometer head is the main working element of this model. The screw and the heel of the product have a hard-alloy surface. This prevents erasure, and makes the device durable and wear-resistant. "Matrix 317255" is suitable for both home use and suitable for repairmen, jewelers or car mechanics.

The measurement range of "Matrix 317255" is from 0 to 25 mm. The price of one division is 0.01 mm. and its error does not exceed 0.004 mm.The size of "Matrix 317255" is 15.1 * 7.5 * 3 cm, and its weight is 280 grams.

The average cost is 800 rubles.

- Compact size;

- Light weight;

- Heel and screw do not wear out with frequent use;

- Overlays for convenient operation;

- Price.

- No.

ZUBR Expert 34480-50_z01

votes 0

This model is a smooth mechanical micrometer. It is suitable for monitoring and making linear measurements of parts, finished products and assemblies. The form "ZUBR Expert 34480-50_z01" is made in the form of a bracket, which has a heel on one side and a stem on the other. The inner part of the stem has a thread, a screw moves along it. The heel and screw diameter is 6.5mm. Also, these parts of the device are covered with a hard-alloy plate, due to which their wear is reduced, but the accuracy will remain unchanged. For convenient operation of the device, the manufacturer has provided thermal protective pads, this will prevent the tool from slipping in your hand. The operation of the product must take place in the temperature range from +10 to + 30 degrees. If the product was transported in an unacceptable temperature range, wait 4 hours before use. Otherwise, an error of more than the permissible norm is possible.

The measurement range of "ZUBR Expert 34480-50_z01" is from 25 to 50 mm. One step of the device is equal to 0.01 mm. The measurement error is 0.004 mm. The size of "ZUBR Expert 34480-50_z01" is 16.5*6.7*1.85 cm, and its weight is 300 grams.

The average cost is 1200 rubles.

- Corresponds to GOST 6507-90;

- Ergonomic design;

- The working parts are coated with a hard-alloy plate.

- Not suitable for operation at temperatures below +10 degrees.

Megaon 80800

votes 0

"Megeon 80800" is a digital micrometer, which will be an excellent assistant when making control measurements of the manufactured product. The device has a liquid crystal display, where the measurement results will be visible. The surfaces involved in the measurement process have a hard-alloy coating. This will prolong the life of the device. The micrometer head, which serves as a reading device, has a division value of 0.1 mm. the staples of the product have a heat-insulating coating, and in addition there are heat-insulating pads. The device has an electronic unit that can take readings, both in inches and in the SI system. It is possible to transfer data to a computer or an APCS controller. For correct operation of the device, the temperature should be in the range from +5 to +35 degrees, and the humidity should not exceed 80%. Also, there should be no aggressive vapors or gases in the air.

The measured range is 0-25 mm, and the error does not exceed 0.002 mm. the size of "Megeon 80800" is 18 * 9 * 4 cm, and the weight is 310 grams.

The average cost is 4000 rubles.

- High accuracy;

- Ability to take readings in several measurement systems;

- Ability to transfer data to a computer.

- No.

Inforce 06-11-44

votes 0

With the help of "Inforce 06-11-44" it will be possible to make accurate measurements when assembling mechanisms or during equipment setup, as well as to take the exact size of parts. The device has a compact size, digital display and intuitive operation. The jaws of the device have a flat surface, and when closed, they fit perfectly to the measured part, which reduces the error to a minimum.There is no point in worrying about the accuracy of the device; at the factory, experts check it using three calibrations. And the possible error does not exceed 0.003 mm. The price of one division is 0.001 mm, and thanks to the smooth movement of the head, the result will be highly accurate. The result will be displayed on the display of the device. You can also choose the system of units of measure.

The instrument uses a lithium battery. If "Inforce 06-11-44" is not used for more than 5 minutes, the device will automatically turn off. When the battery needs to be replaced, the display will dim or flash. After changing the battery, all settings will be saved.

The measuring range is from 0 to 25 mm. the device works properly at temperatures from 0 to +60 degrees. The size of "Inforce 06-11-44" is 19.5 * 12 * 5.2 cm, and its weight is 490 grams.

The average cost is 5000 rubles.

- High accuracy of the obtained results;

- Made from durable materials;

- Works in a wide temperature range;

- Ability to select the unit of measure.

- There are no calibration plates.

Micron MIC 414780

votes 0

This micrometer model is from the Czech manufacturer Micron. For convenient use, the manufacturer has provided 5 rubberized buttons. With their help, you can switch units of measurement, set absolute zero, and also save the results. The steel arch of the device has an enamel coating, which gives additional protection to the metal. Also there is a rubberized pad, which makes the operation comfortable and will allow the device to slip out of your hands. It is also worth noting that "Micron MIK 414780" has protection against dust and moisture, which significantly extends its service life.

The measurement range of the device is from 0 to 25 mm, the measurement step is 0.001 mm. the size of "Micron MIC 414780" is 19.5 * 10.5 * 4.5 cm, and the weight is 410 grams.

The average cost is 10,000 rubles.

- High accuracy;

- Easy control;

- Ability to save data;

- Protection against dust and moisture.

- High price.

A micrometer will be an indispensable device for taking accurate measurements. For home use, a mechanical version of the device is suitable, and for production it is better to purchase an electronic micrometer. Although the cost of a digital micrometer is higher than a mechanical one. But the results will be accurate and the acquisition time will be reduced. Buying a product from a trusted manufacturer, you will receive a device that will last more than one year.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131652 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127693 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124520 -

The best men's sneakers in 2025

Views: 124034 -

The Best Complex Vitamins in 2025

Views: 121941 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2025

Views: 113396 -

Ranking of the best wood paints for interior work in 2025

Views: 110320 -

Rating of the best spinning reels in 2025

Views: 105330 -

Ranking of the best sex dolls for men for 2025

Views: 104368 -

Ranking of the best action cameras from China in 2025

Views: 102217 -

The most effective calcium preparations for adults and children in 2025

Views: 102012