Rating of the best oil filters for 2022

Passing the next MOT, every motorist has to face the responsible task of choosing an oil filter. When changing the oil, you need to decide on the choice of a device that performs the main task of cleaning the engine oil. The degree of filtration is set by the official engine manufacturer. The cleaning index affects the operating time of the motor, depending on the quality of the fluid used and the degree of filtration during operation.

Despite the external similarity of the filter elements, inaccuracy in the choice can lead to negative consequences for the car. Designers develop a specific car engine filtration system individually for each model range. Selection indicators directly depend on the brand of the car.

Content

How to choose

Despite the design simplicity, when choosing a cleaner, it is worth taking into account many specific nuances:

Filter type

There are three types:

- Full-flow - the composition has a bypass valve that regulates the oil pressure in the lubrication system. Its purpose is to protect seals and interblock gaskets from damage and rupture, as well as to ensure that excess pressure is bypassed from the crankcase to the motor part. In case of clogging of the filter or the final exhaustion of its resource, the valve is responsible for the supply of crude oil in order to avoid oil starvation and prevent overheating of the motor unit.

- Partial-flow - in comparison with the first, they produce finer filtration, which will require a longer process and more time. On the other hand, a similar principle of operation will avoid pressure drops if the filter is clogged or the bypass valve is stuck.

- Combined - perform extra-fine cleaning of the oily liquid, combining the advantages of the two previous types, excluding the inherent characteristic disadvantages. The cost will be much higher, but with the greatest probability and an increase in the work of adjoining pairs. Most often used in units characterized by heavy workload.

Bypass valve serviceability

During the purchase of the filter, this aspect is difficult to check, but if possible, the openness of the pressure valve should be checked. Thus, it will be possible to protect the motor from the penetration of crude oil with the presence of a large number of abrasives. Using the analogy, it is possible to organize a check of the check valve for tightness of closure, excluding oil leakage, in the event of a long car downtime.

Paper density

The parameter is a dependent link that affects the working capabilities of the filter. The thickness of the paper affects the susceptibility to clogging and full exhaustion. Some details should be taken into account regarding the maximum degree of heating of the oil in the motor. It is necessary to determine the permissible temperature during operation in order to prevent paper burnout with the usual performance of the engine.

Hull Integrity

An important secondary indicator that directly affects the performance of the filter. Before buying a spare part, you need to check the body and valves for faults and defects, as well as the integrity of the filter paper. A branded product released by a branded manufacturer stands out for its durability. A fake quickly fails and entails a chain of serious breakdowns. To avoid trouble, you should look at well-known manufacturing companies that provide appropriate certified documents for a product that meets the requirements of users.

Which filter is better to buy

When planning a purchase, you need to familiarize yourself with the characteristics and parameters of the installed device to make sure that it matches: thread types, barrel sizes and the circumference of the o-ring.

It is worth familiarizing yourself with the description of the part on the site, taking the necessary measurements, and then buying the part.

The available range of oil filter elements includes original samples and universal devices that are suitable for various car brands.

It is important to take into account the compliance of the motor with respect to the parameters of the cleaner in order to avoid mistakes when choosing:

- admissibility of screening fineness;

- oil pressure at the inlet;

- maximum difference.

A quality filter helps to retain solid particles larger than 0.05 mm that can penetrate inside.

An important condition is the exclusion of all kinds of defects and discrepancies in the constructive part. Appearance should not have even minor violations.

The quality of performance is affected by the fit of the sealing ring. The cleaner must adhere well to the body part, preventing leakage.

The replacement period of the filter depends on various factors and compliance with the installation rules. Most often, this happens at the same time as the replacement of fuel and lubricants (15 - 20 thousand kilometers). Long downtime and operation of a car in conditions of adverse temperatures double the frequency of maintenance.

For passenger cars

Devices are designed to clean the working fluid in the car engine. The oily liquid is pumped through the filter by means of a pump. Such a system will provide cleaning speed and is inexpensive. Elements are easily changed by the owner of the car.

Goodyear GY1202

Oil purifiers of this brand are highly durable and reliable. The filter changes after a certain mileage of the car. The device will provide a constant supply of clean working fluid to the engine of the machine. There is a bypass valve inside the filter. It will ensure the supply of oil, even with high contamination.

The body of the product is rust resistant. Its outer diameter is 68 mm.The part of the filter that is adjacent to the car engine is equipped with an O-ring. The gasket securely seals the two surfaces and will not allow oil to seep out.

- long service life;

- low cost;

- tightness;

- stable at work.

- difficult to install on your own.

Kraft KT 964027

The product has a durable body. Features include a high absorption rate. The filter can work under pressure of 20 kg/cm. Outside, the device is coated with a special compound that will protect the product from the appearance of foci of corrosion.

The filter element is made of paper that has been treated with special resins. This significantly increases the absorbent characteristics and usable area. Inside the fixture is a check valve that, when the engine is turned off, will prevent the oil from returning back.

Kraft KT 964027 is the simplest solution to the problem. The device is perfect for cleaning oil on passenger cars. The product is mounted on such brands as Dacia, Fiat, VAZ, Chevrolet, ZAZ, Ford and many others.

- the device is resistant to rust;

- the presence of a check valve;

- can hold a large amount of dirt;

- sufficient passage area.

- the device can only be used in certain climatic zones.

Luxe LX-05-M

Quality paper "Ahlstrom" was used in the filter element. Its thin layers are well precipitated by impurities. The strength of the element is at a high level.

In circumference, the fixture has 93 mm. The product is highly absorbent. High-quality assembly guarantees a long service life and resistance to wear.

- acceptable cost;

- the base is made of metal resistant to corrosion;

- the filter provides free and fast passage of oil;

- the product will last for a long time.

- the seal responsible for tightness may be deformed.

JS Asakashi C025J

The base of the product is made of metal, which is painted with several layers of rust-resistant spraying. This technology provides the product with long wear. The device is resistant to mechanical shock and rust. The sealing ring will protect the cleaning system from seepage of oil to the outside.

The filter is resistant to different weather conditions. The oil is retained regardless of environmental changes. The retaining valve functions well in any frost. A working element made of a special fiber that retains foreign impurities well. The finely porous structure allows the cleaning system to function reliably.

The filter is suitable for motorists operating their iron horses in harsh climatic conditions.

- the base is made of durable metal;

- the surface is rust resistant;

- reliable seal;

- can retain large volumes of impurities;

- operated in various climatic conditions.

- low throughput.

For heavy vehicles and special vehicles

The filter elements are designed for installation in powerful diesel units. The oily liquid gets dirty in them much more intensively. That is why the products are large. For high-quality cleaning, a large surface of the filter element is required.

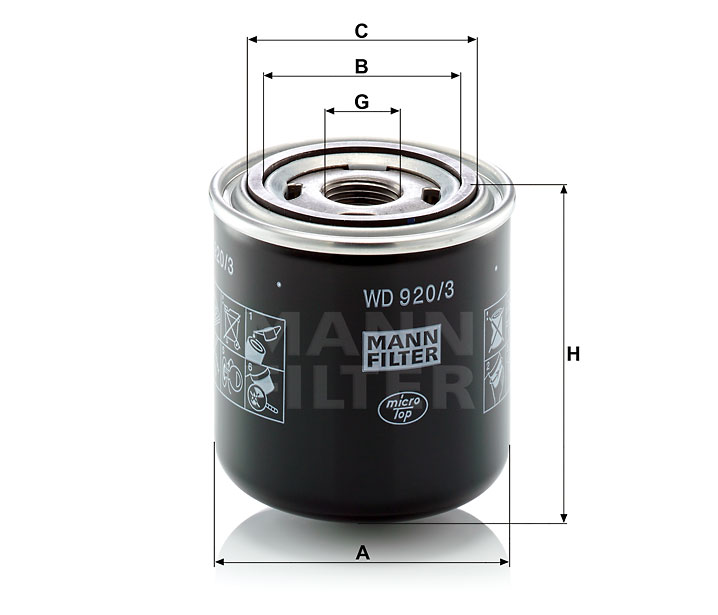

Mann Filter WD 962/32

The famous German brand manufactures high quality products. The low rejection rate is due to very strict production control.The corporation provides almost all European countries with its products. A large number of products are sold to other countries.

Quality control begins with the procurement of raw materials. This allows us to meet all production standards. The slightest deviations from the norm are quickly identified and eliminated. Users note a good degree of cleaning and a long service life.

The large area of the working element increases the wear time of the product. The metal base is treated with a special composition that is resistant to rust. The filter withstands a load of 2.5 atm. At maximum engine loads, the device will work stably without leaks.

The filter can be operated on equipment of domestic and foreign manufacturers. It is installed on buses, tractors and trucks.

- long time of operation;

- a solid foundation;

- the device is able to withstand high pressure;

- can clean enough oil.

- high price tag.

Filtron OR 745/3

Grease-resistant elements made of synthetic materials are used for production. This technology increases the wear of the filter element and the quality of fluid cleaning. The dimensions of the device are 103x147 mm. The steel case is not deformed during the entire service life. The cleaning system will not allow oil leakage at maximum pressure.

The device is popular with diesel power units. For drivers of heavy vehicles, dump trucks and tractors, this is an excellent choice.

- reliable body;

- withstands high pressure;

- tightness;

- operated for a long time.

- high price.

Amsoil EAHD4005

The filter cleans the oil flow reliably and lasts for a long time.Its working element is able to precipitate almost 99% of the contaminants passing through it. This indicator speaks of the high efficiency of the device.

Synthetic materials with fine fibers are used in the production of products. Therefore, the filtering surface has the highest throughput, which is considered one of the best in the world. Innovative technology significantly reduces wear on rotating parts and engine mechanisms, which reduces the frequency of engine oil changes.

The filter can be installed on vehicles with diesel and petrol powertrains. Motorists use the device on heavy equipment, SUVs and trucks.

- durable metal base;

- continuous work;

- can clean large oil flow;

- high quality matches the price tag.

- the absence of a check valve in the design.

SCT SM 101

Another German manufacturer presents a product of excellent quality. The sales market for it is Russia and the countries of the former CIS. Domestic users respond positively to products manufactured by SCT. The model can be used in different climatic zones. The strong case covered with a special sputtering will provide an uninterrupted cleaning system.

The product has a non-separable design (69x93x62 mm). You can use it both on special equipment and on passenger cars.

The design can work at temperatures from -30 to +350. Therefore, the device can be operated in cold climatic zones. Filters are recommended to be installed on cars, the volume of engines, which does not exceed 1.7 m3.

- reliable design;

- high quality seal ensures reliable tightness;

- can be operated at sub-zero temperatures;

- installed on different types of equipment.

- low durability.

For motorcycles and other vehicles

Filters are used for installation in a snowmobile, on a scooter or motorcycle, as well as other small motor vehicles. They have small dimensions, have good throughput, which is enough to drive on the highway at speed or in city conditions, where the engine is running in a stable mode.

K&N KN-138C

Case material - steel with high strength, chrome-plated. Thanks to the procedure, it has anti-corrosion resistance.

In the manufacture of the filter element, synthetic components were used. They have high wear resistance and withstand the high pressure that is present in the engine.

Prevention of "dry" start is carried out by a check valve, as well as blocking the return to the oil filter device. The diameter of the input thread is 1.7 cm, the material of the sealing ring is nitrile rubber. These features provide good sealing performance and the filter can be installed in minutes.

This filter is put on a snowmobile, motorcycle, all-terrain vehicle. It is ideal for those who have motor vehicles of the brands Kymco, Suzuki, Arctic Cat.

- has good throughput;

- the presence of a check valve;

- the presence of an anti-corrosion coating with high reliability;

- easy to install;

- ensures stable operation.

- it costs expensive.

Athena FFP008

The device has a closed body type, which makes it impossible for foreign particles to enter the engine. The dimensions of this filter are 80 x 90.5 x 80 mm, which makes it suitable for many models of different units.

The sealing ring is tightly pressed against the surface of the cap, providing a good sealing performance even in cases where there is high pressure inside. The filter is designed for an engine whose volume does not exceed 750 cm3. With this indicator, his work will be stable with urban-type equipment and sports motorcycles.

- universal device;

- the body is highly durable;

- no leaks;

- special anti-corrosion coating.

- it costs expensive.

Hiflofiltro HF895

The difference of this consumable material is not only that it has a high strength index and a long service life. The filter meets the conditions of 16 quality studies conducted by independent organizations.

The filter has a unique sealing ring, which was developed specifically for this product. The ring has the designation Q-Ring, and elastic rubber is used in its manufacture. It fixes the filter on the engine well.

The specialization of this filtering device is sports motor vehicles. It withstands intense pressure in engines, the volume of which is not more than 750 cm3.

- the body is highly durable;

- sealed filter;

- low cost;

- high dirt holding capacity.

- complex installation.

Emgo 10-99220

This filter absorbs foreign oil impurities to a high degree. Its base material is felt inserts.They are able to filter even small dirt particles without compromising the quality of the throughput.

The open housing design makes it possible to visually check the quality of the elements before the filter is installed.

The use of this consumable is possible in combination with different types of motorcycles and motorized vehicles. It is used on ATVs, various models of motorcycles, all-terrain vehicles. The filter is applied on Honda model ATV TRX 250 and motorcycle of the same brand CBF 125.

- efficiency of the filtration process;

- high throughput;

- long service life;

- universal product.

- low elasticity of the sealing ring.

Conclusion

The oil filter performs an important function - it cleans the oil in the engine, increasing its life by reducing wear. An oil filter should be chosen taking into account the features of its design, what type it belongs to, what is the surface area through which the filtration passes, how good are the sealing rings and other characteristics. It is not recommended to give preference to products with a low degree. There is a chance that they are of poor quality and will quickly require replacement. The choice should be stopped at the original filters, about which there is information in the technical documents for the vehicle.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131652 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127693 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124520 -

The best men's sneakers in 2022

Views: 124034 -

The Best Complex Vitamins in 2022

Views: 121941 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2022

Views: 113396 -

Ranking of the best wood paints for interior work in 2022

Views: 110320 -

Rating of the best spinning reels in 2022

Views: 105331 -

Ranking of the best sex dolls for men for 2022

Views: 104369 -

Ranking of the best action cameras from China in 2022

Views: 102217 -

The most effective calcium preparations for adults and children in 2022

Views: 102012