Ranking of the best floor grinding and polishing machines for 2022

Repair and construction is a topic that is close to every person. And repairing or restoring the floor is a task that many have also faced. Of course, you can hire a team of craftsmen who have the necessary set of tools, and they will quickly and efficiently bring the floors in an apartment or house into perfect condition. But if you want to do it yourself, it will be useful to learn what tools are needed for this and how to use them correctly. Also, this information will be of interest to those who want to start providing repair services and consider such a tool as a source of income.

Content

- 1 What is floor polishing for?

- 2 Main types of floor grinding and polishing machines

- 3 How to choose a grinder

- 4 Leading manufacturers of floor grinders

- 5 Rating of the best floor grinders

- 6 Where to buy a grinder

- 7 Common Mistakes When Buying Grinders

What is floor polishing for?

Grinding and polishing is an important stage of repair or construction work, which should not be underestimated. This is not only a way to give the floor an aesthetic appearance, but also a direct concern for people's health.

The main reasons for grinding:

- arrangement of defects and irregularities on the new coating;

- preparation for installation of self-leveling floor;

- getting rid of the top layer of the screed, which creates dust that is harmful to health;

- restoration of old flooring.

As a rule, concrete floors have a weak top layer, which crumbles during the operation of the premises, turns into dust, enters the air and thus harms the human respiratory system. Sanding removes this layer, making the floor more durable and moisture resistant. It remains safe for much longer and retains an attractive appearance.

Hardwood floors look beautiful, but tend to fall into disrepair.Floor elements begin to crack, deform, creak and cause discomfort with an unpresentable appearance. Polishing gives parquet a second life, giving it its original beauty, eliminating creaks and surface irregularities.

Main types of floor grinding and polishing machines

In a large hardware store, the abundance of grinding units can dazzle your eyes, but in fact they can be easily divided into main types:

- belt type grinders;

- deltoid;

- surface grinding;

- eccentric;

- drum cyclers.

Belt-type machines are equipped with an abrasive belt glued in the form of an endless ring. Suitable for primary floor treatment, as they allow you to quickly process a large surface and remove the top layer of concrete or wood covering. The quality of grinding is not high enough, but for the first stage of work, rough processing, this is not important. Devices of this type have three main standards: 457 mm, 533 mm and 610 mm. The main disadvantages are the high noise level and frequent clogging of the dust removal system.

Tape files can be distinguished into a separate category. They are often used for grouting welds and grinding materials in hard-to-reach places. They weigh less than the rest, but it is extremely difficult to process a large surface with them.

If you need to process small parts, a delta-shaped device will come to the rescue, which is often called an iron due to the shape of the grinding surface. It is suitable for processing hard-to-reach places, blind corners, edges, profiles. It can also be used to clean up exposed adhesive. The main disadvantage of this type of machine is that consumables for them are not sold everywhere, and the price for them is higher than for sanding sheets for other types of devices.

To perform large volumes of work on materials of various types, a vibratory surface grinder is suitable. This type is versatile, making it the best option for professionals. When choosing, you need to pay attention to such an indicator as the size of the platform stroke. Due to its shape, it allows you to easily process internal corners. Among the shortcomings can be noted the high level of noise during operation.

To achieve the highest quality of surface grinding, eccentric-type machines are used, which are also called orbital. They act on the treated surface in two ways at once: rotational and eccentric movements of the sole. This path of movement of the abrasive provides flawless grinding and polishing. The disadvantage is the impossibility of processing recesses and internal corners.

Drum-type units are used for grinding and polishing wooden surfaces. They easily cope with the removal of the top layer and effectively remove the old paintwork from the floor.

The machines of the types discussed above are divided into two types: network and battery. Their pros and cons are obvious. Cordless devices allow you to use tools without being tied to an electrical outlet, but their resource is limited by the battery capacity, while network devices are not so mobile, but can work indefinitely without requiring recharging.

Also, grinders, like other tools for construction, are divided into household and professional. The first, as a rule, differ from the second in smaller dimensions, less power and speed, as well as an affordable price.

How to choose a grinder

When choosing a unit, first of all, it is worth focusing on the conditions in which it will be used. If it is supposed to perform grinding work on weight or on outstretched arms, then the mass and dimensions of the device come to the fore. You should choose a light and mobile tool that will allow you to get less tired.

If only floor processing is planned, and the grinding area is supposed to be large, it is advisable to stop at a powerful version that moves with a handle or is equipped with a mount, like carts. Such devices will allow you to quickly perform surface treatment, but are not suitable for grinding internal corners and hard-to-reach places.

The surface that will be exposed to the grinder is also taken into account. There are universal units that can polish any material, and there are those that are suitable for concrete, wood or stone.

An important indicator is the quality of grinding. If only the work of the first stage, including rough grinding, is supposed to be performed, it is not necessary to purchase an expensive orbital device. But if you need to make a perfectly flat surface without chips and cracks, you can’t do without an eccentric machine.

When you decide on the type of unit, pay attention to its quality. Of course, for the most part, the quality of work will be determined already in the process of use, but even at the purchase stage, you can see how well the case is assembled, if there is any play at the points of attachment of moving parts. You can also evaluate the level of generated noise and the strength of vibration by turning on the device at idle.

Another nuance when choosing a machine is the availability of abrasive consumables and spare parts necessary for it, for example, soles, as well as their cost.

Pay attention to the safety of the device. It must be equipped with a reliable device for collecting dust and fine particles generated during operation.

Leading manufacturers of floor grinders

Grinding machines are produced by many companies that produce tools for construction and repair. Of the Russian companies, one of the most popular is the Zubr company, which supplies powerful and high-quality equipment. Also, units of Ukrainian production of the Sapozhok brand are in demand, combining decent quality and affordable price. Popular brands are Bosch, Skil, Sparky, Makita, DeWALT, as well as Black & Decker, Interskol and Fiolent.

Rating of the best floor grinders

The devices below are selected based on customer ratings on the Yandex Market trading platform. Of the types discussed above, the most popular are selected - eccentric, surface grinders and trowels used for finishing floor polishing. Items are sorted by price, from lowest to highest. The description lists the main characteristics, as well as the advantages and disadvantages of each model.

Rating of eccentric sanders

Eccentric aggregates are essential for high quality grinding and are always in high demand.

Wert EES 125DE

The price for Yandex Market is 1901 rubles.

A hand-held universal tool, one of the most popular on the Yandex Market and has a large number of positive reviews.

- versatility of use: suitable for various surfaces;

- light weight;

- democratic price;

- low power consumption;

- body ergonomics;

- convenient built-in dust collection system.

- high noise level;

- inconvenient plastic network wire;

- too tight speed control;

- there is no adapter for connecting a vacuum cleaner;

- average quality of grinding in comparison with other eccentrics.

ZUBR ZOSHM-450-125

Price - 2990 rubles.

Lightweight and comfortable universal machine with adjustable speed up to 13,000 rpm from a Russian manufacturer.

- suitable for any surface;

- differs in economical power consumption;

- high quality grinding;

- democratic value.

- insufficiently ergonomic body;

- there is excessive vibration, causing hand fatigue;

- inconvenient location of the power button;

- the dust collector is leaking, a lot of dust flies past.

DeWALT DWE6423

Price - 6999 rubles.

Small, reliable and powerful tool, equipped with the necessary adjustments. Sanding sheets are fastened with Velcro. Large warranty period - 3 years.

- a small distance from the working surface to the stop by hand allows you to control the operation of the tool;

- ergonomic body;

- quality assembly;

- long soft cord.

- there is no tool storage case;

- there may be a problem with finding a spare sole;

- inconveniently located power button;

- high noise level during operation.

Einhell TE-DW 225 X

Price - 18900 rubles.

Lightweight and ergonomic tool that is suitable for both floor and ceiling sanding. Equipped with a four-meter cable. Abrasive sheets are fastened with Velcro.

- a light weight;

- comfortable shape of the body and handle;

- triangular nozzle allows you to handle corners;

- the ability to control the speed;

- relatively low power consumption.

- low frequency of rotation of the disk;

- great cost.

ASPRO ASpro-C3

Price - 22900 rubles.

The machine is quite light - 3.7 kg, equipped with a speed controller, a speed stabilization system and a power button lock.

- light weight;

- good equipment (vacuum cleaner adapter, six abrasive wheels, a set of keys).

- high price;

- the impossibility of grinding hard-to-reach places.

The average price of the above popular models of orbital or eccentric grinders is 10,738 rubles.

Rating of surface grinders

Surface grinding units are versatile and relatively easy to use, which makes them popular among both amateurs and professionals.

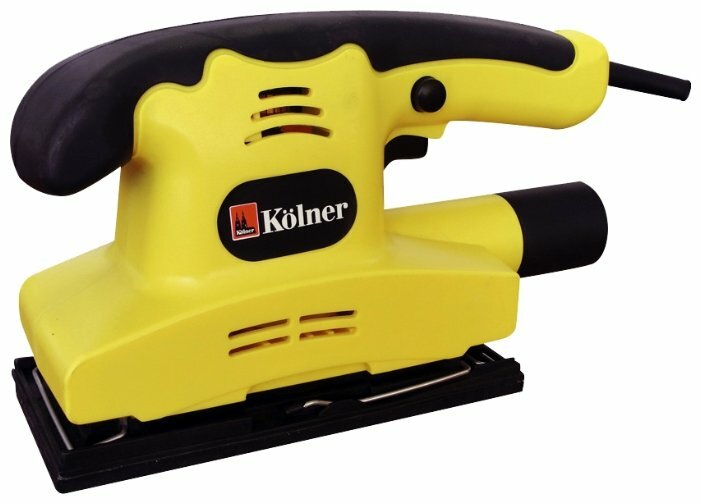

Kolner KFS 187×90M

The price for Yandex Market is 1341 rubles.

Small lightweight vibratory sander, great for small repairs. It is completed with sheets of 187 by 90 mm in size. The kit includes not only abrasive sheets, but also spare brushes.

- good equipment;

- powerful and lightweight.

- weak fastening of the sanding sheet;

- unreliable build.

Einhell TH-OS 1520

Price - 2359 rubles.

A tool that combines an economical power consumption of 150 W with a high output of 23,000 c/min. The size of the abrasive sheet is 230 by 93 mm.

- affordable cost;

- light weight;

- power button lock.

- strong vibration;

- high noise level;

- unreliable assembly;

- poor dust collection.

Hammer PSM 300

Price - 2999 rubles.

Vibration tool is one of the most popular on the Yandex Market. Sanding sheet size - 230 by 115 mm, fastened with clamps.

- great price;

- ergonomic body;

- good power.

- short power cord;

- build quality is satisfactory;

- high noise level.

Interskol PShM-115/300E

Price - 3316 rubles.

A powerful vibrating type tool from a well-known manufacturer, equipped with abrasive sheets measuring 280 x 115 mm.

- ergonomic design;

- almost does not heat up during operation;

- minimum vibration.

- poor assembly, the system for attaching sanding sheets quickly becomes unusable;

- no case;

- high noise level.

Makita BO3711

Price - 4658 rubles.

Vibrating machine, complete with sheets measuring 228 x 93 mm, with a dust collector. The manufacturer provides one year warranty. According to customer reviews on Yandex Market, this machine is one of the most popular.

- quality assembly;

- comfortable case;

- low noise level;

- universal, suitable for any surface;

- fast and convenient replacement of abrasive sheets.

- there is no adapter for a vacuum cleaner;

- not completed with a case;

- hard cord.

The average price of the popular models of surface grinders discussed above is 2935 rubles.

Rating of floor trowels for floor finishing

Zitrek PT-24

The price for Yandex Market is 41570 rubles.

Professional polishing machine equipped with a 5.5 hp gasoline engine that provides autonomy. The processing width in one stroke is 600 mm, the rotation speed is 120 rpm.

- the protective cover protects the mechanism of the machine from breakdowns;

- a gasoline engine allows it to be used in de-energized rooms and in the field;

- equipped with an oil change sensor;

- the machine is easy to transport;

- allows you to quickly and efficiently process large areas.

- disks are purchased separately;

- too noisy;

- the presence of the smell of gasoline during operation.

TSS DMD900

Price - 43660 rubles.

Manual machine with 2.2 kW electric motor. Works from a network 380B. It has four blades and one grinding disc. Suitable for professional work.

- polishes any surface;

- low noise level.

- the need for high voltage limits the possibilities of its use;

- big weight - 89 kg;

- not suitable for polishing inside corners and hard to reach places.

TSS DMR600L

Price - 46546 rubles.

Manual power trowel with 6.5 HP petrol engine. The width of the surface processed in one pass is 600 mm. The weight of the machine is 65 kg.

- high power;

- autonomy of work;

- conscientious assembly.

- increased noise level;

- insufficiently convenient fueling system.

Zitrek PT-36 (HONDA GX-160)

Price - 58400 rubles.

Professional manual power trowel for grinding concrete and cement surfaces. The maximum speed is 160 rpm. Equipped with a gasoline engine. The controls are located on the handle, which has a convenient adjustment for the height of the operator.

- ergonomic design;

- the optimal location of the fuel tank, allowing you to spend a minimum of time on refueling;

- the possibility of surface treatment both with the help of blades and with a disk;

- moving elements are covered with gratings, which minimizes the risk of injury;

- reliable assembly.

- not equipped with a disk, which must be purchased separately;

- too noisy;

- great cost.

TSS DMD1000

Price - 63862 rubles.

Hand sander with 5.5 HP Honda GX160 petrol engine, processing 960 mm wide strip in one pass.

- quickly polishes any surface;

- reliable engine;

- solid assembly;

- ergonomic design.

- the smell of gasoline at work;

- no oil change sensor;

- high price.

The average price of the popular models of floor trowels discussed above is 50,808 rubles.

Where to buy a grinder

In the age of digital technologies, construction tools, like any other things, can be bought not only in real stores, but also on the Internet. Payment is made online, and the purchase itself is delivered by transport companies or by mail.

But buying online, despite a number of advantages, in this case, has many disadvantages. The advantages include the convenience of the buying process itself. No need to waste time shopping, and besides, in online stores, the price of similar products is often lower than in real stores. The disadvantages include the inability to determine the convenience of the tool, its weight and build quality, since the photographs do not provide complete information and an idea about a particular device.

You can safely order those models that you have already seen and held in your hands in a real store, but even here there is a risk of damage to the goods during transportation or the risk of receiving another product instead of the one ordered due to an accidental mistake or deliberate deception on the part of the seller.

Common Mistakes When Buying Grinders

A grinder is a tool that has many subtleties and features in use, so mistakes are often made when choosing it.

- The wrong type of tool is selected. For example, if fine grinding is required, it is not an eccentric or delta-shaped machine that is ideally suited for these purposes, but a belt machine that is purchased.

- The level of noise and vibration is not taken into account, which subsequently complicates the work with the tool.

- The selected model is not suitable for processing the surface for which it was intended.

- The features of working with the tool in terms of the availability of the mains are not taken into account. If a machine with a stationary power supply is purchased, and work is carried out in a de-energized room, it will not be possible to use it. For such purposes, it is necessary to purchase a battery-powered tool.

- When buying, the assortment and interchangeability of the necessary consumables are not studied.

To avoid mistakes and purchase exactly the unit that will be most suitable for specific purposes of use, you can resort to the help of professionals or independently study in detail all the characteristics of the purchased grinder. And then working with this tool will bring maximum positive emotions and allow you to quickly and efficiently perform all the necessary work.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131653 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127693 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124520 -

The best men's sneakers in 2022

Views: 124035 -

The Best Complex Vitamins in 2022

Views: 121941 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2022

Views: 113397 -

Ranking of the best wood paints for interior work in 2022

Views: 110320 -

Rating of the best spinning reels in 2022

Views: 105331 -

Ranking of the best sex dolls for men for 2022

Views: 104369 -

Ranking of the best action cameras from China in 2022

Views: 102217 -

The most effective calcium preparations for adults and children in 2022

Views: 102012