Ranking of the best brands of welding wire in 2025

Welding wire is used for reliable connection of metals. In our review you will find a description of popular models and brands and recommendations on how to choose the right product. We will suggest the best manufacturers, explain: “what is it - welding wire”, the functionality and varieties of the best options, we will orient how much they cost.

Content [Hide]

Types of wire for welding, its classification

Various types of materials are used as a welding mixture. They are aluminum, brass, steel, stainless steel, metal alloy. Products can be coated with copper (copper-plated wire).All "consumables" must necessarily have certificates, be manufactured in accordance with GOST 2246. There are several types of products used in MIG welding:

- Solid sections (solid-state) are used most often, in part because of their lower cost. The selection criteria for one type or another depends on the base metal and its thickness. The thin mild steel does not produce slag and the cord cools quickly.

- Cored wire behaves like conventional electrodes. It consists of a metal shell, a hollow inner space filled with granular powder (flux). During repair or construction, this mixture introduces alloying elements into the weld. They leave slag, and as a result, cooling is slow, which is an advantage when working with thick materials.

- The activated model is similar in composition to the powder one, but has fewer granular additives (5-7% of the total mass), and is used for welding in CO2 and its mixtures.

Products are sold in drums of different diameters 0.8 / 1.0 / 1.2 / 1.6 mm. According to welders, it is better to buy copper-coated wire, it protects against oxidation, facilitates electrical contact between the nozzle of the welding machine and the surface to be welded, reducing friction.

There are many classifications for each type, depending on its composition, the shielding gas used and the area of application. Let's take a closer look at this information. To begin with, we will study international standards, then domestic brands:

1. Solid cord should be similar in composition to the base metal, the mixture contains different amounts of deoxidizers, depending on the application and shielding gas.

The most common additive is silicon, it contains a small amount of various metals that improve the mechanical properties of welding equipment, corrosion resistance. These wires oxidize better and are generally more suitable for CO2 work as porosity is prevented.

Carbon steel wire is listed in the American Society (AWS), under the designation "ER 70 S - x" (imperial units), where: "E" - electrode; "R" - filler; 70 is the minimum tensile strength expressed in thousands of pounds per square inch (psi); "S" - hardness; "x" is a number representing information about the chemical composition of the electrode ("2", "3", "4", "6" or "7"), it corresponds to a variable amount of carbon, manganese and silicon in addition to a fixed mass of phosphorus, sulfur, nickel, chromium, molybdenum, copper and other elements. Consider the properties of products in accordance with the last digit:

- ER70S-2 provides good welding in C-25 gas (75% argon + 25% CO2) even on oxidized steel. Of the entire series, this is the only brand that contains titanium, zirconium and aluminum. Its main disadvantage is the lack of fluidity, it is reluctant to move to the side and cannot properly adhere to heavy materials.

- ER70S-3 is one of the most common and budget MIG models, it is less viscous. The product is successfully used in cars, agricultural and household appliances.

- ER70S-4 has an average cost, suitable for almost all types of steel welding. ER70S-4 has good fluidity, better arc performance than E70S-3 but has more spatter, applicable to structural steels, boats, pipes and boilers.

- ER70S-6, ER70S-7 have the best functions and the highest cost, they contain a lot of silicon, manganese as deoxidizers. Work with any grade of steel, from fine carbon to sheets with a thickness of 1/2 inch. All commonly used gas mixtures are suitable, good fluidity. The products are used in the production of car bodies, furniture, fire extinguishers, pressure vessels and pipes.

These cords can be used for stainless steel welding. However, for better corrosion resistance, attention should be paid to stainless steel wire, one of the most common options is "304", "ER308", with an increased content of silicone in the types "ER308L" and "ER308LS". Applications of these wires: chemical and food equipment, tanks for corrosive chemicals, pumps, heat exchangers.

Products from non-ferrous metals are used to work with aluminum. There are many such wires, including:

- ER-1100, ER-4043 are used with argon, helium, other industrial gas mixtures, ideal for working with thick sheets and castings. The main industries using this type are food, dairy and refrigeration.

- ER-5356 contains 5% magnesium, this wire will work in most situations. Its high tensile strength makes it suitable for the manufacture and repair of rolling fuel tanks.

It is impossible to provide universal advice: “Which product is better to buy?” the popularity of models depends on the specific working situation.

2. Flux-cored electrodes ("FCAW" welding) are carbon steel, low alloy steel, stainless steel and cast iron. They are classified according to the mechanical properties of the weld metal.

The marking, based on the British system of measures, looks like this: “E 7 1 T - 1 C / M”, where: E is the electrode; 7 is the minimum tensile strength of the weld metal, expressed in thousands of pounds per square inch; 1 - welding position (sometimes "0" or "1"). "0" - flat and horizontal position; "1" denotes all positions; T - tubular (1 indicates the correct use of the electrode in terms of polarity and general performance, varies from "1" to "14" or from "G" to "GS".

"G" indicates that polarity and overall performance are not specified. The letter "S" after "G" means that the cord is only suitable for one pass); C / M - shielding gas required. "C" - 100% CO2, "M" - a mixture of argon and CO2. If there is no letter, then the flux-cored wire is used for welding without gas.

The advantages of MIG Cored Cord are low spatter loss, easy slag removal and high resistance to impact, extreme temperatures and cracking. These wires are used in heavy industry, mining and shipbuilding.

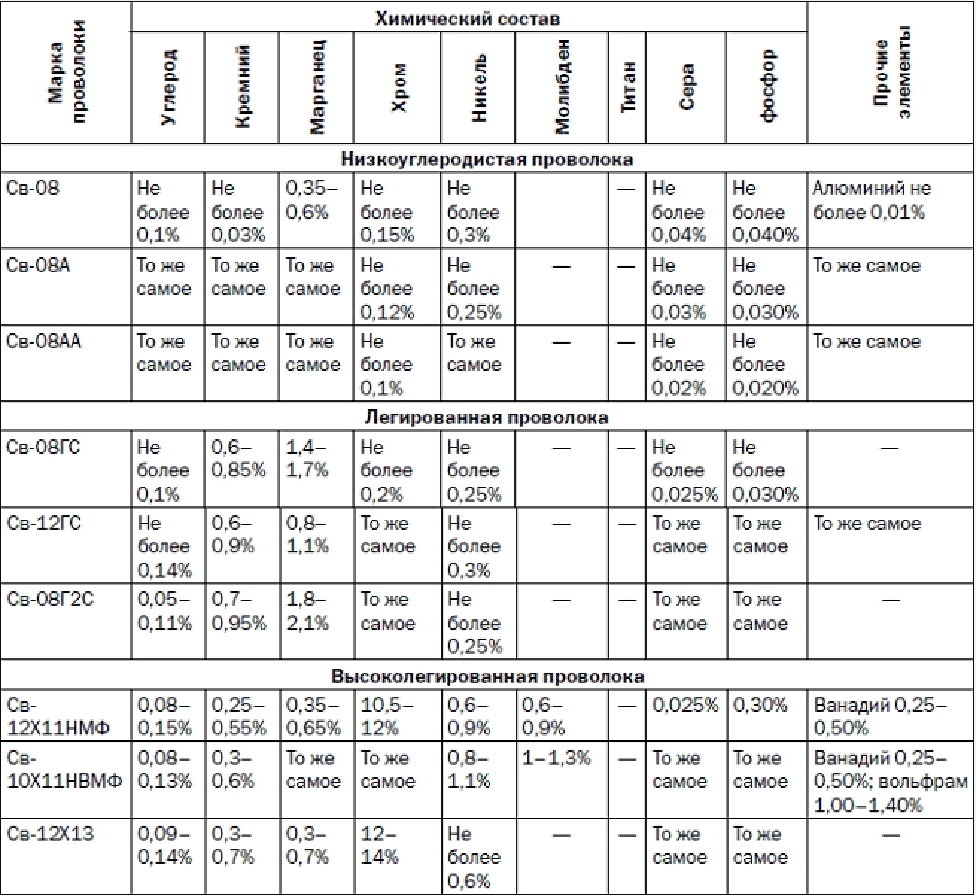

Below we provide a comparative table, domestic brands, according to GOST:

Rating of quality grades of welding wire for 2025

Our list is based on real reviews, it takes into account the opinion of buyers who are familiar with the characteristics of the products.

solid section

Elitech 0606.010000

votes 28

5th place went to the copper-plated model "Elitech 0606.010000", used by semi-automatic welding machines ("MIG-MAG") with shielding gas. The cord is made of strong, high-quality steel, providing excellent performance. Wire diameter - 0.8 mm, weight 1 kg.

The protective copper layer protects the product from oxidation, improves the conductivity of the electric current, and reduces the consumption of tips. "Elitech 0606.010000" is wound on a plastic bobbin, improving the performance of the welder.

Technical indicators:

| Options | Characteristics |

|---|---|

| Diameter | 0.8 mm |

| Material | Steel |

| Coating type | Copperplated |

| Type of wire | solid section |

| Atmosphere for welding | Carbon dioxide, inert gas |

| Package | Spool |

| The weight | 1 kg |

| Country of Origin | China |

| Brand's homeland | Russia |

- does not boil;

- well "lays down";

- ergonomic packaging.

- not detected.

ELKRAFT ER5356

votes 5

4th place - at the aluminum cord "ELKRAFT ER5356", its diameter is 0.8 mm, weight - 2 kg, the product is placed on a spool (20 cm). The wire is used for semi-automatic welding of aluminum-magnesium alloys, metal structures containing > 3% "Mg": AlMg3, AlMg4, AlMg5, AlMg6, similar mixtures. Welding is used with direct current (DC plus), shielding gas - argon.

Technical indicators:

| Options | Characteristics |

|---|---|

| Diameter | 0.8mm |

| Material | Aluminum |

| Type of wire | solid section |

| Atmosphere for welding | inert gas |

| Suitable for welding | aluminum |

| Yield strength | 120 |

| Relative extension | 26 |

| Tensile strength | 265 |

| Package | Spool |

| The weight | 2 kg |

- even seam;

- price quality.

- not detected.

MONOLITH 20312

votes 18

Bronze - for the copper-plated cord "MONOLITH 20312", with a diameter of 1.2 mm, weighing 5 kg. The model is used for "MIG-MAG" welding.

Technical indicators:

| Options | Characteristics |

|---|---|

| Diameter | 0.8mm |

| Material | Copperplated |

| Type of wire | solid section |

| Atmosphere for welding | Carbon dioxide, inert gas |

| Suitable for welding | carbon steel |

| Package | spool |

| The weight | 4 kg |

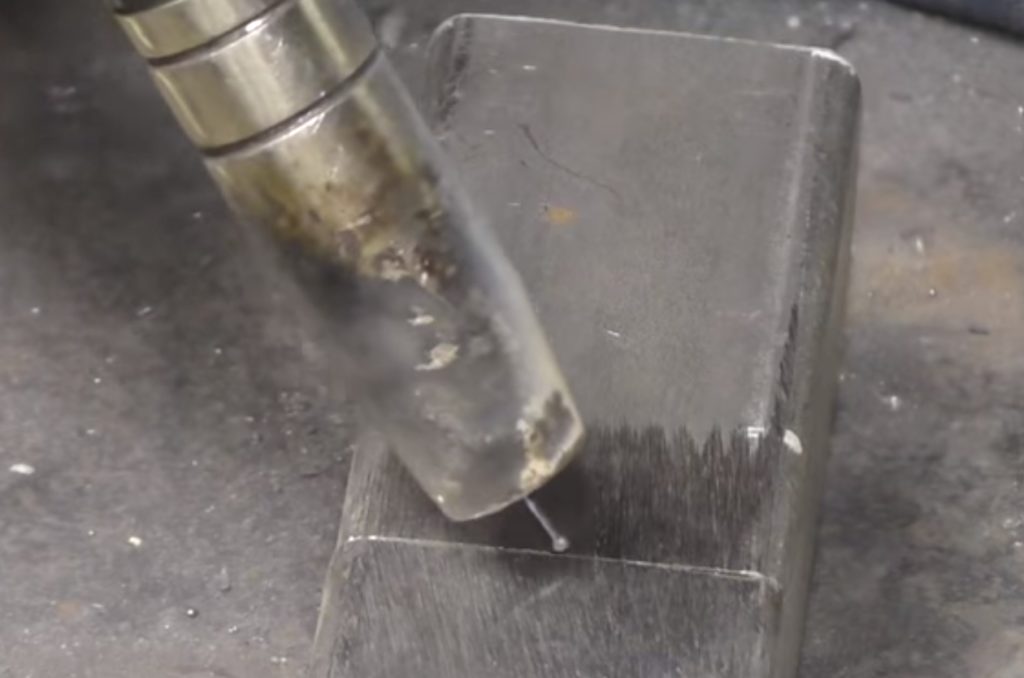

- during operation, the plasma vacuum-arc nozzle provides excellent cleaning of the welded surface;

- in-line winding significantly increases the life of expensive semi-automatic MIG equipment;

- "MONOLITH 20312" has a stable arc burning, which is maintained in most operating modes of the product.

- not detected.

Esab SV-08g2s

votes 10

The 2nd place is occupied by Esab SV-08g2s, which is used to work with low-carbon and low-alloy steel with a yield measure exceeding 400 MPa, carbon dioxide and its mixtures are used as protection.

The 2nd place is occupied by Esab SV-08g2s, which is used to work with low-carbon and low-alloy steel with a yield measure exceeding 400 MPa, carbon dioxide and its mixtures are used as protection.

Manufacturing technology "Esab SV-08g2s" provides a uniform supply of the cord and a little splashing during operation. The product has a strict limit on the content of impurities in the chemical composition, which guarantees excellent mechanical and impact parameters of the weld metal (KCU at -60°C). The finished seam is characterized by increased resistance to the formation of chips, even in conditions of violation of the level of "interpass" temperature during prolonged operation. "Esab SV-08g2s" is used in the following industries:

- energy;

- car building;

- heavy engineering;

- shipyards;

- special equipment;

- bridges, building structures.

Technical indicators:

| Options | Characteristics |

|---|---|

| Diameter | 0.8mm |

| Material | metal alloy |

| Coating type | Copperplated |

| Type of wire | solid section |

| Atmosphere for welding | Carbon dioxide, inert gas |

| Suitable for welding | low carbon steel |

| Yield strength | C1 (100% CO2) - min. 390 MPa, M21 (80%Ar+ 20%CO2) - min. 400 MPa |

| Relative extension | C1 (100% CO2) - min. 20%, M21 (80%Ar+ 20%CO2) - min. 22% |

| Tensile strength | C1 (100% CO2) - min. 490 MPa, M21 (80%Ar+ 20%CO2) - min. 510 MPa |

| Mark according to GOST | 2246-70: Sv-08G2S-O |

| EN ISO grade | EN ISO 14341: EN ISO 14341-B-G S18, EN ISO 14341: EN ISO 14341-B-G 49A 2 C1 S18, EN ISO 14341-B-G 49A 2 M21 S18 |

| Package | Spool |

| The weight | 5 kg |

| alloy type | Manganese carbon steel |

- high-quality seam in conditions of multi-pass welding;

- acceptable price.

- not detected.

ER-70S-6 Brima 0011991

votes 23

The winner is "Brima 0011991", used for semi- and automatic welding "MIG / MAG", the cord successfully works with carbon, low alloy metals, using shielding gas mixtures. Among the advantages of this model are a small spatter of metal, a high-quality straight seam, the ability to work with increased efficiency.

Mechanical properties:

- yield limit - 420 Mpa;

- tensile strength - 530 MPa;

- comparative elongation - 27%;

- impact hardness - 90 J/cm2.

Technical indicators:

| Options | Characteristics |

|---|---|

| The weight | 5 kg |

| Analogues | ER-70S-6; CB-08G2S; SG2 |

| Material | Metal alloy copper plated |

| Brand by AWS | ER70S-6 |

| IN ISO brand | SG2 |

| Mark according to GOST | SV-08G2S |

| Diameter | 0.8mm |

| Item unit | Thing |

| Weight of packed goods, kg | 5.03 |

| Packed goods dimensions, mm | 50x50x1000 |

| Home of the brand | Germany |

| Type of wire | solid section |

| Welds | Carbon, low alloy steel |

| Atmosphere | Carbon dioxide, inert gas |

| Package | Babin |

- little splashes during operation;

- price quality.

- not detected.

Powder

Elitech 0606.016000

votes 15

5th place - at the powder cord "Elitech 0606.016000", this model is used by semi-automatic welding machines "MIG / MAG" without the use of gas. The birthplace of the brand is the Russian Federation.

Technical indicators:

| Options | Characteristics |

|---|---|

| Diameter | 0.8mm |

| Material | metal alloy |

| Type of wire | Powder |

| Atmosphere for welding | submerged |

| Package | Spool |

| The weight | 1 kg |

- applied without gas;

- relatively low price.

- not detected.

CEDAR MIG E71T-GS

votes 8

The 4th place is occupied by the MIG E71T-GS powder wire, the wire is capable of welding materials in one “pass” with an overlap joint, while it is possible to work in all directions. The product is successfully used in the shipbuilding industry, the manufacture of various metal structures, works with rotating parts, and in other areas where it is difficult to use semi-automatic welding equipment in a shielding gas environment. The device must operate on direct current (DC), the polarity is straight, the winding of the cord on the reel is in-line.

Technical indicators:

| Options | Characteristics |

|---|---|

| Diameter | 0.8mm |

| Material | metal alloy |

| Type of wire | Powder |

| Atmosphere for welding | submerged |

| Yield strength | 400 MPa |

| Relative extension | 0.22 |

| Tensile strength | 480 MPa |

| Brand by AWS | E71T-GS |

| Package | Spool |

| The weight | 1 kg |

- price quality.

- not detected.

Innershield NR-232

votes 0

Bronze - for a flux-cored wire operating without gas. Model "Innershield NR-232", used with carbon metals, while the nozzle can be held in all spatial positions.

The features of "Innershield NR-232" include: increased speed and depth of weld welding during out-of-position work; relatively fast setting of parts; easy sludge removal. Lot Quality Inspection complies with AWS D1.8. Scope of use "Innershield NR-232":

- construction industry, including metal structures that meet seismic safety requirements;

- general construction plates

- production of shipbuilding parts, fittings;

- heavy engineering, various containers, bunkers, supports, bridge elements.

Technical indicators:

| Options | Characteristics |

|---|---|

| Classification and approvals | AWS A5.20/A5.20M EN ISO 17632-A : E71T-8 : T 42 2 Y N 2 H10 |

| Yield strength σt, N/mm² | 490 |

| Tensile strength σv, N/mm² | 590 |

| Elongation δ, % | 26 |

| Impact strength KCV, J/cm² | 65 at -20°C 35 at -29°C |

| The chemical composition of the overlay. metal | C, % 0.18 Mn, % 0.65 Si, % 0.27 Al, % 0.55 P, % 0.006 S, % 0.004 |

| Diameter | 1.7mm |

| The weight | 4*6.1kg |

- strong seam;

- simple sludge removal.

- not detected.

Filarc PZ 6113

votes 1

2nd place is occupied by a universal multi-position rutile powder cord that works without protective gas, made to work in the argon mixture "M21", carbon dioxide "C1", without impurities. The equipment must be configured for DC reverse polarity.

"Filarc PZ 6113" welds carbon, low-alloy metal structures, ship elements. The wire has excellent technological parameters, forming an even deposited seam with an easily detachable slag crust, while spatter is practically completely absent.It is important to note that when forming the back bead by one-sided welding, it is necessary to use ceramic pads with a trapezoid-shaped groove. The seam must be led with an angle back, squeezing the slag into the back of the bath.

Technical indicators:

- no splash;

- multi-position work.

- not detected.

WESTER FW 12300

votes 2

The WESTER FW 12300 powder (flux) product wins, the wire is wound on a bobbin with a diameter of 20 cm. WESTER FW is used to work in various spatial positions, welds low-carbon and low-alloy metals, with and without shielding gas. The model is supplied to the market in a moisture-proof vacuum package. The product complies with AWS HTE71T-1 regulations.

Technical indicators:

| Options | Characteristics |

|---|---|

| Diameter | 1.2 mm |

| Material | metal alloy |

| Type of wire | Powder |

| Brews | Low carbon, low alloy steel |

| Brand by AWS | HTE71T-1 |

| Package | Spool |

| The weight | 3 kg |

| Welding | Without shielding gas |

-

- price quality;

- even seam;

- light hose.

- not detected.

We hope that our article will help you understand among the various brands of welding wire. Successful work!

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131650 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127689 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124518 -

The best men's sneakers in 2025

Views: 124031 -

The Best Complex Vitamins in 2025

Views: 121938 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114979 -

The best paint for gray hair - top rating 2025

Views: 113394 -

Ranking of the best wood paints for interior work in 2025

Views: 110318 -

Rating of the best spinning reels in 2025

Views: 105328 -

Ranking of the best sex dolls for men for 2025

Views: 104365 -

Ranking of the best action cameras from China in 2025

Views: 102215 -

The most effective calcium preparations for adults and children in 2025

Views: 102011