Rating of the best petal circles for grinders 2022

Over the past 15 years, flap discs for grinders have become the fastest growing category of abrasives in the metalworking and other industries. The reasons for their rapid progress are varied. In terms of their performance, they offer fast machine start-ups, grinding, deburring, surface finishing operations, all at an affordable total cost.

They are able to perform clean cuts without vibration, cracking and burnout, which distinguishes them from conventional abrasive discs. The price of products ranges from 50 to 5000 rubles, depending on the quality and functionality. In our review, we will provide recommendations: “what to look for in order not to make a mistake when choosing a product”, “which company model is better to buy”. We will get acquainted with popular manufacturers, a description of abrasives, and we will orient you at an average price.

Content [Hide]

Types of petal circles, how to choose them correctly

From the user's point of view, the device has many advantages, it is light, easy to operate, and it does not take much time to replace it. A significant advantage is the reduced vibration during operation, as a result, the operator does not accumulate fatigue during operation. With all the advantages that petal models offer today, it is important to study them in more detail, determine the criteria for choosing products, which will undoubtedly have a positive effect on the implementation of your projects.

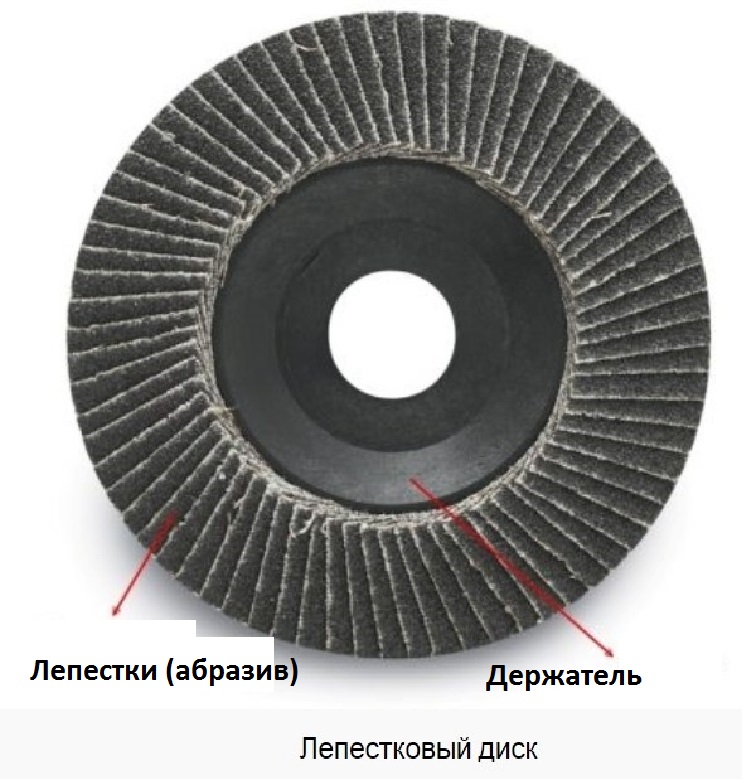

The name of this cutting tool corresponds to its own structure. The circle consists of flaps coated with abrasive of various grain sizes. The sandpaper petals are attached to a base plate, which, as we will see later, can be made from different materials. This backing is then cut into smaller sheets, folded radially in several layers to form vanes (flaps or fins) that remain attached to the central core.

The first flap models of high-speed angle grinders were developed about 40 years ago, they were quite simple, current versions offer more variety.Professionals prefer the superior quality and ease of use of flap discs, and the popularity of their models far outstrips conventional grinding discs.

The best flap products are more expensive than abrasive wheels, but in the long run, higher investment results in higher productivity. Let's look at some of the advantages of these devices:

- lightweight design reduces worker fatigue;

- ease of use, as high surface pressure is not required;

- cold cutting allows you to process the surface, preventing burning;

- long service life, wear resistance is 10-15 times better than conventional wheels due to the overlapping flap design;

- Aggressive material removal, similar to the characteristics of deep center grinding wheels, but with more safety, since the use of a protective cover is not required;

- stable performance, since all grains are constantly exposed to the same impact throughout the life of the blade;

- conical grinding angle ensures optimal contact between the workpiece and the wheel surface;

- Robust design allows for aggressive edge finishing without cracking or tearing.

Petal models consist of a support and a number of flaps arranged radially. Both the base and the abrasive can consist of different materials and have advanced characteristics. So let's see what these types are.

The backing plate material is an important design variable and determines its application. The most common are the following models:

- Fiberglass is stronger, more durable, lighter and safer, it is currently the most popular of materials, it creates a reliable base without contaminating the work surface. This type is consumed during use, absorbs vibration very well. The fiberglass pole has a layered structure bonded and pressed into a lattice. The more layers, the higher the mesh density, the stronger and more durable the base, so this should be taken into account when selecting the technical characteristics of the device.

- Plastic (nylon) is almost as popular as the previous model, a support made of this material has many advantages. The advantage of these holders is that they can be cut off, allowing the abrasive flaps to be used longer, especially during deburring and grinding. Today, nylon is becoming an increasingly attractive option due to its moldability and low cost.

- Metal skid plates, usually made of aluminium, are the safest option and excel when extra reliability is required. Since they are expensive, they should be used when justified, such as when working with concrete or stone at maximum speed. The aluminum holder is not consumed during use, the plates can be easily recycled when the disk reaches its end of life.

Flap wheels have found their way into the steel industry and can be used for a wide variety of purposes, whether it be metal or wood, concrete grinding or finishing, stone polishing, paint or rust removal, and more. The quality of the material that makes up the abrasive grain is important for specific job needs and can be of different types.Below is a description of the most common of them, consider what they are.

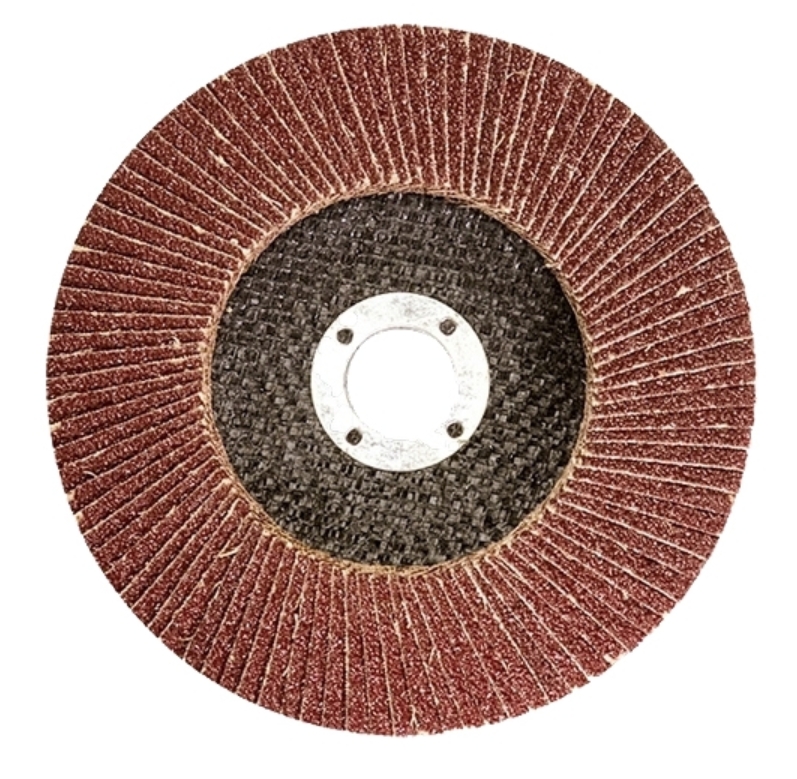

- Aluminum Oxide is the original material used for grinding metals in the 1970s when flap machines first appeared, it is the cheapest option. Today, aluminum oxide abrasives are recommended for small jobs where quality requirements are low to medium.

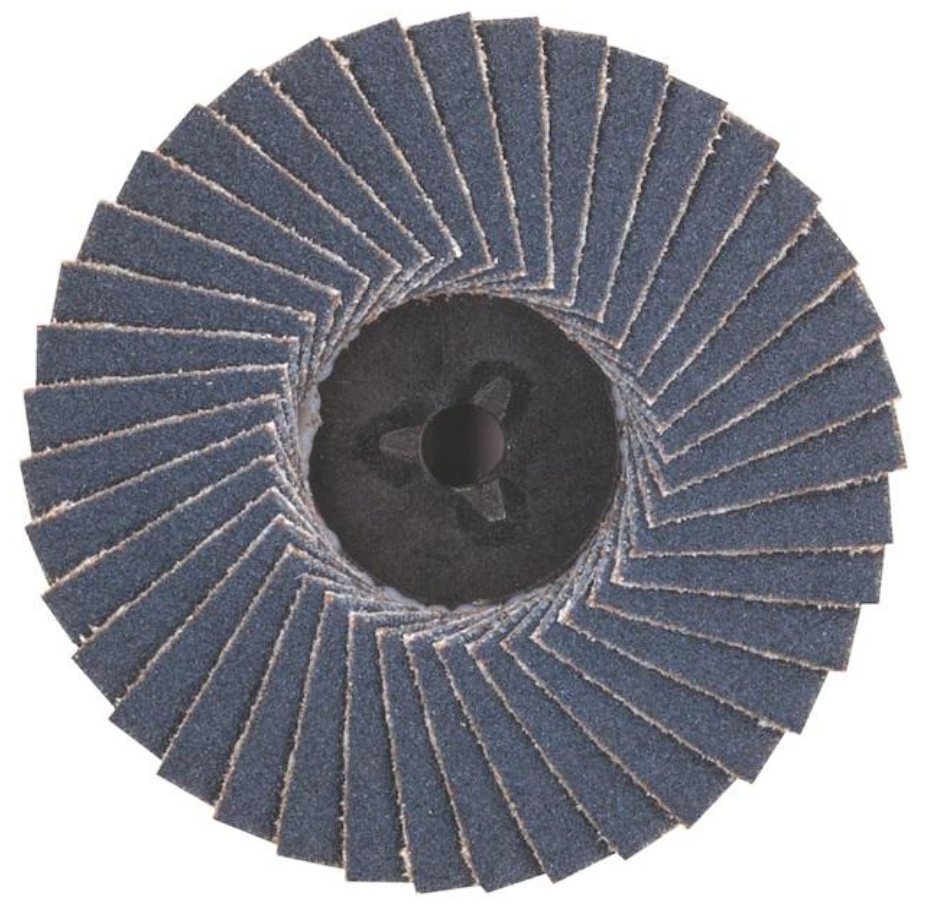

- Zirconium has good thermal properties, hardness and high wear resistance, its higher cost guarantees long life and less downtime. It is superior to alumina and is currently the most common metalworking material. Usually used for grinding steel, including stainless, finishing work.

- Silicon carbide is a natural mineral form that produces a thin and sharp abrasive, a patchwork circle covered with thousands of tiny but sharp blades. As a general rule, silicon carbide blades are ideal when a clean cut is required on non-ferrous surfaces (brass, aluminum or titanium), they work on natural stone, brick, tile, wood, leather, glass, plastic. This abrasive is not effective if a lot of pressure is required on the disc.

- Ceramic oxide has a microcrystalline structure and is more uniform than alumina or zirconia abrasives, allowing it to break down more slowly, expanding the range of applications available. However, it is important to note that ceramic abrasives are particularly sensitive to heat, pressure, and this means that a properly planned workflow is important for their successful use.At the same time, they show excellent performance in the production of aluminum castings, mild steel, stainless steel finishes and titanium alloys commonly used in the aerospace industry.

To buy the right product, you need to choose the right characteristics, design:

- When we talk about density, we must keep in mind the total area of the abrasive created by the blades of the device. It depends on the number of lamellas (petals), their angle relative to the center of the device and the distance at which they are located from each other. Each of these variables can affect the total area of the disk that will be in contact with the workpiece. To this end, we must distinguish between two types of densities: standard lamellae are optimal for fast sanding and heavy duty applications; The high density of petals is best suited for working with curved or uneven parts, as well as during surface finishing. To correctly distinguish between the two varieties of these products, you just need to look at their density rating, you must always take into account the number, angle of inclination and the distance between the lamellas.

- Everyone who works with grinding wheels is familiar with the concept of abrasive size (coarse, fine). Petal models are no exception. The former are used for roughing, the latter for finishing, the middle option for normal work.

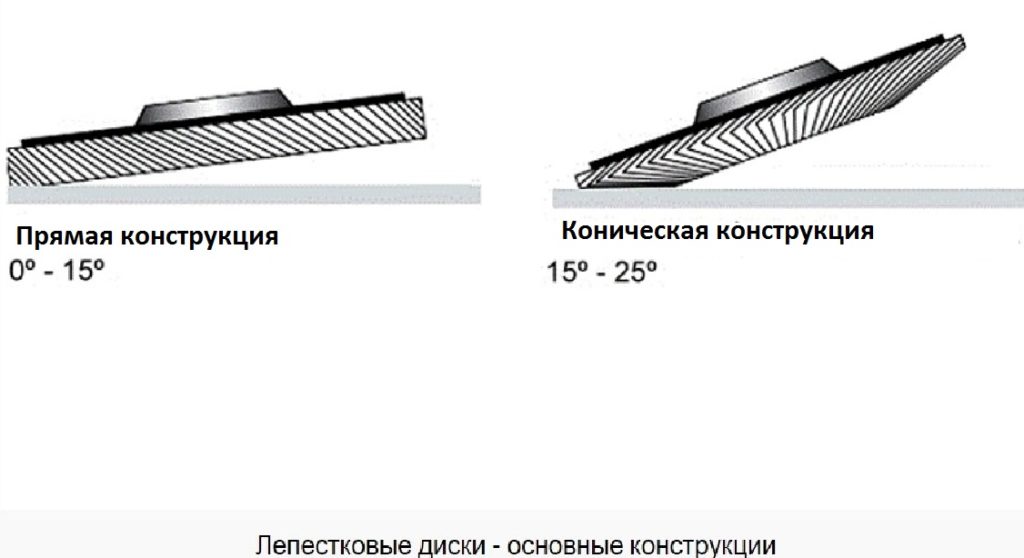

Flap wheels can be used in angle grinders, i.e. they are able to process a plane located at an angle with respect to the surface of the workpiece. The design of the device will have a direct impact on the grinding efficiency. To do this, you need to know two basic designs, shown in the figure below:

- Flat wheels are generally preferred for more controlled machining or finishing operations where less pressure is applied to the workpiece. They have a smooth grinding surface, mainly used for processing flat workpieces and external corners. The angle between the disc and the workpiece varies from 0° to 15°, which allows grinding and polishing at the same time, which reduces the workload. Wheels of this type can have a different bore diameter, a convex or depressed central zone, which provides a large contact surface between the device and the workpiece.

- Conical designs imply the location of the lamellas at an angle, so the products have a large working surface area on horizontally located parts. During grinding, the device forms an angle of 15° to 25° with the workpiece. This makes them ideal when large amounts of chips need to be removed in a short time. Tapered designs can be used for contouring and edging.

After acquiring this knowledge, you will be able to decide which petal model is suitable for the intended purpose.

Where could I buy

Budget novelties are purchased in construction supermarkets. Managers will tell you the points you are interested in: how much the model you like costs, they will provide information about domestic and foreign manufacturers. The product can be viewed in the online store by ordering online.

Rating of high-quality petal circles for grinders 2020-2021

Our list is based on real reviews, it takes into account the opinion of buyers familiar with the product, its functions. Here you will find photos and tables of characteristics.

Inexpensive

FIT 39554

votes 2

The “FIT” emery wheel is used by grinding machines for processing iron, stainless steel, cleaning welds. The disc has an inclined shape, which is well suited for processing uneven surfaces. The tool holder is made of fiberglass, and the abrasive is made of aluminum oxide, so the sanding is very high quality.

Technical indicators:

| Options | Characteristics |

|---|---|

| Manufacturer | fit |

| Model | 39554 |

| Type of equipment | Petal, end |

| Recommended tool | angle grinder |

| Purpose | Grinding materials |

| The form | Straight |

| Diameter, mm | 125 |

| Landing diameter, mm | 22 |

| Quantity in a package, pcs. | 1 |

| Other | Grain size - Р80 |

| Dimensions, mm | 12.5x12.5x1 |

- the conical design of the product allows processing uneven surfaces.

- not detected.

Stayer 36581-125-060

votes 0

"Stayer 36581-125-060" is an end wheel for wood, metal for "grinder", used for preliminary and intermediate grinding of metals, welds and wood. The electrostatic method of drawing provides uniform distribution of an abrasive on all working surface. The elastic fabric base allows you to grind complex workpieces. Due to the special structure of the lamellas, the quality and speed of processing are significantly improved.

Durable polyamide construction guarantees the safety of the work performed. The abrasive grain is aluminum oxide.

The main advantages of the popular Stayer tools are: extended service life, high efficiency and versatility in the processing of many materials. Modern technologies are used for the production of this device. The base is made of fiberglass, synthetic resins and abrasive material.The reinforced construction gives the product additional strength and tear resistance.

Technical indicators:

| Options | Characteristics |

|---|---|

| Manufacturer | stayer |

| Model | 36581-125-060 |

| Type of | sanding sheet |

| Color | Combined color |

| Color description | Black, yellow |

| Purpose | Flat grinding, processing of edges and welds of parts and structures made of various grades of steel, non-ferrous metals, wood, plastic |

| Diameter, mm | 125 |

| Grain size | P60 |

| Dimensions | 125mm x 22.2mm |

| Quantity, pcs | 1 |

| Additional Information | Due to the special structure of the location of the abrasive plates, the quality and speed of processing are significantly improved. |

| Material | Polyamide, electrocorundum, tough cotton fabric |

| Number of holes | 1 |

| Dimensions | 12x1x12mm |

- polyamide base;

- the design of the lamellas increases the processing speed.

- not detected.

Meadows d-115x22 mm, P60 KLT

votes 7

KLT "Luga-Abrasive" is used together with "grinders" for processing the ends of workpieces and flat surfaces of workpieces made of steel, wood, plastic. Equipment equipped with a Luga-Abrasive disc will successfully be able to clean welding seams and burrs, remove rust, paint, etc. The lamellas are attached to a flexible plate, they are highly efficient and resistant to wear. Safety complies with the regulations of GOST 52588-2011 and EN 13743.

Technical indicators:

| Options | Characteristics |

|---|---|

| Diameter | 115 mm |

| Grit, P | 60 |

| Type of | Grinding wheel |

| Amount in a package | 1 PC. |

- favorable price/quality ratio.

- not detected.

Medium

Belgorod Abrasive Plant, KLT-1 36563-125-40

votes 0

"KLT-1 36563-125-40" was created specifically for "grinders", designed for processing wooden, metal, plastic and other surfaces with different relief at a speed of up to 12,250 rpm. The high-quality petal coating is made of aluminum oxide, it has a longer service life and guarantees a quality finish on the parts. The electrostatic process of applying abrasive grain ensures its uniform distribution over the entire working surface of the disc. Reinforced fiberglass base provides increased strength and protects the product from tearing.

"KLT-1 36563-125-40" was created specifically for "grinders", designed for processing wooden, metal, plastic and other surfaces with different relief at a speed of up to 12,250 rpm. The high-quality petal coating is made of aluminum oxide, it has a longer service life and guarantees a quality finish on the parts. The electrostatic process of applying abrasive grain ensures its uniform distribution over the entire working surface of the disc. Reinforced fiberglass base provides increased strength and protects the product from tearing.

Technical indicators:

| Options | Characteristics |

|---|---|

| Manufacturer code | 36563-125-40 |

| Rotation frequency | 12250 rpm |

| Material | Aluminium oxide |

| Application | angle grinder |

| Brand | BAZ |

| Producing country | Russia |

| The weight | 0.091 kg |

| Dimensions (L x W x H) | 125mm x 125mm x 10mm |

| Shipping Weight | 0.091 kg |

| Dimensions with packaging (L x W x H), mm | 125x125x10 |

- fiberglass base;

- finishing a wide range of materials.

- not detected.

Matrix 74042

votes 0

This design is made of square elements of a cloth-based abrasive cloth, which are arranged radially, on a fiberglass backing. Grinding disc "Matrix P40 7404", 125 x 22.2 mm is used as consumables for various angle grinders.

This wheel is designed to work with metal surfaces and details. The key feature of the product is the zirconia corundum lamellae, interconnected by synthetic resin. This design can significantly increase the life of the consumables. The abrasive has a P40 grit.

Technical indicators:

| Options | Characteristics |

|---|---|

| Brand | MATRIX |

| Diameter | 125mm |

| Grain | P40 |

| The form | Straight |

| Landing | 22.2 mm |

| Type of packaging | Without packaging |

| Packed length | 125mm |

| Packed Width | 125 mm |

| Packed Height | 13mm |

| The weight | 0.101 kg |

- working corundum coating;

- increased wear resistance.

- not detected.

Makita D-28553

votes 0

The product from the famous Japanese brand "Makita D-28553" has a flat design, it is suitable for finishing even workpieces. The slats are fixed on the holder radially, which, in turn, is made of high-quality fiberglass. "Makita D-28553" are used for finishing stainless steel, hardened iron, cast iron, non-ferrous metals, removing enamel, rust. The product is used for processing, stripping, chamfering.

Technical indicators:

| Options | Characteristics |

|---|---|

| Type of | Petal |

| Purpose | For metal |

| Diameter | 180 mm |

| landing hole | 22.23 mm |

| Max RPM | 8600 rpm |

| Fiber | Fiberglass |

| Grain | Ce80 |

| Set | 1 PC. |

- thoughtful, ergonomic design;

- working part ceramics, aluminum oxide;

- high quality finishes;

- high wear resistance;

- silent operation;

- water resistance;

- the possibility of recovery.

- not detected.

Expensive

125x22mm P40 Vulcan NORTON (63642502315)

votes 0

Abrasive disc size 125x22mm, grit (P40) "Norton Vulcan" (63642502315) can be useful when cleaning the surface from old paint or rust before finishing. The product is able to smooth chamfers, remove burrs, clean welds. The advantage of the device is a highly effective grain based on NorZon zirconium corundum."Norton Vulcan" guarantees its owner excellent performance, abrasive wear resistance.

Technical indicators:

| Options | Characteristics |

|---|---|

| Purpose | For metal, stainless steel |

| Diameter | 125mm |

| The form | Straight |

| Landing diameter, mm | 22.2 |

| Package weight, g | 135 |

| Packing dimensions, mm | 125x0x10 |

| Country of manufacture | Poland |

- the ability to work at a speed of 12250 rpm, 80 m/s;

- effective grain based on zirconium corundum "NorZon";

- lamellas made of reliable cotton canvas;

- fiberglass holder;

- wear resistance of the structure;

- Aggressive sanding is possible.

- not detected.

125x22r36 V, 10 pcs. Scrab 35880

votes 0

Your attention is a set of wheels (KLT), the number of pieces in a package is 10. SKRAB products are used by angle grinders for preliminary, intermediate and final processing of iron, welded joints, wood, glass, plastic, the device is screwed onto the grinder with a special fixing bolt.

"Skrab 35880" is used for finishing flat and concave-convex surfaces from various materials. The set has grit wheels (P22), they are used, depending on the needs, for processing materials and roughening the surface from 0.32 to 0.8 microns or for final grinding.

Technical indicators:

| Options | Characteristics |

|---|---|

| Manufacturer | SKRAB |

| Diameter | 125 mm |

| Grit, P | 22 |

| Type of | Grinding wheel |

| Amount in a package | 10 pieces. |

- the unique design of the location of the flaps significantly increases the quality, speed of surface treatment;

- the circle has elasticity;

- a large area of interaction between the working part of the tool and the surface to be trimmed;

- maximum rotation speed 13300 rpm, linear 80 m/s.

- not detected.

"Russian Master" 125; P60

votes 5

The flap discs consist of cloth-based abrasive flaps fan-shaped around a central holder. It is made of fiberglass. Due to the radial arrangement of the lamellae, a high elasticity of the working surface of the product is achieved, which greatly increases productivity compared to other tools. The special position of the abrasive material contributes to its cooling during operation, providing cold grinding. The maximum number of revolutions per minute is 13300 rpm.

Technical indicators:

| Options | Characteristics |

|---|---|

| Type of | Petal end |

| Diameter, mm | 125 |

| Grit (according to ISO-6344) | P60 |

| Manufacturer country | China |

| Packed weight, g | 999 |

- favorable price/quality ratio;

- fiberglass holder;

- cold working parts.

- not detected.

Wurth 0578605012060-10

votes 1

KLT "Redline" is intended for grinding surfaces, processing edges, deburring and cleaning welds on products made of structural and stainless steel. Used with angle grinders ("grinders"). The disc holder is made of fiberglass, the petals are made of reinforced polyester fabric, the grain is aluminum oxide. Manufactured in accordance with European safety requirements EN 13743. Curved construction, size 125×22.23 mm, grit is 120 (NC120).

Technical indicators:

| Options | Characteristics |

|---|---|

| Production | WURTH (China) |

| Gross weight | 0.101 kg |

| Purpose | D/construction and stainless steel become |

| The size | 125x22.23 mm |

| Grain | 120 (NC120) |

| The foundation | Fiberglass |

| Corn | Aluminium oxide |

| Safety | EN 13743 |

- aluminum oxide abrasive;

- slats based on reinforced polyester fabric.

- not detected.

We hope this review will help you decide on the choice of a suitable petal disc for the grinder, and you will successfully achieve your goals.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131651 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127690 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124519 -

The best men's sneakers in 2022

Views: 124033 -

The Best Complex Vitamins in 2022

Views: 121939 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114980 -

The best paint for gray hair - top rating 2022

Views: 113395 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105329 -

Ranking of the best sex dolls for men for 2022

Views: 104366 -

Ranking of the best action cameras from China in 2022

Views: 102216 -

The most effective calcium preparations for adults and children in 2022

Views: 102011