Rating of the best cremators for waste disposal for 2022

Waste cremators are a special type of equipment that is designed for the thermal destruction of municipal solid waste, the elimination of the corpses of various animals, as well as biomaterial and medical waste. This type of disposal allows you to protect nature from contamination by chemicals, harmful bacteria and even radionuclides. More recently, such garbage was simply dumped into pits and ravines, often without even burying them. All this led to the fact that poisons penetrated into the ground and groundwater, and this already led to their chemical / biological contamination. The same can happen with ordinary household waste if it is not disposed of separately.In any case, almost every enterprise dealing with waste production should be provided with its own cremator for the purpose of competent disposal.

These may include:

- Manufacturing companies.

- Hospitals and Hospitals.

- Veterinary clinics.

- Meat and poultry factories, etc.

Proper disposal is the key to maintaining a clean environment.

Content

- 1 Cremator and its meaning

- 2 Main operating parameters and elements of the cremator

- 3 Types of waste and features of their disposal

- 4 Types of incinerators and their differences

- 5 Device and work

- 6 Advantages and disadvantages of using crematory devices

- 7 Price formation factors for cremators

- 8 Rating of the best models of cremators for 2022

- 9 Instead of an epilogue

Cremator and its meaning

The cremation process itself is a relatively new phenomenon in the field of nature protection. In order to save money, and sometimes because of banal indifference, business entities buried not only hazardous waste, but also the corpses of infected animals, one might say, “anywhere”. The reason for this was also the fact of the absence of a normal environmental regulatory framework.

The essence of the work of the cremator is to process waste using ultra-high temperatures, after which, in the processed garbage material, all potentially dangerous poisons, pathogens, microbes and viruses are eliminated, and for MSW (solid household waste) - all of their recyclable is qualitatively reduced (or practically destroyed). volume.

Differences between cremators and incinerators

An incinerator is essentially the same cremator, only it has more advanced functionality. In particular, the incinerator has large volumes of the incineration tank, has increased power, and more different types of garbage can be burned in it. They are also characterized by a rather short operating time. In addition, they are equipped with an integrated afterburner, thanks to which environmental damage is minimized. But it is impossible to connect even an external afterburner to some models of cremators.

Main operating parameters and elements of the cremator

Loading volume - it is usually calculated in kilograms, which means the mass of material that can be placed at one time in the combustion chamber. It is worth noting that this parameter is in most cases overestimated by the manufacturer, but this does not mean some kind of "worldwide conspiracy". Here the main role is played by the density of the material to be destroyed: for example, the feather of a bird will have a larger volume, but less weight compared to the bones of cattle, where inverse proportions will appear. Thus, the manufacturer, when specifying the loading volume, focuses primarily on the type of waste that will be more profitable to destroy.At the same time, a similar rule will apply to the apparatus itself - there is no need to think that the larger its overall dimensions, the larger its loading volume. Often, when specifying the dimensions of the chamber, the manufacturer “forgets” to indicate that a separate place in it is occupied by:

- The burner itself;

- Bracket for control panel;

- Loops for transporting the device, etc.

Accordingly, the loading volume must always be equivalent to the actual factage, and its cubic capacity must be suitable for the destruction of a certain type of waste.

IMPORTANT! A good sign is the fact that the manufacturer in the documents indicates the volume not only in cubic meters, but also in kilograms and liters.

Type of fuel used – thermal disposal equipment can operate on three main types of fuel:

- Diesel;

- Natural gas;

- Liquefied gas.

It should be mentioned that there are models that can use different types of fuel at the same time, however, they will be more difficult to operate and maintain (such devices are called universal and a dual-fuel burner system is installed in them).

Natural gas is considered the most economical type of fuel, but for its use in industrial conditions, a pipeline must be properly arranged on the territory of the enterprise that complies with design standards.

Regarding liquefied gas, it can be noted that when working on it at low temperatures, its evaporative qualities are sharply reduced, and unevaporated residues in cylinders can be very significant.

Waste disposal rate - Another parameter that will completely depend on the type of waste burned.It, again, may be overestimated by the manufacturer, based on the density and volume of recycled materials. But still, it can be calculated based on the power range of the heat generated by the burner, the working size of the flame, and the cubic capacity of the combustion chamber. The higher all these parameters, the faster the recycling will occur.

combustion chamber - its effectiveness directly depends on the material of manufacture of the outer layer of the metal case, and the material that makes up the inner thermal insulation (refractory) layer will play an important role. An ideal option for an external structure is a metal case with a thickness of at least 10 millimeters, made on the basis of a hot-rolled electric-welded pipe. This system is most resistant to resistance to high temperatures, and increased strength characteristics will be provided due to the heat treatment of the ESP pipe, because modern technologies make it possible to produce steel with a high degree of resistance and with a reduced content of non-metallic inclusions and various gases. In turn, if the body is made on a “sheet bend” (rolling machine), then the risk of falling out of the internal thermal insulation layer instantly increases, because with increased use, the body constantly expands / contracts (when heated / cooled), which is why the metal “fails”, especially if it the thickness is quite small.

Regarding the refractory layer - here its structure and thickness play an important role. Its reliability can be checked only by many days of work. However, if you constantly change the type of material burned, i.e. use an internal coating for various, often non-specialized purposes, then the probability of its failure will increase significantly.

IMPORTANT! Standard refractory material (for example, light fireclay) is categorically not adapted to constant cooling / heating. Based on the total weight of the cremator, one can, in principle, assume what type of internal thermal insulation is installed in it. The greater the mass of the apparatus, the better type of thermal insulation is installed in it.

Permits and supply contract - one of the most important parameters for waste incineration equipment. If the manufacturer does not have the proper certificates and permits for the production of such equipment, then its purchase itself will not make sense. Any check by supervisory authorities that reveal violations in this area may prohibit the use of the device, or it will be withdrawn and destroyed altogether, as special equipment that does not comply with applicable standards.

It is also worth paying close attention to the supply agreement, the subject of which should contain a link to the necessary licenses and certificates of the supplier. The ideal situation is when the manufacturer and supplier are the same legal entity. Otherwise, the supplier may not have the necessary documents for warranty repairs, which means sending the equipment to the manufacturer, and here we can already speak directly about forced downtime and lost profits.

Types of waste and features of their disposal

biological waste

Modern cremators can destroy almost all types of such materials:

- Animal corpses;

- Expired food products;

- Medical waste;

- Waste food and procurement industry.

Depending on the volume of the combustion chamber, such raw materials can be disposed of at a rate of 50 to 570 kg/h.This process can be accelerated if the cremator model is equipped with a special ignition system. The presence of an automatic on / off installation will help save up to 40% of fuel when burning waste weighing up to 300 kilograms.

Cremators of biowaste can be useful not only in production, but also in everyday life. They can burn fallen leaves, rotten wood, withered grass, as well as the remains of domestic and farm animals. A special effect will be extremely evident for small farms, because a special license for small-scale cremation is not required.

Destruction of corpses of farm animals

Until recently, the process of disposal of diseased farm animals that were subjected to forced slaughter was extremely unsafe. Their remains were simply dumped into the so-called "Beccari pits", which were covered with earth and a large area of the nearby territory was declared a biological burial ground. But even after a lapse of time, when the dead bodies of cattle had already decomposed, it turned out that the resulting compost still releases toxic substances and carcinogens into the atmosphere. At present, with the advent of cremators, such a situation is practically excluded. The whole process looks like this:

- Carcasses of livestock are placed in the loading chamber.

- Turn on the burner on the electronic control cabinet.

- Set on the timer a certain time of operation of the cremator.

- In the afterburner (if the apparatus is equipped with it), the remaining 7-8% of the mass (usually bones) is disposed of.

After the chamber cools down, the remaining ash is simply raked out and it can be dispelled even in the wind, even buried in the ground - it will not bring any harm.

IMPORTANT! The combustion chambers of such cremators usually contain carcasses weighing from 300 to 3000 kilograms. The main thing is not to forget to constantly clean out the remains of ash, then the device will last a long time and practically will not need permanent maintenance.

medical waste

Such garbage material is the most dangerous type to be disposed of, because it carries a direct bacteriological threat. Both inorganic and organic waste can contain volatile chemicals, pathogenic microbes, radionuclides, and toxic substances. Modern cremation equipment is capable of reliably destroying any materials (both organic and synthetic) that show traces of biological contamination. The process itself is quite simple and does not even require sorting of such waste, and this indicates a significant time saving. The standard volume of medical waste that can be destroyed in 3-4 hours is 500 kilograms. Such equipment should be mandatory installed in large hospitals and medical institutions, whose personnel are in direct contact with highly hazardous biomaterials.

Types of incinerators and their differences

As mentioned above, the types of waste incineration devices are divided into cremators and incinerators. Both of these devices are used for the destruction of waste using high temperatures. The difference between these devices is only in the design and type of material they are designed to burn. Thus, incinerators are superior to cremators in many parameters and, in fact, are more professional equipment.

Cremators can also be produced in the form of household samples, but their older counterparts are no longer there.They are more suitable for the thermal elimination of especially dangerous raw materials: medical waste, oil sludge, biological waste, etc. In addition, they are necessarily equipped with an afterburner and have systems for additional heat treatment and exhaust cleaning. All these additional "features" significantly reduce the release of toxins into the atmosphere and have an extremely good effect on the natural environment. At the same time, incinerator devices have fans in their design, thanks to which the elevated combustion temperature is maintained, which means that the combustion process is accelerated.

Nevertheless, it is worth mentioning that it is possible to equip the cremator with additional devices (for example, an external afterburner), but in terms of its efficiency it will never reach the level of incinerator equipment.

However, both the cremator and the incinerator will (absolutely!) surpass the standard incinerator in all respects.

Devices for thermal disposal differ in the following parameters:

- Hopper capacity/size - it can hold from 300 kilograms to 3 tons, one-time loading can vary from 50 kilograms to 1 ton.

- Productivity - the possible time of continuous operation from 1 hour to 1.5 days.

- The fuel source is usually diesel or liquefied gas, less often natural gas (large industrial enterprises).

- Way of movement - stationary or mobile options.

Device and work

The two main devices in the cremator are the material storage bin and the high performance burner. The internal refractory lining of the bunker is also considered important, allowing the equipment to withstand extremely high temperatures up to 1000 degrees Celsius.

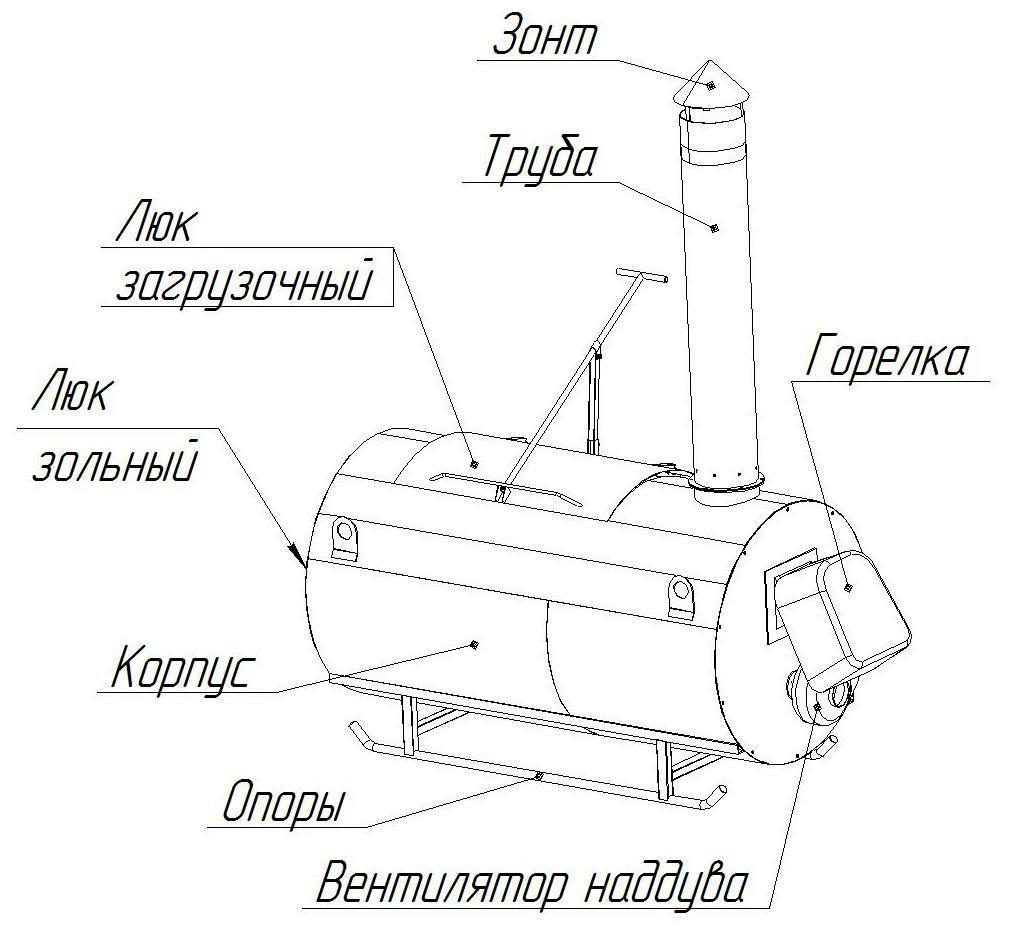

A typical crematory device consists of:

- Hatch for disposal of salvage.

- Bunker for burning.

- Cabinet (panel) control and management.

- Afterburners.

- Chambers for shoveling ash.

- Smoke pipes.

The devices themselves can have one or two burners, the second, as a rule, is located in the afterburner, which guarantees almost 100% disinfection of any waste.

With the help of burners, it is possible to regulate the level / strength of combustion and the temperature in the bunker. The inside of the device is equipped with grates with grates, which are responsible for the circulation of additional heat in the oven. A special need for grates arises when it is required to burn material with high humidity. The usual incineration temperature is about 800 degrees Celsius, which is enough to destroy most materials. At this temperature, most bacteria die, and the minimum amount of ash is formed at the exit. And such ash can generally be used to fertilize the soil.

IMPORTANT! It is always worth remembering that the combustion bunker (chamber) should not be overloaded! Even if the maximum volume of its capacity is precisely known, then it should be filled no more than 70%.

Advantages and disadvantages of using crematory devices

Their advantages include:

- Ease of use.

- Increased sterility.

- Tangible economic benefits.

- Causing minimal harm to the environment and ecology in general.

- Variability of combustion temperature regulation.

- Almost complete autonomy of the device.

The disadvantages include:

- Increased risk of fire.

- The operator is forced to work with hazardous materials in manual loading.

- Unloading of the spent burnt raw materials is carried out manually.

Price formation factors for cremators

Basically, the price of this equipment will depend on its technical characteristics: chamber volume, type of fuel source, additional equipment.

The volume of the combustion chamber has completely different variations:

- 50 - 100 kg (household options).

- 200 - 300 kg (middle segment, small businesses and sanatoriums).

- 500 - 1000 kg (industrial plants and large hospitals).

Gas models (any, even those running on liquefied gas, even on natural gas) will always be cheaper than diesel ones, since it is much more difficult and costly to make a diesel burner than a gas one.

Separately, it is necessary to mention the thickness and the material itself, from which the internal refractory coating of the bunker is made - the thicker the layer and the stronger the material, the higher the price of the apparatus.

The presence of additional accessories - additional doors, blowers, a modernized chimney, an ergonomic loading hatch - all this will increase the cost of the equipment. Also, if an additional burner is also installed in the additional chamber, which will minimize the volume of the remaining burned raw materials, then such an application will also increase the price.

Based on the practice of a medium-level private business, if you stock up on certain licenses (for example, for the right to destroy medical waste) and purchase a device from the middle segment for these purposes, then the price of the equipment can pay off in about 1 year. Moreover, the installation does not require special skills for operation. Still, you should not buy very cheap models, because. the operating conditions of this equipment are regarded as extremely extreme and a low-quality model will quickly wear out.

Rating of the best models of cremators for 2022

Economy class

3rd place: K-50 (without lining)

The simplest version of the crematory apparatus, characterized by good reliability and ease of operation. Designed for a wide range of materials disposal - from small poultry to class B medical waste. Guaranteed hermetic closure of the hatch.

| Name | Index |

|---|---|

| Total weight, kg | 560 |

| Loading weight, kg | 50 |

| Burning temperature, degrees Celsius | 760 |

| Price, rub | 62000 |

- Democratic price;

- Sealed construction;

- The light overall weight means transportation.

- Small loading volume.

2nd place: K-100 ("HIT")

This model deservedly received the "Hit" marking, because it is a very popular model among businessmen and mid-level farmers. Despite the fact that it is in the economy segment, it has a special winch that simplifies loading, lining bricks for installation, and a special refractory coating. Has a one year warranty.

| Name | Index |

|---|---|

| Total weight, kg | 1005 |

| Loading weight, kg | 100 |

| Burning temperature, degrees Celsius | 760 |

| Price, rub | 137000 |

- Unique exhaust system;

- Ceramic covering of the hatch;

- Runs on diesel.

- Big weight for a mobile model.

1st place: K-300 ("DIZ")

The most professional model from the lower segment. The burner in it is installed at an angle, which provides vortex ignition, shortening the overall cycle of operation. The outer case is made of low-alloy steel and has a thickness of 8 mm. Auto-ignition of the burner facilitates quick and easy start-up.

| Name | Index |

|---|---|

| Total weight, kg | 1850 |

| Loading weight, kg | 300 |

| Burning temperature, degrees Celsius | 760 |

| Price, rub | 199000 |

- Work on a diesel source;

- Auto timer and temperature sensor available;

- Internal gasket prevents overheating of the outer case.

- Extremely heavy for its characteristics.

Middle price segment

3rd place: KRN 500 KR

Model from the famous Russian manufacturer "ROScremator". More positioned as equipment for long-term operation in conditions close to industrial ones. It can be used for both municipal solid waste and biological waste.

| Name | Index |

|---|---|

| Total weight, kg | 2540 |

| Loading weight, kg | 500 |

| Burning temperature, degrees Celsius | 870 |

| Price, rub | 350000 |

- Loading through several hatches;

- The presence of an afterburning chamber;

- Simple control panel.

- Low burning rate (about 9 hours).

2nd place: K-1000 (“G”)

This sample is quite possible to apply in large enterprises to solve problems on an industrial scale. It has not only a capacious chamber, but can also work with any source of gaseous fuel - even from a highway, even from a cylinder. The control panel is simple and convenient. The body additionally accommodates up to 11 grates.

| Name | Index |

|---|---|

| Total weight, kg | 5500 |

| Loading weight, kg | 1000 |

| Burning temperature, degrees Celsius | 800 |

| Price, rub | 504000 |

- Fuel source variability.

- Big bunker.

- The hatch lining is fiberglass.

- High price.

1st place: K-2000

A massive and powerful specimen from the Russian leader Agrotrest. In fact, it is a universal apparatus, capable of withstanding frequent changes in the types of waste materials. The internal refractory lining is made using the patented technology "Keramblanket" and does not allow overheating of the outer casing.The spread of the flame occurs in a spiral.

| Name | Index |

|---|---|

| Total weight, kg | 6200 |

| Loading weight, kg | 2000 |

| Burning temperature, degrees Celsius | 850 |

| Price, rub | 660000 |

- Special flame development technology;

- Economical consumption of diesel fuel;

- The number of grates is 14.

- Completely stationary.

Professional Options

2nd place: K-3000

A completely professional option, the use of which will pay off only with an industrial scale of work. It has a hermetic closure of the ash pan, during operation the flame spreads in a vortex type, which indicates the reliable destruction of materials. The outer case is made of alloy steel, has a thickness of 18 mm.

| Name | Index |

|---|---|

| Total weight, kg | 8400 |

| Loading weight, kg | 3000 |

| Burning temperature, degrees Celsius | 900 |

| Price, rub | 930000 |

- Number of grates - 17;

- Thick walls eliminate the possibility of fire;

- Vortex motion of the flame.

- Not identified (for its segment).

1st place: K-3000 (“G”)

The described device is designed for serious, long and daily work. Perfectly will be suitable for large poultry farms and meat and dairy plants. It has the maximum load available today. It copes well with ash residues (after passing through the additional chamber, hardly 5% of the original mass remains).

| Name | Index |

|---|---|

| Total weight, kg | 6200 |

| Loading weight, kg | 3000 |

| Burning temperature, degrees Celsius | 950 |

| Price, rub | 1020000 |

- Maximum load;

- Practically non-waste mode of operation;

- Easily replaceable bearing parts.

- For professional use only (otherwise it simply won't pay off).

Instead of an epilogue

The analysis of the market of monitored devices found that the domestic consumer prefers Russian models. And first of all, this is due not to the fact that they are characterized by high quality and efficiency, but to the fact that their suppliers necessarily have all the permits. And this cannot be said about a foreign manufacturer, because the process of certification of such special equipment in Russia is quite long and, moreover, not cheap.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131651 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127691 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124519 -

The best men's sneakers in 2022

Views: 124033 -

The Best Complex Vitamins in 2022

Views: 121940 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114980 -

The best paint for gray hair - top rating 2022

Views: 113395 -

Ranking of the best wood paints for interior work in 2022

Views: 110319 -

Rating of the best spinning reels in 2022

Views: 105329 -

Ranking of the best sex dolls for men for 2022

Views: 104366 -

Ranking of the best action cameras from China in 2022

Views: 102216 -

The most effective calcium preparations for adults and children in 2022

Views: 102011