Ranking the best outdoor paints for 2025

Exterior paint (paint and varnish material - LKM) is intended both for protection and decoration of the building at the same time. Today's market can offer the user a wide range of its colors, with different consistency and specialization in a narrow area of facade work. Usually, exterior coatings are used to finish already plastered facades, but modern samples are already able to process a poorly prepared surface, perfectly lying on wood, concrete or brick. In any case, the choice of coloring material for exterior decoration will largely depend on the natural conditions of the area where the object of work is located.

Content [Hide]

Exterior paints: general information, functions and technical parameters

The compositions under consideration are particularly durable, they are resistant to the manifestation of external influences, are characterized by vapor permeability and elasticity. Their minimum service life is 10 years. The facade coloring material is made in such a way that it can evenly be applied even to complex-shaped bases, but most samples from the middle price segment are preferable to be applied to a pre-plastered surface.

Facade paints must perform the following functions:

- Properly pass steam, prevent the accumulation of moisture and condensate on the surface of the building, thereby preventing the walls from slowly collapsing;

- Mask the building flaws of the wall due to its elastic consistency, filling small cracks and chips;

- Do not allow large drops of rain to penetrate through the protective layer;

- Prevent the formation of cracks when the ambient temperature drops;

- Easy to apply on the base;

- Give the building a more presentable appearance.

The composition of the considered coatings includes various binders, fillers and solvents, suspensions and hardeners. All of them form the main technical parameters of the mixture and determine the direction in a narrow specialization in the field of application. The main mandatory parameters include:

- Resistance to interaction with water - in contact with external walls, moisture will gradually destroy them, create cracks, promote the formation of fungus and mold, etc. Therefore, the exterior paint must support the protective layer while providing adequate thermal insulation.

- Vapor permeability - the painted base must conduct water vapor. If this parameter is at a low level, then the applied coating will certainly swell, and the film will begin to peel off. This situation will be the result of condensation between the paint film and the wall.

- Pollution resistance - this parameter affects the visual "freshness" of the wall appearance. Volatile substances from the environment will always penetrate into the coating - from banal dust to vehicle exhaust gases. From this it is clear that the paintwork coating simply must be easily cleaned with plain water (at least in the rain) or with manual washing. The composition itself should preferably also prevent the deposition of contaminants.

- Long service life - outdoor formulations must maintain their technical / external initial properties for a long time, despite the impact on them of adverse weather factors or various mechanical loads.This parameter of the substance can be significantly increased by adding special reinforcing elements and inclusions to the structure.

Basic types of exterior paints

They are categorized according to their structure. The determining component, as a rule, becomes the type of solvent. Thus, two large groups are water-soluble and organic-soluble coatings.

- silicate

This type is used for painting brick/concrete substrates, and they can also be used on facades that are finished with lime. The basis of the structure of such mixtures is liquid glass or silicate glue. The advantages include resistance to mechanical stress, successful resistance to dirt deposition, UV protection and a long service life.

- Oily

This type of material is produced on the basis of drying oil and contains protective inclusions along with coloring pigments. Oil-based materials are rarely used today for exterior decoration, due to their outdated and very weak protective properties.

- latex

These paints are almost universal and can be used both outside and inside structures. Most often they are made on a water basis, they are distinguished by good qualities in terms of adhesion (adhesion to the base), resistant to premature abrasion and excessive contamination.

- Acrylic

Such material is rightfully considered the most popular among all exterior paints. It can perfectly protect the treated surface, has good weather resistance, and has a long service life. It is applied very simply, it comes in sufficient containers at an adequate price.Most acrylic paints are water-based, although there are some samples made on the basis of organic solvents.

- Textured

These paints have a highly specialized decorative purpose and are used to cover relief walls (for example, made in the Baroque style). They contain a variety of fillers that allow you to apply the substance to brick, concrete, wood, plaster. Moreover, they are especially unpretentious to the level of preparation of the painted surface. Their use is allowed on the bases, replete with small cracks and chips.

Features of the use of external coatings on various types of bases

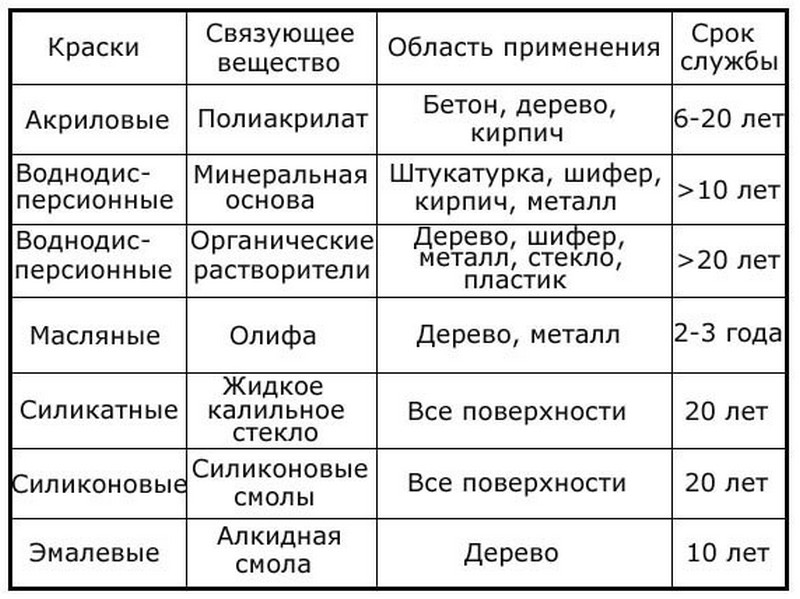

In order to ensure that the facade parts of buildings retain their appearance for a long time, the paint for their coating should be selected based on the material that was used during construction. The table below reflects the ratio of the capabilities of paintwork materials and building bases:

IMPORTANT! For long-term preservation of the cleanliness of the facade, it is preferable to use self-cleaning mixtures. They are made on silicone bases and pigments that have been processed with synthetic polymers. The greater the percentage of resins present in their structure, the easier the treated surface will be cleaned. In extreme cases, the final washing of such facades can be done manually using plain water.

On plaster

On plastered bases, facade mixtures retain well and even improve overall integrity. As a rule, they work on plaster with water-based acrylic, silicone / silicate compounds. Such paints do not have a pronounced unpleasant odor. The layer formed by them leaves open pores in the plaster, which ensures unhindered removal of moisture from its surface. Among other things, the plastered surface will be properly protected from the negative effects of weather conditions, the occurrence of fungus and mold, and the formation of the smallest cracks. The applied layer will last at least more than ten years.

Concrete

Water-based acrylic paints are usually used for this type of exterior walls. They easily provide the wall with adequate protection against temperature changes, contribute to the filling of the smallest cracks, while completely preserving the concrete structure for a long period of time. Also, water-soluble compositions can be used for concrete, in which the base component is acrylic resin and its copolymers. However, before applying such coatings, the surface will require preparatory work, namely the application of a primer. In order to increase the service life of the painted surface up to 20 years, it is preferable to cover the concrete with two layers of paint. A two-layer coating will help increase protection against mechanical stress, prevent the damaging effects of various chemicals, and also provide good moisture and weather resistance.

woodwork

Oddly enough, outdated oil formulations will become optimal for wooden facades. In their structure, they contain astringent, coloring and protective inclusions, which penetrate very well into wood surfaces, firmly fixing there. For oil coatings, the main advantage is their low cost. Nevertheless, the tree from the outside can also be finished with modern types of alkyd compounds, which have the following advantages:

- Accelerated drying of the applied coating;

- Extended service life;

- The ability to successfully counteract low temperatures.

At the same time, it is worth mentioning that acrylic substances will increase the environmental friendliness of wood and increase its wear resistance.

By brick

The materials used to cover brick facades are simply required to have an increased level of adhesion, as well as breathability, while adequately protecting the brick surface from ultraviolet radiation and weather precipitation. For such requirements, silicate samples are the ideal choice. It is always worth remembering that the brick is laid using a solution containing alkali, which can burn through a fragile coating. Thus, the super-strength qualities of brick paint, in terms of interaction with alkaline substances, are extremely important.

For metal

For painting metal objects, mixtures should be used that will not only decorate the surface, but also protect it from corrosion and the negative effects of moisture. Also, the mixture must have the qualities of fire resistance and heat resistance. For example, oil and alkyd materials can withstand temperatures up to +80 degrees Celsius, and individual acrylic and epoxy mixtures up to +120 degrees. The compositions created on the basis of silicone resins will freely restrain the temperature effect of +600 degrees Celsius. It is worth noting that for metal facades it is even allowed to use oil-based coloring materials, but they will not cope well with the effects of water, which is why their use on this front of work is not very successful (except perhaps only for arid regions).

Acrylic variations are considered the classic choice for metal processing today, which will allow the protected surface to “breathe”. However, acrylic is extremely weak in resisting low temperatures, which is why the coating will quickly lose its original external presentability. It is allowed to re-apply alkyd layers on top of each other, which are able to tolerate the negative effects of the environment well, have an increased degree of adhesion, and can give the surface an attractive sheen of a glossy shade. The disadvantages of alkyd include only high toxicity, which does not play a big role in outdoor conditions (but the staining process should be carried out exclusively with the use of personal protective equipment).

IMPORTANT! Professionals do not recommend the use of so-called universal coatings, which are positioned as "suitable for all types of facades." Practice shows that they have unimportant technical characteristics and have a short service life. It is preferable to use a specific type of paint for a specific surface.

Difficulties of choice

Coloring materials for outdoor work are designed to "preserve" the treated surface, creating a reliable layer of protection on it. This layer should not absorb water, but should repel it, because permanent contact of snow / rain with the wall will necessarily (over time) lead to the destruction of the cladding or the formation of cracks in the erected monolith. At the same time, indicators of heat resistance and frost resistance are important for street paint. Such a finish is simply obliged to withstand multiple freeze-thaw and heating cycles.The presence in the mixture of inclusions in the form of UV filters will not allow the color of the cladding to fade and will slow down its overall fading. It must always be remembered that mineral pigments are better able to withstand sunlight than organic ones.

Important parameters also include vapor permeability, whose sufficient indicator for facade use starts from 130 grams per cubic meter. Here it is necessary to make a reservation that if waterproofed metal structures act as a facade, then vapor permeability will not be important. Antiseptic additives will also contribute to the safety of the treated base, because they will not allow mold and fungi to develop. And the presence in the composition of additives that improve the level of resistance to mechanical stress will add additional “points” to the selected coloring composition.

The choice of color shades for facade coatings

It is always important that the chosen shade of the facade decoration of the building harmonizes well with the surroundings, neighboring buildings, without getting out of the general picture with the ridiculous colors of windows, roofs and walls (unless this is the purpose of the artistic design). Modern manufacturers offer their customers such an extensive range of colors that it becomes difficult to choose just one. Thus, during the purchase, you must follow a few simple rules:

- For decoration, it is preferable to choose natural (natural) shades;

- The color of the facade should be lighter than that of the roof;

- If the roof already has bright colors, then the facade will require lighter shades;

- When painting the facade, it is better to combine 2-3 almost monochromatic colors, one of which will become the base one, and with the help of the rest you can emphasize the outline of doors and windows or some architectural forms, designers do not recommend using more than three colors on the facade;

- Structures located in areas with a warm climate should be painted in light shades so that the walls do not heat up excessively in summer;

- The choice of color should not be made from the photo in the catalog or from the picture on the seller's website, it is best to take a can of paint with a small amount of paint outside under natural light - this way you can better see all the nuances of the play of light;

- Pastel colors are considered universal;

- For buildings with irregular geometry, differing in their parts by number of storeys, you should not use bright colors;

- If the facade of the building faces the sunny side, then it is better to paint it with matte paintwork materials, because the glossy material will give constant glare.

Ranking the best outdoor paints for 2025

Budget segment

3rd place: "Finlux Classic 215"

votes 0

This sample is characterized by increased weather resistance, elasticity, vapor permeability, guarantees reliable protection. After complete drying, the finish film will show excellent waterproof/moisture resistance, as well as hydrophobic qualities, which will protect plinths and building facades from getting wet, from damage caused by constant exposure to water. UV resistance, fast drying, easy and convenient application make the paint an excellent choice for high-quality and inexpensive repairs. The recommended cost for retail chains is 432 rubles.

- Resistance to temperature extremes;

- Protection against UV radiation (fading);

- Crack protection;

- Even flow and easy application.

- Not detected.

2nd place: "VTEME FACADE" acrylic super white with a matte effect"

votes 0

This coating is recommended for use on the facades of structures whose operational load is increased. Perfectly hides surface defects, and the super-white color does not change over time. Tinting is available in any shade according to any tinting system. For tinting 100% saturated colors, you must use "Base C". Multiple repainting is allowed. At the end of the work, it forms an even matte vapor-permeable coating with dirt and water-repellent properties. The recommended cost for retail chains is 455 rubles.

- Atmospheric and wear resistance;

- UV protection;

- Virtually odorless;

- Does not contain volatile, toxic components, environmental friendliness.

- It has a slightly thicker texture.

1st place: "Z19 FACADE", water-dispersion, matte"

votes 0

The goods perfectly are suitable for responsible works on decorative finishing of facades of all types of buildings and constructions. It is characterized by excellent decorative and protective qualities, the sample is resistant to atmospheric influences. Environmentally safe, easy to apply, easy to use, has high vapor permeability and good hiding power. After application, it creates an elastic, wear-resistant, breathable, matte white film. Tinting in various colors and shades is allowed. The recommended cost for retail chains is 467 rubles.

- Adequate price;

- Sufficient container volume;

- Possibility of tinting.

- Before work requires thorough mixing (preferably with a construction mixer).

Middle price segment

3rd place: "MASTERFARBE" facade, weather-resistant, moisture-resistant water-dispersion for mineral surfaces"

votes 0

The product is used for painting facades and plinths of buildings, concrete fences and other elements that are exposed to atmospheric influences in areas with difficult climatic conditions. It is applied on concrete, plastered bases, bricks. Eco-friendly - odorless, easily diluted with water. It is tinted with dyes for high pressure paints and in tinting systems. Covers in 2 coats. Fireproof (fire hazard class KM1) certificate APB.RU.OS003/4.N.00385. The recommended cost for retail chains is 760 rubles.

- Quality corresponds to the price;

- Has an average density;

- It is densely superimposed from the first layer.

- Not detected.

2nd place: "EUROPAINT" facade white, color weatherproof"

votes 0

The material is intended for facades, for external works (on plaster, putty, brick, concrete, drywall, foam concrete, natural and artificial stone, on primed metal), it can be used for open outdoor premises with a canopy with a high working load and operated in difficult weather conditions . Possesses reliable coupling with the painted surface. The recommended cost for retail chains is 868 rubles.

- Excellent hiding power;

- Fast drying;

- Virtually odorless.

- Not detected.

1st place: "FACADE Under Tinting "DEKO" 12 kg"

votes 0

This weatherproof coating has good vapor permeability, which allows the surface to breathe. Does not harm human life. Possesses strong adhesion with the painted surface. When painting, it does not leave smudges, does not splatter, does not drain from the tool, which makes the work simple and comfortable. Forms an even, matte layer that is resistant to abrasion and weathering. Tinted in dark and saturated colors. The recommended cost for retail chains is 1486 rubles.

- Drying to "tack" - 60 minutes;

- Work for any reason;

- Adequate price tag.

- Not applicable without tinting!

Premium class

3rd place: "Finlux Svatozar-26"

votes 0

This material is intended to work on the base. It has special dirt-water-repellent properties, which are necessary for the treatment of mineral surfaces, which are very often used for arranging plinths and other facade elements. It has high resistance to atmospheric precipitation and temperature changes. Tinted in any color. Consumption: 260-300 grams per square meter, preferably applied in two layers. The recommended cost for retail chains is 4122 rubles.

- Large container;

- Industrial packing;

- Simple application.

- Not detected.

2nd place: "Dulux Tade" white, 2.5 l"

votes 1

After processing, the paint forms a breathable coating. Protection is provided up to 15 years. Contains active additives against the formation of algae, fungus and mold. Has resistance to fading and high vapor permeability.Diamond technology combines the environmental friendliness of a water base and the strength of an alkyd coating. Successfully resists precipitation within half an hour after application. Suitable for mineral and wooden substrates. The recommended cost for retail chains is 4848 rubles.

- Availability of bio-protection;

- Economic consumption;

- Fast drying.

- Not detected.

1st place: "Finlux F-556 Universal Polyurethane impact-resistant enamel with DF effect"

votes 1

This universal enamel of the next generation has waterproofing-antiseptic and protective-decorative properties and is included in the Finlux™ export series. It can maximally protect any metal, concrete, wood and other mineral surfaces from the outside for a period of at least 20 years. Used wherever increased strength and maximum surface protection are required. The patented "VodoStop" effect and antiseptic components will prevent the formation of mold and fungus, which is important for a damp climate. Thanks to the use of high-quality Finnish and Japanese polymers in the production, the final coating creates a beautiful semi-gloss finish film that is resistant to washing, temperature, weather and mechanical stress and does not fade in the sun. The recommended cost is 10650 rubles.

- Resistance to detergents and disinfectants;

- High water resistance (VodoStop);

- Mechanical and chemical resistance;

- Resistance to solutions of acids and alkalis;

- It tolerates sea and fresh water well;

- Has dirt-repellent properties.

- Too high price tag.

Conclusion

The type of paintwork material under consideration is designed to protect the facade of the house from difficult weather conditions, so its composition must have many protective qualities. In addition, when choosing, you should always focus on the type of surface on which the paint is supposed to be applied, and select only fully appropriate coatings for work. In any case, before buying, you should carefully read the manufacturer's recommendations.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131652 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127693 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124520 -

The best men's sneakers in 2025

Views: 124034 -

The Best Complex Vitamins in 2025

Views: 121941 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2025

Views: 113396 -

Ranking of the best wood paints for interior work in 2025

Views: 110320 -

Rating of the best spinning reels in 2025

Views: 105330 -

Ranking of the best sex dolls for men for 2025

Views: 104368 -

Ranking of the best action cameras from China in 2025

Views: 102217 -

The most effective calcium preparations for adults and children in 2025

Views: 102012