Rating of the best gage blocks for 2025

For any industrial sector, the basis of linear measurements is plane-parallel end blocks of length (abbreviated as "KMD"). They are used to store a unit of length and reproduce it later. They are also used for checking measuring instruments, transferring dimensions for the required settings and marking the zero mark on instruments, in addition, they can serve as a natural measuring instrument for the dimensions of various objects. A set of plane-parallel end blocks of length will allow you to carry out marking work with increased accuracy and adjust the machine. The main function of CMD is considered to be maintaining the identity of measures in various industrial areas.

Content [Hide]

- 1 General information

- 2 Background

- 3 Production material

- 4 Operating principle

- 5 Required accessories

- 6 Optional accessories

- 7 Instruments for verification and calibration of the KMD themselves

- 8 Rating of the best gage blocks for 2025

- 9 Instead of an epilogue

General information

Any instruments that are used to make measurements in repair and service organizations or in industrial enterprises must necessarily and on a permanent basis be checked for the accuracy of the results issued. Of course, for verification it is impossible to deliver the tested instrument to the very institution where various measuring standards are stored. Therefore, to carry out all such procedures, without leaving their own location, they are carried out using plane-parallel measures of length, which are the standard or sample on which this length is fixed. As a rule, the device itself is made in the form of a cylinder with numbered dimensions between the measuring planes.

Thus, the main task of the CMD is to preserve the established unit of length and its subsequent transmission. Plane-parallel CMDs are an indispensable tool for checking, calibrating or setting dimensions on various measuring instruments:

- Micrometer;

- Caliber;

- sinus ruler;

- Indicators, etc.

Also, KMD can be used for control production devices and templates. Due to the fact that KMD are an accurate measuring tool, their production is regulated at the legislative level and regulated by GOST 4119 of 1976 (as amended).

IMPORTANT! Due to the fact that the volume of tasks for calibrating measurements is quite wide, CMDs are rarely sold in single copies - most often they are supplied in large sets, which are far from cheap, due to the accuracy of their production.

Background

The first release of gauge blocks was carried out by the Swiss company Ioganson. They were made of steel and were rectangular parallelepipeds, their first presentation took place in 1900 at the World Exhibition in Paris. Thanks to the manufacturer, this toolkit was called “Joganson tiles” and it (the name) was used for a long time to designate KMD, later turning into just “tiles”.

The first production of KMD in the USSR was carried out at the Tula and Sestroretsk plants, and their serial production began in the mid-30s at the Kirov plant "Krasny Instrumentalshchik" and the Moscow "Caliber". In the modern world, with the advent of non-contact laser interferometers, length gauges and other electrical measuring instruments that carry out measurements using coordinate points, as well as altimeters, the use and purpose of CMD has changed significantly.However, their main quality - to be a material carrier of a certain size - remained unchanged. At the same time, their significance remains to this day, despite the presence of a huge range of electronic and optical measuring instruments.

Plane-parallel end measures of length (or “Joganson tiles”) are produced with dimensions that range from 0.5 to 1000 millimeters between measurement planes. If it becomes necessary to set an arbitrary size that is not established by this measure of length, it is possible from suitable tiles-parts by grinding CMD to each other. This lapping process should take place until the tiles are tightly connected, i.e. there should be no decay.

Production material

Modern gauge blocks (plane-parallel) are made of high-alloy steel, as well as glass, ceramics or hard alloys.

steel models

Measures of length made of steel, for example, from its chromium appearance, are perfectly capable of lapping with subject bases of measuring racks and other measures. Their operational surfaces are wear-resistant, which indicates their increased service life. Steel samples of measures are necessarily subjected to hardening, after which they are artificially aged. This procedure allows you to maintain accurate dimensions for a long time. The hardness of the working base for steel "Joganson tiles" is at least 800 HV. The disadvantages of steel models include high sensitivity to mechanical scratches, as well as the likelihood of corrosion on the surface. Before the start of operation of such tiles, the protective material in the form of a lubricant is removed from them, and upon completion of the work, the lubricant for protection is applied again.It is worth noting that steel samples are very susceptible to changes in operating temperature, which harms their accuracy (for example, metal can expand, receiving heat only from the hands of the user).

Carbide Models

These tiles are made of tungsten carbide, and their strength is several times higher than that of steel. In addition, they have a high resilience. The hardness of the working surface of hard alloys is almost twice as high and is 1400 HV when compared with steel samples. The main disadvantage can be identified - a large mass. Thus, it will be difficult to assemble a measuring block of large sizes from carbide samples.

Ceramic models

Plane gauges made of zirconium ceramic are the most resistant to mechanical scratches and wear of the operational base. Ceramics, by their very nature, are completely immune to corrosion, and their basis will not be affected by the heat of the user's hands, which distinguishes these samples from steel or carbide. Ceramic tiles are characterized by the greatest stability and they have the longest service life, and this, in turn, makes it possible to increase the time interval between inspections. Ceramic CMDs are not magnetizable, do not require special rust protection, and do not attract dust. They are also quite stable and can maintain a fixed size for a long time. An analysis of their work shows that both ceramic and steel tiles have a coefficient of linear thermal expansion that is close in value.This parameter will allow you to fold complex KMD blocks from steel and ceramic tiles, which indicates the interchangeability of such models.

glass models

As the name implies, these devices are made of glass. Not bad for checking flatness and lapping. Also great for checking precise, flat work surfaces, such as desk tops. They can be produced in variations with a diameter of 50 to 75 millimeters, with a flatness of at least 0.125 micrometers and with a thickness of 15 to 20 millimeters.

Operating principle

Preservation and transfer of dimensional accuracy by means of plane-parallel KMD is carried out in the following steps. On a special installation for carrying out measurements, the dimensions are checked according to the first category of exemplary end measures. KMD, which have the certificate of tiles of the highest accuracy, are stored only in special halls of the laboratories of the State Standard, and at industrial enterprises, depending on the need for appropriate measures of accuracy for manufactured products, KMD from the second to the fifth category are used. To broadcast the corrected size means to make a periodic comparison between the tiles of the first and second ranks. Further, the second digit is compared with the third, the third with the fourth, and so on up to the fifth. Accordingly, in industrial organizations, all measuring devices are checked, ranging from accurate to coarse. The result of the verifications carried out is recorded in the passport of each device.

Lapping "tiles"

The lapping process refers to the process of their sticking together. The KMDs themselves are polished in such a way that when they are joined, the remaining air is removed, and only atmospheric pressure acts on the two tiles.The surface tension of the liquid droplets between the tiles from washing off the protective lubricating substance, as well as the interaction at the molecular level between the materials for the manufacture of KMD, only increase the adhesion force. In cases where the tiles are properly polished, they are able to rub in perfectly. This ability of KMD is mandatory. The loss of the described quality indicates the wear of the surface of the measure; accordingly, it will not be possible to achieve the desired results.

Required accessories

In order to collect blocks from KMD tiles and fix them, in order to provide the assembled structure with ease of use, a set of special accessories is used. They, for example, will be needed to install and check the dimensions of various measuring tools. These include:

- Calibers;

- Nutrometers;

- Micrometers;

- Various indicators.

The kit, as a rule, includes side panels of various dimensions, which makes it easy to carry out both internal and external measurements. This circumstance is especially important in the production of high-precision products in limited series. Thus, all production should be focused on the maximum size of the product and on the minimum. This shows that KMD should be used as a gauge with two sides (non-passing and passing side).

For marking work, a special marking set is used, in which there are holders for very accurate measurements. It may also include:

- Various ties;

- Radial and plane-parallel sidewalls;

- The ruler is trihedral;

- Ink and central sidewalls;

- Base;

- Probes and crackers.

Separately, it is worth highlighting the probes, which are designed to determine the size of the gap between the ground surfaces.They are steel plates with a minimum size of 0.02 mm to a maximum size of one millimeter. The step of change for them can be from 0.01 mm to 0.05. The process of determining the size of the gap consists in placing the probe between the surfaces. Next, the probe should be moved with a little effort, while it should not sink or move freely. As a result, the sum of the thickness of the probes included in the gap will determine its value.

Optional accessories

The convenience of carrying out measurements can be ensured by using additional accessories. Their use will be more than justified in the production of precision measuring instruments in small batches. Most often, they are produced in full sets, in accordance with the standards of GOST 4119. These include:

- Set No. 0 - includes a set of ties for connecting tiles into blocks;

- Set No. 1 (complete) - contains a set of additional devices for internal and external measurements up to 320 millimeters;

- Set No. 2 (small) - contains a set of additional devices for internal and external measurements up to 160 millimeters;

- Set No. 3 (extended) - used for marking work in conjunction with a small and full set.

Any set has separate grooves for storing each element, and in order to ensure the comfort of using and removing tools, there are selections in the sockets. Each set is sold with accompanying documents that confirm the current standard of accuracy.

Instruments for verification and calibration of the KMD themselves

Gauge measures are an important step in the hierarchy of devices for transmitting the standard length dimension, because they are a stabilized material carrier of a constant size.The transfer of the reference size, which is based on the wavelength of light, to the reference QMD is carried out by means of deep interference measurements. It can be seen from this that the standard obtained at the output belongs to the class "K". Then, according to the verification scheme, it can be transferred to other measures. Based on the main purpose of CMD, that is, ensuring the equality of measurements and the transfer of dimensions of the length of the standard, verification schemes were developed. For similar purposes, they also produce measures of a different accuracy, which differ in classes and categories. The process of verification of KMD is carried out by special instruments of the highest accuracy.

These include a micrometer due to its high accuracy characteristics. Since its invention, it has undergone many improvements and has reached the highest accuracy class. Other devices for measuring the accuracy of measures include inductive or incremental photoelectric comparators (comporators), which are allowed for civil circulation. The advantage of using them is that the verification scheme for them is significantly simplified. A minus can be called the condition of increased requirements for the experience and education of a specialist using them, as well as the high cost of this toolkit. This condition is due to the extremely low error that can be allowed during the check/calibration of the CMD.

- The main verification methods are:

- Indirect measurements of a certain length;

- Measurements of a certain length directly;

- Comparison using a comparator;

- Direct comparison with the standard.

The error factor for CMD is so small that it is very, very difficult to detect it using other instruments.

Rating of the best gage blocks for 2025

IMPORTANT! It is worth mentioning that high-precision KMD devices in the budget segment up to 10,000 rubles are produced only in separate copies!

Budget segment (individual copies)

3rd place: “Measure A3 Engineering CO-3 acc. with GOST R 55724-2013 with verification 8243321568541"

votes 0

This measure is supplied in a single copy and is intended for the production of non-destructive testing of welded joints. It is light in weight and has second class accuracy. It is used in most cases for specific measurements in the production of welding work. The country of manufacture is Russia, the established cost for retail chains is 5350 rubles.

- Second class of accuracy;

- The presence of a confirmed verification;

- Production material - durable steel.

- Not detected.

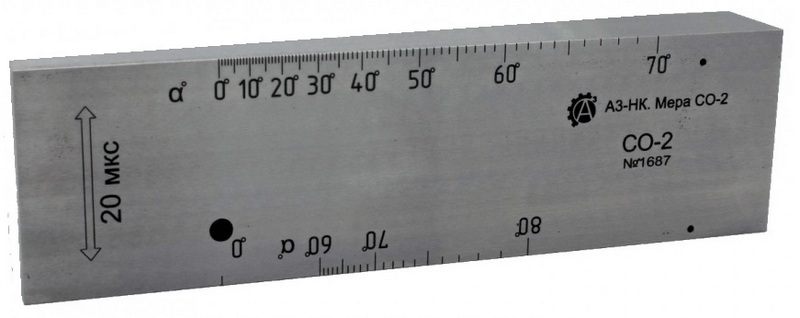

2nd place: Measure A3 Engineering CO-2 acc. with GOST R 55724-2013 with verification 4814251653245"

votes 0

Another representative of measures for the production of measurements in the field of non-destructive testing. It is also supplied in a single copy and is intended for measurements from the field of welding. The structure is made of high-strength steel. Standards for the initial verification of the error are pre-carried out in the factory laboratory. Country of origin - Russia. The recommended cost for retail chains is 5400 rubles.

- Initial verification carried out;

- Second class of accuracy;

- Light weight.

- Not detected.

1st place: Gauge block INSIZE PP 90.0 class 1 4101-B90

votes 0

It is a representative of the first class of accuracy and is produced by a foreign manufacturer. It can be used for measurements of standard complexity, for verification of measuring instruments, and it is also possible to use it as an element of a combined measure. Due to the manufacture of the body of alloy steel, it may well interact with ceramic products. The country of origin is Austria, the recommended price for retail chains is 6,400 rubles.

- The measure is made of alloy steel;

- Possibility to work with ceramic KMD;

- First class accuracy.

- Not detected.

Middle price segment (sets and kits)

3rd place: "Set KMD Tulamash 126551"

votes 0

This set is a selection of standard CMD and is designed to compare standards with the required parameters of workpieces. The set includes most standard sizes. It is perfect for working in small workshops and laboratories. The tiles are made of a solid steel construction, which makes it possible to assemble them (due to good adhesion) into block measures. The country of origin is Russia, the recommended cost for stores is 10,700 rubles.

- Rugged construction;

- Good prefabricated adhesion between elements;

- Second class of accuracy.

- Not detected.

2nd place: "Set Range No. 2 class 1 GOST 9038-80 8-005"

votes 0

This set has a large number of elements, which means that it can be used without additional accessories.Perfect for setting up and adjusting measuring instruments, it will help to detect an error in the measurements taken, to make direct measurements of various objects. All elements of the kit are made of durable steel and comply with Russian standards. The country of origin is Russia, the established cost for retail chains is 17,700 rubles.

- Extended set of tools;

- Durable performance material;

- Convenient case for transportation.

- Not detected.

1st place: "A set of prismatic measures of a flat angle CHIZ N8-1 122634"

votes 0

A rather rare and highly specialized set of measures for the prismatic angle. The accuracy class is defined by the manufacturer as the second. Allows you to measure objects with non-traditional geometry, to identify errors in non-linear measuring tools. There are 10 different measures included in the kit, they are packed in a durable wooden case for easy transportation. The country of origin is Russia, the recommended retail price is 39,000 rubles.

- Ability to non-standard measurements;

- High class of accuracy;

- Manufacturing quality.

- The case is made of wood, so the likelihood of its early wear is high;

- Heightened cost with a small configuration.

Premium class (sets and kits)

3rd place: Micron MIK 76013

votes 0

This set is a highly accurate instrument for making most possible measurements. Passed a preliminary factory verification at the factory, about which there is an entry in the passport.A handy wooden case contains 12 pieces of accessories and measures to produce a more accurate measuring process. It is characterized by the fact that reliable technologies of the times of the USSR were used in the manufacture. The country of origin is Russia, the established cost for stores is 55,000 rubles.

- A good set of measures and accessories;

- High class of accuracy;

- Reliable manufacturing techniques.

- Wooden case;

- Overcharge.

2nd place: "KMD CHIZ PK-1 116087"

votes 0

Another representative of the Russian manufacturer, made according to the proven technologies of the USSR. All elements are made of alloyed steel, and the presence of additional accessories will make the measuring process easier and more convenient. The whole set has 11 items and is lightweight. The country of manufacture is Russia, the established store price is 85,000 rubles.

- The case for transportation is made of wood and covered with a protective varnish;

- Instrumentation of the first class of accuracy;

- Light weight.

- High price.

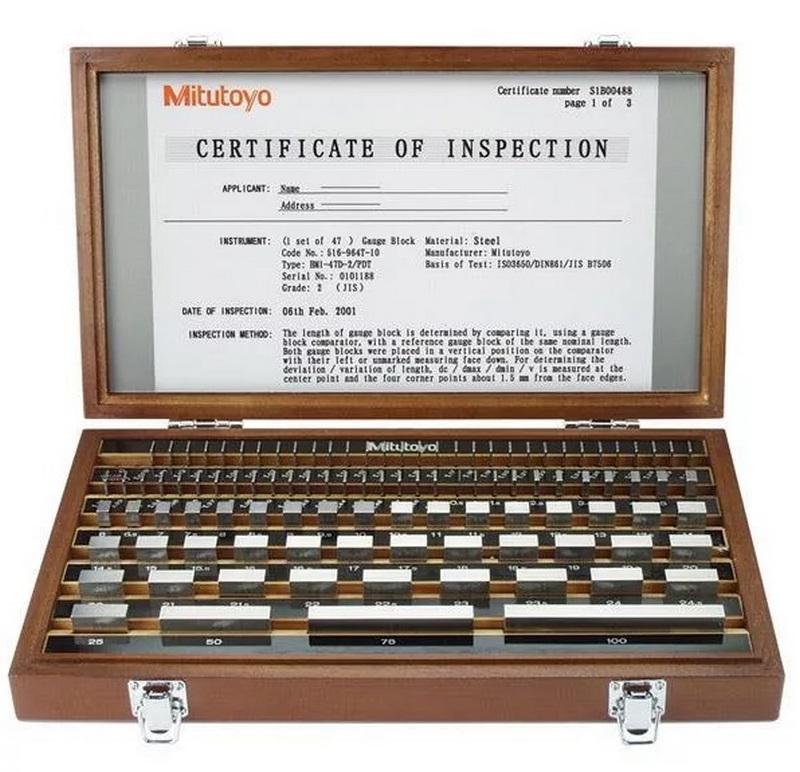

1st place: "Set of plane-parallel gage blocks 47 pcs., Accuracy class 1 MITUTOYO 516-959-10"

votes 0

A very expensive and multifunctional CMD kit for high-precision measurements from a Japanese manufacturer. The kit contains 47 pieces of different tiles, so it is possible to make any measurement, and even more so, it is possible to compose any measuring block of a non-standard type without resorting to the use of elements from third-party kits. Production material - high-alloy steel. The country of manufacture is Japan, the established cost for retail chains is 185,000 rubles.

- Reasonable price for its versatility and accuracy class;

- Convenient case for storage and transportation;

- Compliance with both Russian and European standards.

- Not detected.

Instead of an epilogue

The analysis of the market of the instruments under consideration established that the majority of positions, in almost all segments, are occupied by domestic manufacturers. However, this does not in the least affect either the cheapness of goods (which is bad) or their quality (which is good). The reason for this may be the accelerated process of certification of measuring equipment in Russian conditions, as well as the presence of a good industrial school for the manufacture of such instruments, the history of which will soon reach a hundred years. At the same time, the foreign manufacturer is represented in the premium class and a small number of commodity items. However, the foreign manufacturer is trying to make their kits as versatile as possible, which significantly increases their price. Also, their cost will increase due to the fact that foreign goods undergo double inspection - both Russian and European. At the same time, I would like to emphasize that the quality of accuracy of both our and foreign models is always at a high level. Regarding the acquisition of KMD: it is necessary to purchase them only on trusted Internet sites and it is imperative to check the presence of a mark in the passport on the factory verification (“inspection” - for Western samples).

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131652 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127691 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124519 -

The best men's sneakers in 2025

Views: 124034 -

The Best Complex Vitamins in 2025

Views: 121940 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114980 -

The best paint for gray hair - top rating 2025

Views: 113396 -

Ranking of the best wood paints for interior work in 2025

Views: 110319 -

Rating of the best spinning reels in 2025

Views: 105330 -

Ranking of the best sex dolls for men for 2025

Views: 104367 -

Ranking of the best action cameras from China in 2025

Views: 102217 -

The most effective calcium preparations for adults and children in 2025

Views: 102012