Rating of the best compressors for filling cylinders in 2022

Compressors are mechanical devices used to increase pressure in a variety of liquids and gases. They are often used for filling industrial equipment, abrasive and pneumatic tools, paint sprayers or oxygen cylinders with compressed air.

In our review, we will provide recommendations on what to look for in order not to make a mistake when choosing, we will deal with the functionality, average prices, and identify the best manufacturers and popular models.

Content [Hide]

Compressor types

Product descriptions vary depending on the compression method used. Classic looks include:

- The first design relies on the reciprocating movement of one or more pistons within the cylinders. They allow compressed gas to be released through a valve into a pressure vessel. The tank and the machine, as a rule, are united by a common frame. The main purpose of reciprocating equipment is the transmission of air as an energy source or the distillation of natural gas through pipelines. The criterion for choosing a product is determined by its power. Higher pressure is achieved by a two-stage unit.

- Diaphragm (membrane) equipment is a piston design improved by a concentric motor. At the heart of the product is a flexible disk that compresses the gas, constantly changing in volume. Such machines have a small capacity relative to other types, but generate a clean mixture. They are used in laboratories, medical organizations.

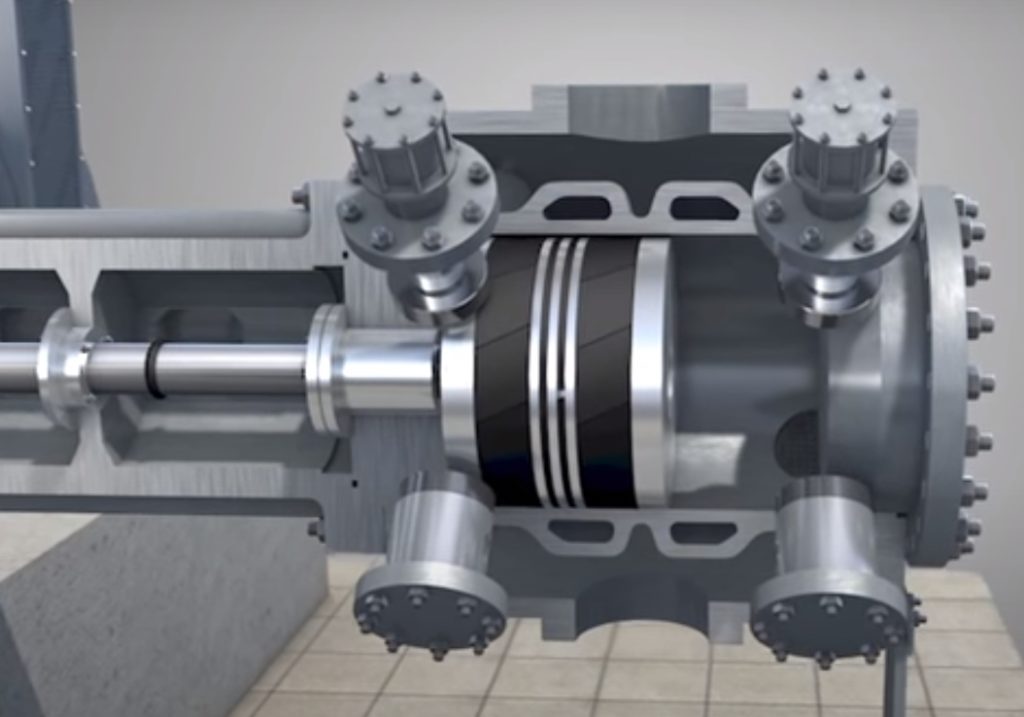

- At the heart of screw products is the rotor. Their well-known feature is continuous operation. Such equipment is ideal for construction or road improvement. An important advantage of the screw over the piston: less vibration, which makes the equipment quieter. The injected mixture is free from pulsations. The product is lubricated with oil or water.

- The "winged" version works with a series of blades installed in the rotor. They spin in the eccentric cavity, reducing its volume and compressing the gas that has entered the space.Such devices are not used to supply clean air, but are capable of generating compressed gas free from pulsations. They are more resistant to contaminants entering the system from the atmosphere, thanks to the use of bushings rather than bearings, quieter, but less powerful than screw versions. They are able to function in continuous production. They are used in the oil and gas, processing industries.

- The following design provides for stationary and orbital spirals. The flow of gas occurs along their outer edge, and the release is closer to the center. Since the spirals do not touch, lubrication of the parts is not needed, they are "oil-free". The performance of the device is somewhat lower than other designs, often used in budget models, home air conditioners.

- Rotary vane products supply a large volume of gas at low pressure, they are most often called blowers.

- Centrifugal designs work by high speed wheels, like pumps. They generate large volumes, can be used in commercial refrigerators from 100 HP, in large processing plants up to 20,000 HP, where gas volumes can reach 200,000 m3. The expansion occurs in the casing volute where the flow rate slows down and the pressure increases. Centrifugal equipment has a lower compression ratio than reciprocating equipment, but handles a larger volume of gas. In some devices of this type, several stages are used with coolers that improve the compression ratio.

- The axle unit has the best performance (from 215 to 350,000 m3 per minute). Such devices are used in jet engines.Along with centrifugal devices, they increase the pressure by increasing the speed of the gas, and then slow it down by passing it through curved fixed blades.

Buying the right product on your own is not an easy task. There are many types for different purposes and tasks, from portable to large-sized, for charging breathing apparatus cylinders or distillation of explosive gases.

How to choose a compressor machine

Piston or screw systems are in high demand. The first option is usually cheaper than the second, easier to maintain and operate. However, screw products are quieter, more protected from oil entering the system.

An important difference between the above designs is the different time of the working cycle. If the piston 25% of operation is at rest, and 75% is on the move, then the screw can function 100% of the time. They are not designed for frequent starting and stopping.

For example, an auto body shop that routinely uses a spray gun might find advantages in using a radial screw machine, while a repair shop that rarely uses compressed air can get by with a piston system.

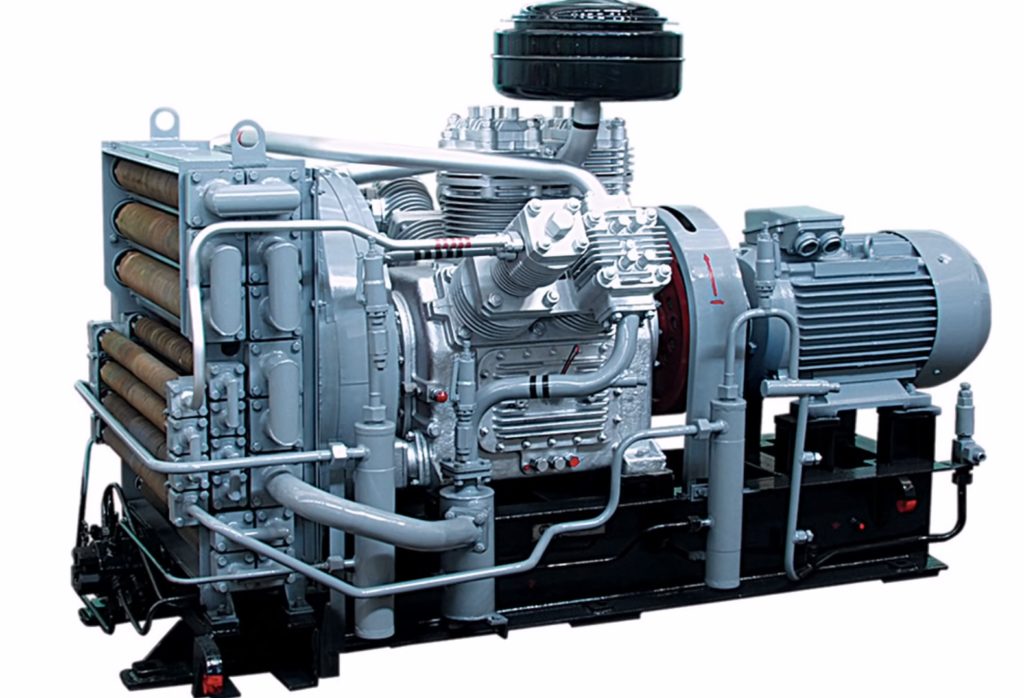

Large-sized rotary screw devices are transported to the place of operation on trailers, they work thanks to the motor. They are designed for continuous use in the construction and improvement of roads.

Spiral models are indispensable in refrigerators. The mixture emanating from the device is pure, corresponds to class "0", therefore it is suitable for pharmacology, the food industry, and electronics.

If the use of equipment involves the compression of hazardous gases (propane, butane), you should look at membrane, sliding-vane, kinetic structures.

Additional factors to consider when choosing:

- oil product or not requiring lubrication;

- dimensions;

- air quality;

- control.

The oil plays an important role because it serves to remove the heat generated during the compression process. In many designs provides sealing of system elements. In the case of piston devices, it lubricates the crank bearings, the side walls of the cylinder. For bladed products, oil helps to seal the smallest space between the tips of the blades and the opening of the body. Scroll machines do not use lubrication, so their performance is limited. Centrifugal systems do not introduce oil into the compression stream. Which mechanism is better to buy depends on the needs of production.

Compressed air is usually quite hot and condensed, so it collects in a reservoir. Receiving tanks have manual or automatic valves that allow you to drain the accumulated water. Heat can be removed by passing the mixture through an additional cooler. Refrigerant-based dryers are added to the system. Filtration is installed to remove lubricant from the supply pipe.

The piston unit is controlled by the start / stop button, while it feeds the storage tank. When the lower level is reached, the mechanism turns on and works until it is completely filled. This control minimizes the number of engine starts during periods of increased load.

Propellers, in addition to the start/stop system, have modulation of the inlet, sliding valves, automatic double control, variable speed drive. When choosing control schemes, the idea is to find the best balance with the desired functions between meeting the needs and the cost of idling versus the cost of equipment depreciation. When choosing a technique, in addition to the above indicators, it is important to consider 3 main parameters:

- Volumetric productivity determines how much mixture the machine generates per unit time (l/m). When refilling cylinders, it must be remembered that the amount of compressed gas supplied to the outlet of the mechanism will always be less than the working volume of the machine, due to losses during the purge of the system.

- The primary parameter is pressure (measured in bar).

- Power consumption required to operate the unit.

Buyers also need to decide on drive, belt or direct, gas or diesel engine, etc. Efficiency curves are often published so that you can evaluate the performance of the system when pumping different volumes, depending on the speed of the shaft and the dimensions of the impeller.

Scope of use

Compressors are used in various industries, are operated at home. Everyone, having studied our article, will be able to assemble the necessary system with their own hands. The portable 12V DC electric air machine, often carried in the trunk of a car, is a typical example of a simple version of a compressor. It is used to inflate car tires. Here are examples of industries where the equipment is used:

- trucks, cars;

- medicine, dentistry;

- laboratories;

- food and beverage processing;

- oil and gas industry;

- for scuba diving.

Below we give a rating of models whose popularity has been tested by time.

Where could I buy

Inexpensive new items can be purchased at the nearest construction supermarket. Managers will provide advice on which company the device is best for you, orient on the price, tell you how to replace the broken part. You can look at the device in the online store, order it online.

Rating of quality compressors for filling cylinders in 2022

Our review is based on real reviews. It takes into account the opinion of buyers, photos of the equipment are attached.

For diving

FROSP KVD 200/300

votes 2

In 3rd place is an effective mechanism that generates clean breathing air of excellent quality (for water sports), technical gases:

- nitrogen;

- air.

Passing through the intake filter, the mixture is free of contaminants. It is contained in high pressure cylinders.

It is important to place the machine in a well-ventilated area that is free of dust, corrosion, or fire. If the temperature is above 45°C, an air conditioner must be installed. There must be enough light (natural or artificial) in the working area to see all the elements of the machine, information labels, stickers.

Technical indicators:

| Options | Characteristics |

|---|---|

| Pumped medium | nitrogen, air |

| Working, bar | 300 |

| Productivity at 1 bar, l/min | 200 |

| Filling time 10l/0-200 bar, min | 10 |

| Engine | Electric 3-phase, 50/60 Hz |

| Type of | Piston |

| Rotation frequency, rpm | 1300 |

| Engine power, kW | 4 |

| Noise level, dB | 81 |

| Weight, kg | 160 |

| Compliance standard | DIN EN 12021 |

- reliable construction.

- not detected.

Paramina Mistral M6-ET

votes 3

Silver for Mistral M6-ET. It has a 3-stage air-cooled high pressure piston design. The product is used at home, it does not make noise, there is no vibration, it is mobile, it is indispensable for divers, divers, firefighters.

The gas is compressed at a low piston speed, which is a guarantee of equipment operation for many years. The design features of the Mistral M6-ET allow it to be used on dive boats and support ships. If necessary, it is possible to install a filter that forms an oxygen mixture. Another area of application of the machine is paintball. The quality of the resulting mixture complies with EN 12021 regulation.

Technical indicators:

| Options | Characteristics |

|---|---|

| Performance | 103 l/min |

| Compression | 330 atm. (4785psi) |

| Drive unit | Electric |

| The size | 0.72 x 0.38 x 0.47 meters |

| The weight | 54 kg |

| Power, drive | 3 phase. 380 V, 2.2 kW |

| Rotation frequency, rpm | 1200 |

| Number of compression stages | 3 |

| Unlimited continuous work time | + |

- high capacity filter;

- high pressure connection with DIN or YOKE fastening standards;

- pressure gauge 400 bar;

- manual discharge of condensate;

- automatic stop;

- spare filling hose;

- not detected.

Coltri Sub MCH6 SH

votes 2

1st place is occupied by Coltri Sub MCH6 SH - a great option for amateur diving. The machine is powered by a gasoline engine. Lightweight, mobile, cost-effective, rugged construction is surprisingly efficient for its size and incredibly easy to maintain.

Such a device will increase the geography of diving.It can be placed in the luggage compartment of a car and set off to explore the underwater world.

Technical indicators:

| Options | Characteristics |

|---|---|

| Performance | 100 l/min (6.0 m³/h) |

| Refueling time | bottle 10L (0-200 bar), 20 minutes |

| Working compression | 225-300-330 bar |

| Drive unit | 4-stroke petrol engine, Honda GX200 |

| Power | 4.8 kW (6.5 hp) |

| The weight | 37 kg |

| Noise level | 80.5 dB |

| Number of steps | 4 |

| Oil volume | 300 ml |

| Oil used | Coltri Oil CE 750 |

| Fuel consumption | 1.7 l/h at 3600 rpm |

| Engine oil volume | 600 ml |

| Recommended oil | 10W30, 10W40 |

| Frame | powder coated steel |

| Oil/moisture separator | after the last step |

| Filtration | Cartridge with activated carbon and molecular |

| suction filter | 2 micron paper |

| Cooling | air, forced |

| Length | 780 mm |

| Height | 350 mm |

| Width | 320 mm |

- mobility;

- reliable design;

- price quality.

- not detected.

For air filling

Patriot Remeza

votes 1

4th place for a product used for painting, inflating tires, blowing filters, various operations using pneumatic tools. The unit is equipped with a 200-liter receiver, which reduces the number of repetitions of work cycles. The design provides a strong support, which ensures the stability of the Patriot Remeza during operation. The kit includes, in addition to the compressor, packaging, step-by-step instructions for use.

Technical indicators:

| Options | Characteristics |

|---|---|

| Gross weight | 146 kg |

| Max compression | 10 bar |

| Power | 3000 W |

| Country of origin | Belarus |

| Three phase | + |

| wheels | + |

| Engine | Electric |

| Homeland of the brandBelarus | |

| Cylinders/Stages | 3/1. |

| Receiver | Horizontal |

| Net weight | 145 kg |

| Max. performance | 580 l/min |

| Receiver volume | 200 l |

| View | piston oil |

| Voltage | 380 V |

| Drive unit | belt |

| Dimensions, mm | 1460x640x1150 |

| Mobility | Mobile |

| Connections | 1/4"(EUR) |

| Receiver | + |

- convenient management;

- high efficiency;

- stability;

- simple operation;

- powerful motor;

- excellent cooling;

- available visual control during operation.

- not detected.

Denzel

votes 1

Bronze at the product from the company Denzel. It will come in handy for anyone who intends to provide pneumatic equipment with compressed air. It can be used at home or in small production.

The Denzel PC 2/100-370 has a 2.2 kWt electric motor capable of pumping 370 l/min at a pressure of 8 bar. The design of the motor provides for a V-shaped shaft, a piston mechanism. The device has a hundred-liter receiver. It can be used to inflate tires, pneumatic equipment: spray guns, screwdrivers, etc.

The machine has a pressure gauge that displays the parameters in the receiver. The device can automatically turn on, replenishing the volume of compressed air in the cylinder. Denzel operates from a single-phase network, the voltage in which should be 220 V. Ergonomic handle, wheels add convenience during transportation.

Technical indicators:

| Options | Characteristics |

|---|---|

| Brand | Denzel |

| Package: | |

| Length, m | 1.05. |

| Width, m | 0.85 |

| Height, m | 0.39 |

| Volume, m3 | 0.35 |

| Amount in a package: | 1 |

| Packing weight, kg. | 56 |

| View | Piston |

| Engine | Electric |

| Lubricant | Oil |

| Power | 2.2 kW |

| Compression | 10 bar |

| Input performance | 400 l/min |

| Drive unit | Coaxial (straight) |

| Voltage | 220 V |

| Receiver | horizontal |

| Receiver volume | 100 l |

| Number of cylinders | 2 |

| Number of compression stages | 2 |

| Connections | Rapid (euro) |

| Functions: | |

| Safety valve | + |

| overheat protection | + |

| pressure gauge | + |

| Design: | |

| Transportation | Two wheels |

| Carry handle | + |

| The weight | 102 kg |

| Guarantee period | 3 g |

- individual channels at the pistons;

- strong construction;

- protective cover for the motor;

- efficiency;

- price quality.

- blows out gaskets.

DGM AC-254

votes 2

In 2nd place DGM AC-254, designed to provide pneumatic tools, spray guns with compressed air. The equipment is successfully used in construction and repair. The piston machine has two heads, direct drive, a 50 l receiver with a limit of 8 bar. Productivity is 440 l/m.

Technical indicators:

| Options | Characteristics |

|---|---|

| View | Piston |

| Engine | Electric |

| Lubricant | Oil |

| Power | 2.2 kW |

| Pressure | 8 bar |

| output performance | 440 l/min |

| Drive unit | Coaxial (straight) |

| Voltage | 220 V |

| Receiver | Horizontal |

| Receiver volume | 50 l |

| Number of cylinders | 2 |

| Functions: | |

| Pressure regulation | + |

| Oil level indicator | + |

| pressure gauge | + |

| Transportation | two wheels |

| Carry handle | + |

| The weight | 40 kg |

- wheels for moving the device;

- slight vibration;

- performance;

- V-shaped block with 2 cylinders;

- mobility;

- two manometers;

- two euro connectors for attaching tools;

- 1 year warranty;

- fasteners included;

- pressure regulator;

- start valve;

- peephole to control the oil level.

- not detected.

Metabo BasicAir

votes 1

Metabo Basic wins. This machine is balanced. It is ideal for home use or small workshops. With its help, you can supply compressed air to the necessary equipment.The device has wheels that facilitate transportation, a rubber handle that is comfortable to grip.

Receiver for 50 l, productivity 200 l/m, pressure 8 bar, pressure gauge that controls readings, makes the system optimal for comfortable work. It is important to note that the Metabo Basic has a low noise level (97 dB). The motor is protected against overheating, which eliminates problems when the unit is under load.

Technical indicators:

| Options | Characteristics |

|---|---|

| View | Piston |

| Engine | Electric |

| Lubricant | Oil |

| Power | 1.5 kW |

| Compression | 8 bar |

| Input performance | 240 l/min |

| output performance | 120 l/min |

| Drive unit | Coaxial (straight) |

| Voltage | 220 V |

| Receiver | Horizontal |

| Receiver volume | 24 l |

| Number of cylinders | 1 |

| Number of compression stages | 1 |

| Number of posts | 5 |

| Functions: | |

| Pressure regulation | + |

| Safety valve | + |

| pressure gauge | + |

| Transportation | Two wheels |

| Carry handle | + |

| Noise level | 87 dB |

| Dimensions | 31x60x55.5 cm |

| The weight | 28 kg |

- quality assembly;

- ergonomics;

- easy start, drain valve.

- low power.

For propane refueling

FROSP KVD-GS-15

votes 1

Bronze at FROSP KVD-GS-15. This compressor is capable of compressing gas, filling it with cylinders. The kit includes: pump, engine, cooling cooler, oil filter separator, safety and drain valves, pressure regulator. To get started, just press the start button. The design provides a timer showing how long FROSP KVD-GS-15 has been operating.

It is important to say a few words about the rules for using the product. The equipment is installed outdoors, because This is required by the fire safety regulations of the Russian Federation.The device must be placed on a reliable, flat surface, in a place protected from precipitation, ventilation is mandatory. Before starting, compare the characteristics of the current strength, voltage in the network and equipment, they must match.

Technical indicators:

| Options | Characteristics |

|---|---|

| Pumped medium | Methane, biogas, natural, hydrocarbon gas |

| Productivity, m3/hour | 15 |

| Productivity, l/min | 250 |

| Working, bar | 200 - 250 |

| View | Piston |

| Engine | Electric 3-phase, 50/60 Hz |

| power, kWt | 7.5 |

| Recommended inlet gas pressure, bar | up to 0.03 |

| Mains voltage, V | 380 |

| Dimensions, mm | 1500x1200x1650 |

| Weight, kg | 500 |

| Recommended gas pipe diameter for connection | 3/4″ |

- safety;

- simple operation;

- reliability;

- low level of noise, vibration;

- low operating costs;

- automatic shutdown.

- not detected

Paramina Typhoon Classic 18E

votes 1

The Paramina Typhoon Classic stationary unit is designed for professional use. It can continuously work for a long time. It ranks second on our list. Sophisticated cleaning successfully filters out moisture, oil, increasing the life of the product, and reduces repair costs. The Typhoon Classic line of machines has an automatic stop and drain system for condensate:

Technical indicators:

| Options | Characteristics |

|---|---|

| Model | Classic 18E |

| Productivity, l/min | 320 |

| Drive unit: | |

| View | Electro |

| Part. rotation, rpm | 1360 |

| power, kWt | 7.5 |

| Filter system | BAx4 |

| Number of chargers | 2 |

| Weight, kg | 175 |

| Dimensions, cm (LSHV) | 107*54*70 |

- the start key has thermal protection;

- the starter has a battery;

- automatic stop/start, emergency stop;

- sensitive filter;

- low noise level;

- operational safety;

- removes oil, condensate after the 2nd stage of compression;

- productive stainless steel heat exchangers;

- safety valves;

- oversized cooler (50 cm);

- two chargers with hoses (1200 mm), DIN mounts;

- automatic adjustment of the drive belt;

- Pressure Sensors;

- low oil level alarm;

- pressure gauges.

- high price.

Corken 91

votes 1

Gold takes a stationary apparatus from Corken. It is indispensable for pumping liquids, liquefied gases (propane-butane or ammonia), vapor phase extraction for subsequent compression and further use as intended. The product provides acceptable NPSH performance. Corken 91 is ideal for filling pressure tanks: cisterns, underground storages. They have a top mount for pumping, so the system will come in handy.

The company has been operating on the market for more than half a century, manufacturing reliable devices. The produced compressors comply with the most stringent safety and quality regulations and are in demand among the Germans, Japanese, and Americans.

Corken's focus is on the production of vertical or horizontal "lubrication free" units with one or two stage compression systems. Branch pipes fasten by means of a carving or a flange (ANSI, DIN). The machine is easy to maintain, the valves are replaced without disassembling the pipes, and the piston without removing the block head. The advantage of equipment from Corken is its versatility.

Technical indicators:

| Options | Characteristics |

|---|---|

| Cylinder diameter | 114.3 mm |

| piston stroke | 101.6 mm |

| Performance: | |

| minimum at 400 rpm | 49.6 m³/hour; |

| maximum at 825 rpm | 102.3 m³/hour. |

| Max. pressure | 24.1 bar; |

| Max. drive power | 26.1 kW; |

| Max.piston load | 2494.8 kg; |

| Max. outlet temperature | 177°C; |

| Weight | 283.5 kg; |

| propane capacity | 82.0 m³/h; |

| Flanged spigot option | F691 |

- reliable design;

- multifunctionality;

- fastenings ANSI, DIN;

- high price.

We hope that our review has provided all the necessary information: what compressors are, why they are needed, how much they cost. The choice is yours. Using the data obtained, you can confidently navigate the market.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131653 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127693 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124520 -

The best men's sneakers in 2022

Views: 124035 -

The Best Complex Vitamins in 2022

Views: 121941 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2022

Views: 113396 -

Ranking of the best wood paints for interior work in 2022

Views: 110320 -

Rating of the best spinning reels in 2022

Views: 105331 -

Ranking of the best sex dolls for men for 2022

Views: 104369 -

Ranking of the best action cameras from China in 2022

Views: 102217 -

The most effective calcium preparations for adults and children in 2022

Views: 102012