Rating of the best compression meters for 2025

To assess the condition of the piston-cylinder group of the engine in a vehicle (other units using an internal combustion engine), the compression measurement method is used. For gasoline engines, the normal figure is from 9.5 to 10 atmospheres, and for diesel engines - from 28 to 30 atmospheres. The measuring process is carried out using a special device, which is called a compression gauge. The method of its use is simple and intuitive even for a non-professional, and the accuracy of its readings is quite high, which is due to the increased sealing properties and the use of optional devices.

Content [Hide]

- 1 Purpose and types of compression meters

- 2 Classification by connection method

- 3 Operating principle

- 4 Causes/consequences of low compression

- 5 Operating rules

- 6 Self-creation of a compression gauge (for use in a spark plug hole)

- 7 Difficulties of choice

- 8 Rating of the best compression meters for 2025

- 9 Conclusion

Purpose and types of compression meters

The very concept of "compression" means the maximum pressure present in the cylinders of an internal combustion engine when it is idling. The compression gauge measures this indicator, and the unit itself is a diagnostic device focused on the following functions:

- Timely detection of malfunctions in cylinders, valves, filters, starter or gas distribution mechanism;

- Determining the degree of wear of individual elements, identifying problems of tightness and clogging of the engine. Such signs will just be indicated by a reduced level of compression pressure in the system.

There are two types of devices under consideration, which differ in the object of their application:

- For gasoline engines - they work only with engines operating on a gasoline mixture.The basic package of such measuring devices includes a manometer, a nozzle with a rigid cone tip, two adapters and a flexible nozzle. It is also possible to use other accessories to facilitate the measurement process.

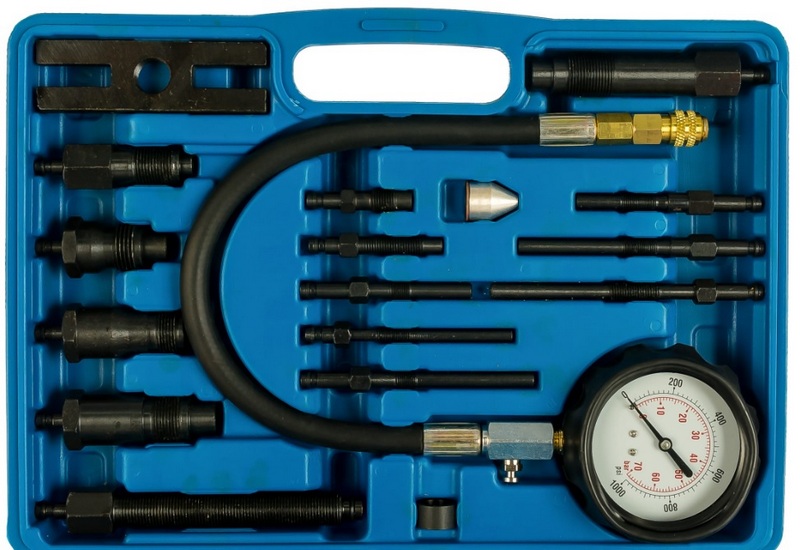

- For diesel engines - only works with diesel engines. It is produced with a much larger number of optional nozzles, various extensions and tubes (made of metal, rubber, composite materials), a lot of adapters.

There are also universal samples of the specified equipment, capable of diagnosing both gasoline and diesel engines. Models of one-way orientation differ among themselves in the maximum allowable measured values: for gasoline it is 16 atmospheres, and for diesel it is 40.

Classification by connection method

The measuring equipment under consideration can be:

- Clamping - aggregates of such an action can only be used in tandem with another person; it is almost impossible to perform all actions with him alone. To do this, the unit must be positioned properly, otherwise the risk of obtaining incorrect data is very high. In addition, pressing devices during operation will require a tight hold of the nozzle in the nozzle or candle socket, which is best done by holding with two hands, and this is easier for a second person to do. The first one will manually start the engine.

- Threaded - for such devices, the nozzle has a special thread, which guarantees a more reliable installation. Thus, by screwing the nozzle, you can get the most accurate results and the help of a second person is not required.

Operating principle

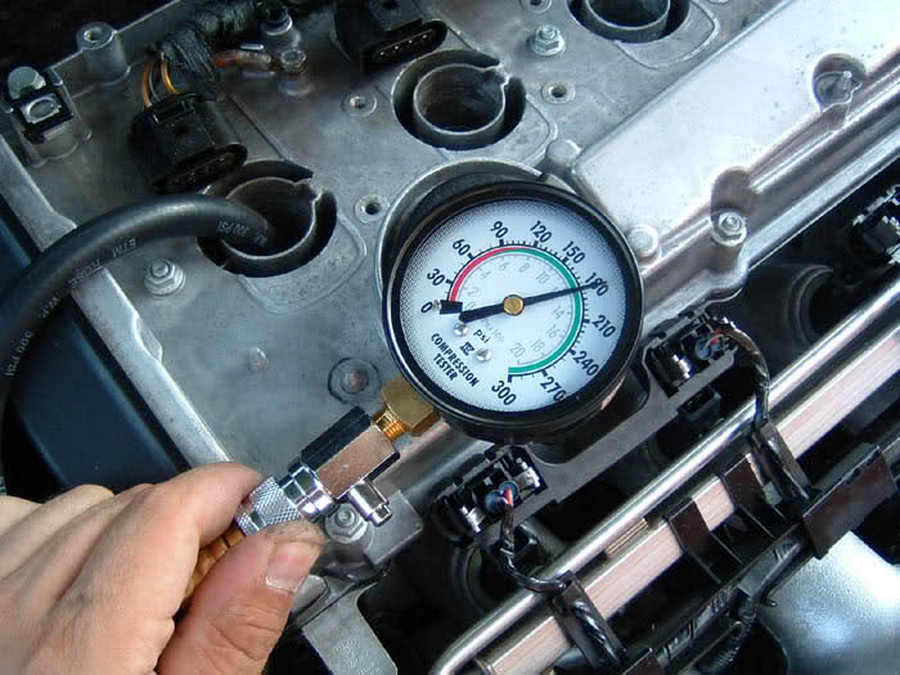

To perform measurements using a compression gauge, you must first unscrew the candle, install the appropriate tip instead (or press it tightly). Further, during the manual movement of the cylinders, air under pressure will enter the device hose, and when it reaches the limit value, this result will be recorded by a pressure gauge. Despite the obvious ease of operation, handling the type of instrument in question will require some skills from the operator. Any obtained results need a special analysis in order to make a conclusion about the presence/absence of problems in the system based on them. From this it is clear that measurements must be taken at least three times in order to obtain an arithmetic mean. To prevent possible errors, the result should be multiplied by a factor of 1.3 (this action is typical for applying to the results of a similar group of devices, since their error can reach 3 atmospheres). To find out what indicator is normal for a given motor, you can refer to its technical documentation.

At the same time, the accuracy of the compression level will depend on:

- oil viscosity;

- The quality of the fuel used (i.e. its octane number);

- Engine warm-up level;

- Battery charge level.

IMPORTANT! It is advisable not to take as a final result a test performed for only one cylinder - a comparative analysis of the compression performance for all cylinders should be carried out.

Causes/consequences of low compression

If, during the test, reduced compression rates were revealed, then urgent measures must be taken to restore the pressure level. Otherwise, irreversible consequences may occur for the motor.This can be expressed in the difficulty of starting the engine, constant jumps in speed in it, the appearance of extraneous loud noises, a decrease in power, an increase in fuel consumption, the appearance of blue smoke from the exhaust pipe while starting the car. The main reasons for low compression are:

- Burnt cylinder block gasket;

- Burnt piston or valve;

- Excessive wear of the cylinder elements;

- Valve seat failure.

The easiest solution would be to replace the above unusable elements with new ones. In most cases, after this, the pressure will return to normal, which must be confirmed by repeated measurements.

Operating rules

Before starting the measurement process, several preparatory steps must be completed:

- In order to achieve the most accurate results, the car battery must be fully charged. The engine speed should be 200 rpm or more, provided that the starter is fully functional.

- All candles and wires must be removed - this is a guarantee of the accuracy of the obtained indicators. The most common mistake is that the operator unscrews only one candle, to the cylinder of which the device is connected.

- All wires are disconnected from the coils, and if the air filter is dirty, then it must be changed to a new one.

- The fuel supply to the cylinders should be turned off by disconnecting the fuel pipe or removing the wires from the injectors.

- Before starting measurements, the motor must be warmed up to about +80 degrees Celsius (this is the recommended temperature).

- As an exception, it is allowed to take measurements on a cold engine with the throttle valve fully open or closed - this way it is possible to identify various malfunctions, but only for gasoline units.

The measurement procedure consists of several steps.First you need to connect a compression gauge to the holes for glow plugs or injectors. With each connection, the engine starts (scrolls) for about 5 seconds. The maximum value that the pressure gauge of the device will show is subject to fixation. The compression level in diesel engines is much higher than in gasoline engines, so before working with them, you need to make sure that the device is able to measure and display a pressure of 30 atmospheres. For work on gasoline engines, readings are obtained by depressing the gas pedal and scrolling the engine. This is necessary to obtain values with an open throttle and low input resistance.

With the help of the diagnostic equipment in question, the following malfunctions can be detected:

- Piston destruction, leakage;

- Wear of the cam, piston rings, gaskets, cylinder mirror;

- Destruction of the combustion chamber of the fuel mixture;

- "Blackout" of the valve function in the form of hanging, deformation, burnout, etc.

Making measurements on a "cold" engine

In some cases, it is possible to make measurements on a "cold" internal combustion engine (internal combustion engine). For gasoline models, the compression ratio will immediately fall below the optimal values by half as much as when performing a similar operation on a warm one. The error in this case can reach 4.5-5.5 atmospheres. The reason for this will be the depth of the piston rings, which in itself is a malfunction. The procedure will be similar for diesel internal combustion engines, but it is always worth remembering that at 17 atmospheres of pressure such an engine can no longer be started, and 24 atmospheres is the minimum that shows that the engine needs immediate repair.In addition, when checking "cold" diesel models, the presence of oil in the cylinders should not be allowed, so the propulsion unit must be given time to "sit" so that the oil flows into the crankcase and then the readings obtained will become more real.

Self-creation of a compression gauge (for use in a spark plug hole)

To create a handicraft device you will need:

- Pressure gauge with a range of measurements from 0.1 to 20 kilograms per square centimeter;

- Copper or brass adapter;

- A pair of valves from the chamber of heavy vehicles;

- Brass / copper tube with a diameter of 10-15 millimeters;

- Rubber conical nozzle (it is allowed to use a rubber nozzle for high pressure complete with various adapters for different threads);

- Soldering iron and gas burner;

- Flux (rosin), solder POS 40 or 60.

The basis of any compression gauge is a manometer. If it is supposed to work on checking gasoline internal combustion engines, then a device with a measurement limit of up to 15 atmospheres can be adapted to a home-made device. If it is planned to make a universal model, then the scale should allow the display of at least 30 atmospheres. The pressure gauge itself can be purchased at any specialized store or even removed from an old electric pump. Valves from the chambers are useful for pressurizing the check and drain valves. Adapters, a tee and tubes are needed as a single base for assembling the entire system under test. And with the help of a rubber nozzle, you can ensure a tight clamp.

Difficulties of choice

Before buying, you should decide to what extent the device will be used for the most part.For single household measurements, a simple car model in the minimum configuration is also suitable, which will be quite enough to obtain proper results. If the device is planned to be used permanently on a commercial basis (for example, as part of a service station or car service), then it would be preferable to purchase a professional set with various expanders, plugs, connectors, valves, pipes, adapters and adapters. The most expensive sets have a universal package and a double-scale pressure gauge is provided in their design - such equipment can be used on any type of internal combustion engine. However, you should immediately focus on the need to use a tube made of a specific material:

- Rubber - such pipes are needed to use the device in confined spaces in order to provide the possibility of using bending capabilities (for example, situations where dismantling the internal combustion engine is impossible);

- Metal - these products are particularly rigid, more designed for use in clamping devices;

- Combined materials - the tube consists of both rubber and metal sections, which adds to the ease of use.

Rating of the best compression meters for 2025

Budget models

3rd place: "KRAFT 16 Atm., threaded, gasoline KT 831014"

votes 0

The model is intended for measuring compression in automobile internal combustion engines, mainly in domestic conditions. Main technical characteristics: the upper limit of pressure measurement, MPa (kgf / cm2) - 1.6, the measurement error (no more than) MPa (kgf / cm2) - 0.01, the length of the aluminum rod - 130 mm.Required operating conditions: ambient temperature - from -60 to +60 degrees Celsius with relative humidity in the range from 30 to 80%. The recommended cost for retail chains is 760 rubles.

- Simple construction;

- Metal tube;

- Verification certificate.

- Requires very careful insertion.

2nd place: “KRAFT 16 Atm., clamping, extended GAZ 406 doors. 16V KT 831010"

votes 0

The sample is used to measure compression in A / M Gazelle and Volga engines of models 402 and 406 (16 valves), as well as in other automobile gasoline engines, at home or professionally. Main technical characteristics: upper limit of pressure measurement - 1.6 (16) MPa (kgf / cm2), measurement error (no more) - 0.01 (0.1) MPa (kgf / cm2), aluminum rod length - 170 mm . Operating conditions: relative humidity from 30 to 80%. Net weight, kg, is 0.23, and dimensions without packaging, mm, are 31 x 10 x 4. The recommended cost for retail chains is 870 rubles.

- Affordable price;

- Sufficiently accurate readings;

- Small error.

- An accurate selection of the rubber gasket is required.

1st place: AvtoDelo 4 pr. 40063 10552

votes 0

This universal petrol model is used for vehicle diagnostic inspection. It is designed to measure the pressure in the engine cylinders.Main characteristics: flexible hose provides convenient work in hard-to-reach places, a steel rod with a rubber tip is included in the kit, a pressure gauge has a contrast scale on a white background, a pressure relief valve increases the service life of the device, an adapter with M18 x 1.5 thread, a plastic case is provided for storage. The compression tester is suitable for use in repair shops and service stations.

- Semi-professional sample;

- Durable storage case;

- Adequate evidence.

- The hose can be quickly replaced.

Middle price segment

3rd place: "AE&T TA-G1005"

votes 0

The sample is packaged in a plastic case for ease of use and portability. The tool is suitable for cars. The presence of a dial for checking the pressure in the cylinders of the internal combustion engine simplifies the reading of data and allows you to more accurately check the operation of the engine. The recommended cost for retail chains is 2100 rubles.

- The presence of different adapters;

- The best ratio of price and quality;

- Does not require improvement.

- Not detected.

2nd place: AvtoDelo 40064 12640

votes 0

This universal kit is used to measure and control the pressure in the cylinders of a diesel engine. Its key features: an adapter for glow plugs, injectors and screws, a pressure gauge with a scale of up to 70 bar, a flexible rubber hose, a quick-release adapter for easy replacement of nozzles, a pressure relief valve protects the device from damage, and an H-shaped clamp is supplied. The set is stored in a convenient plastic case.The kit is used in car repair shops, service centers and service stations. The recommended cost for retail chains is 4600 rubles.

- Versatility;

- Quick release adapter;

- Good defense system.

- Not detected.

1st place: "0-1000PSI and 0-70atm with adapters for all diesel engines in the world AE&T TA-G1011"

votes 0

This is a very easy to use device with which you can quickly determine the condition of the engine by valve compression. For convenience it is completed with a plastic case. The kit includes a wide range of adapters for a variety of diesel engines. The recommended cost for retail chains is 4800 rubles.

- Affordable price;

- It is possible to carry out measurements even on special equipment;

- Simple use.

- Not detected.

Premium class

3rd place: "For AE&T TA-G1033 trucks"

votes 0

The model is used to check the degree of compression in ICE cylinders of any type. The pressure gauge of the device is reliably protected from accidental impacts by a rubberized bumper. There is a reset valve. Net weight, kg - 3.2, there is a storage case. Fastening - threaded, device type - mechanical. The recommended cost for retail chains is 12,700 rubles.

- Many attachments included;

- Excellent protection system;

- Clan reset results.

- Not detected.

2nd place: "Compression tester for diesel engines with a set of adapters JTC 4302"

votes 0

The sample is suitable for most existing modes of transport - for cars, trucks, buses, marine transport and even for agricultural machinery. With the help of these devices, any user, both a service center professional and a novice motorist, will be able to quickly and with high accuracy determine the percentage of air leakage supplied to the cylinder. The total number of tools in the set is 37 pcs. The principle of operation is based on measuring the amount of air leakage supplied to the cylinder. The kit is used to diagnose the tightness of the engine combustion chamber. The device allows you to assess the condition of piston rings, cylinder walls, valves and head gaskets. The recommended cost for retail chains is 33,400 rubles.

- Light weight and dimensions;

- Supplied in an ergonomic plastic case, equipped with a transport handle, special latches, as well as an individual cell for each of the tools;

- High strength;

- Ease of use.

- High price.

1st place: "MASTAK 0-70 atm, case, set of adapters 120-12170"

votes 0

This device allows you to measure the intra-cylinder pressure in two ways at once - through the holes of the glow plugs, as well as through the holes of the injectors. It is used for vehicles running on diesel fuel, both with direct and conventional injection. The measurement range of this model is from 0 to 70 atm. Weight - 2.583 kg. The recommended cost for retail chains is 44,900 rubles.

- Reinforced flexible hose with a length of 355 mm is equipped with a quick-release adapter that allows you to quickly and easily change adapters for use on different vehicles;

- Ease of use;

- High strength;

- Long service life.

- High price.

Conclusion

Checking the compression pressure in the internal combustion engine is one of the ways to diagnose the problems of the main component of motor units, or rather, it is aimed at more accurate detection of defects in its piston-cylinder group. If such a check does not immediately pinpoint a specific violation, then the incorrect pressure parameters issued will force the operator to conduct a more thorough analysis.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131651 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127691 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124519 -

The best men's sneakers in 2025

Views: 124033 -

The Best Complex Vitamins in 2025

Views: 121940 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114980 -

The best paint for gray hair - top rating 2025

Views: 113395 -

Ranking of the best wood paints for interior work in 2025

Views: 110319 -

Rating of the best spinning reels in 2025

Views: 105329 -

Ranking of the best sex dolls for men for 2025

Views: 104366 -

Ranking of the best action cameras from China in 2025

Views: 102216 -

The most effective calcium preparations for adults and children in 2025

Views: 102011