Rating of the best coaxial chimneys for 2025

Any equipment in heating systems that runs on natural gas or solid fuels needs to install smoke or exhaust gas exhaust devices. In country houses where conventional / condensing boilers, stoves or fireplaces (open / closed) are installed, a coaxial chimney is traditionally used. Almost always, such equipment is included in the package of the purchased boiler, which allows you to immediately install a complete chimney system that will work efficiently without any problems. However, it is possible to buy a chimney separately (if a different power is required), or to make such elements yourself and they are suitable for any boilers.

Content [Hide]

- 1 Coaxial chimney - general information and principle of operation

- 2 Installation requirements and direct installation process

- 3 Difficulties of choice

- 4 Wind protection and de-icing

- 5 Rating of the best coaxial chimneys for 2025

- 6 Instead of an epilogue

Coaxial chimney - general information and principle of operation

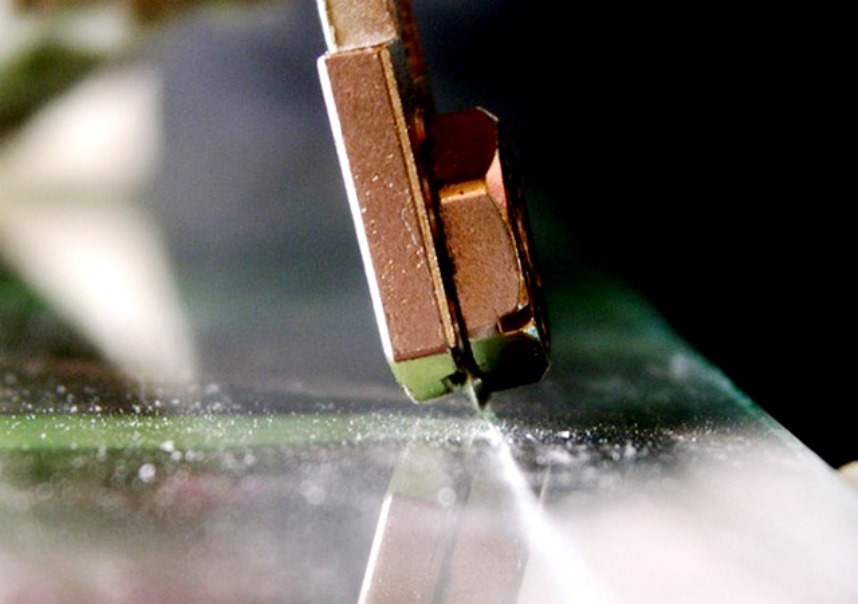

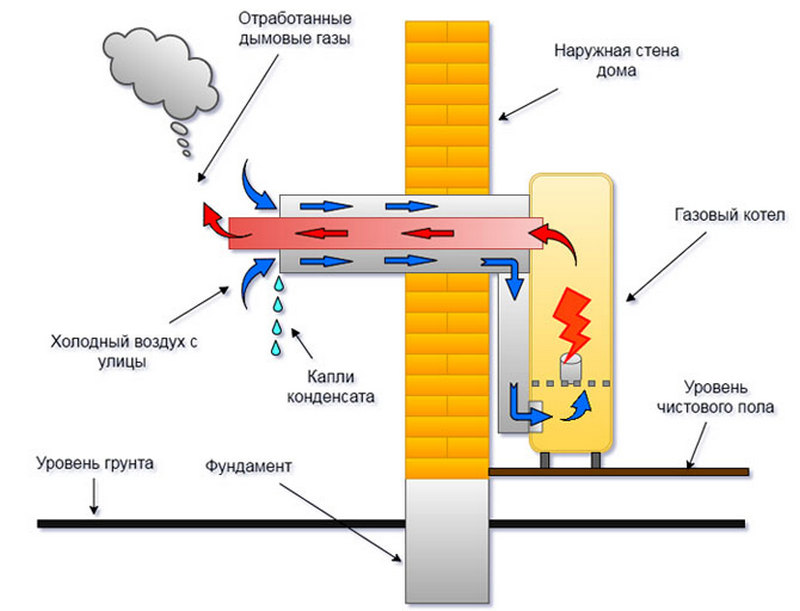

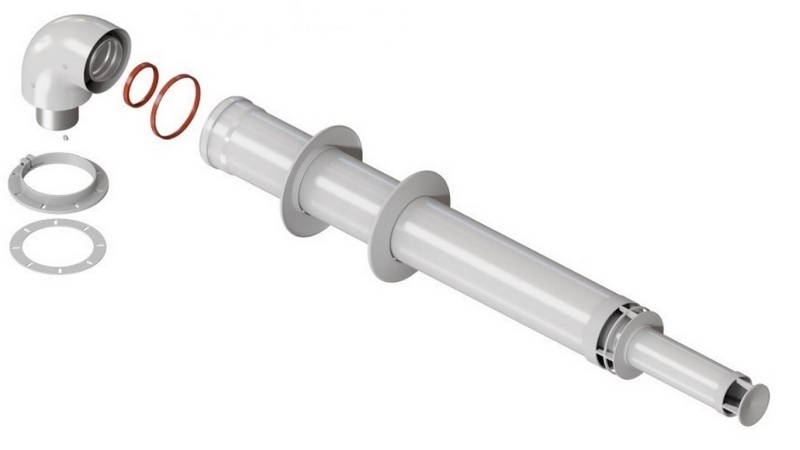

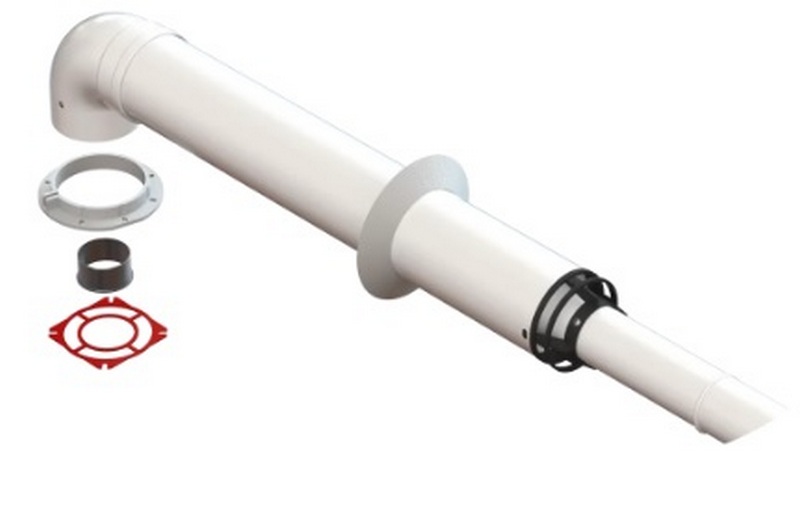

The equipment in question is a structure that consists of a pair of pipes, one of which has a diameter smaller than the other and is inserted into it. Simply put, the chimney has two axes, each of which performs its own tasks during the operation of the system. It is worth noting that a free space gap of several centimeters is always observed between the outer and inner pipes. Most often, such chimneys are used in conjunction with gas boilers.

The chimney works according to the following principle:

- A smaller pipe installed inside removes exhaust gases (other combustion products) through the boiler pipe;

- A large outer pipe brings fresh air into the combustion chamber, saturating its space with oxygen.

During the passage of street air through the external channel to the combustion chamber, it warms up due to contact with the hot walls of the inner pipe. This process makes it possible to reduce heat energy losses in the boiler when a new portion of air is heated, while at the same time reducing the consumption of solid fuel/natural gas. Further, the air masses cool the inner small pipe, thereby protecting all structural elements from excessive heating.

Advantages and disadvantages of coaxial chimney systems

Their undoubted advantages include the following characteristics:

- Small dimensions, thanks to which the installation of equipment is greatly simplified (namely, to install a drain pipe, you just need to drill a small hole in the wall);

- The overall safety of the system is achieved through the forced removal of exhaust gases, as well as through the simultaneous intake of oxygen from the street, so its amount in the room with the boiler never decreases;

- Universality of use, which means that it is possible to equip not only private houses, but also ordinary city apartments with such chimneys (despite the fact that there is no need to create separate boiler rooms);

- Increase in boiler efficiency due to the fact that the used air reaches the furnace already in a heated state, because it managed to come into contact with the heated walls of the inner tube of the structure, through which the exhausted hot gases are additionally discharged;

- Placing a short chimney in a horizontal position makes it possible not to lay long outlet lines, which would be replete with bends, holes and various clamps, for which it would be necessary to change the roof and ceiling.

However, the described equipment also has disadvantages:

- In general, a complete set of heating equipment that works with such chimneys is far from cheap;

- Condensation may form in the air duct, which threatens with severe icing during the frosty period, and this occurs due to the proximity of hot and cold chimney elements;

- There is also a risk of freezing of the internal elements of the device at too low external temperatures, the reason for this is the small dimensions of the chimney.

Nevertheless, all the pros and cons of coaxial pipes mentioned above indicate that heaters using them in their work are much more efficient than their classical counterparts. For this reason, they have become a quality solution for heating those residential premises for which it is impossible to arrange a conventional chimney brought out through the roof. From this it is clear that the advantages of coaxial systems actually exceed their disadvantages, especially since most of them can be compensated. For example, the formation of condensate can be prevented by simply insulating the pipe, and providing a separate outlet channel for the liquid. The problem of freezing of internal elements in the heat generator can be solved by installing a coaxial chimney with protective valves in the design, coupled with a boiler that has the option of controlling the change in air temperature outside. When critical temperature values are reached, the valves will close automatically.

Modern types of pipes

Today, for coaxial chimneys (two-channel), pipes are made of plastic or metal. Each of these materials has its own advantages and disadvantages:

- Plastic models are preferably used in condensing temperature boilers. They are made of special heat-resistant plastic and can withstand temperatures up to +205 degrees Celsius. They are considered more affordable in terms of price, not particularly difficult to install, due to their low weight. Their main disadvantage can be called a short service life, as well as the existing restrictions on the scope of the temperature regime for the boiler, plus relative vulnerability from the aggressive elements present in the exhaust gases.

- Metal models are made of aluminum or stainless steel, have a long service life (about 30 years), and are resistant to chemicals. They can withstand temperatures up to +550 Celsius. However, they are extremely susceptible to the formation of internal condensate, so their insulation with basalt wool or other heat-insulating material is a solid necessity.

Installation requirements and direct installation process

The operation and installation of coaxial chimneys is regulated by two regulatory documents, namely: Building Regulations No. 2.04.08 of 1987 and No. 2.04.05 of 1991, which indicate installation methods, safe use standards, as well as types of compatible boiler equipment. During installation, the type of wall material, layout, area of the heated room play an important role. The main conditions that apply to the installation include:

- When installing a chimney head on the facade of a building, its placement must be at least 2 meters above ground level;

- For wooden walls, the outlet should be 5 centimeters larger in diameter than the structure itself, and for brickwork, this figure is one centimeter;

- Indoors, the pipe should be located at least one and a half meters from door and window openings;

- If the pipe passes under the windows, then the distance between them must be at least one meter;

- The gap between the wooden wall and the pipe is set at least 5 centimeters;

- Street buildings, distances to neighboring houses should be at least five meters from the removed pipe;

- Embedding a coaxial chimney for a gas boiler into a standard boiler is not allowed;

- The protrusion of the head of the chimney structure above the wall of the building must be at least 30 centimeters;

- When laying a horizontal pipe through an adjacent non-residential premises, the length of the resulting line should not be more than 5 meters (there is a risk of smoke).

In total, it is possible to connect a coaxial chimney in two ways - vertical and horizontal. The first is suitable for those who cannot bring the pipe out through the wall or the boiler equipment itself does not have forced ventilation. A feature of the second method is that the maximum pipe length for it should not exceed 5 meters (however, depending on the design, this figure can be either reduced or increased - this feature is prescribed by the manufacturer in the accompanying documents). In addition, for a horizontal arrangement, it is necessary to observe a slope of one centimeter for each meter of pipe length.

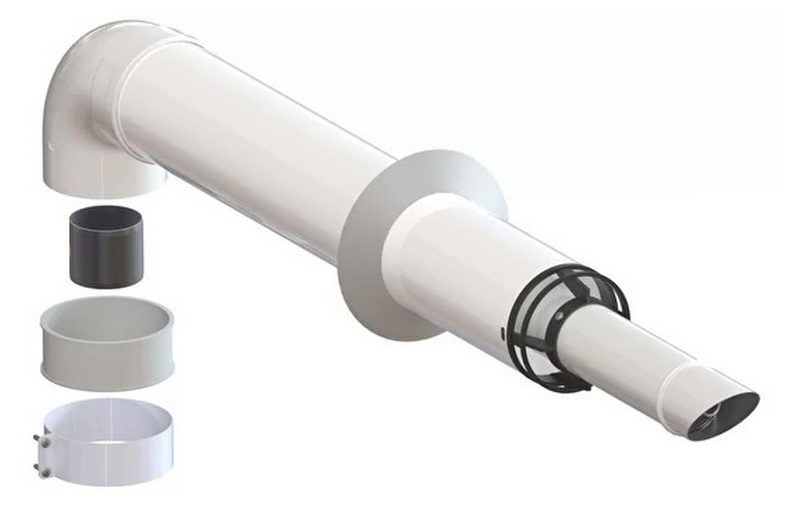

Before starting the installation process, you need to correctly choose a place, because you will have to install the boiler and the chimney at the same time. Also, you need to prepare all the relevant tools so that the search for the desired building item does not take much time. The process itself takes place in the following steps: first of all, a hole is drilled in the wall with a diameter that slightly exceeds the outer pipe. Next, the pipe is inserted into the hole made and is connected through a clamp (tee) to the boiler. At the same time, the angles must be observed so that the condensate has the opportunity to drain into the sump without falling on the boiler body or walls. The gap between the pipe and the wall can be walled up with ordinary building foam (according to the usual instructions, the volume of unexpanded building foam should be about two-thirds less than the total space that needs to be sealed). It is also possible to install special linings at the joints, in order to increase their aesthetic appearance, while the outlet can also be closed with a nozzle.

If the features of the room being equipped allow the pipe to be led out only to the roof through the ceiling, then it is imperative to use heat insulator pipes made of non-combustible materials. Of course, coaxial pipes are considered safe by default, but additional reinsurance does not hurt. It is better to test start the entire system immediately (without waiting for the onset of cold weather and the heating season) - it will be easier to fix all possible defects that cannot be detected with a simple visual inspection.

Typical installation errors

These include:

- Incorrect calculations of the permissible pipe length - the smaller the channel through which the flue gases pass, the less they cool down and better heat the incoming air at the outlet.If the pipe is too long, then the risk of a large amount of condensate (especially on frosty days) increases significantly. At the same time, frost forms on the walls, which very soon turns into large icicles on the head. All this will reduce traction, reduce the efficiency of the boiler itself, and allow carbon monoxide to penetrate into the heated room if a complete blockage of the outlet channel suddenly occurs.

- Insufficient slope of the pipe placed in a horizontal position - again, in this case there is a risk of condensation, which then turns into ice on the head.

- Lack of a condensate collector - if the chimney passing through the wall is short, the passing flue gases will not be able to cool down enough to cause condensate. If, on the contrary, the pipe is long, then it is imperative to adapt a tee with a moisture collector to it, otherwise water will enter the combustion chamber of the boiler, thereby lowering its efficiency.

- Violation of fire safety standards when installing a pipe through wooden structures - in this case, the head must be removed from wooden surfaces by at least 60 centimeters so as not to cause them to overheat.

- The absence of a wind protection diaphragm and an anti-icer - all this will also lead to a decrease in the efficiency of the entire system as a whole.

Difficulties of choice

Due to the fact that one of the main disadvantages of coaxial chimney systems is their increased susceptibility to freezing, the competent selection of the material of manufacture and the diameter of the pipe will play a big role. In principle, you can make a chimney yourself, but it will be difficult to provide such a design with proper rigidity without special tools. From this it is clear that it is better to rely on the factory manufacturer.Moreover, the equipment in question has a warranty period.

However, in order to make the right choice of device, it will be necessary to make specialized calculations - it is better to entrust such work to the appropriate specialists. To make a decision, you will need the following input:

- Power of the main fuel apparatus (boiler);

- Type of fuel used;

- The lowest temperature threshold on the street during the heating season;

- wall thickness;

- Reliability of the heat-insulating system in the room where the boiler is installed.

As for manufacturing brands, Russian companies are very poorly represented in it (for example, UDTK OJSC), but high-quality European brands occupy almost the entire segment. These include:

- Vaillant;

- Protherm;

- Viessmann;

- Baxi;

- Ferroli;

- Ariston.

All these companies have certified their products in Russia.

Wind protection and de-icing

Icing is a real problem for the devices in question and is a rather annoying side effect, which is inherent in all coaxial chimneys. The presence of ice can be detected by the following signs.

- The boiler goes out very quickly after starting work;

- An error message "Flame break" appears on the monitor of the boiler equipment;

- Condensation begins to appear on the duct.

This problem can be solved in several ways, the simplest of which is to simply increase the power on the heater. It is also possible to carry out air intake in the room by installing a special plug for the supply pipe. Another way is to lower the boiler delta, i.e.during the heating period, it is required to use the equipment only at high and medium temperatures, and stop using it at low temperatures.

Wind protection is used to prevent the boiler from blowing out and to prevent back draft. If you do not provide protection from drafts and wind, then the risk of carbon monoxide penetration into the heated room will increase significantly. It is recommended to avoid this situation as follows:

- By installing a windproof diaphragm;

- Through the proper location of the pipe next to window and door openings;

- Properly calculating the distance to the nearest building from the chimney (at least 1.5 meters, otherwise the smoke will return back).

IMPORTANT! In areas where stable and strong winds are permanently present, the installation of wind protection from recommended measures becomes mandatory.

Rating of the best coaxial chimneys for 2025

Budget segment

3rd place: Ecoplastic "UTDK" 60X100(PL)-750 WITH FLANGE AND ADAPTER"

votes 0

Simplified and standard version, made of plastic with aluminum for some elements. It is characterized by reliable protection against icing, complete and high-quality resistance to corrosion manifestations. The outer elbow and the outer duct are made of plastic, while the inner elbow is made of die-cast aluminium. The applied aluminum alloy is one millimeter thick. The inner part is produced by seamless technology by extrusion, which means complete tightness and the presence of anti-corrosion properties. The color of the entire structure is white. The recommended cost for retail chains is 1800 rubles.

- The presence of sealed and anti-corrosion properties;

- Small dimensions;

- Ice protection.

- Premature destruction of plastic parts is possible with a sharp temperature difference.

2nd place: "Vaillant Prok PR068476"

votes 1

This model is compatible with Ariston boiler equipment. The kit includes all the elements necessary for installation, up to the fasteners. The body is made of fairly durable plastic. Installation of equipment is very simple. The device differs in workmanship, adequate cost and sufficient durability. Can also be used at very low temperatures. A successful fight against condensate will require the connection of an additional outlet. The recommended cost for retail chains is 2099 rubles.

- High-quality plastic case;

- Work in a wide temperature range;

- Adequate price.

- Compatibility only with thermal equipment "Ariston".

1st place: "UTDK Standard VAILLANT ANTI-ICE COAXIAL CHIMNEY KIT"

votes 1

The body of this device is made of solid aluminum die casting, and the material of the internal flue is aluminum alloy, the thickness of which is one millimeter. Seamless technology is also used in the internal gas duct, which indicates resistance to corrosion and absolute tightness of the structure. The outer air duct is made of galvanized steel with a thickness of half a millimeter. The case is painted with a special glossy polyester paint, which is extremely UV resistant. The recommended cost for retail chains is 2250 rubles.

- UV resistant;

- Use of seamless technologies in the design;

- The use of high-quality metal materials in production;

- Suitable for most popular boilers.

- Not detected.

Middle price segment

3rd place: "Universal kit Grosetto 2035594"

votes 0

This kit is made in China, but this does not mean that its quality leaves much to be desired. The kit contains all the necessary components, the device itself is made of heat-resistant plastic. It is distinguished by a rather large weight of three kilograms, which contributes to the strength of the entire structure and its stability during the final installation. It can work with most modern boilers, with the exception of two companies - Immergas and Navien. The recommended cost for retail chains is 2300 rubles.

- A fairly complete set of accessories;

- Heat-resistant plastic case;

- Adequate price.

- Not suitable for all boilers.

2nd place: "Special set Grosetto 2036812"

votes 0

In this model, the manufacturer wished to justify himself for the incompatibility of the previous model with the equipment of some companies and released a special chimney for the Navien 60/75 and Immergas 120 boilers. The set includes an anti-icing system based on an anti-ice tip. The design can be rotated 90 degrees, and the use of silicone pads will provide the desired level of tightness. Any joints can be masked with decorative nozzles. The recommended cost for retail chains is 2350 rubles.

- Specialized model;

- The presence of the tip "ANTILED";

- Equipped with decorative overlays.

- Not detected.

1st place: "Federica Bugatti K60/100 original L750 with antiobl. 2034496"

votes 1

This sample was developed using backward compatibility technology, i.e. can be suitable for both old models of gas boilers, and for new ones. In particular, it is compatible with Bugatti, Navien, Wolf, Bosch, Proterm, Buderus. The kit includes (in addition to the direct functional parts) two silicone pads, a decorative nozzle, an Anti-Ice tip. The model is able to work with wall variations of boilers. The recommended cost for retail chains is 2700 rubles.

- Acceptable price;

- Wide area used (compatibility with many models of boilers);

- Italian quality production.

- Installation by a specialist is required (depending on the boiler model).

Premium class

3rd place: "UTDK Premium ANTI-ICE COAXIAL CHIMNEY FOR IMMERGAS"

votes 0

This chimney has a relatively light weight of 2.5 kilograms and both elbows are made of die-cast aluminium. The thickness of the reinforced walls is 2 mm. The outer part is made of solid aluminum, and the inner part is made of aluminum alloy with an additive of anti-corrosion components. The body is welded using seamless technology, which increases the tightness. Painted with glossy white polyester paint with UV protection. The recommended cost for retail chains is 3600 rubles.

- There is a whole range of protective properties;

- Application of polyester paint;

- Thick body walls.

- Not detected.

2nd place: "Chimney kit for coaxial system (DN 60/100 mm; 740 mm) Vaillant 303810 apartment heating"

votes 0

This equipment is famous for its German manufacturing quality and can be used with most models of boiler heating. Focused on use in city apartments, rather than in country houses. This is evidenced by very small dimensions, but at the same time, the sample has an amazing margin of safety and durability. The kit includes: decorative cuffs, 74 cm pipe, clamp and 90 degree elbow. The whole complex of protective properties is available. The recommended cost for retail chains is 3990 rubles.

- Good equipment;

- The strength of the body with small dimensions;

- Wide scope of use;

- Focus on urban apartments.

- High price.

1st place: "Premium "UTDK" COAXIAL SET 60Х100(AL)-1100 UNIVERSAL ANTI-ICE"

votes 0

Due to the presence of many adapters and nozzles supplied with this equipment, it is exactly compatible with any boiler manufactured in Europe, as well as with some Asian modifications (more than 70 manufacturing companies are covered in total). The body is made to the highest standard of aluminum (using seamless technology), and the alloy of the internal parts has anti-corrosion additives. The outer side is painted with white polyester, which gives additional protection against fading in the sun.The recommended cost for retail chains is 4200 rubles.

- Compatible with all European manufacturers;

- Reliable construction;

- UV protection.

- Very high price.

Instead of an epilogue

Chimneys of coaxial types are a relatively new solution in the field of today's heating equipment. Experts note a significant reduction in the dimensions of the boiler structure, due to the fact that the air inside the room is not used. The equipment in question has a compact size, most of the models are made according to European quality, which made them worthy competitors to traditional models. Separately, it is worth mentioning that the materials of their production can successfully withstand chemically aggressive substances, which indicates their long life. The positive points can be listed for a long time, but the basis of their popularity lies in high performance, environmental friendliness and simple installation.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131652 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127691 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124520 -

The best men's sneakers in 2025

Views: 124034 -

The Best Complex Vitamins in 2025

Views: 121940 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2025

Views: 113396 -

Ranking of the best wood paints for interior work in 2025

Views: 110319 -

Rating of the best spinning reels in 2025

Views: 105330 -

Ranking of the best sex dolls for men for 2025

Views: 104367 -

Ranking of the best action cameras from China in 2025

Views: 102217 -

The most effective calcium preparations for adults and children in 2025

Views: 102012