Rating of the best crimping pliers (crimpers) for 2022

Crimpers (aka “tip pliers”) are the tool that is designed to make a contact connection at the end of the wire in a high-quality and proper way, and at the same time, so that the transmission of electrical impulses through the wires occurs clearly and without failures. With their help, the necessary contact area is provided, however, to obtain a sufficient effect, it is necessary to correctly select both the matrix of the tool itself and various consumables.

IMPORTANT! Do not confuse the concepts of "sleeve" and "tip". With the help of a sleeve, the two ends of the wire are connected into one, and the tip is the end of the wire and provides for its connection to the terminal of the peripheral device. The tips also include computer connectors and plugs for SCS networks and telephony.

Content

- 1 The division of tools into household and professional

- 2 Features of production and design

- 3 Features of crimping lugs of Internet wires (connectors)

- 4 Step-by-step mechanism of the crimping process

- 5 Difficulties of choice

- 6 Rating of the best crimping pliers (crimpers) for 2022

- 7 Instead of an epilogue

The division of tools into household and professional

The use of crimpers is a very specific area that requires strict adherence to many rules and scrupulous adherence to precise technologies in the field of connecting wires. Any deviation from the standards and resorting to half measures will necessarily lead to damage to the connections made or breakage of contacts. Modern technological regulatory documents (PUE and PTEPP) have long and categorically banned wire connections by cold twisting. Therefore, the only sure way is to use ticks. However, not all crimpers will fit certain types of cable cross-sections, and they may not be suitable for connection purposes.

Pincers, according to the type of actuation, can be divided into manual (mechanical) and automatic (operated by an electric motor / hydraulics). Mechanical options can be both household and professional. So, with the help of household samples, wires with a small cross section are crimped: only 2.5 millimeters for aluminum and from 1 to 2.5 millimeters for copper. Professional mechanical pliers can work with large diameters and work on wires with a circumference of 4 millimeters.

But automatic pliers always have only professional use - only with their help it is possible to compress stranded wires with a large cross section (up to 6 millimeters), which is usually in demand in industrial production.

Features of production and design

A tip press will only be of high quality if certain standards have been met during the manufacturing process. A prototype of the device is always developed first and tested in specialized laboratories. The testing procedure consists in checking the following qualities of the prototype:

- The tightness of the resulting connection;

- Tensile strength of the connection;

- General ease of use.

To launch a tong model into mass production, reliable, strong and durable materials are specially selected to ensure the maximum number of press cycles. Today's market standard for a classic crimper is a minimum of 40,000 presses.

Modern types of crimping pliers for ferrules

The toolkit under consideration is used, as a rule, in two cases: for preparing conductive parts for fastening to the terminals of various electrical equipment and for connecting cables and wires to each other. Thus, they can have two principles of action:

- By type of pliers;

- Diaphragm.

The first option is the most popular. The crimping process takes place by pressing the two working jaws on the body of the ferrule with the wire. Such crimpers differ from ordinary pliers by the presence of corresponding recesses on the working jaws, which are the guarantor of a strong fastening of the consumable to the cable and establish the most reliable connection. The convenience of using pliers for crimping lies in the fact that there is no need to select the correct position of the consumable, because the action (top / bottom) can be performed from any side. However, you should carefully monitor that the tip fits the matrix (recesses in the working jaws).

IMPORTANT! Before performing any electrical work on fixing the tips, you should make sure that the working tool matches the consumables. Possible problems can be avoided if you use a universal crimper with several different recesses for the sleeves and the section diameter.

The second option (diaphragm) press for lugs crimps from four or six sides, despite the fact that they themselves are able to adapt to the thickness of the cable section. This method is considered more reliable, since the crimp density increases significantly.

Directions for using crimping pliers

Crimping work can be episodic or be performed on an ongoing basis.For domestic use, the first option is typical, and with it it is unlikely that you will need to purchase a universal tool that has a lot of auxiliary functions. In any case, classic crimpers should be used in the following areas:

- Crimping is standard - to perform this process, you will need devices that may differ in the size of the matrix and the shape of the structure. Regarding the second condition, then in their body there may be a flange as an auxiliary element, with the help of which the connection will be of better quality.

- Removing the insulation layer - using pliers, it is possible to remove the desired section of the insulation coating, while preventing damage to the core itself. To perform this process, you must correctly set the length of the cutting element (there are models where this parameter is set automatically). Samples with knife function cost a little more.

- The crimping of the tips is special - for this process a special rod is used, which, when performing the crimping procedure, is placed on the separating seam. Tools with this function are used when processing brass and bare wires.

- Work on twisted pair - with this procedure, the working part of the device must have a special recess for the connector.

Press tongs hydraulic

Such equipment is by far the most convenient and at the same time the most expensive. It allows you to perform most of the work in various areas with a minimum of effort. Hydraulic models consist of

- handles;

- Working axis;

- heads;

- Marking matrix.

For this variation of crimpers, the head can be either closed or open.In the closed type, the stopper is first opened, then the matrix is pulled out, a wire with a tip is inserted into it, the structure is closed, and only then is crimping. In the variation with an open head, no preparatory steps are required, which makes the entire workflow much faster. Any model of hydraulic pliers can only be used for a certain range of cable cross-section diameters. The maximum size is 400 millimeters and it is practically not used in everyday life. At the same time, it is convenient to use hydropliers for crimping even for small sizes (from 6 millimeters), the main thing is to prevent pinching.

IMPORTANT! If it is supposed to work with hydropliers with a wire made of very soft metals, then for this it is better to use a device with a limiter. Through it, it is possible to avoid the risk of pinching.

The process of working hydropliers is quite simple. By swinging the pump piston handle and performing reciprocating movements, the necessary pressure arises in the housing, at which oil enters the working cylinder. The oil advances the cylinder, and it already creates pressure on the working matrix, which acts on the tip with a set force.

Features of crimping lugs of Internet wires (connectors)

Proper operation in any cable network will depend on several factors. First things first, here you need to include the quality of the wire itself. In second place is the degree of professionalism of network installers. The last place can be put on the quality of connections in communications (however, such a gradation is clearly unreasonable, according to many professionals).

It is the contact, in most cases, that causes the transmission of an unstable or weak signal.To produce the most reliable connection, all system cables must be properly crimped using crimpers that can accept special connectors.

Any connection of Internet cables begins with the removal of the insulating coating. You can use a separate tool for these purposes, called a "stripper", or use a crimper with a built-in blade function. Thus, with the help of the cutting element, the insulation is stripped. The next step is to install the connector. In the modern world, most often, RJ45 type connectors (Register Jack - a special network interface) are used for the installation of SCS (structured cabling systems). The body of this connector is slightly larger and surpasses the outdated RJ11 in terms of connection performance. The latter cannot be used for computer networks and is only suitable for telephone communications. The crimping process itself is carried out according to the standard scheme: the connector with the end of the stripped wire threaded into it is clamped into the working jaws of the device, after which, with the application of mechanical / automatic force, crimping occurs.

Step-by-step mechanism of the crimping process

In theory, it is not complex enough. The main thing is the availability of the right tool, suitable consumables and the ability to apply some muscular effort (if the design of the crimper is not automated). However, illiterate observance of crimping technology can make the contact unstable, which will force the installer to repeat the entire procedure again. The sequence of the traditional procedure will consist of the following steps:

- Preparatory measures - at this stage, it is necessary to process the wire, remove the protective insulation from it by means of a cutting element, while leaving a margin of 3-5 millimeters.Separately, it is worth making sure that during the stripping of the coating, the carrier core was not damaged. If damage is found, then such a section will have to be cut off completely.

- Connection preparation - a sleeve / lug or connector is put on the wire, while the open part of the cable must be degreased or a special paste is applied to it (for SCS cables);

- Tool preparation - in the matrix of the tongs, the required size of the section and the tip is set (the tip is inserted until it stops).

- Direct compression - pressure is applied to the working handles of the device or its hydraulics are started. Upon the appearance of a characteristic click, the process is considered completed. The handles of the device return to their original position.

- The final step - if necessary, the remaining piece of braid is returned to the junction and warmed up with a building hair dryer (or other tool).

Difficulties of choice

In order to correctly select pliers for crimping lugs or special crimpers for connecting cables of SCS systems, you need to pay attention to the following tips:

- The choice of instrument begins with a clear definition of the tasks for which it will be used. It is from this generated list that it is necessary to select both the functionality and dimensions of the press tongs. If you have to do not one-time, but permanent work, then universal equipment will be the best choice.

- Not the last criterion will be the price, on which the performance of the equipment will depend. Naturally, world famous brands are considered a guarantee of quality. If the cost of the device is low, then it is unlikely that you will have to rely on its long service life.

- At the time of purchase, the device must be checked for defects, at the same time, the overall build quality of the structure must be assessed. First of all, attention must be paid to the presence of all kinds of dents and chips, as well as to check the accuracy of contact between the jaws and the position of the handles.

- Special attention is required to honor the shape of the handles. If they have special recesses, they will help to more securely hold the device in your hands.

- Also, it will not be superfluous to simply hold the device in your hand - all possible inconveniences associated with mass or shape will immediately appear.

Rating of the best crimping pliers (crimpers) for 2022

Budget segment

3rd place: ZUBR Expert 22668-23

This model is a bright representative of an inexpensive and at the same time versatile crimping tool. The working part is designed in such a way that it allows you to perform many works with wired cables. The tool is perfectly suited for stripping, stripping at a finishing level, at which the risk of damage to the core itself is minimal. Capable of crimping insulated/non-insulated ferrules and even cutting brass bolts. The recommended retail price is 520 rubles.

- Durability of the structure;

- Control comfort;

- Multifunctionality.

- Not detected.

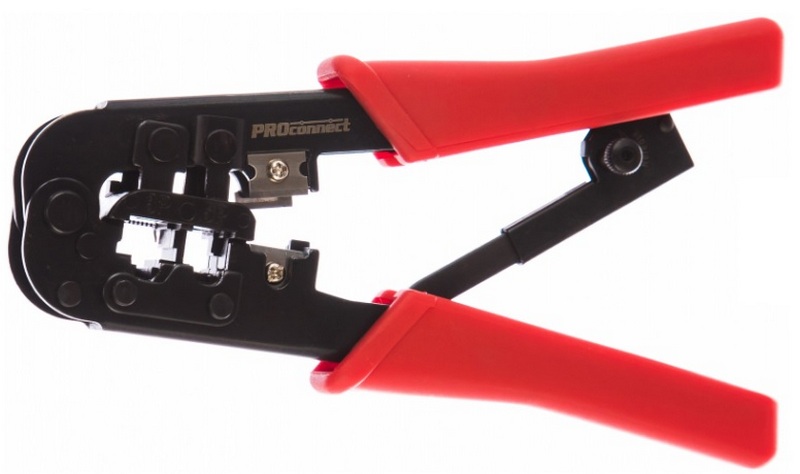

2nd place: "PROconnect HT-568R 8P8C, 6P6C 12-3432-4"

Not a bad tool, however, requiring some experience for more accurate handling. A cutting knife is installed in the design, which must be correctly adjusted before use.During the crimping process, the matrix protrusions rest firmly against the contacts and not against the connector baffles, making the entire operation more productive. The indentation occurs evenly along the entire contour. The recommended cost for retail stores is 690 rubles.

- Quality crimp;

- Adequate cost;

- Coincident matrix pressure.

- Fine adjustment of the scoring knife is required.

Video about this crimper:

1st place: "Hyperline HT-210C 3446"

Specialized crimper for working with RJ45 type cables in structural cabling systems. With its help, it is convenient to crimp modular connectors. It can also be used for stripping conductors and cables. The working part is made of medium carbon steel, which means the proper strength of the device and its relatively long service life. The operating elements of the structure are covered with black chrome plating, which guarantees resistance to corrosion manifestations, while at the same time increasing the wear resistance of the device as a whole. The working range of cables is from 5 to 11 millimeters in diameter. The established retail price is 860 rubles.

- Budget price;

- Specialized application;

- Good wear resistance.

- Over time, contact failure may occur.

Middle price segment

3rd place: "REXANT HT-376E 8P8C, 6P6C, 6P4C, 6P2C 12-3435"

Specialized device for working with structural cable systems. It can work not only with the most popular RJ45 computer connector, but is also able to crimp wires based on "middle-aged" RJ11-12 telephone connectors.Due to its low weight (only 350 grams), it is very convenient for transportation and storage. The manufacturer provides a one-year warranty for the instrument. The recommended cost for retail chains is 1030 rubles.

- Adequate cost;

- Ability to work with various connectors for SCS networks;

- Extended warranty period.

- Not detected.

2nd place: "KNIPEX KN-975110"

This hand-operated mechanical crimping tool is capable of crimping Western ferrules with high quality. The workflow is greatly simplified by the ratchet linkage mechanism, which greatly contributes to a quality crimp. The design of the device has a blued surface, which perfectly counteracts corrosive manifestations. With this device, it is possible to cut and remove the sheath from flat, unshielded telephone wires, as well as to remove the insulating coating from round cables. Recommended retail price - 3700 rubles.

- Stable quality of crimping;

- The knife does not require sharpening for a long time;

- Interchangeable matrix.

- Not detected.

Video review of the device:

1st place: "Unior 3838909215532"

This hand operated mechanical crimper is used to crimp six and eight lane Western plugs for RJ 11-12 and 45 connectors. Can be used with a suitable tool to strip and cut 6 and 12 mm wide unshielded telephone ribbon cables. The structure is made of carbon steel grade "plus". Two heavy-duty two-component handles are available, adjustable with a spring mechanism.Crimping takes place in parallel processes, which increases its accuracy. The established store price is 4600 rubles.

- Ability to work with SCS-type and telephone cables;

- Adequate cost;

- Rugged housing.

- Not detected.

Premium class

3rd place: "KNIPEX KN-975112"

This device is of the universal type and is intended for removing the insulating coating from round cables and flat unshielded telephone wires. It can also be used to crimp four-, six- and eight-pole plugs. In the design of the crimping tool, a longitudinal cutter and a knife for removing the insulating sheath for lengths of six and twelve millimeters are installed. The applied force for notching/crimping is increased due to the transmission lever, which qualitatively reduces the energy consumption indicator on the part of the installer-operator. The established cost for the retail network is 13,700 rubles.

- Two-component lever handles;

- High-quality performance of all declared operations;

- Versatility.

- For some time now, the kit does not include a "native" screwdriver.

2nd place: "KNIPEX KN-975304"

This hand-held crimping tool is designed to crimp contact tips in a wide range from 0.08 to 10 square millimeters. Square type crimping is used to form optimal contact surfaces for connections to peripheral terminals. The working surface of the crimping tool has an appropriate bluing, which reliably protects it from corrosive formations. The manufacturer has set a super-extended warranty of two years. The recommended cost for retail chains is 17,300 rubles.

- Work safety for the installer;

- Comfort and ease of use;

- Ultra-precise result;

- Ergonomic execution.

- Too overpriced.

Video about this tool:

1st place: "KNIPEX KN-975205"

The tool in question is of the professional type and is intended for crimping nozzles on wires of various types without the use of soldering. The main advantage of this device is its elongated handles, which allows you to work with two hands at once. Increased force may be required when crimping over 6 square millimeters. The head is angled and has a blued surface, which effectively resists the formation of rust and, in general, increases the service life. The recommended cost for retail chains is 20,800 rubles.

- There is a built-in lock function;

- At the machine level, the center of gravity is verified and balanced during production;

- Ability to work with American types of nozzles "AVG";

- Extended warranty period for two years.

- Too overpriced.

Instead of an epilogue

The analysis of the market of the tools under consideration found that almost all of its niches are occupied by models from a foreign manufacturer. If in the budget segment you can still find Russian samples, with pretty good characteristics and at a normal price, then they simply do not exist at higher levels. At the same time, it should be noted that the entire premium segment is completely “occupied” by samples from the German company Knipex. This brand has existed since 1885 and it is not surprising that he managed to capture the top lines completely.However, the price of Knipex tools is very “biting” - it is simply impossible to find their crimper-type device specifically for tips with a price of less than 10,000 rubles. However, if such a crimper was nevertheless found, then it means that it is the essence of a banal fake.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131654 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127695 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124522 -

The best men's sneakers in 2022

Views: 124039 -

The Best Complex Vitamins in 2022

Views: 121943 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114982 -

The best paint for gray hair - top rating 2022

Views: 113399 -

Ranking of the best wood paints for interior work in 2022

Views: 110321 -

Rating of the best spinning reels in 2022

Views: 105332 -

Ranking of the best sex dolls for men for 2022

Views: 104370 -

Ranking of the best action cameras from China in 2022

Views: 102220 -

The most effective calcium preparations for adults and children in 2022

Views: 102014