Rating of the best terminals for connecting wires for 2022

A modern residential building is crammed with electrical equipment, shields and other devices connected to each other by wires of a single electrical network. Connection points of contacts become the most vulnerable places, the failure of which can lead to sad consequences. An important task is the selection and installation of such small fittings for installation as terminals, which are difficult to do without when connecting conductors or equipment.

The element base is constantly updated with advanced developments, excluding old samples from use. Therefore, this review will help you not to get lost in the vast assortment of these electrical products. For a home master who independently equips the electrical wiring in an apartment, it will be useful to learn how to choose the right models, what to look for, and also what mistakes are made when choosing to avoid when buying.

Content [Hide]

General information

Terminal - a metal element or plate for fixing and connecting conductors in electrical circuits, devices and devices.

There are two types of terminals available:

1. Electrical:

- for inductors;

- in generators, starters, power supplies;

- in transformer windings, electric motors, etc.

2. Electrical:

- for electrical panels;

- in energy networks.

A slight difference lies in the values of the permissible current load, which must be taken into account when selecting the desired product.

The use of terminals has a number of positive aspects:

- there is no danger of a spark;

- reliability and long service life;

- connection security;

- increased rigidity;

- ease of installation.

Classification

Terminals are divided according to different parameters.

1. According to the material of manufacture:

• copper

• nickel

• brass

• bronze

2. By insulation:

• isolated

The color informs about the permissible operating currents: red - up to 10 A, blue - up to 15 A, yellow - up to 24 A.

• uninsulated

3. According to the contact method:

• knife

They are used in pairs for conductors with a cross section of up to 6 millimeters. Installed by crimping shank.The connection is made by inserting one terminal into another (male-female contact).

Used in household appliances - irons, refrigerators, etc.

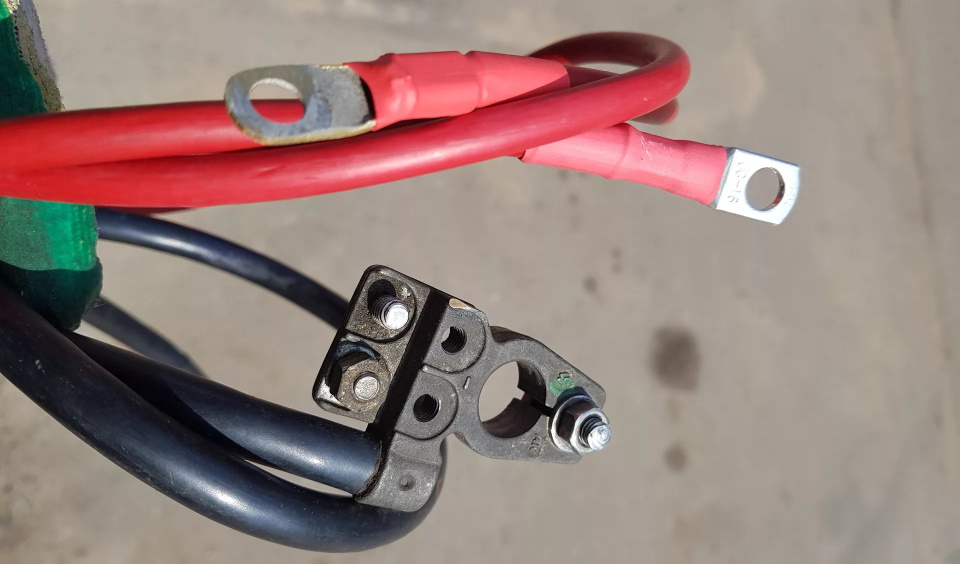

• ring type "O"

For installation in electrical circuits with screw-type contact connections. The screw-on nut prevents the wire from slipping and increases the contact area. The connection is made by soldering, welding or crimping.

Suitable for use not only on cable routes of large diameter, but also in electrical circuits with low currents.

• fork type "U"

Designed for electrical circuits of different power consumption, when it is necessary to frequently reconnect or temporarily connect conductors. The tightness of contact is provided by the twisted screw. Connection is carried out by pressing.

• plug-in type "B"

Detachable product, consisting of a socket with a plug, for mounting on conductors up to 6.6 mm. Marking "A" refers to the plug, "B" - socket.

They are used in low voltage electrical circuits.

• connecting sleeves

Fast and solid contact is made by pressing with special tongs - a crimper. Sleeves are used from:

- copper - GM;

- tinned copper - GML;

- aluminum - GA.

If it is necessary to connect a copper conductor to an aluminum conductor, a GAM sleeve is installed.

- maximum strength;

- outdoor use;

- fireproof;

- resistance to oxidation;

- the impossibility of an accidental break.

- inseparability;

- single use.

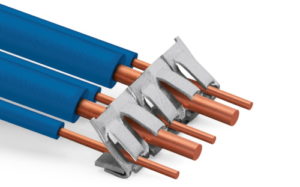

• coupling clamps A wide range of terminals suitable for electrical circuits with small current loads, as well as powerful cable routes with a cross section of up to 16 mm². The connector is fixed by crimping or using bolts. As a rule, they are not used for wiring single-core wires.

A wide range of terminals suitable for electrical circuits with small current loads, as well as powerful cable routes with a cross section of up to 16 mm². The connector is fixed by crimping or using bolts. As a rule, they are not used for wiring single-core wires.

Traditional switching devices

Terminal blocks, unlike terminals, which are an integral part of the conductors, act as devices for switching wires:

- isolated;

- naked;

- with fixed terminals.

Material:

• ceramics - for installations with special temperature conditions or heating devices

• polypropylene - for lighting fixtures

• polyamide - in heavy duty pads

• carbolite - for cars and devices with high vibration loads

• polyvinyl chloride - in low-voltage connections

• textolite and ebonite

To reduce contact resistance and reduce heating, conductive pastes are often used to improve anti-corrosion properties.

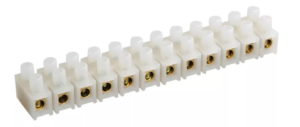

Screw terminals

Electrical installation (construction)

They are made in the form of steel or brass sleeves, equipped with clamps with screws and mounted in a non-combustible polymer block. Permissible load of connected wires with a cross section of up to 35 mm² up to 100 A. Permissible voltage up to 600 V. Mounted in the machine to install fuses that protect the terminal block installation line and outgoing connections.

- ease of operation;

- reliability of contact;

- suitable for vehicles;

- minimum price.

- the possibility of crushing the wires with a screw during installation due to the softness of aluminum or copper;

- high probability of overheating with subsequent loss of contact;

- the need to use brass lugs for stranded copper conductors;

- gradual weakening of the clamping force of the screw with the need to periodically check the fastening.

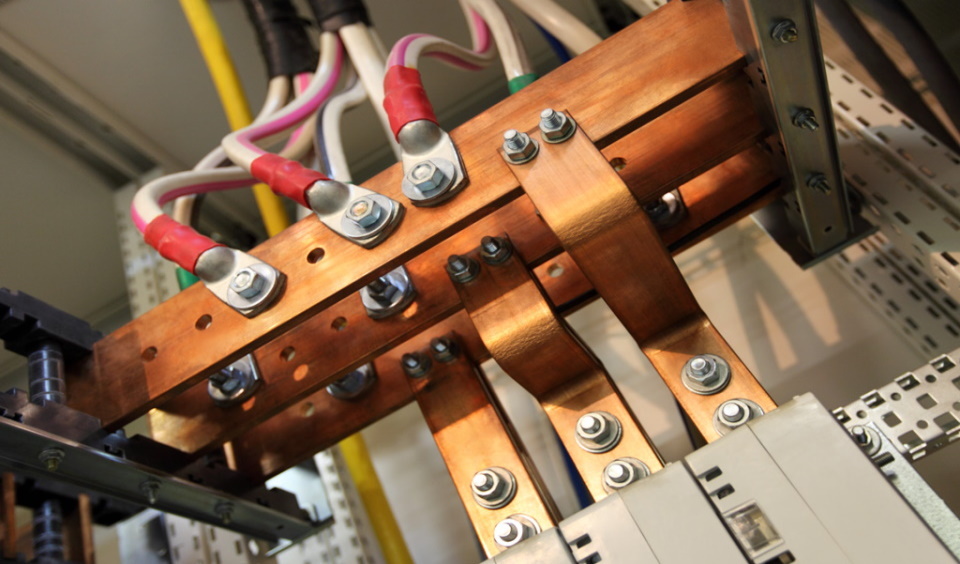

Barrier

They are made in the form of copper or brass plates installed in a getinax case. The permissible current strength at an operating voltage of up to 1 kW is up to 200 A.The cross section of the cable can reach 100 sq. mm. Usually used on powerful power plants.

- reliable connection contact;

- collapsibility of the structure;

- organizing conductors;

- mounting on the dashboard, din-rail, printed circuit board;

- the presence of plexiglass for protection against short circuits or accidental contacts;

- visual control of the state of connections.

- increased transition resistance;

- installation duration;

- the need to equip conductors with tips for reliable contact.

Screw terminals

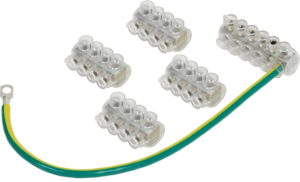

Self-clamping

In a solid polymer case there is a clamping metal plate with a brass coating, which is triggered when the conductor is installed until it stops. Then the bare core is reliably pressed against the tinned busbar.

- ease of installation;

- connection reliability;

- good order;

- low price;

- the possibility of connecting copper-aluminum;

- with the function of improving the contact when heated.

- use for fastening a cable of small cross section no more than 4 mm²;

- low value of permissible current up to 25 A, which limits the use on powerful networks;

- the impossibility of using stranded wires due to the low rigidity when pushing through the plates.

Spring

The polymer housing contains two contact plates made of brass. One is movable and the other is fixed. After installing the conductor, the moving contact is lowered with the latch. The installed spring is compressed, providing pressure and reliable connection.

- easy installation and replacement;

- prevention of accidental contact;

- the admissibility of connecting different materials - aluminum and copper;

- the possibility of using stranded wires;

- the presence of a contact for external grounding.

- the possibility of weakening the pressure of the spring over time or as a result of heating;

- suitable for wires with a small cross section of not more than 2.5 mm²;

- application for currents with a low value up to 25 A.

Terminal blocks of foreign production

The best manufacturers have developed user-friendly technologies and innovations that have made it possible to transform classic terminals into unique connection interfaces.

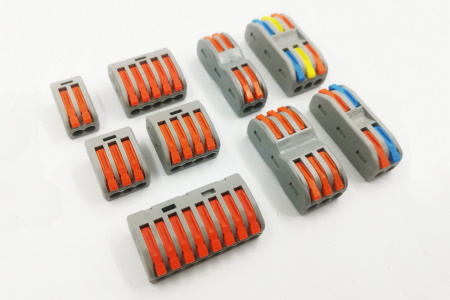

Clamping Push Wire

A one-piece product that uses stiffness properties for secure fastening. Installation is carried out by pushing the stripped end of the wire into the hole. Extraction is carried out by twisting the wire.

Connector types:

- for single wire;

- for wires with reduced stiffness.

It is almost impossible to pull out the installed wire without damage!

Power spring Power cage clamp

Universal terminal block for all types of electrical wires with a cross section up to 95 mm². It consists of a double cage equipped with a spring with a press and a metal bar.

The connection is made with a hexagon for tightening. After installation, the key turns and the lowered press securely presses the conductor.

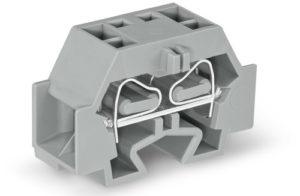

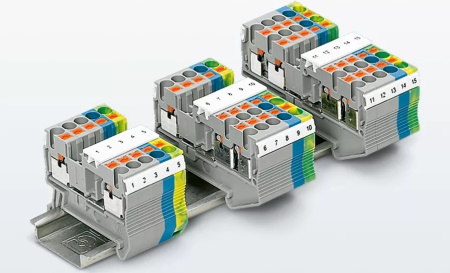

Type-setting self-clamping Cage clamp

Exclusive technology, patented by WAGO, for conductors of all strands up to 35 mm². The connection is made by lifting the spring clip using a special lever. After installing the conductor, the clamp is lowered back.

Self-clamping Cage clamp S

Use does not include the use of electrical tools. The connection is made by installing the bare end of the wire until it stops.

Criterias of choice

The following parameters are taken into account in the process of choosing the appropriate type of terminal block for electrical wiring:

- method and method of installation;

- brand and material of manufacture;

- operating voltage and allowable current;

- number of connected conductors;

- minimum cross section;

- the need to connect wires of different metals.

Section selection table

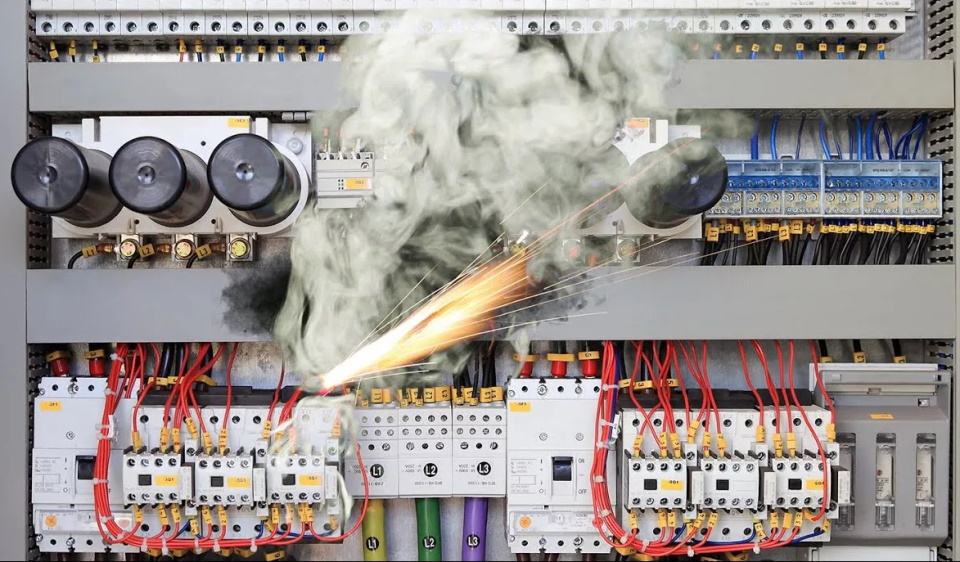

The choice of suitable terminals must be approached thoroughly. After all, it is often necessary to connect different metals, which gradually heat up and deform. As a result - a short circuit and a complete loss of the integrity of the electrical circuit.

Screw terminals or spring terminals are not suitable for connecting aluminum and copper wires!

Where could I buy

Before going to a specialized department of an electrical engineering store to buy the necessary accessories, it is advisable to read the best reviews and recommendations from customers, as well as learn the advice of a professional electrician.

A wide range of terminal blocks is presented in the Electrical Goods stores, so you need to choose budget products that are suitable for a particular installation. You can find out which company is better to buy in advance or directly from a consultant who has undergone special electrical training.

In addition, you can order terminals online in the online store of construction or electrical marketplaces. The Yandex.Market aggregator also offers to find out how much the required terminal block costs, read the description, compare functionality, choose a store and order online.

Rating of quality terminals from the best manufacturers

The domestic market of electrical goods is saturated with products of Russian, European and Chinese manufacturers. Many do not pay much attention to the homeland of the origin of the terminal blocks. However, these small devices, in the event of failure, can significantly affect the safety of property.Therefore, it should be borne in mind that inexpensive Chinese consumer goods at a budget price rarely meet the requirements of standards.

The products of Russian enterprises are distinguished by reliability, but, according to buyers, they are technologically and aesthetically inferior to goods from Europe, which are more expensive, but of the highest quality.

STEKKER

votes 0

The models of the German company are used for reliable installation of electrical circuits with a large number of wires of different cores in a small limited volume, as in a junction box. They are made in a transparent case, which allows you to control the state of the contact. The installation speed is ensured by the rounded ends of the working levers.

Characteristics:

| LD222-412 | LD222-413 | LD222-415 | LD222-418 | LD226-10A | |

|---|---|---|---|---|---|

| Current, A | 32 | 32 | 32 | 32 | 10 |

| Voltage, V | 250 | 250 | 250 | 250 | 250 |

| Section, sq. mm | 0,08-4,0 | 0,08-4,0 | 0,08-4,0 | 0,08-4,0 | 4 |

| Number of contacts | 2 | 3 | 5 | 8 | 12 |

| Amount in a package | 1 | 50 | 40 | 5 | 10 |

| price, rub. | 87 | 900 | 1080 | 247 | 700 |

- special tools or skills for quick installation are not needed;

- convenient marking;

- long service life up to 10 years;

- high quality materials;

- good fire resistance;

- modern design.

- clearly expressed were not identified.

Legrand

votes 2

French manufacturer of electrical products known throughout the world. The most popular product in this segment are screw terminals.

Nickel-plated brass products with high resistance to sudden changes in temperature. The popularity of models is due to the strength and a large range of sizes.

Characteristics:

| Block 2.5-4 sq.mm | Block up to 10 sq. mm | Block up to 16 sq. mm | Terminal block 4x1.5-16 sq.mm | Terminal block 1x6-25 sq.mm | ||||

|---|---|---|---|---|---|---|---|---|

| Current, A | 24 | 57 | 76 | 80 | 100 | |||

| Voltage, V | 250 | 250 | 250 | 400 | 400 | |||

| Number of clamps | 12 | 12 | 12 | 4 | 1 | |||

| Section, sq. mm | 2,5 - 4,0 | 10 | 16 | 16 | 25 | |||

| Average price, rub. | 167 | 310 | 579 | 262 | 649 |

- reliability;

- heat resistance;

- long service life;

- high build quality.

- clearly expressed were not identified.

Legrand Viking 3 terminal blocks - in the video review:

WAGO

votes 1

One of the leaders in the production of terminals from Germany. Products are manufactured at nine factories. Single or reusable products are characterized by high connection reliability and ease of operation.

Models in a durable ceramic case have good anti-vibration resistance and are used for automotive wiring. The current-carrying element is tinned copper, which provides low resistance to strong contact. Some popular models are filled with anti-corrosion gel.

Characteristics:

| 221-412 | 221-413 | 222-412 | 222-413 | 222-415 | 2273-203 | |

|---|---|---|---|---|---|---|

| Current, A | 32 | 32 | 32 | 32 | 32 | 24 |

| Voltage, V | 450 | 450 | 400 | 400 | 400 | 450 |

| Section, sq. mm | 0,14-4 | 0,14-4 | 0,08-4 | 0,08-4 | 0,08-4 | 0,5-2,5 |

| Number of contacts | 2 | 3 | 2 | 3 | 5 | 3 |

| Amount in a package | 20 | 20 | 5 | 20 | 5 | 20 |

| price, rub. | 508 | 570 | 88 | 443 | 164 | 186 |

- tight connection;

- high build quality;

- fast installation;

- stylish design.

- not suitable for use in power circuits with a load power of more than 7 kW;

- requires regular maintenance, therefore, must be in the public domain without covering with plaster;

- many Chinese fakes and similar analogues, but with different characteristics.

Video about WAGO terminals:

Phoenix Contact

votes 0

The world famous brand of the German manufacturer of electrical equipment, operating since 1923. Production is carried out at 12 enterprises.

Consumers are offered over 200 types of terminal blocks used for various connections and mounted on a din rail. Products differ in the increased moisture resistance and fire safety. Current-carrying components are made of anticorrosive copper alloys.

Characteristics:

| Terminal block UT 6 | Terminal block UK35 | Screw terminal UT 35 | Plug-in terminal RT 4 | Universal terminal TB2,5-QUATTRO I | |

|---|---|---|---|---|---|

| Current, A | 41 | 125 | 125 | 32 | 24 |

| Voltage, V | 1000 | 1000 | 1000 | 800 | 500 |

| Section, sq. mm | 0,2-10 | 0,75-50 | 1,5-50 | 0,2-4 | 0,5-4 |

| Connection type | screw | screw | screw | plug clamp | screw |

| price, rub. | 55 | 490 | 226 | 63 | 95 |

- high quality;

- reliable connection with fixation of the longitudinal disconnector;

- visibility of the current state;

- blocking from accidental switching;

- automatic shorting;

- flexible connection;

- compact dimensions.

- clearly expressed were not identified.

Video about the production process of the terminals of this brand:

Conclusion

Thus, choosing the appropriate terminals for connecting wires is only the beginning of the difficult path of an independent electrical circuit for a house during repair or construction. Now you need to make the correct connection so that the entire circuit works reliably for many years without any excesses.

Enjoy the shopping!

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131655 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127695 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124522 -

The best men's sneakers in 2022

Views: 124040 -

The Best Complex Vitamins in 2022

Views: 121943 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114982 -

The best paint for gray hair - top rating 2022

Views: 113399 -

Ranking of the best wood paints for interior work in 2022

Views: 110323 -

Rating of the best spinning reels in 2022

Views: 105333 -

Ranking of the best sex dolls for men for 2022

Views: 104371 -

Ranking of the best action cameras from China in 2022

Views: 102220 -

The most effective calcium preparations for adults and children in 2022

Views: 102014