Ranking of the best adhesive tapes for 2025

For many years now, adhesive tape has been indispensable in decoration, construction, industrial production, and in terms of domestic needs. However, most Russians are accustomed to its other name - "scotch". From the date of the invention of adhesive tape to the present day, more than a hundred years of its evolutionary improvements have already passed. This article will answer the questions of how tape differs from adhesive tape, what types of tapes currently exist, and what they are used for. At the same time, the criteria for selecting this material will be considered depending on the tasks for which it is intended.

Content [Hide]

- 1 Differences between duct tape and tape

- 2 Existing types of adhesive tapes

- 3 Questions of competent choice of teip

- 4 Film base material

- 5 Adhesive layer

- 6 Colors Used

- 7 The most important areas of application

- 8 Masking tape is the most versatile type of tape

- 9 Ranking of the best adhesive tapes for 2025

- 10 Instead of an epilogue

Differences between duct tape and tape

The disclosure of this riddle is rooted in the history of the creation of teip (from the English - tape - "tape"). In the English manner, adhesive tape can also be called that. In early 1930, 3M, based in the US state of Minnesota, applied for a patent for an adhesive tape called Scotch. This application was granted by the Patent Office, and the patent was registered. Scotch tape was originally intended to be applied to car bodywork, in order to maintain an even line of paint in the right places, especially where it was necessary to maintain a clear distinction between two or more colors. Already in the process of long-term use of teip, its additional useful properties were discovered, such as the bonding of certain elements or surfaces.

From the foregoing, it becomes clear that "scotch tape" is just a brand name, which, with large-scale use around the world, has become a household name (as a similar example, the term "photocopy" is used instead of the term "photocopy", which has become widely used thanks to widespread use of Rank Xerox copiers). This shows that there is only one difference: adhesive tape is the name of the brand of the product, and adhesive tape is the product itself. At the moment, there are many manufacturers of such a quality product in the world, among which the most prominent are Universal, Unibob, Staff, Broberg and Officemag.

The scope of adhesive tape is extremely large-scale and completely depends on the materials and production technologies that are used in its production. For example, a reinforced crepe tape will securely fasten wood, plastic, and metal, while a simpler sample made on the basis of a polypropylene film is only suitable for gluing cardboard or paper.

Tape dispensers

As a rule, world-famous companies produce tapes on a dispenser, which means a simplified procedure for their use. Some manufacturers offer adhesive tape installed in snail holders, which is also quite convenient. However, few understand what a dispenser is. And this is just a convenient holder for a roll of adhesive tape (especially a wide one), which speeds up and facilitates packaging and, in general, its use on wide surfaces. Usually, world-famous brands, along with a set of tape spools, immediately supply a dispenser where the tape is already filled. But this device can be picked up and refueled independently.

Below you will find instructions for collecting the simplest variation of this tool:

- It is necessary to choose the right holder, in accordance with the width of the installed tape.

- Fix the tape on the coil, after unwinding a small piece.

- One end of the adhesive tape must be stretched under the clamping roller, before moving the locking plate.

- Fasten the fixing plate back.

- Leave the edge of the tape free at the level of 5-7 centimeters.

Thus, having pressed the free end to the surface to be glued, you just need to pull the roller towards you, measuring the required length, and then cut off the end of the tape using the built-in knife.

Existing types of adhesive tapes

Today's market offers a huge number of their types. For greater convenience, it was proposed to classify it according to the material of manufacture and intended use. According to the scope of use, adhesive tape can be conditionally divided into:

- Economic.

- Painting.

- Packing.

- Clerical.

- Decorative.

- Building.

According to the material of manufacture, it can be conditionally categorized into:

- Polypropylene (as a rule, it is made in a transparent or tinted form, used for packaging or stationery needs).

- Polyethylene foam (used in double-sided variations of adhesive tapes).

- Polyurethane foam (it uses synthetic dense fiber, which has a higher density than the polypropylene film base).

- Paper samples.

- Samples made on the basis of foil.

In more detail, the types of film base and their functionality will be discussed below.

Questions of competent choice of teip

Despite the fact that teips are widely used in production, in the office, and at home, the goals and objectives of such use can be completely different.Thus, in order for the adhesive tape to last for a long time, it is required to comply with its technical characteristics so that it firmly glues the necessary materials.

Dimensions - thickness, width, length

The most important parameter to pay attention to is the size of the adhesive material. It will depend on them what area they can cover, how long it will last, whether it is strong enough for those surfaces that are planned to be connected with it. Using these criteria, it is worth selecting a dispenser.

Standard tapes come in the following widths:

- Narrow standard - suitable for thin cardboard or paper, its width can be 5-35 millimeters.

- Normal standard - will become indispensable when packing small-sized goods or for gluing medium-strength materials (thick cardboard, plastic, corrugated cardboard), its width varies between 48-50 millimeters.

- Wide standard - it is used for increased sealing of seams in heavy parcels or for packing bulky goods, such a standard will be 70-75 millimeters.

In terms of length in a roll, they can have the following length, which will directly depend on the purpose of use:

- 40 meters - simple repair of paper documents, gift wrapping, other small household needs;

- 66 meters - perfectly cope with the packaging of small parcels;

- 100 meters - gluing various seams (medium and small);

- 132-150-200 meters - the use of a dispenser is mandatory, suitable for marking goods and even sealing them (used in commercial cargo transportation);

- 990 meters or more - used in the industrial sector, most often for machine packaging.

Features of the choice of tape thickness

It is measured in microns and in order to determine its strength, it is necessary to pay attention to this, one might say, the most important of the criteria. Depending on this indicator, teips can be divided into the following thickness options:

- 40 microns - office and domestic use, it is possible to securely fasten narrow seams or pack light cargo.

- 45 microns - commercial and industrial use, bonds surfaces more securely due to enhanced adhesion technology (also has frost resistance properties).

- 50 microns - cargo transportation and warehouse tasks, it is able to perfectly adhere even rough surfaces, it will perfectly cope with packing with a load weighing 20-25 kilograms.

IMPORTANT! The adhesive tape thickness indicator consists of two other indicators - the thickness of the base materials and the thickness of the adhesive layer. The standard total thickness used on polypropylene film is 25 microns and the rest is adhesive. This shows how this parameter will affect adhesion.

Film base material

The ergonomics of the adhesive tape, its main properties and application features will directly depend on this indicator. Conventionally, all types of foundations can be divided into:

- Polypropylene - the usual packaging and stationery type of base used to work with documents and photographs, paper and cardboard, decorative packaging.

- Foil - the second name for this type of base is aluminum. It is distinguished by high adhesive properties, so it is suitable even for gluing metal surfaces. Most often used for sealing seams and repairs.

- Foamed - their texture increases the overall thickness of the adhesive tape, but not more than 0.5 millimeters, it perfectly adheres to rough, as well as to porous materials.

- Fabric - synthetic or cotton raw materials are used for their production. Their flexible and lightweight base at the same time has increased adhesion. This tape is used in the manufacture and decoration of furniture fittings, in construction and repair.

- Paper - the oldest samples of adhesive tape, also known as paper stationery tape, are characterized by increased elasticity, capable of stretching strongly before tearing. In the days of the USSR, window slots were pasted over with them for the winter.

Adhesive layer

It can be applied on one or both sides. Accordingly, depending on the task, it will be necessary to choose a certain type of adhesive layer. It will also matter here:

- Purpose of application;

- Type of surfaces to be glued;

- The size and weight of the fastened elements.

Features of using double-sided adhesive tape

It is required to follow certain rules when using a double-sided tape, which is associated with the peculiarity of its manufacture and areas of application:

- Before pasting, it is required to carefully remove all dust and dirt from the surface, and then completely degrease it.

- Prepare the required pieces of teip in advance.

- Having chosen the bearing surface to which another element will be glued, it is necessary to fix a piece of adhesive tape on it (usually, this is either a rough surface or a large one).

- Further, this segment must be pressed tightly against the bearing surface, applying sufficient muscular effort.

- Then the protective film is removed from the second layer of glue.

- And at the end, you need to attach the attached element to the second layer.

IMPORTANT! In most cases, it will be necessary to use a strong and reliable double-sided tape that does not leave marks.However, they usually use an acrylic emulsion in their production, therefore, finding a similar sample is quite problematic. At the same time, acrylic tape retains its adhesive properties for up to two years.

Colors Used

Modern manufacturers produce adhesive tape in various colors (tinted, transparent, brown, yellow, green, red, etc.). Color film is used for labeling goods in warehousing or trade, as well as for shipments. So colors help:

- Systematically track goods and parcels in a warehouse where most of the same boxes are present.

- Protect the contents of the package from UV exposure (tinted samples).

- Pay attention to one or another feature of handling the parcel during its transportation (for example, pasting with a red film means that there is fragile cargo in the box).

- Easily find the seam to open the package.

In trade and cargo transportation (when sealing cargo), a film with a logo is often used. It simultaneously protects the parcel from unauthorized opening, and is also an advertising logo. The logo can be applied in two ways:

- Interlayer printing - the pattern is applied to the substrate before the adhesive layer, which provides additional brightness and durability.

- Surface printing is a simple drawing on the top of the tape. The advantage of this method will be the rapid production of such a base.

The most important areas of application

From the areas of use will envy the type of tape that needs to be applied.

In everyday life, in office activities or typographic, the main areas will be as follows:

- Decoration and artistic packaging.

- Handicraft skills (creating applications and scrapbooking).

- Repair of photos and various documents (most often they use a film on a paper-silk basis).

- Usual packaging of sent items and documents.

- For rubrication purposes (informative notes are made on the film, after which it can be freely peeled off).

Construction and repair:

- Insulation of cracks (for example, masking tape is used for professional window insulation).

- Seam sealing (e.g. reinforced double-sided tape can be used as a moisture absorbent pad).

- Protection from cold and heat (operations with foil-based materials are more often practiced here).

- Fixing elements made of chipboard, plastic, metal or wood.

- Uniform application of the ink layer (for this, the necessary surfaces are delimited with a tape, and excess paint remains on the surface of the tape).

Masking tape is the most versatile type of tape

Although it is believed that this type is most often used by artists and creative people, it has the most non-standard uses. Here are a few of them:

- Checking paint adhesion.

- Creation of various panels in the style of decor.

- Cleaning sticky surfaces from dirt/lint.

- Collection of broken glass objects.

- Collection of small items that were scattered on the surface (beads, needles, etc.).

- Create entries on vertical surfaces when you want to clearly define the outer edges.

- Sealing gaps in wooden windows in winter.

- Sealing joints / seams, in order to prevent the influx of sealant into unnecessary areas.

- Pasting the front parts of the doors during installation in order to avoid the smallest damage (chips, scratches, etc.).

- Pasting the front parts of furniture during its transportation.

A few reasons against using cheap masking tape:

- It may come off during the pasting process.

- Can pass paint when completely saturated when used as a delimiter.

- It may not stick tightly enough, because of which the paint will fall under the film.

- Can be removed with difficulty, leaving behind significant adhesive traces.

- It can peel off together with the applied paint even as a result of a short contact with the glued element.

It is always worth remembering that masking tape, in principle, is not intended for a very long period of gluing. It must be removed in a timely manner and in accordance with the manufacturer's recommendations. Otherwise, small colored areas and large layers can peel off together with adhesive tape. Thus, the painting border will be violated, which will require additional painting, or even a complete repainting.

However, there are a couple of ways to check quality.

Checking the quality of the use of masking tape No. 1

Experts strongly recommend that before the full use of adhesive tape, stick it on a small area of \u200b\u200bthe surface and paint it. After drying, peel off this segment. It is possible to understand in advance whether a given type of masking film is suitable for the paint and material used.

Checking the quality of the use of masking tape No. 2

You just need to pull a few centimeters of the tape from the coil, and then press it firmly back, with sufficient muscular effort. After 5 seconds, pull this segment back - if it moves away from the main coil without problems, then this will be an indicator of high-quality adhesive material. It is worth noting that its thickness will also speak about the quality of the painting type of crepe tape - it should not be less than 125 microns.

Several ways to remove traces of masking tape

Among professionals, the best methods are:

- The use of ordinary soap solution (when it comes to mineral surfaces).

- If the adhesive tape is firmly stuck to the tiled wall, then you can simply moisten it with water, and after a minute wipe it off with a dry cloth.

- On painted metal or plastic (such as double-glazed windows), you can use rubbing alcohol, lotion, WD-40.

- Heating with an ordinary household hair dryer will help remove the film from wood or plastic (in the latter case, the main thing is not to overdo it, because the plastic can be deformed under the influence of hot air).

- As a last resort, you can try a household steamer.

- Traces are removed from plastic window panes with a solution - a teaspoon of soda mixed in water to a mushy state.

Ranking of the best adhesive tapes for 2025

Economy class

3rd place: Brauberg

votes 0

More than a standard sample of Russian production, but made using European technologies. Perfect for packing small parcels and pasting surfaces for domestic needs. Fits perfectly on all types of existing dispensers.

| Name | Index |

|---|---|

| Producing country | Russia |

| Type of | Packing |

| Material | Polyethylene |

| Dimensions, mm | 66000x50x0.05 |

| Weight, gr. | 190 |

| price, rub. | 50 |

- Democratic price;

- Frost-resistant;

- 8 layers of winding can withstand 100 kg.

- Not found (for its segment).

2nd place: SPINO

votes 0

Able to work on plastic, wood and even plastered surfaces. The adhesive layer is made on the basis of synthetic rubber and leaves almost no residue after peeling off.The sample is oriented to work at sub-zero temperatures.

| Name | Index |

|---|---|

| Producing country | Italy |

| Type of | Painting |

| Material | Polyethylene |

| Dimensions, mm | 50000x50x0.05 |

| Weight, gr. | 200 |

| price, rub. | 100 |

- Frost resistance;

- Excellent adhesion;

- Good adhesive backing.

- Not detected.

1st place: Beorol

votes 0

The material is durable and does not come off in separate segments when gluing. Leaves almost no sticky marks on the surface. It can work on puttied surfaces, as well as on brick, plastic, metal and wood.

| Name | Index |

|---|---|

| Producing country | Serbia |

| Type of | Painting |

| Material | tissue |

| Dimensions, mm | 45000x43x38 |

| Weight, gr. | 180 |

| price, rub. | 190 |

- Extended versatility;

- Strong adhesive layer;

- The density of the adhesive base.

- Does not tolerate low temperatures.

Middle segment

3rd place: Aviora TPL

votes 0

A special type of tape designed for automotive work. However, due to its reinforced composition, it can also be used in the plumbing industry, for example, for sealing pipe joints. Differs in the increased moisture resistance. Not whimsical to sudden changes in temperature.

| Name | Index |

|---|---|

| Producing country | Russia-Italy |

| Type of | Reinforced |

| Material | Acrylic polyethylene |

| Dimensions, mm | 50000x50x24 |

| Weight, gr. | 450 |

| price, rub. | 180 |

- reinforced composition;

- The evenness of the overlay;

- Rolls up easily.

- Weak in sealing corner joints.

2nd place: Rexant 09-6130

votes 1

The adhesive base of this type of crepe tape has an EVA base. Perfectly fastens metal profiles, glass and plastic, as well as wood. It is applied both to external, and to internal works.

| Name | Index |

|---|---|

| Producing country | Russia |

| Type of | double sided |

| Material | Expanded polyethylene |

| Dimensions, mm | 5000x30x30 |

| Weight, gr. | 40 |

| price, rub. | 230 |

- Not afraid of ultraviolet;

- It is resistant to compression and various deformations;

- Possesses resistance to chemically aggressive substances.

- Reliable fastening is provided only in a day.

1st place: TESA

votes 0

It is used as a delimiter for painting surfaces inside and outside buildings. The resulting boundaries are particularly clear. Let's combine with the majority of types of paint and varnish materials. Easily separated from the surface even with prolonged adhesion.

- Versatility;

- European quality;

- Easily removed.

- Not detected.

Professional Samples

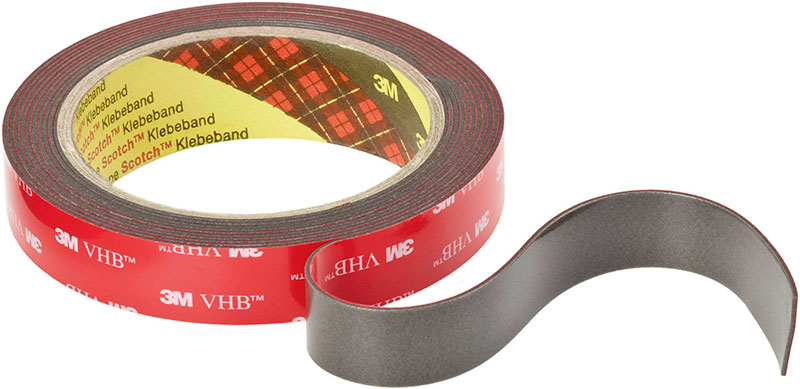

2nd Place: 3M VHB

votes 0

It is a worthy replacement for liquid nails or even self-tapping screws. However, it does not reach the level of welding or threaded fasteners. Used everywhere - from home to production. It is considered the best option for bonding dissimilar materials: plastic, wood, and metals. The load is distributed equally along the entire length of the segment.

| Name | Index |

|---|---|

| Producing country | USA |

| Type of | double sided |

| Material | Foamed polyurethane |

| Dimensions, mm | 1500x12x10 |

| Weight, gr. | 20 |

| price, rub. | 450 |

- Reliability of fastening;

- quality basis;

- Versatility.

- Too high price for a small amount of material.

1st place: 3M BLUE

votes 0

It is characterized by dense adhesion to almost any surface and any shape. Possesses the refined elastic form. Unpretentious to temperature changes. It is rightfully considered a professional-level working material.

| Name | Index |

|---|---|

| Producing country | USA |

| Type of | Painting |

| Material | fabric |

| Dimensions, mm | 1500x48x10 |

| Weight, gr. | 50 |

| price, rub. | 500 |

- Quality;

- Reliability;

- Immunity to temperature changes.

- Short skein;

- High price.

Instead of an epilogue

Scotch has long and firmly entered a person's life as one of the solutions to many problems. But it is always necessary to remember that depending on the task, it is required to select a certain type of this material. But regarding the quality of the samples present on the Russian market, we can say the following: it is not so often that frankly low-quality adhesive materials come across, because the technology for making adhesive tape is quite simple and it is difficult to spoil anything in it. However, absolutely cheap samples should not be used, especially when some very high qualities are claimed for them (for example, the level of adhesion).

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124517 -

The best men's sneakers in 2025

Views: 124031 -

The Best Complex Vitamins in 2025

Views: 121937 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2025

Views: 113393 -

Ranking of the best wood paints for interior work in 2025

Views: 110318 -

Rating of the best spinning reels in 2025

Views: 105327 -

Ranking of the best sex dolls for men for 2025

Views: 104363 -

Ranking of the best action cameras from China in 2025

Views: 102214 -

The most effective calcium preparations for adults and children in 2025

Views: 102010