Ranking of the best cold welding adhesives for 2022

The term "cold welding" is used for the process of joining materials without the participation of external heat sources. In this process, a special adhesive composition is used, which allows gluing various materials - plastic, wood, metals. The purpose of this process is to quickly and reliably attach objects to each other, either to seal them, or to restore their lost parts.

Most professionals consider the popular naming of this method "welding" fundamentally wrong. This welding process is directly related to the effect of high temperature diffusion on the objects to be welded through a special electrode. In this case, individual parts of the object are deformed and even cracks can form. The cold gluing method is devoid of these disadvantages, but in terms of the strength of the resulting seam it is quite capable of competing with the original one.

Content

Varieties of cold welding

It is conditionally possible to classify it by density (consistency) and by scope of use. Based on the density criteria, welding can be divided into:

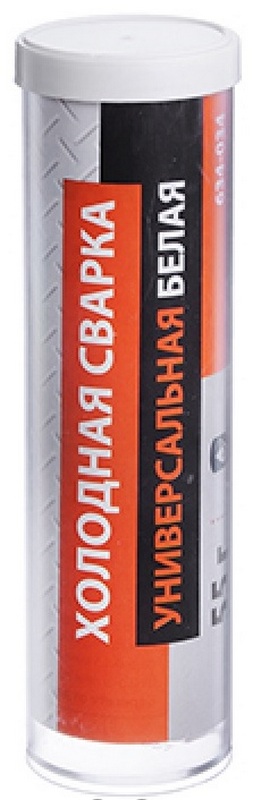

- Plastic or dry - the main advantage of such a composition is the possibility of its immediate use. It is only necessary to cut off a piece of the desired size from the bar on the rod, knead it and apply it to the prepared surface. The rod itself with the substance should immediately be packed in a protective film so that it does not dry out and deteriorate. Such paste, as a rule, is supplied in airtight containers, in which it can be safely stored until required.

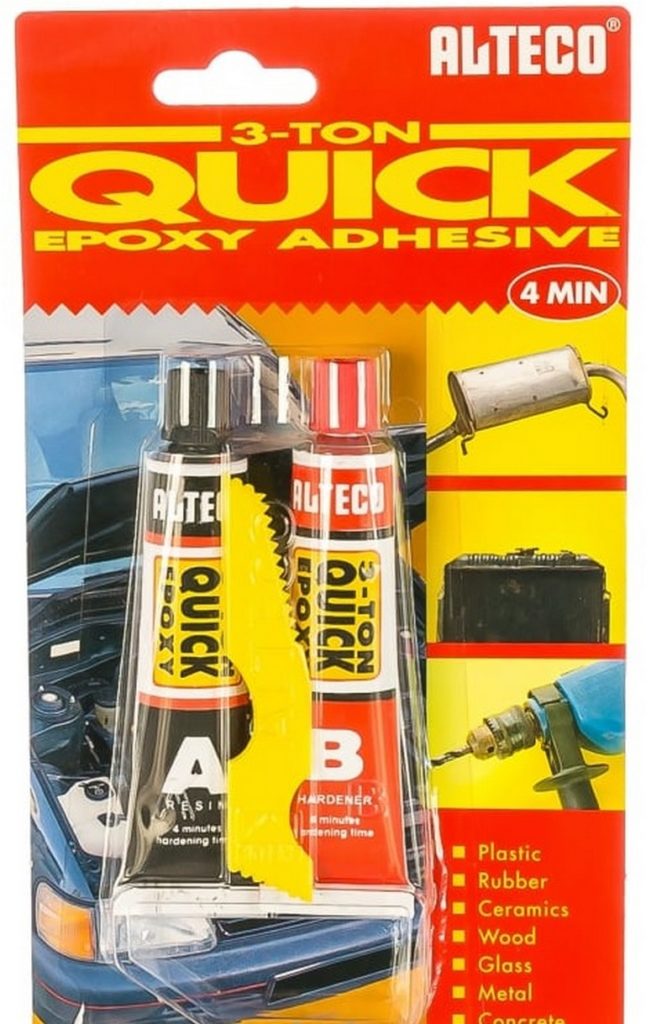

- Liquid - this type also does not require special preparation before use.It consists of a hardener and epoxy resin, which are in different tubes in the kit, and which must be mixed to work. Moreover, it should be mixed in the proper proportions, otherwise the strength of the seam will leave much to be desired. Storage in tubes will ensure the preservation of the beneficial properties of both substances for a long time.

According to the scope of use, cold welding is divided into:

- Universals - such compositions are very useful in the household for various small gluing jobs. They are able to work perfectly on plastic, wood, metal and other materials. The main disadvantage is that the seam is too high quality and long.

- For bonding specific materials - for working with certain materials, various substances are used and it is important to use them in strict accordance with the purpose. The range of such compositions is much wider - in addition to standard wood, plastic, metal, it is possible to use concrete, glass or ceramics. Bonding objects with this method of cold welding means applying high-quality seams.

- For auto repair - for these purposes, heat-resistant and resistant to many negative effects of adhesive welding is used.

- Heat-resistant - such adhesive welding is used on objects, the use of which is expected in conditions of high temperature background.

- For the performance of work in specific conditions - these substances are used in the performance of work under certain conditions. For example, there are adhesive masses that can be used under water, as well as substances that work with objects from the surface of which it is impossible to remove oils or oil products.

IMPORTANT! The range of qualities and areas of use for cold welding is extremely wide and will directly depend on its composition. As a rule, most modern compositions have some properties of versatility, to one degree or another. For example, they are resistant to low temperatures, can withstand the effects of solvents and various acids. Also, they are able to cope well with the function of a sealant.

Glue welding work on metal

The scope of metal work is quite wide. In most cases, this concerns the repair of plumbing and metal parts of household objects. Most often it is used to repair:

- Sewerage and water supply;

- heating radiators;

- Tanks made of metal (cast iron, steel or iron).

- It is worth noting that although the adhesive substance provides a strong seam, it will never completely replace full-fledged electric welding.

At the same time, auto repair work can also be attributed to metal work, because most car parts are made of metal. With the help of cold welding it is convenient to repair:

- Radiator;

- Car body;

- Fuel tank capacity;

- Exhaust pipe.

IMPORTANT! If work is expected on automotive elements that are subject to increased heating during operation (for example, a radiator or exhaust pipe), then a heat-resistant composition should be used. Also, you should pay attention to the impact properties of the future seam.

Step-by-step recommendations for working with metals:

- Preparation of the processing site is a very important step, because the welding compound hardens quite quickly within 5 to 20 minutes, so it must be applied to the prepared surface.As a rule, it must first be degreased with an acetone mixture and cleaned of dust and dirt. The ideal option would be to clean the object with sandpaper, which forms a rough surface, which will later help a more reliable grip.

- Prepare an adhesive substance - this stage is different for different types of cold welding. The most common and simplest way is to use a homogeneous plastic composition, which you only need to knead in your hands.

- Filling the area to be treated - the prepared adhesive mass is applied to the cleaned base. It is important to process not only the target site, but also some area around it for reliability purposes.

- Waiting for drying and finalization - the final stage will be the drying of the applied mass (usually this stage takes 24 hours). It is important to achieve complete drying and only then carry out sanding and coating with enamel / paint of the applied seam.

- The connection of two metal objects must take into account some features. As a rule, welding is carried out with an overlap, that is, an adhesive substance is applied to one metal object, and a second metal object is already attached to it. This is followed by the stage of their tight squeezing. As a result, a chemical reaction occurs, in which the upper layers of metal objects undergo melting, and as a result of pressure, they are attached. Thus, their crystal lattices intermingle. However, this seam will be less durable than with electric welding.

It is worth noting that cold welding for metals usually consists of three components:

- Epoxy resin - responsible for the adhesiveness and plasticity of the composition;

- Metal element - the ability to work on different metals depends on its properties;

- Reinforcing additives - their properties are responsible for the strength of adhesion (adhesion).

Glue welding on plastic

Another option for home use of cold welding. Also suitable for small repairs in relation to various household items. So, by cold welding you can fix:

- Some fishing tackle;

- Garden tools;

- plastic utensils;

- Pipelines made of metal-plastic structures;

- Plastic car parts (elements of interior decor, bumpers).

Step-by-step work on a plastic base, in general, is not much different from working on metal:

- Initial preparation - degreasing and cleaning the surface, and in the case of working on a crack - cleaning its edges with sandpaper;

- Applying the adhesive mass - after preparing the adhesive welding (if plastic - kneading, if liquid - mixing the components in the proper proportions), the banal application of the substance to the target area, followed by processing the edges;

- The final stage is to wait one day until completely dry.

Glue welding on linoleum

Cold welding is very convenient to eliminate various gaps at the joints of different types of linoleum sheets. The principle of operation of the composition will be to melt the edge of the sheet by means of the applied mass, and then connect it with the help of the resulting seam, which is almost invisible to the naked eye.

However, the phased work of welding the linoleum base has its own characteristic differences:

- Initial preparation - it is necessary to carefully cut the sheets of linoleum, especially if they are overlapped, so that a clearly visible border forms between them.Then it is necessary, with the help of masking tape, to secure the surface that is not supposed to be affected from melting. The composition of the welding mass may contain special solvents, which can harm the surface of the bonded material (stains and burns may remain).

- Direct welding process - in this case, a nozzle in the form of a needle or a cone is necessarily used. The nozzle is inserted into the recess until a drop forms (3 mm in diameter minimum), and then slowly stretches along the incision line.

- The final stage - after 24 hours of drying, is checked for plasticity and solidification, and the protective masking tape is removed. The result should be a smooth and almost imperceptible seam.

It is worth noting that for cold welding on linoleum, various compositions can be used, which may have different markings. This will depend on the filler (liquid PVC and solvent) included in the composition, as well as on their proportions used:

- Type "A" - it is characterized by a high solvent content, which means its high liquidity. For its use, a working needle nozzle is mandatory. This type of welding is needed to seal seams that are at least 1 millimeter;

- Type "C" - in this type of solvent composition, it is slightly less, so its density is immediately noticeable. It is used for gaps from 2 to 4 millimeters. For its application, you can use a wide nozzle in the form of a cone, it smooths out uneven edges well;

- Type "T" - the consistency of this mixture is very saturated, which is more suitable for joining multi-component materials than standard linoleum. As a rule, it is used in the field of industrial tasks for wide seams.For its application, a T-shaped nozzle is used, which does not allow the surface to quickly absorb glue, which makes the formation of a seam better.

Glue welding work on ceramics

One of the advantages of cold welding is that it is able to work with brittle materials, and not only close cracks, but also glue individual parts of objects. This process has some features, so it is worth considering its stages in more detail:

- Preparing the parts - first you need to collect all the broken parts, even the smallest ones.

- Surface preparation - all found parts should be cleaned of dust and dirt and heated to a temperature of 40-50 degrees Celsius (in order to better bond). This process can be carried out using a gas burner (ceramics are not afraid of it).

- Welding procedure - each part is installed in its place, and the joints are fastened with a previously prepared welding substance. The leaning part must be supported for some time, and then calmly left. By sufficient (but may not be complete) drying of the seam on one part, the next one is glued. Thus, the entire broken structure is assembled.

- Sealing joints and holes - due to the fact that some parts may be small or simply lost, gaps may form in the structure. These shortcomings are also eliminated by glue welding. It is advisable to use a plastic substance.

- The final stage - after hardening of all seams, it is required to sand them with sandpaper and paint with enamel.

Recommendations for use

Despite the fact that the process of using cold welding is quite simple, you should still know some of the features of its use.

Drying period

It is individual for each type and even for each brand, but it usually dries completely within 24 hours. However, there is such a thing as “pre-drying” - it means that the substance has already created the final form, is no longer deformable, but has not yet reached a stable connection with the processed object. In this position, the applied seam is still vulnerable, so you should not subject the processed object to excessive loads. The “pre-dry” usually occurs in the first 5-20 minutes after application, so this period is sufficient for the user to form the seam itself. Some brands of cold welding reach final drying in half a day, but professionals recommend that you start using the glued object only after 24 hours.

Precautionary measures

At first glance, cold welding itself may seem like a harmless composition, but certain safety measures must be observed when working with it:

- It is preferable to work in goggles and gloves - do not allow the composition to get on open skin or eyes. In the event of a traumatic situation, you need to rinse the damaged area of \u200b\u200bthe body with clean water and immediately consult a doctor;

- Storage of the adhesive mass should be carried out in a place inaccessible to children and pets;

- Do not allow particles of cold welding to get on food.

Typical errors at work

First of all, these include:

- Inattention to the expiration date - the expired expiration date will cause poor-quality seams;

- Surface preparation contrary to the recommendations of the welding manufacturer - the weld can simply fall off;

- Leaky storage of the adhesive composition - the composition will simply harden and will not be suitable for use (for plastic compositions, it is possible to heat them in warm water, but this will reduce the quality of the seam);

- Use of the composition for other purposes - the use of the composition for welding materials for which it is not intended;

- The use of the composition without taking into account the conditions of future operation - if we are talking about the operation of a repaired object in conditions of an elevated temperature background, then the welding applied to it must have heat resistance;

- Non-compliance with proportions when mixing liquid formulations - improper proportions can lead to an almost complete lack of adhesion (adhesion) for these formulations.

Storage rules

The storage conditions of the adhesive substance will be the key to safe and high-quality work with it:

- Exclusion of welding raw materials from getting under ultraviolet rays;

- Storage should take place in a cool and dry place;

- Storage is carried out in sealed packaging (usually this applies to plastic formulations - it is better to pack them in a wrapping film or a tightly closed tube. Liquid formulations are supplied in tightly twisted tubes).

Ranking of the best cold welding adhesives for 2022

Budget segment

3rd place: "ERMAK white"

This cold welding is of the universal type and is based on a solid substance. With its help, it is easily possible to process plastic and ceramics, wood and glass, concrete and plastic. The main composition is epoxy resins, the type of hardening is reaction. A prerequisite for drying is the presence of oxygen. Supplied in a convenient tube, which ensures tightness and durability of storage. The mass of the composition is 55 grams, the country of manufacture is Russia.The recommended cost for retail chains is 55 rubles.

- Versatility;

- Quick preparation for use;

- Two-component composition.

- Small tube volume.

2nd place: "Diamond AZ-0039"

This type of adhesive substance is positioned by the manufacturer as "cold welding for highly specialized purposes" and is used for car repairs. However, no one forbids the use of welding for other needs. It perfectly glues ferrous and non-ferrous metals, glass and plastic. Regarding auto repair: suitable for sealing cracks in the exhaust system and other mechanical components located in hard-to-reach places. It can be used in conditions of high humidity and on oily surfaces. The weight of the plastic substance is 58 grams, the country of manufacture is Russia. The recommended cost for retail chains is 100 rubles.

- Heating is possible in case of excessive hardening;

- Withstands temperatures of +150 degrees Celsius;

- Economic cost.

- Requires fully sealed storage.

1st place: "KUDO Cold welding 60g"

Another representative of a highly specialized direction - the manufacturer offers to take this substance for the repair of plumbing equipment. However, processing of other materials is also possible: most of the existing types of plastic, wood and ceramics, metals and glass. The composition shows particularly excellent results when processing hot and cold water supply pipes made of polyvinyl chloride. Has frost resistance. The mass of the substance supplied in the tube is 60 grams. Country of origin - Russia. The set price for a store sale is 105 rubles.

- Frost resistance;

- High-quality PVC bonding;

- Special application.

- Small volume.

Middle price segment

3rd place: "Cold welding with steel filler ELTRANS plastic chuck"

This type of welding is designed to bond parts made of durable types of steel, and it is also capable of restoring fasteners and their threads. The substance itself has extended tightness, the frozen seam is able to withstand significant dynamic and static loads. After the seam has hardened, it is possible to carry out mechanical processing (grinding and drilling, as well as threading). Excellent resistance to cold, oily substances, moisture, gasoline. Works can be carried out on oily and damp surfaces. The mass of the supplied substance is 58 grams, the type of application is the mixing of 2 components. Country of origin - Russia. The set price for shops is 105 rubles.

- 2-component composition;

- Versatility;

- Resistance to many negative phenomena.

- Not detected.

2nd place: "WOG high-strength, metal-filled WG0740"

This welding pattern is characterized by high versatility, because it is able to glue as many materials as possible. In addition to the standard ones, it is possible for them to process: rubber, stone, drywall, aerated concrete and even paper. The composition is based on synthetic resin. The hardening condition is the mixing of the components. Has a brown color. After processing, it is not very amenable to finalization (grinding and cleaning). The mass of the supplied substance is 60 grams, the country of origin is Germany.The recommended cost for retail chains is 140 rubles.

- Ability to work with non-standard materials;

- Excellent adhesion;

- Convenient container for storage.

- Finalization issues.

1st place: "Universal fast cold welding ASTROhim Аc-9319"

This welding belongs to the category of universal, is high-speed, so it is convenient to have it in a portable repair kit. Ideal for bonding most types of PVC and plastics, glass and ceramics, and metal. It has an extended temperature operating range - from +150 to -60 degrees Celsius. The composition is one-component. A prerequisite for curing is the presence of oxygen. The weight of the supplied substance is 55 grams. Country of origin - Russia. The established cost for retail chains is 150 rubles.

- Hiking specialization;

- Sealed storage;

- Extended operating temperature.

- Small tube capacity.

Premium class

3rd place: "ALTECO 56.7g 6H11E"

This type of welding is characterized by increased adhesion. Able to work on most materials: stone (natural and artificial), wood, glass and ceramics, rubber and plastic. The composition is resistant to acid environments, low combustible, slightly flammable. Adhesion occurs within 3-5 minutes. It has a two-component composition and requires mixing. Supplied in large tubes with a total capacity of 90 grams. The country of origin is China. The established price for store chains is 190 rubles.

- Almost instant adhesion;

- Excellent value for money and quality;

- Large container volume.

- At first, it emits a pungent odor.

2nd place: "HOBBY for plastic 55g 314"

An excellent and high-quality option for solving small household tasks. Great for repairing plastic items. Able to provide almost instantaneous setting and can successfully resist the effects of water. The composition itself is a plastic bar, consisting of a hardener and an adhesive base. After mixing and kneading, a homogeneous mass is obtained, which is very convenient to apply. Works great for micro cracks. The mass of the supplied substance is 55 grams, the country of origin is Italy. The established cost for store chains is 290 rubles.

- Ease of use;

- High-quality adhesion;

- Successful work with microcracks.

- Too narrow focus.

3rd place: "Transparent cold welding POXIPOL 70ml 00269"

An excellent quality sample of transparent welding for industrial use. It has the ability to apply wide seams, perfectly smooths out irregularities and fills the resulting cracks. The composition does not contain excessively active solvents, and it is also low-flammable. With its help, it is easy to connect almost any material, up to joining water reservoirs to each other. The mass of the supplied substance is 120 grams, it requires mixing the components. Country of origin - Uruguay. The recommended price is 660 rubles.

- Working with all kinds of materials;

- Fast adhesion;

- Ability to apply wide seams.

- High price.

Instead of an epilogue

It is very gratifying that the market for the materials in question is almost entirely owned by Russian manufacturers. And even those brands that are originally of foreign origin are already quietly produced under license in the territory of the Russian Federation. Thus, a potential consumer only needs to decide on the processing material, and it will not be difficult for him to choose cold welding for him. Moreover, the price of the adhesive substance is not exorbitant.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131662 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127701 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124527 -

The best men's sneakers in 2022

Views: 124045 -

The Best Complex Vitamins in 2022

Views: 121948 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114986 -

The best paint for gray hair - top rating 2022

Views: 113403 -

Ranking of the best wood paints for interior work in 2022

Views: 110330 -

Rating of the best spinning reels in 2022

Views: 105336 -

Ranking of the best sex dolls for men for 2022

Views: 104376 -

Ranking of the best action cameras from China in 2022

Views: 102225 -

The most effective calcium preparations for adults and children in 2022

Views: 102019