Rating of the best adhesives for baseboards and moldings for 2025

Finishing almost any room should be completed with the installation of skirting boards or moldings (decorative overhead strips). They are considered an integral part of the renovation, made in a highly artistic, residential style. It is possible to fix these elements in various ways, but the most common and effective of them is to attach the overlays to glue. Even a person without experience in the finishing business can perform such work, because mounting on glue does not require the use of any special tools. The main point is to choose a high-quality adhesive composition for this operation.

Content [Hide]

- 1 Moldings and skirting boards - features and differences

- 2 Existing types of adhesive for moldings and skirting boards

- 3 Features of the use of certain types of adhesives and control of quantitative costs

- 4 Required technical properties of the adhesive

- 5 "Pros" and "cons" of fastening moldings / skirting boards to adhesive mixtures

- 6 General rules for gluing

- 7 Features of gluing some types of skirting boards

- 8 Features of working with polyurethane strips

- 9 Rating of the best adhesives for baseboards and moldings for 2025

- 10 Instead of an epilogue

Moldings and skirting boards - features and differences

If we talk about skirting boards, then they are more or less familiar to everyone. With their help, the free space between the walls and the floor covering is isolated. Thus, the skirting boards are only in contact with the flooring.

Moldings are also called special decorative elements, which are structurally picture frames, imitation stucco moldings or patterned ceiling linings.

For both elements, the main purpose is the ability to mask empty joints, gaps and minor imperfections in the finish.Thus, it is convenient to decorate mirror frames, door frames or decorate ceiling joints.

At the same time, the elements under consideration can also have an applied purpose, namely: with their help it is possible to zone residential / working areas or protect individual finishing details from mechanical influences. All this will help to visually change the spatial forms of the room. The material from which the moldings / skirting boards are made is extremely diverse and can be matched to any type of finishing work, especially since it can qualitatively differ in the type of relief.

Existing types of adhesive for moldings and skirting boards

The need to use a certain type of adhesive will directly depend on the material from which the part is made, as well as from the material from which the base is made, on which this part will be attached. Thus, the decision to use the appropriate adhesive substance will most often be quite individual. However, there are several common types of glue that are suitable for most cases:

- Polymer glue - it is quite versatile and can be used on almost all materials - it can be foam, plastic, and even polyurethane. The initial density of this substance is very viscous, which means that adhesion is carried out in a very short period, so it is not necessary to manually hold the attached part at the base for a long time. However, these mixtures may have an unpleasant pungent odor, or they may not harden very quickly. Nevertheless, there are already samples on the modern market that are devoid of these shortcomings (but their price is very high).

- "Liquid nails" - this type of glue got its name due to the increased adhesion properties when connecting objects - "it's the same as nailing on nails." In fact, the composition is a very viscous adhesive, which can be applied in a thick layer and even on uneven surfaces. From this it is clear that if the master does not have time for preparatory work on cleaning the mounting surface, then “liquid nails” will be the ideal solution. However, some types of "liquid nails" interact very poorly with various synthetic materials, such as polystyrene foam or polystyrene foam - they can simply corrode such skirting boards or moldings. Therefore, before use, you should read the instructions from the manufacturer of the “nails”, which will definitely mention the compatibility of the composition with similar materials.

- Polyvinyl acetate glue - roughly speaking, we are talking about PVA glue and its various variations. Its undoubted advantages include the absence of pungent odors, but a major drawback can be called a large quantitative consumption. In addition, it has a rather liquid consistency, which is why it dries longer than other adhesive substances.

- Putty is a classic, versatile and profitable option for gluing moldings and skirting boards. Especially good for fixing ceiling strips. The putty itself is characterized by its density, which ensures reliable adhesion to the surface. It is especially important to use the putty method when installing planks even before closing the outer layer of the wall. In addition, cracks can also be sealed with putty.

Features of the use of certain types of adhesives and control of quantitative costs

As mentioned above, there is practically no universal type of glue for skirting boards, and the use of each specific brand will depend on many factors. For example, polymer-based adhesives should only be used in well-ventilated areas, and the same Moment, due to its special viscosity, once it hits the surface, is very difficult to remove. In addition, if the substance is transparent, then unauthorized contamination is unlikely to be noticed the first time. In any case, for synthetic adhesives with similar qualities, it is better to use a gun.

If we touch on the topic of "liquid nails", then in their series there is a special variety - neoprene "liquid nails". They are ideal for mounting skirting boards at low temperatures or when the environment is extremely saturated with moisture. However, this type of "nails" is very toxic and it is possible to work with them only in conditions of constant ventilation of the room where the work is carried out.

But acrylic-based glue is completely safe for the human respiratory system. However, it is not able to maintain its functional fastening properties at low temperatures. From this we can conclude that it is better to use it for finishing interior residential premises, because, as a rule, low temperatures are not set in them.

Regarding cost calculations. Based on the fact that strips, moldings and skirting boards rarely exceed rather narrow dimensions in width, the approximate consumption can be set based on the number of strips that need to be glued. Thus, half a liter of adhesive will be enough for ten square meters of area.From here, the following pattern can be traced - glue for skirting boards and moldings is never sold in bulk containers.

Required technical properties of the adhesive

To achieve the best result in the process of gluing moldings and skirting boards, the selected adhesive must have the following properties:

- Operational strength;

- Ease of layering

- Reasonable drying time;

- Absence of a pungent odor (or its complete disappearance after drying);

- The product is directly focused on working with the selected material.

Guided by these simple moments, it will not be difficult to choose an adhesive substance for a specific task. Nevertheless, professionals call the main criterion on which the choice should be based, this is the material from which the strips and the mounting base are made. Traditionally, ceiling moldings contain elements of synthetics and are made of PVC, foam or polyurethane. It is important here that the adhesive base does not conflict with these materials. Things are easier with traditional bases - clay, gypsum and wood - for them it is much easier to choose a mixture. It is important to remember that properly selected technical qualities of the adhesive will make the result of work more durable.

"Pros" and "cons" of fastening moldings / skirting boards to adhesive mixtures

Among the undoubted advantages of the considered method, the following can be distinguished:

- Strong adhesion to the mounting base;

- Relatively short time finishing process;

- A wide range of fasteners in the current Russian market;

- The ability to fix skirting boards / moldings even on unprepared bases;

- The ability of some types of compounds to successfully withstand temperature extremes and an increase / decrease in humidity (and this allows the compositions to be used in rooms where there is no thermoregulation for a certain period of time, for example, a country house in winter).

Among the shortcomings, it is possible to note:

- 100% need to level the base surface for fixing planks made of rigid materials (wood, gypsum, clay, rigid polyurethane, MDF);

- The likelihood of a long period of adhesion for some types of adhesive substances and materials - it takes some time through muscular effort to maintain the connection until hardening occurs.

General rules for gluing

Any plank, be it a molding or a plinth, can be glued quickly and without problems, using the following procedure:

- The selected segment must be turned with the back, and the adhesive should be applied to it in small drops at a distance of 3-5 centimeters from each other (for narrow parts);

- If the width of the part exceeds 6 centimeters, it is preferable to apply the mixture on the back side in the form of a wavy line;

- The lubricated element is unfolded and attached to the desired place of the base - the ceiling, plinth, wall and pressed tightly (should be held for 10-15 seconds on average);

- On their own, the seams should carry out a tight hold after 15-20 minutes;

- It is worth remembering that it is necessary to glue the fillets from the beginning of the corner;

- If the molding is glued to the stretch ceiling, then fixing occurs exclusively on the wall surface, but not on the unstable surface of the stretch ceiling;

- The ends of the planks should also be smeared with a thin layer, then they are attached in the desired corner, and the remaining adhesive is quickly removed with a thin spatula.

Features of gluing some types of skirting boards

Wooden

On them, it is preferable to apply the composition with a thin line along the entire back. However, if their width is small, then the spot application method can also be used. However, the edges of the plank must be properly lubricated to prevent gaps from forming at the seams. The main thing is not to fix the part right away, but to wait a few seconds and only then press the bar to the surface - this is how the adhesion will occur as efficiently as possible.

Plastic

Basically, they are used to neatly disguise wires and cables in residential areas. The adhesive substance must be applied to the stiffener and immediately pressed to the desired surface for several minutes. It is worth remembering that the coupling process most reliably occurs with carpet, linoleum, wood and tile bases.

However, it is for plastic strips that there are several significant points:

- It is always worth considering the level of rigidity of the molding rib;

- Skirting boards made of foamed PVC break quickly due to their lightness;

- If a type of PVC is required with semi-rigid qualities, then it is mounted as a long strip;

- Baguettes made of plastic have the greatest strength;

- Before gluing, these skirting boards need to be laid out around the perimeter and the joints cut in the right places;

- If it is assumed that there are decorative plugs at the corners and joints, then they are installed simultaneously with the main array of the plank;

- It is better to apply the composition in small drops within 8-10 centimeters from each other;

- On short segments, this distance can be equal to 4 centimeters, and on complex transitions - every 2 centimeters;

- It is preferable to cover wide planks with a wavy line of the adhesive mixture;

- Any plastic corners/joints are covered additionally.

Self-adhesive options

They are the ideal solution for uneven walls and are able to create a type of finish between the walls and the floor that the uneven joints will simply be invisible. Perfectly combined with linoleum and laminate, look great in large rooms. According to their structure, self-adhesive skirting boards can be made of aluminum or polyvinyl chloride. They can also have their own coloring, for example, wood or stone. External and internal corners in such models are easily formed due to the fact that the base itself bends very easily. In some cases, masking tape will help improve the artistic look. The only negative is that it is required to fix the self-adhesive plinth as accurately as possible, because then it will be very difficult to separate it from the wall.

Features of working with polyurethane strips

Adhesive selection

The most common and popular type of connecting substance for them will be the domestic brand "MomentMontazh". In principle, any other type of substance with increased adhesion strength or "liquid nails" can also be used. In extreme cases, for lack of better options, it is possible to attach them even to compositions intended for tiles. But still, from the point of view of professionalism, a specialized option should be used. Moreover, it must be understood that if the work is supposed to be carried out in a city apartment, then the adhesive must cause excellent adhesion to the concrete base of the walls.

At the same time, a special type of glue can be used to coat the joints, in which, after being applied to the bar, the latter melts.Thus, after butt shrinkage of all elements, the risk of structural divergence will be eliminated.

Foundation preparation

For this process, the following algorithm can be applied:

- The surface of the walls and ceiling must be thoroughly cleaned of dust and dirt;

- It is extremely important to wipe off any existing grease stains;

- To consolidate the cleaning effect, it is better to re-degrease the base;

- Before gluing, it is worth waiting for the base to dry completely;

- For a better overlay, it is preferable to prime the walls and ceiling.

Rating of the best adhesives for baseboards and moldings for 2025

Budget options

3rd place: "Master Klein"

votes 0

A good option for rare work on gluing various planks. The manufacturer positions this sample rather as not the main finishing tool, but as a means of restoration and repair work. Made on the basis of acrylic, has a high degree of adhesion. Works great on synthetic materials, while natural adhesion is not guaranteed. The volume of the bottle is 310 grams, the birthplace of the brand is Russia, the recommended price for stores is 190 rubles.

- Budget price;

- Ease of application (special nozzle);

- Sufficient volume.

- Weakly adheres to high density materials.

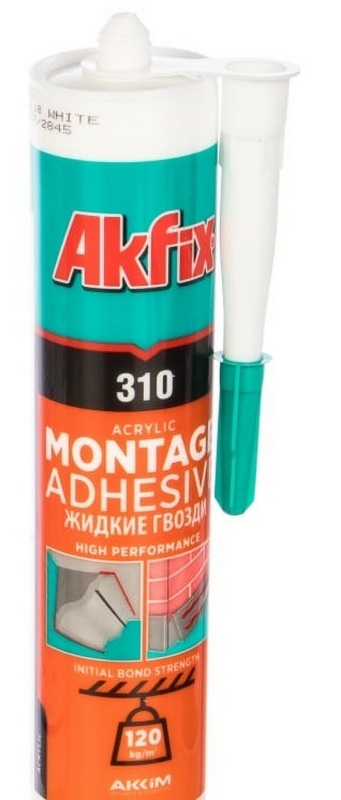

2nd place: "Akfix 310"

votes 0

A universal composition from a Turkish manufacturer with enhanced adhesive properties. Works great with almost all materials - synthetic moldings, wooden skirting boards, polystyrene foam, ceramics, MDF and chipboard. The composition is based on acrylic, which means that there are no harsh odors during operation.The total volume of the container is 310 grams, the home of the brand is Turkey, the recommended price for stores is 260 rubles.

- Adequate price;

- Ease of use through the construction "nose";

- Practical versatility.

- Reduced viscosity.

1st place: Zubr 41337

votes 0

This domestic sample is directly intended for the installation of moldings on various surfaces, such as plastic, wood, brick and concrete, metal and ceramics. Gluing occurs quickly and reliably, docking structures, even in a decorative solution, are easy to install. Work can be carried out both inside and outside the premises. The composition is resistant to low temperatures. The container volume is 300 grams, the brand originates from Russia, the recommended price for retail chains is 270 rubles.

- Specialized functionality;

- Sufficient container volume;

- Adequate cost.

- Not detected.

Middle price segment

3rd place: "TriS GFIX Force KS09"

votes 0

Another version of a highly specialized substance, specially designed for gluing ceiling skirting boards and slabs on hard surfaces made of gypsum, concrete, wood and chipboard. The substance itself is transparent, full coupling occurs 15-20 minutes after application, the mixture is environmentally friendly and absolutely harmless to humans. The base element is polyvinyl acetate. The container volume is 500 grams, the brand is from Russia, the recommended retail price is 280 rubles.

- Quick hitch;

- Ease of application;

- Ecological purity.

- Not found.

2nd place: "Moment Montage Super Strong Transparent"

votes 0

A legendary sample from a Russian manufacturer with enhanced adhesive properties, which is the best solution for working with polyurethane strips. It has a transparent color, can be used for various types of work, regardless of the ambient temperature - frost-resistant ingredients are used in the chemical composition. The main types of processed materials are: foam, wood, PVC, ceramics, chipboard and polyurethane. The volume of the tube is 185 grams, the birthplace of the brand is Russia, the recommended store price is 290 rubles.

- Frost resistance;

- High adhesion;

- Versatility.

- Small container volume.

1st place: "TEGRA 280"

votes 0

Another variation of "liquid nails", directly designed for gluing trim and skirting boards, wall panels and various decorative elements. Processing of ceramic bases and insulating materials is possible. The chemical composition does not contain solvents, and the use of innovative ingredients provides high stickiness to concrete and cement, brick and wood, as well as to plasterboard. The container volume is 280 grams, the brand originates from Poland, the recommended retail price is 400 rubles.

- Narrowly focused option;

- Good combination of price and quality;

- European brand.

- Not detected.

Premium Samples

3rd place: "Stayer 41327"

votes 0

This sample is characterized by increased moisture resistance and is used for mounting moldings, corners, skirting boards, as well as ceiling tiles. Works great on substrates such as ceramic tiles, drywall, brick and concrete. There are no solvents, harmful toxic substances in the chemical composition, it is non-flammable, has no pungent odors.Application is carried out using a construction spout. Able to work in a wide temperature range. The volume of the container is 280 grams, the birthplace of the brand is Germany, the recommended cost is 310 rubles.

- Wide operating temperature range;

- Versatility;

- Ease of application.

- Not detected.

2nd place: "TYTAN PROFESSIONAL Classic Fix"

votes 0

This option also specializes in gluing panels and moldings. It has a beige color and is able to work on both porous and even base surfaces. The chemical composition is based on synthetic rubbers. The formed seam receives increased elasticity. The container volume is 310 grams, the brand is from Poland, the recommended retail price is 360 rubles.

- Specialized material;

- Rubber in the chemical composition;

- Increased elasticity of the seam.

- Not detected.

1st place: "TYTAN PROFESSIONAL HEAVY DUTY"

votes 0

Such a sample is characterized by a very strong initial fixation, because it contains both hydropolar and rubber ingredients. The time for complete hardening is extremely short - only 5 minutes. Can be used on almost all surfaces. Considered a generic product. The temperature regime of application is set within the range from -20 to +60 degrees Celsius. The container volume is 310 grams, the brand originates from Poland, the recommended retail price is 450 rubles.

- High thermal stability;

- economical consumption;

- Fast curing.

- Not detected.

Instead of an epilogue

An analysis of the market for adhesives for skirting boards found that for the most part, universal variants of the “liquid nails” type are presented on it in the Russian Federation.The rest of the samples are unpopular due to their underestimated functional properties, the lack of good equipment (for example, a construction spout), as well as outdated chemical composition. At the same time, it is worth noting that, as such, highly specialized formulations will soon sink into oblivion and most adhesives will simply be combined under the simple name of “mounting adhesive”. The cost of such goods in Russia is very democratic, and the assortment range provides the maximum breadth of choice. At the same time, up to 80% of goods in this segment are represented by foreign manufacturers.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131661 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127700 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124527 -

The best men's sneakers in 2025

Views: 124044 -

The Best Complex Vitamins in 2025

Views: 121947 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114985 -

The best paint for gray hair - top rating 2025

Views: 113402 -

Ranking of the best wood paints for interior work in 2025

Views: 110328 -

Rating of the best spinning reels in 2025

Views: 105335 -

Ranking of the best sex dolls for men for 2025

Views: 104375 -

Ranking of the best action cameras from China in 2025

Views: 102224 -

The most effective calcium preparations for adults and children in 2025

Views: 102018