Rating of the best wood flooring adhesives for 2025

In the vast majority of cases, parquet boards are laid using a floating method using special grooved joints. This flooring installation option is most suitable for small spaces and is convenient to use in small areas. In rooms with large areas, the method of laying parquet with glue is more suitable, which will allow you to especially securely fix the parquet board on the main surface. Thus, it is for laying parquet boards that it is necessary to correctly prepare the base and select the adhesive composition.

Content [Hide]

- 1 Requirements for the technical parameters of adhesive for parquet

- 2 Issues of competent consumption of glue

- 3 Existing types of parquet glue

- 4 The use of parquet adhesive for various types of coatings

- 5 Difficulties of choice

- 6 Rating of the best wood flooring adhesives for 2025

- 7 Instead of an epilogue

Requirements for the technical parameters of adhesive for parquet

During the operation of a parquet board, it suffers from various negative influences - from mechanical to chemical-physical. These include a sharp change in ambient temperature, a decrease / increase in humidity, as well as the intensity of the load - all this can lead to deformation of the floor material. In order to reduce the negative impact on the board, the correct adhesive composition should be used. It must meet the following requirements:

- The minimum required amount of water should be used as a solvent in the composition - this is due to the fact that moisture has a destructive effect on wood and can cause it to deform / swell, as well as warp the top layer of the finish. After drying, the material should restore its original dimensions, however, its surface will need some restoration. Sometimes the scale of the resulting deformation can take on such dimensions that the coating will require serious repairs or even its complete replacement. Thus, the less moisture is present in the adhesive composition, the more effectively the board will adhere to the base surface, and the board itself will not undergo excessive deformation.

- After laying the dies, their shrinkage should be minimal - with a decrease in the thickness of the adhesive layer after drying, the plane of the outer coating may be violated. Hence, gaps may arise between individual decorative elements, which later become a source of unwanted squeaks.

- Glue elasticity - this requirement should be taken into account without fail, because when interacting with water or when sudden temperature changes occur, parquet panels can change their original dimensions in the direction of decrease or increase. These circumstances, in turn, can affect the size of the seams between adjacent dies. Thus, the adhesive layer must be able to expand/compress, ensuring the mobility of the parquet elements. If this requirement is not met, the coating may begin to deform when the humidity or temperature conditions change again. Excellent elasticity characteristics are available for silicone formulations of Western European production. They fit wonderfully on the base surface, do not really stick to hands, and are able to dry out quickly.

- The operational durability of the adhesive should be as close as possible to the operational life of the parquet board itself - this criterion is also mandatory, because otherwise the dies mounted on the screed may begin to peel off ahead of time. In such a situation, a full-fledged restoration of the entire coating will invariably be required, and there will be a need for an accurate selection of dies that require replacement, based on a pattern and color equivalent to the original ones. And this task can cause certain complications;

- The chemical composition of the adhesive must necessarily comply with certain sanitary requirements - this means that it should not contain substances harmful to humans.

IMPORTANT! A good adhesive composition is able to easily lay down on any base, regardless of its type, have excellent elastic properties and dry quickly. Moreover, it should be easily removed from the treated surface, leaving no marks or stains.

Issues of competent consumption of glue

The consumption of the adhesive substance for the installation of parquet directly depends on its density, and additionally on the type of base on which it will be applied (i.e., the dice can be glued on a pre-smooth concrete floor or on straightened plywood). The consumption for different types of parquet will be different, but the fundamental principle is the same - the smaller the parquet board, the less glue is required. Some types of adhesive substance can only be applied after a preliminary primer. So it is better possible to fill all the gaps / cracks, which will quantitatively reduce the consumption of the solution.

It is on the parquet board that it is not recommended to use compositions based on various solvents. Such samples are able to penetrate deeply into the basic structure of the material, and the moisture accumulated in this way inside the parquet can cause the formation of mold or fungus over time, or even deform the wood. If, nevertheless, it is decided to use a composition using a solvent, then the best option for installing a parquet board will be to mount it on moisture-resistant plywood, or, alternatively, on a well-prepared and pore-free concrete base.

Consumption can also be reduced if the base base is as level as possible.In principle, self-leveling compounds can also be used, or the base base can be processed using an angle grinder. Consumption will decrease due to the uniform distribution of the adhesive substance over the most even surface. As an example, the following figures can be cited: about 800 grams of glue is spent on one square meter of a very even surface, while about 1.2 kilograms will have to be spent on the surface with roughness for the same area.

Existing types of parquet glue

Dispersive

This substance is prepared on the basis of natural ingredients - water and adhesives, as well as with the addition of plasticizers. This composition can be used for mounting the floor base in various residential premises. During its drying, no harmful fumes are emitted into the environment. Due to the presence of natural substances in its structure, such a composition does not have a sharp smell.

In retail sales on the domestic market, a similar sample can be represented by many brands, which may differ from each other in the ratio of the base substance to the volume of water required as a solvent. The less water required, the higher the cost of the material becomes. At the same time, it is worth remembering that compositions that require a significant amount of water for the solution will harden much longer. Experts recommend using dispersion mixtures for mounting parquet planks on a base of moisture-resistant plywood sheets.

IMPORTANT! Most manufacturers of dispersion mixtures position their product as the best for laying hardwood floorboards, such as ash or oak.Due to its increased density, this material is able to successfully withstand the water component in the adhesive structure, respectively, it will be slightly susceptible to deformation. At the same time, manufacturers note that it is better to process small dies with dispersion mixtures.

It is strongly not recommended to use dispersion substances on parquet made from soft fruit wood (cherry, apple or pear). Their soft structure is particularly susceptible to penetration and accumulation of moisture, which in turn will invariably (over time) lead to deformation of the board. This applies especially to thin parquet boards, which are glued with a dispersion mixture containing more than 36% aqueous solvent. Additionally, it should be noted that dispersion adhesive is absolutely not suitable for parquet based on beech or alder.

Substances on other solvents

Similar mixtures can be used for fastening parquet planks from any type of wood. Instead of water, various synthetic substances play the role of a solvent in them. This reduces the setting time of the substance and improves adhesion to the base surface. It should be noted that such a solution can be in a liquid state for no more than 15 minutes, after which the process of its solidification begins. This time is enough to correct the already laid parquet board in terms of correcting the location of the dies. Complete solidification of the substance occurs within 120 hours.

The most popular type of the described composition is rubber-based glue. It has high adhesion, excellent astringent properties and dries fairly quickly.However, its components are highly flammable, therefore, until the moment of complete drying, near the elements processed by it, it is forbidden to carry out work with open sources of fire (welding, gas cutting).

Substances of two components

Two-component solutions have improved strength indicators and durability. Unlike their one-component counterparts, special hardeners are added to their composition immediately before installation work. However, water is also present in their structure, but it quickly evaporates after drying and does not have time to harm the parquet board. Drying in full occurs within 24 hours.

There are solutions belonging to this group, which are able to dry in just 12 hours. However, the price of such a quick drying has its downside - the adhesion of the mixture will be three times stronger, so it is extremely difficult to remove the parquet planted on such samples. Such powerful mixtures are desirable for use on surfaces that require strong adhesion, such as conventional wood flooring.

Reactive compounds can be used for mounting dies from any type of wood and their size will not matter. They can also carry out high-quality installation of a massive board in rooms where a high intensity of throughput loads is expected. However, even reactive specimens will need to be treated with protective layers of lacquer in order to increase their strength properties.

The main disadvantage of adhesive on two components is its overpriced cost, however, the investment will pay off in full due to the increased service life, reliability and strength of the mounted coating.At the same time, it must be remembered that the considered mixtures will release harmful chemicals into the surrounding space until the end of the complete solidification time. Therefore, while working with them, it is imperative to use personal protective equipment, work in a respirator and gloves. But after drying, the solutions cease to pose a threat to human health.

The use of parquet adhesive for various types of coatings

Depending on the type of parquet being laid, experts recommend using their own type of glue for each specific case. Such variability will ensure reliable adhesion and long service life:

- Industrial parquet - this type of flooring has an industrial purpose and is specially designed for rooms with intensive traffic and increased loads. This material is considered quite new, its use has not yet reached a large scale, so practical recommendations are not very common. However, a two-component composition based on polyurethane is best suited for it.

- Solid board more than 12 cm wide - the mixture used for this coating should have maximum strength and elasticity. In many ways, these requirements are met by the qualities of polyurethane adhesives. Moreover, polyurethane mixtures can be applied directly on the screed, avoiding the use of a substrate.

- Mounting the board on a screed (except for options with a width of more than 12 cm) - two options can be used here: the first is to glue everything with a two-component polyurethane base and fix it directly on the screed, which will qualitatively reduce the consumption of adhesive material. The second is to use the Multimol substrate, but then the consumption will double, but the process technology itself will be simplified.

- Mounting the board on a fragile screed (except for options with a width of more than 12 cm) - again, you will need a mixture with excellent hitch properties, because the application will be carried out on a fragile base. The best solution would be single-component variations. In addition, their increased elastic properties will reduce the risk of temporary deformation of the seams.

- Fastening a solid board with a width of more than 12 cm to plywood sheets - in this situation, it is necessary to ensure resistance to vertical separation, which one-component adhesive will do just fine.

- Laying the board to plywood - such a wide-format material does not interact well with moisture, which means that dispersion options cannot be used. Experts advise using strong and elastic one-component samples.

- The installation of piece parquet elements from fruit wood on plywood sheets is an extremely unstable version of parquet, therefore, the use of dispersion compounds is prohibited.

- Installation of a coating with a varnish bottom layer - such parquet structures are characterized by a high probability of delamination of their lower part, which can be caused by intense loads. However, professionals for this situation call the standard one-component glue the best option.

Difficulties of choice

As practice shows, an ordinary buyer is hardly able to independently and without proper experience correctly select one or another adhesive for a particular type of parquet. The adhesive composition must necessarily meet a number of criteria, on which the strength, reliability and durability of the laid parquet board will depend. Such criteria may include:

- Working convenience - the mixture should be comfortably applied with a spatula, not contain extremely harmful and hypertoxic elements, not harden too quickly in order to possibly adjust the position of the board (except for two-component samples, in the structure of which there is a hardener).

- Structural homogeneity - upon completion of application, the resulting layer should not contain air bubbles, which may adversely affect the quality of bonding. The glue reef must hold its shape and not spread, thus preventing possible shrinkage, sagging and tension in certain areas of the floor covering. All this directly affects the initial strength and is important for the primary stage of adhesion.

- The period of "life" of glue is an extremely important criterion, because some types of glue may lose their performance characteristics after a year. When using cheap samples, it is possible to get a divergence of the seams or even a lag of the parquet from the base. Unnecessary squeaks may also occur.

- Environmental properties - the selected composition must have an appropriate certificate recognized by the Russian state. This will ensure that such glue is harmless to humans after it has completely dried (some release of toxic substances is still allowed in the process of working with individual samples).

- Strength characteristics are another important criterion. Mounted parquet or parquet board is still a wooden material capable of accumulating moisture, as a result of which it is subject to expansion and deformation. Only high-quality glue is able to prevent the penetration of moisture into the wood structure, which will significantly increase its strength properties.

Rating of the best wood flooring adhesives for 2025

Budget options

3rd place: Titebond 2104

votes 0

Specialized composition, one-component, designed for any floor coverings that are connected in a floating type (including parquet boards). The structure contains a polyphatic emulsion, which means an additional quality of adhesion. This option itself, in fact, is a simplified version of the professional Premium sample from the same brand. The difference lies only in reduced adhesive properties and a small volume of containers sold. It has a white color, after drying the seams become transparent. Can be used both indoors and outdoors. The brand is from the USA. The recommended retail price is 640 rubles.

- Passed the Russian certification;

- Perfectly survives "freeze-thaw";

- Increased layer strength.

- Small volume of container;

- Narrow specialization.

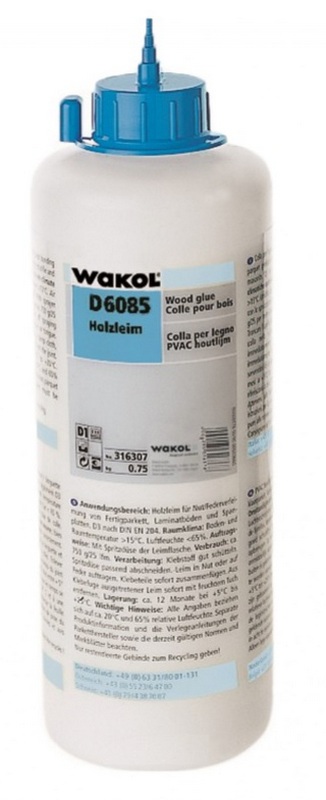

2nd place: WAKOL D 6085

votes 0

An excellent waterproof adhesive that can securely fasten the joints of the parquet board. Quietly works on any type of connection - tongues, grooves, dowels, trunnions and ridges. It does not contain toxic solvents in its structure. Can easily form a grip on any surface. Due to the small size of the container in which it is supplied, it is more suitable for restoration work. The brand is from Germany. The recommended price for retail chains is 890 rubles.

- Freezes in 3 hours;

- Withstands operating pressure up to 5 bar;

- The basis is a synthetic dispersion.

- Insufficient container volume.

1st place: "KIILTO Eco 2 K-PU"

votes 1

This sample is a reliable polyurethane mixture based on two components. Able to reliably process any type of parquet board, regardless of the size of the dies or the type of wood. However, if a tree with a high resin content in the structure is used, it is recommended to carry out a trial bonding. Possesses qualities of frost resistance. The brand is from Finland. The recommended cost for the store is 1900 rubles.

- Polyurethane base;

- Sufficient container volume;

- Excellent combination of price and quality.

- The hardener is supplied separately.

Middle price segment

3rd place: Bostik TARBICOL PU 2K

votes 0

An excellent option, produced on the basis of two components with a polyurethane base. With its help, it is easy to carry out high-quality laying of parquet on almost any basis. When making a seam, it provides reliable protection against moisture penetration into the structure of the board. Easily works with any type of wood. The composition forms a reliable connection, at the same time providing protection from UV rays and temperature extremes. The brand is from France. Recommended retail price - 3600 rubles.

- Able to work with varnished parquet;

- Provides reliable protection;

- Suitable for mosaic parquet elements with irregular geometry.

- Not detected.

2nd place: "TYTAN PROFESSIONAL"

votes 0

Probably the most popular sample in Russia from an Eastern European manufacturer. It successfully combines advanced functionality, a good volume in the supplied container, as well as an adequate price tag. Works great on both absorbent and non-absorbent substrates.Easily works with any kind of wood, up to exotic ones. Perfectly adheres even a decorative board with an industrial topcoat. It can be used as a restoration (repair) mixture, and as a primary adhesive. Separately, it is worth mentioning the special ability to withstand sharp and fast mechanical loads, which makes it indispensable for the arrangement of gyms. The birthplace of the brand is Poland. The recommended price for shops is 4500 rubles.

- Resistant to various kinds of negative influences;

- Adequate ratio of quality and price;

- Sufficient container capacity.

- Not found.

1st place: "Akfix HB260"

votes 0

This substance uses a particularly reliable type of MS polymer, which makes parquet laying better. The composition is based on a single component. Excellent way to work on both porous and non-porous substrates. It is easy to apply on the inside of the varnished board, which in no way reduces the reliability of adhesion. Does not require mixing and is immediately ready for use. The brand is from Turkey. The recommended retail price is 4900 rubles.

- Fast adhesion to the bases;

- Ecological cleanliness;

- Even application.

- Not detected.

Premium class

votes 0

2nd place: "SikaBond-537 Parquet"

votes 0

A good option, however, which has earned its popularity only thanks to the increased container. The adhesive used is acrylic. The glue itself belongs to the category of water-dispersion. In addition to parquet, it is easy for them to work on plywood and OSB boards. The brand is from Switzerland. The recommended retail price is 6000 rubles.

- Large container;

- Viscous consistency;

- Low cost (for its size)

- dispersion base.

1st place: WAKOL MS 230

votes 0

This material is based on an innovative MS polymer and is specifically designed for laying wood flooring. The structure does not contain any solvents and is perfect for arranging a “warm floor”. Similarly, it will work well with standard tongue and groove parquet flooring. Consists of a single component, does not include water, which means excellent protection of the tree from swelling and deformation. Able to create a reliable moisture barrier. The brand is from Germany. The recommended cost for retail chains is 12,000 rubles.

- Bulk container;

- High adhesive properties;

- Eco-friendly composition.

- Extremely high price.

Instead of an epilogue

The analysis of the market of adhesives in the Russian Federation for parquet boards showed an almost complete absence of a Russian manufacturer in this segment. Such circumstances are associated with the lack of appropriate technologies in domestic firms, and even their presence will not be able to bring down the competitive price of Western companies. Still, it is worth recognizing that our buyer is provided with good and high-quality adhesive options for a very reasonable price. Moreover, most of the samples are universal and are able to work not only with wood. It is also worth noting that the mixtures have additional functionality, for example, frost resistance, and most products from the medium and premium segments constantly use innovative technologies (meaning reinforced MS polymers for one-component samples).This suggests a legitimate conclusion - although this market in the Russian Federation is not replete with an abundance of options, for the most part it is able to satisfy any request of a potential buyer both in terms of the functionality of the product and its price.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131652 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127691 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124519 -

The best men's sneakers in 2025

Views: 124034 -

The Best Complex Vitamins in 2025

Views: 121940 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114980 -

The best paint for gray hair - top rating 2025

Views: 113396 -

Ranking of the best wood paints for interior work in 2025

Views: 110319 -

Rating of the best spinning reels in 2025

Views: 105330 -

Ranking of the best sex dolls for men for 2025

Views: 104367 -

Ranking of the best action cameras from China in 2025

Views: 102217 -

The most effective calcium preparations for adults and children in 2025

Views: 102012